In order to have fresh and clean air in an apartment or house, the kitchen must have very good ventilation. Natural ventilation cannot cope with the task of timely removal of odors during cooking, so a special forced ventilation device is hung above the stove - a kitchen hood. How to install the hood correctly, how to secure it and connect it to the ventilation system - more on that later.

Installing a hood in the kitchen is a wise decision

How to hang a hood over the stove

With the correct size, it is equal in width to or even slightly larger than the width of the slab. To install the hood correctly, you need to place it correctly and secure it. The electric hood is located exactly above the stove. The installation height depends on the type of hob:

- The minimum permissible height for hanging a hood above a gas stove is 75 cm.

- Above the electric value is slightly less - 65 cm minimum.

You determine the exact height yourself - based on the height of the housewife who will cook. The bottom edge of the hood should be slightly higher than her head. You shouldn’t hang it lower than the minimum distance, but you can hang it higher. But if you need to hang equipment higher than 90 cm from the level of the stove, you need a unit with increased power so that contaminated air is removed effectively.

Minimum height for installing hoods above gas and electric stoves

The hood is attached depending on the type. Built-in - to a specially ordered cabinet size. Wall hung (flat) and dome (fireplace) - to the wall. The fireplace hoods themselves can consist of two parts - a unit with a motor and filters and a dome. Both parts are attached independently of each other, but so that their outputs coincide.

It is worth mentioning separately about island hoods. They are attached to the ceiling. The kit includes a suspension system and clear instructions on what to do and how to do it.

Types of hoods

The variety of exhaust hoods is quite large, so it can be difficult to decide which hood to choose. All of them are divided into circulating and evacuating, that is, they differ in the way air masses are removed.

The circulation device draws in air, purifies it through a built-in filter and then releases it into the room. This hood has its advantages:

- Easy to install (you can do it yourself).

- Does not require installation of additional communications.

- Does not affect the functioning of standard ductwork.

At the same time, it does not clean well enough, since the filter often does not cope with its task. Consequently, incompletely purified air returns to the apartment. They cost more than evacuation filters, and the filters require periodic replacement, which is an additional waste of money.

The advantage of an evacuation hood is the removal of excess heat from the kitchen area. Of course, it is more difficult to install than a circulation device, but the result of the work will be much higher. Installation of an evacuation type hood is complicated by securing the corrugation or duct through which the air will pass.

We recommend that you read: Types of built-in 90 cm hoods for the kitchen

Depending on the location of the hood, there are:

- desktop;

- ceiling or island;

- fireplace;

- built-in (integrated).

A tabletop hood is a socket located in a horizontal position above the working part of the stove. It is an integral element of professional kitchen equipment.

Ceiling or island mounted to the ceiling. Typically, such a hood is located in the same place where the stove is installed - in the center of the kitchen, which is why it is called an island hood. Installation of the device will require a complex system of false ceilings and air ducts, which requires a professional approach.

A fireplace hood usually decorates the design of large luxury kitchens. The installation diagram and design are drawn up individually. Installation is carried out by specialists.

Judging by the technical characteristics of the available type of hoods, we can conclude that the best option for an ordinary family would be a built-in (integrated) device with simple installation and an affordable price. The retractable hood does not take up much space and is very convenient.

Installation stages

The entire installation and connection process can be divided into several stages:

- First you need to install the hood in the right place. This involves physically attaching it to a wall or ceiling.

- The second stage is connecting to the power supply. If there is an outlet nearby, there shouldn't be any difficulties. Otherwise, you will have to pull the wire from the nearest source; you can use a carrier (extension cord) as a temporary measure.

- The last stage is relevant only for models with exhaust air discharged into the ventilation system. At this stage, the air duct is connected and discharged into the ventilation duct.

It’s easy to properly hang a hood in the kitchen with your own hands

If there is an outlet nearby, there will be no problems with connecting to electricity. The other steps are also not very complicated, but let’s look at them in more detail.

