When firing a stove or igniting a fireplace, their body becomes very hot, transferring this temperature to the surrounding surfaces. In accordance with fire safety techniques, it is necessary to insulate the furnace body from adjacent surfaces using fire-resistant materials if a safe distance is not maintained. This is a distance equal to 30 cm for a brick stove, more than 1 meter for a metal stove and 70 cm for a metal-lined stove. If it is impossible to dissipate heat naturally in a room (especially a small area), fire-resistant materials are used for the walls around the stoves.

SNiP standards for the location of the furnace from the walls

The standards for these requirements are specified in 2 main documents:

- SNiP III-G.11-62;

- SNiP 2.04.05-91.

Based on these regulatory documents, each owner of a solid fuel stove is required to maintain minimum clearances from the wall and ceiling, taking into account the surface material:

| Parameter | Requirement |

| Installing the stove on a floor made of flammable materials. | The distance to the bottom of the stove must be at least 140 mm. |

| Foundation size. | When installing a steel stove on a wooden floor, the size of the foundation should be 1000 mm larger than the dimensions of the stove. |

| The ceiling is protected by asbestos slabs, plaster and sheet metal up to 1 cm thick. | In this case, the brick-lined stove is made in height so that the gap to the ceiling is at least 250 mm. |

| When installing a steel stove with a protective layer of thermal insulation. | The minimum distance to the floor slab is 700 mm. |

| Installation of a steel stove without a protection layer. | This size increases to 1000 mm. |

| Minimum dimensions for walls according to SNIP from 1962 | |

| Distance from stove to wood stove with unprotected surface. | From 1000 mm. |

| The walls are lined with brick and plastered with lime mortar with a layer of 25 mm. Or an asbestos heat insulator 4 cm thick is fixed. | 130 mm |

| The wooden walls are lined with brick, 120 mm thick and plastered with lime and asbestos. When installing protection on the walls in the form of a 40 mm asbestos-vermuculite slab. | 300 mm |

By maintaining the minimum dimensions, or better yet, making gaps with a small margin, every owner of a wooden house can be sure that its walls and ceiling are protected from high temperatures.

One of the main methods of protection is the manufacture of devices installed to protect the front and side surfaces near the stove itself.

Installing a stove in a bathhouse with an external firebox: fire safety rules

Regardless of what type of stove is installed, there are a number of requirements that must be met. In particular, we are talking about ensuring that surfaces heated to high temperatures (up to several hundred degrees) do not come into contact with flammable materials.

The main source of danger in a bathhouse is the stove . Both the floor and the ceiling need to be protected from it. By the way, you don’t have to protect the walls if you place the stove at a sufficient distance from them.

And even if you are busy installing a stove in a bathhouse with an external firebox, the first thing you need to do is protect its base . It doesn’t matter whether you place it on a foundation or directly on a wooden floor - in any case, you need to lay a sheet of fire-resistant material (asbestos or basalt cardboard, for example) under the stove, on top of which you need to place a sheet of metal .

Foundation diagram for a massive furnace (see more about furnace foundations).

Asbestos cardboard for placing under a not very heavy stove (see more about installing stoves).

Another universal point of fire protection is the correct installation of the chimney through the ceiling and roof.

Ceiling passage box

The walls remain. Since in this case we are talking about installing a stove with a remote firebox, the main “problem” will be the passage of the fuel channel directly through the wall , and the distance between the wall and the stove will be minimal - about 5 cm on average. This means that covering the wall with fireproof materials alone will not do.

Related article: DIY wall decoration ideas

Therefore, we will analyze two options: installing a stove in a bathhouse with an external firebox, when the walls are flammable (that is, wooden) and non-flammable (brick, block concrete). The material is also a criterion for dividing stoves into separate types; in accordance with this classification, metal and brick stoves are distinguished. Some experts classify cast iron stoves as a separate category. In addition, there are other types of stoves:

Protective screens near or around the oven

Such a system will need to be implemented when installing a potbelly stove in the corner of the room. You can mount or lay out several screens from brick, installed at a short distance from each other. In this case:

- The first screen protects a person from touching the iron stove and getting burned. It is usually made of refractory or fireclay bricks;

- To protect walls made of flammable material, a second layer of protection is provided. It can be made of brick or covered with a barrier made of sheet steel with a mirror-like front surface. In this case, heat waves will be reflected from the mirror and spread faster throughout the room;

- if the foundation is insufficient in size or it is impossible to manufacture it, it will be necessary to lay a protective screen made of durable fire-resistant material on the wooden floor. This can be a sheet of steel or a decorative layer of heat-resistant clinker tiles or porcelain stoneware. The surface will first have to be covered with a layer of thermal insulation.

