If you are planning to build a small house, bathhouse, garage or other light-weight buildings, then know that there is no point in overpaying for the foundation. It would be much more correct to use a columnar foundation as an option for an inexpensive but durable foundation. The main thing is to approach construction issues correctly, choose the right option, and comply with technological standards and design features.

Conditions for installing a support-column structure for a future home

The use of strip concrete foundations carries an impressive financial burden on the total estimated cost of construction. The installation of a support-column foundation allows you to save money.

Its construction is possible under certain conditions:

- The calculated resistance of the soil foundation (R0) must be equal to or less than that of the point support. This will prevent the house from sagging under its own weight.

- It is advisable to install poles on rocky, coarse soils. Such a foundation is not built on heaving and swampy soils.

- The heel of the point support must be below or above the groundwater level.

- The foundation material must withstand the load and have a safety margin of + 10%.

- The bottom of the foundation should be below the freezing depth of the soil.

Assessment of soil bearing capacity

Before proceeding with the design of the foundation, it is necessary to examine the conditions and physical characteristics of the soil to a depth of at least 2 meters from the surface . You can do this yourself by taking soil samples using a hand auger.

To avoid making mistakes in assessing soil characteristics, you can order a soil analysis from a geological exploration service. Another option is to contact your local land management department for a copy of the vertical survey linked to the construction site.

What is the basic version of a columnar foundation?

Like any other technology, foundation pillars have a basic sequence for arrangement, from which they build upon during construction. This sequence of work performed is conventionally divided into stages:

- Equipment of depressions in the ground, which depends on the design strength, freezing depth and type of soil.

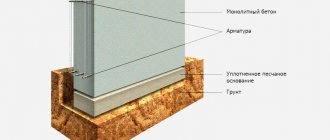

- Arrangement of the pillow. It is advisable to pour 10 cm of concrete under the pillow. If this is not possible, then fill the hole with sand 10-20 cm deep, which will create drainage that repels water. It is thanks to the cushion that the columnar foundation, the technology of which has been actively used in the last 10 years, is resistant to soil heaving.

- Arrangement of formwork. This option is considered the most time-consuming at the beginning of work. At this stage, boards are assembled from boards, the geometry of which should be close to a rectangle. This will allow you to pour durable and aesthetic pillars. The construction of a columnar foundation involves leveling the general plane of the house along the line and level.

- Reinforcement. Each pillar needs to be reinforced. To do this, weld a frame of reinforcement according to individual dimensions, 4 or 6 rods. He is lowered to the bottom.

Often they resort to waterproofing each pillar separately. To do this, at the first stages of construction, a film is laid that protects the concrete from direct contact with the ground.

If you are working without formwork, intending to remove the pillars from brick, then waterproofing must be placed between the first row and the base so that the pillars do not absorb moisture and collapse.

Types of materials used

To begin the construction of a columnar foundation foundation, you need to make the right choice of materials from which the supports will be created. The solution to this issue must be approached based on the above conditions and the type of structure.

Commonly used:

- tree;

- brick;

- asbestos and metal pipes;

- foundation blocks;

- monolithic reinforced concrete.

Tree

Support posts are made from logs (pieces of logs) or timber.

This base is suitable for light buildings such as bathhouse sheds, gazebos , etc. Wooden posts are cleaned of bark and impregnated with antiseptics.

The part of the wood that will be immersed in the soil is coated with bitumen compounds, and roofing felt is placed at the bottom of the hole.

Brick

For the construction of light frame and wooden houses on dense soil, a brick columnar foundation is erected. For this, red, rarely silicate, brick is used .

This option is acceptable for shallow foundations. The columns are laid out in the form of a square in plan with sides 1.5 bricks wide.

2-4 pieces of reinforcement are placed in the central hole of the masonry for subsequent connection with the grillage. Then the opening is filled with concrete.

Asbestos and metal pipes

Concrete pipes are structures with high load-bearing capacity . The metal or asbestos shell is both formwork and part of the foundation.

For the support-column base, pipes with a wall thickness of at least 4 mm are used. Pipes filled with concrete have proven themselves well when constructing foundations in loose soil.

Supports made of steel pipes are susceptible to corrosion, so they are primed and coated with anti-corrosion coating compounds. The underground part of the pipes is subjected to especially careful treatment with mastics.

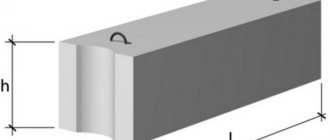

Foundation blocks

These structures are designed for heavy loads and can be safely used as columnar foundations.

The only drawback is that the blocks cannot be accurately calculated for the load from the house , and this leads to unnecessary costs, which can significantly increase the total cost of construction.

However, in comparison with monolithic supports, there is no need to delay construction for 30 days until the load-bearing capacity of the concrete poured into the formwork is fully achieved.

Monolithic reinforced concrete

This is a classic version of a columnar foundation. It is installed, as a rule, for private houses with a height of 2 floors . Formwork is placed in the pits, into which the frame is immersed.

The structure is then filled with liquid concrete. After 30 days, the supports reach the required level of load-bearing capacity acceptable to continue construction.

Influence of foundation depth

The correct structure of a columnar foundation can be shallow or recessed. A shallow foundation is considered the most affordable because it requires a minimum investment of money. It is used on clayey, rocky and other soils of high density. At the time of arrangement, a depression of 60-70 cm is dug in the ground, where 10-20 cm is filled with sand in the form of a pillow.

Experts recommend pouring concrete in the form of a first, preparatory layer, up to 10 cm in size. For reasons of economy and expediency, M100 grade concrete is used here.

After hardening, the cushion is built and only then the main pillar of the future foundation is poured.

On this topic:

Main types of foundations for a private house

Apr 12, 2019

Mistakes when laying the foundation of a house

Apr 11, 2019

BACK FORWARD 1 of 7

For unstable soils, as well as for soil that freezes to a depth of more than a meter, a buried foundation is suitable. Its depth can reach two meters, which may be required by the project after geological exploration of the area.

Construction technology (with photo)

The classic version of a support-column base is supports made of monolithic reinforced concrete. Arrangement of the foundation of the house consists of the following stages:

- Design and calculations.

- Marking.

- Excavation.

- Construction of a sand and gravel cushion.

- Manufacturing and installation of reinforced frames.

- Installation of formwork.

- Pouring concrete.

- Waterproofing.

- Installation of grillage.

Design and calculations

Preparatory work consists of the steps described below:

Determination of total load

At the design stage of a house, a specification of building materials and structures is created , where their weight is indicated.

To calculate the load on the ground from a construction site, in addition to the total mass of the building, the weight of the internal contents is taken into account - this is equipment (boiler, pipelines, air conditioning system, furniture, etc.).

The snow load on the roof is also taken into account.

Having collected the necessary data, calculate the reference area of the building using the formula: S≥ KNF/RO, where:

- S – total support area;

- F – full load from housing construction;

- KN—safety factor 1.2;

- RO – calculated soil resistance.

Distance between pillars

Based on the total supporting area, calculated soil resistance and the size of the pillar heel, the number of point foundations is calculated.

The distance between the pillars is determined by their location on the plan in the corners of the building, at the intersection points of walls and places where heavy equipment is installed.

The remaining gaps are evenly filled with the remaining supports in accordance with their calculated number.

Depth

The level of laying the support-column foundation is determined according to the depth of soil freezing at the building site. This parameter is requested from your local land surveying and architecture office .

Also, the level of freezing is determined by experimental drilling at a construction site in winter. The corresponding tables are in SNiP 01/23/99. For example, if this indicator is 1.9 m, then the laying depth should be 1.9 - 2 m.

Marking

The position of the point supports is marked according to the house plan. For this use:

- roulette,

- cord,

- benchmarks in the form of wooden pegs, slats or pieces of reinforcement.

If you don’t have your own laser level, you can rent one.

The building plot is marked as follows:

- the land is cleared of vegetation and debris, the fertile layer of soil is removed;

- benchmarks are driven into the ground sequentially, starting from one of the corners of the plan;

- The correctness of right angles is checked by measuring the diagonals of a rectangle or square of the building plan with a cord;

- mark the points of intersection of the walls;

- the remaining supports are placed at intervals of 1.5 - 2 m.

Excavation and sand and gravel bed

The holes are dug with an entrenching tool to a level below the freezing level of the soil by 150 - 200 mm. The bottom of the pits is covered with a layer of sand and gravel mixture. The formed pillows are spilled with water to compact them, and then thoroughly compacted.

After this, the level of all pillows is checked using a laser level and a rod . Discrepancies are corrected by adding or removing sand. Geotextiles are laid on the bottom, its edges are brought up to the height of the heel of the columnar support. The film is attached to the walls of the pit with ordinary nails.