Installation of metal screens

This is the easiest way to make surface protection. It is better to use sheets with a polished front surface. Before fastening, the wall surface at the required level along the height of the screen is covered with a layer of thermal insulation. In this way, we protect the surface of the walls from the effects of heat.

You can lay a layer of thermal insulation or fasten the metal with self-tapping screws with inserted ceramic spacers. But it is better to attach the screen to strips or a metal profile treated with a layer of protection. In this option, the air gap will not allow heat to pass freely to the walls, and reliable insulation of the stove from the wooden wall is ensured.

A special gap is made at the bottom of the wall for the passage of cold air, ventilation of the wall and screen. When arranging a wall with a layer of thermal insulation, a number of longitudinal guides are installed on the surface. The space between them is filled with a layer of mineral wool or other material. Then sheets of metal are installed and screwed to the sheathing with self-tapping screws.

In this design, there is no need to leave a gap at the bottom. The air will not be able to pass through calmly, but the wall will be reliably protected from high temperatures. To protect the floor of the house, a slab made of non-flammable durable material can be used.

Brick screens

This protection option is usually installed near the stove. Thus, you can protect not only the wall, but also the person from burns. By installing a brick wall, you can reduce the distance from the stove to the wall. For laying, it is better to use ceramic or fire-resistant bricks.

The work is carried out in several stages:

- you will need to make a small foundation or remove boards from the floor along the marking lines for laying the screen and, by drilling holes in the concrete of the base of the building, insert metal rods to fasten the bottom of the wall and the foundation;

- Having leveled the floor surface, lay out a layer of mortar and lay the first row of bricks; you need to place the bricks in the same plane without distortions. This determines how level your entire wall will be. Do not forget to make small grooves for ventilation; for this you can move several bricks of the bottom row.

- checking the level and pulling the twine for laying each subsequent row, all bricks are laid on a mortar of clay and sand. Having raised the wall to the required height, the top is sealed with a layer of mortar or covered with a board. This way you can make a shelf for decorative ornaments and all sorts of little things.

The brick is laid no higher than the top of the furnace at a distance of at least 40-100 mm from it.

Using both types of protective screens, you can reduce the distance from the oven to 500 mm.

Examples of installation of protective brick screens in the photo:

Photo 1

Photo 2

Photo 3

When is this required?

There are times when there is no need to protect walls. If the stove is located at a safe distance from the wall from a fire safety point of view, the installation of protective screens and other measures can be neglected. The distance from the walls that is required to reduce the heat from the source varies:

- A stove laid in a quarter of a brick should be located no closer than 35-40 cm from the wall;

- A metal stove without lining should be placed a meter away and no closer;

- A metal one with a lined furnace can be installed 70-75cm from the wall.

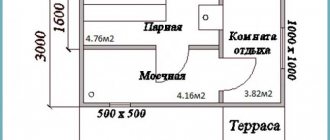

However, not every steam room has the opportunity to fulfill these requirements, due to the small area. The layout of steam rooms with an area of 6-8 m² can hardly accommodate the necessary set of items for the steaming procedure. Therefore, the need to insulate walls with special sheathing is relevant.

Tags: stove, wall, thermal insulation

« Previous entry

Protective non-combustible wall coverings

If there is no need to carry out work to protect walls using screens, in this case, you will still need to reliably protect the surfaces from exposure to high temperatures.

You can use classic mineral wool or use mineralite slabs. We get a reduction in the distance from the wall to the stove in the house, without the risk of fire and deformation of building materials.

Minerite

Installation of reflective trim

This is one of the main methods of protecting surfaces from high temperatures. To do this, you can use a sheet of thin cold-rolled metal with its glossy surface or buy more expensive stainless steel sheets with a mirrored face. This heat-reflecting protection allows you to quickly heat the room without wasting firewood and reliably protects the walls and ceiling from deformation.

First, the sheathing strips are secured. The bars should be selected taking into account the thickness of the insulating material. A thermal insulation layer is embedded in the spaces between the sheathing parts. On top of it, sheets of reflective sheathing are attached to wood or metal screws (this depends on the material of the bars).

Using this method of protection, you can reduce the distance from the stove to the wall to 380 mm.

Protecting walls from the heat of the stove can be used as decorative decoration for premises.