In loose soils, the walls of the pits often crumble, which nullifies the work done. To prevent this phenomenon, the side surfaces are formed at a slope with the opening narrowing downward.

Manufacturing and installation of reinforced frame

How it is produced:

- Knit meshes with cells measuring 100 x 100 mm. To do this, sections of smooth reinforcement are twisted with knitting wire.

- The mesh is installed on plastic supports. This is necessary to form a protective layer of concrete.

- For the manufacture of a vertical reinforced frame, periodic profile reinforcement ø 8 mm and knitting wire are used.

- Homemade devices are used to bend reinforcing bars. How to do this is clearly shown in the video, the link is below.

- Vertical frames are connected to horizontal meshes and lowered into pits.

- The bottom of the pits is filled with concrete to the top edge of the film.

- After 10 - 15 days, when the base plate has hardened, the formwork is installed.

Making a reinforced frame - in the video:

Formwork

The following are used as formwork elements:

- boards,

- wooden boards,

- tin,

- thin metal and thick polymer sheets.

Formwork boxes are prepared at the site. Then they are put on reinforced frames. The verticality of the fences is controlled by the level on both sides of the formwork.

To prevent lateral movement of the boxes, they are fixed with spacers. All structures must be aligned in the same horizontal plane - this is also checked using a building level.

The formwork is formed in such a way that the gap between its inner surface and the reinforcement is 15 - 20 mm . This is necessary to form a protective layer that prevents corrosion of the steel frame.

How to pour concrete correctly?

For concreting foundations, you need to use a mortar mixer. It can be rented.

If the volume of concrete work takes up more than 2 m3, then it is better to order an automixer with a concrete pump . They can be used to concrete a large number of formwork glasses during one work shift.

Concrete is poured in layers with a height of 150 - 200 mm. Each layer is compacted with an electric vibrator. Many construction companies rent this tool.

After pouring is completed, the head is covered with plastic film, passing the outlets of the fittings through the holes. This will prevent moisture evaporation and protect against precipitation.

Waterproofing

After dismantling the formwork, the surfaces of the pillars are covered with bitumen mastic . It is heated with gas burners or in a tank over a fire. There are waterproofing compounds that are brought into a liquid state with special solvents.

For more reliable protection of the supports, they are additionally covered with roofing felt. After the waterproofing has hardened, the foundations are backfilled.

How to make a grillage?

The tying of the heads (grillage) of the pillars is made from:

- metal profile (angles, T-beam or I-beam),

- reinforced concrete tape,

- for wooden houses - made of timber.

The grillage is needed to uniformly transfer the load from the building to the columnar foundation.

It is advisable to install a monolithic reinforced concrete strip for 2-story houses. The outlets of the pillar reinforcement are welded to the grillage or screwed with wire to a wooden frame.

Pouring the grillage formwork with concrete - in the video:

Do you need a grillage, or how to fill a columnar foundation level

A grillage is installed on top of the foundation on piles. This is an important structural element that allows you to connect all the piles and pillars into a single whole. The grillage can be monolithic or wooden. The wooden option is suitable for the construction of houses made of logs and timber. A beam with a cross-section of 20 by 20 cm is used here as a base. For houses made of logs, the grillage is often made from the same material as the house, being the first crown of the structure.

In the case of a reinforced concrete structure, formwork is installed for a columnar foundation. It consists of boards or shields, knocked down to the required size. In places where the formwork touches the column, there is a cut, which allows the reinforcement released from the pile to pass into the formwork. Ultimately, the frame is set together, which allows you to pour the monolith for the future home. It is the correctly positioned grillage that allows the foundation to be poured on concrete pillars at a level.

After the columnar foundation is poured, it is necessary to take care of the concrete. This must be done within 28 days, because it is during this time, according to SNIP standards, that it gains its design strength.

Concrete care includes moisturizing with plenty of water, as well as protection from direct sunlight. The latter protects the grillage from drying out and cracking, which is important for a suspended structure. For protection, cover the concrete with a film and water it with water, opening it for a short time.

Strengthening the foundation

Over time, the owner of the house construction may notice signs of subsidence of the columnar foundation. This can manifest itself in the form of cracks in the walls, subsidence of floors inside the house and other violations of the integrity of building structures.

To prevent the destruction of the building, it is necessary to carry out work to strengthen the pillars . There are two ways to increase the bearing capacity of the foundation.

Option 1

Identify a sagging pole. Place a jack under the heel and support it. A certain volume of soil is removed from under it. The resulting voids are filled with concrete. After 30 days the jack is removed.

Option 2

The sagging supports are supported with jacks, and additional pillars are installed between them . After the concrete has hardened and the formwork has been dismantled, the jacks are removed. To monitor foundation subsidence, beacons are installed on the supports.

If, as a result of the above measures, subsidence of the foundation of the house continues, then you need to contact a specialized service for a professional examination of the condition of the foundation and identify the causes of these negative phenomena.

Repair

If the supports become deformed or destroyed, they should be replaced.

The house is raised using a jack, placed on temporary supports , which should be slightly higher than the main ones, after which the old supports are dismantled. In place of the dismantled pillars, new ones are installed and the building is lowered onto them.

If the pillars sag, they are dug under them, raised to the required level, and then their tops are additionally tied with rigid strapping. Read more here.

Possible mistakes and how to avoid them

The most common mistakes during the construction of columnar foundations are:

- the calculation of the bearing capacity of the support is incorrect;

- violation of the verticality of the pillars;

- incorrect calculation of the number of pillars, the size of the supporting area;

- poorly executed waterproofing;

- carrying out work in winter;

- use of low quality materials.

Information on the Internet or advice from experienced builders will help you avoid mistakes when erecting pillars. If you still have doubts, it is better not to engage in construction yourself, but to turn to professionals.

You will find a lot of important and useful information about columnar foundations here.

Buying logs

Before buying logs, you must calculate the required number. Remember that the thicker the floorboards, the less joists you will need, but excess joists will not hurt and will give the floor additional strength. The maximum distance between the logs is 80 cm if the boards laid on them are 45 mm thick. Based on this example, calculate the required number of joists for your floor.

Speaking about the choice of logs, the first thing to note is that they should be made of coniferous wood, for example, pine or larch. Coniferous wood has high moisture resistance, as well as antiseptic properties that prevent the formation of mold and mildew.

Remember that during construction it is often necessary to resort to alternatives, so here too you can replace the timber with double pine boards. This method of laying a floor is almost as strong as a floor on blocks, but choose boards with a large cross-section without any defects.

When purchasing timber for construction of logs, inspect it carefully. You cannot use material with many large knots, however, by using support posts under the joists, you can allow a large through knot, remembering that it must be strictly above the support. There should also be no cracks or rot on the surface of the joists. It is better to buy a more expensive material that will last a long time than to change the floor several times using cheap wood.

Don’t forget to also buy an antiseptic, which should additionally be used to treat the logs before installation (for more details: “How to treat logs against rotting - choosing an impregnation and antiseptic”). It will protect the wood from fungus and most pests.

Features of choice

Before carrying out work, it is very important to determine the technology by which it is planned to build the house, the type of structure and site. The depth of the foundation columns and the material for them depend on this. Materials may be as follows:

- blocks;

- bricks;

- reinforced concrete or rubble concrete;

- wood;

- natural stones;

- pipes made of plastic or asbestos.

Before building a columnar foundation, you should stock up on a number of tools and materials.

Do-it-yourself columnar foundations are usually divided into three types. Determined by depth. This is also worth considering:

- Recessed. The depth is below the ground freezing mark.

- Shallow. On average, forty to seventy centimeters from the soil level.

- Not buried. They are located on the ground in the absence of an underground part. During installation, the fertile layer is removed from the ground, adding non-metallic material.

It is important to know how to calculate the volume of concrete in cubes + calculator

Cost of work

Of course, the total cost will be the sum of the money spent on the required amount of materials and the cost of the work itself. This option is always cheaper than other foundation options. This is due to the fact that all columnar foundations, if desired, can be erected independently, guided only by the instructions.

If you first want to make an approximate cost calculation, you usually resort to the help of special calculators or programs on the global network. There you can do all the calculations yourself. Online calculators are easy to use, they have a clear interface, and even a novice master will be able to understand all the intricacies of the work.

In general, a columnar foundation is a good option for those who do not want to resort to the services of specialists, but want to do all the construction work themselves, without spending a lot of money and effort on them.

With the right approach and patience, you will get an excellent foundation for a future building. If you follow all the recommendations and use only high-quality material, it will last a long time without requiring repair work.

This is interesting: an alternative to concrete for pillars.