Examples:

Photo 1

Photo 2

Installation of sheathing with cladding

This method will require increased costs for the purchase of materials, but will also make your home cozy and beautiful. Porcelain stoneware or expensive tiles can be used as cladding, it all depends on the capabilities of the owner of the house.

Work on the protection and decorative finishing of walls is carried out in several stages, the result is a kind of cake:

- a ventilation gap is made on top of the wall, 20-30 mm thick;

- then a layer of thermal insulation is laid and fire-resistant drywall is attached on top of it;

- A layer of decorative finishing is laid on fire-resistant glue or mastic using beacons to ensure an equal gap between the rows. It is important not to use large tiles. Such parts are more susceptible to deformation, unlike small tiles.

Using this method, you can reliably isolate the stove from the wall and make a gap of 150 mm between them.

Example

Fire resistant structures

A special heat-resistant cladding is used as protection for the walls. To do this, the fire-resistant cladding is covered with heat-resistant tiles. Non-flammable glue is used for its installation. The following facing materials have good fire-resistant qualities:

- terracotta tiles;

- tiles;

- porcelain stoneware;

- soapstone and so on.

In addition, fire-resistant plasterboard, mineralite, glass-magnesium sheet and other fire-resistant boards for a bathhouse can be used as fire-resistant protection for walls. It must be taken into account that for each type it is necessary to provide ventilation in the form of a gap at the bottom. Practice shows that the use of cladding as heat-resistant protection for walls in a bathhouse has almost the same thermal characteristics as reflective cladding. The only drawback is the cost, which is several times higher than standard options.

Protecting the walls of the bathhouse from the heat of the stove requires a careful approach and selection of the right materials. Modern manufacturers offer ready-made solutions in the form of metal protective screens that are easy to install and use. Brickwork also has high thermal insulation characteristics, which is why it is also popular.

Other methods of insulating walls from the furnace

Thermal insulation of a stove from a wooden wall can be carried out using modern materials, with which it is possible to apply a sufficient layer of thermal insulation not only to the walls, but also to apply it to the stove:

- Sheets of environmentally friendly basalt wool with an outer layer of foil. This material can withstand temperatures of at least 7000. This material can be used to insulate fireplaces and chimneys;

- Gypsum fiber sheets. They are produced by pressing natural gypsum material and cellulose. This material does not require additional surface treatment with a layer of waterproofing. Can be used for thermal insulation of the combustion chamber and the body of the potbelly stove from the outside;

- The use of calcium silicate allows you to reliably insulate the firebox and internal surfaces of fireplaces. But the material is expensive, so it is not in high demand.

Calcium silicate panels

Step-by-step instruction

The first structure is insulated in the following cases:

- reduction of heat consumption - thermal insulation work is carried out when the fireplace or stove is not designed correctly, when all the heat comes out through the chimney (due to excessive draft or the use of materials with high heat transfer);

- insulation retains heat;

- elimination of condensate: if the pipe is not insulated, condensate collects in it, it destroys the pipe masonry or welded coating joints.

Experts recommend insulating the surface of the stove located close to the walls of the house. Otherwise, cracking of the brick will occur due to temperature fluctuations. Thermal insulation between the wall and the stove is carried out using the following materials:

- asbestos slabs;

- thermofoil (as a heat reflector).

The method under consideration is used if the space between the stove and the wall exceeds 5 mm. If the distance is small, then asbestos cannot be used (due to the composition of the material).

It is possible to carry out thermal insulation work using the following technology:

- strengthening the wall using metal sheet hangers;

- installation of slabs of ceramic or asbestos insulating material;

- filling gaps and seams with mineral wool;

- winding the pipe with an external reflector (foil).

Since mineral wool does not tolerate condensation, a special material should be used to insulate this seal. A similar technology is used for furnace thermal insulation. At the same time, the wall does not heat up or heat up.

Fireproof mineralite slabs

This material is characterized by high heat resistance and is made only from environmentally friendly substances:

- white/gray cement - up to 90% of the total material;

- mineral fibrous materials;

- Fibers reinforcing the slabs - give the slabs durability and strength.

The composition does not contain asbestos fibers, making these fire-resistant high-temperature boards suitable for home ovens. The slabs are quickly mounted on the wall using screws to the wall itself. To ensure higher reliability of the structure, you can install two sheets of minirite.

When installing, you need to leave a small distance, because When heated, the material may expand slightly.

Wall finishing with fire-resistant mineralite slabs