Some tips

When installing a hood, based on the experience of specialists, you should follow some tips.

- When installing, you need to focus on the height of the owner. If her height is below 160 cm, then it is better to install the hood lower. In this case, the optimal distance between the stove and the hood will be 60 cm.

- Do not place any wires above the device. Firstly, this violates fire safety regulations; the wires can become hot and cause a fire. Secondly, it spoils the overall aesthetic appearance. Agree, wires hanging above the hood will only spoil the overall picture.

- Any device makes noise when it operates. No matter what model of hood you purchase, it will still make noise. To somehow reduce noise, you should use a plastic air duct. Its design features help reduce noise.

- When installing the hood, you should pay close attention to the included instructions. It contains all recommendations for installation; they were developed taking into account extensive operating experience.

- If the walls in your house are made of sibit, then you can use simple self-tapping screws. This will facilitate the installation process, while the fastening will be quite reliable. But the main thing here is to accurately calculate the installation location. This material crumbles quite easily, and re-screwing the screw will be impossible.

Now you can safely start installing a hood in the kitchen, there is nothing complicated about it, everything has to be done for the first time. The main thing is to follow all the recommendations and instructions for the device and then your hood will work for a long time and efficiently.

Attaching a wall or dome model to a wall

Although these two models differ in appearance, they are attached to the wall. They have four holes on the back wall of the case - two on the left, two on the right. Many manufacturers provide their products with a mounting template on which the locations of the fasteners are marked. All you need to do is lean the template against the wall and move the marks. If there is no template, measure the distance between the holes and transfer it to the wall. If you have an assistant, you can ask them to hold it at the selected height and make the marks yourself.

The hood must be attached to the wall through the standard holes in the housing.

Then everything is simple: use a drill to make holes of the appropriate size, insert plastic plugs for the dowels, then hang the hood on the dowel-nails. Naturally, we check that the installed equipment is horizontal.

This method is good if the wall is smooth and nothing interferes. Often there is a gas pipe running next to the stove, which makes it impossible to hang the hood close to the wall. In this case, you can nail wooden blocks to the wall, and attach the hood to the bars. This is a simple option, but not a very good one - the bars become covered with soot and are difficult to wash.

The second option to install the hood behind the pipes is to use a hairpin screw (the second name is a plumbing pin). They have a thread for screwing into the wall, a smooth part, which makes it possible to carry the hood some distance from the wall, and a smaller thread with two nuts, which will be used to secure the body. There are these studs in different sizes, choose which one you need, but all the nuts are made for a bit or an octagonal wrench.

How to install a hood on a wall if a gas pipe is in the way or the wall is uneven

This option for mounting the hood is universal, simple to implement, and reliable. It is also more convenient to clean - the metal is usually stainless, and it is easy to clean it from deposits.

Installing a built-in hood in a cabinet

The built-in hood is almost completely hidden in the cabinet made for it. It is attached in exactly the same way as described above - with screws, only they are screwed into the walls. Only in advance it is necessary to make holes for the air duct in the shelves located above. This is done after the hood has been purchased, since the location of the air outlet depends on the company and model.

Example of installing a built-in hood

If the cabinet is hanging, it is better to remove it. In the removed cabinet, install the hood in place, mark the location of the air outlet on the bottom shelf, and cut it out. To do this, it is easier to use a jigsaw and a file with fine teeth. The laminate file leaves almost no chips. If desired, you can seal the cut area with a plastic C-shaped furniture profile. They are rigid and flexible. The flexible one is easy to use - it bends at any angle; the rigid ones will have to be heated with a hair dryer before installation. These profiles are “set” with glue; most often “liquid nails” are used. After installation in place, remove the remaining glue (with a damp, clean rag) and secure it to the shelf with masking tape. We cut off the excess profile with a fine-tooth file, and clean the cut with fine-grain sandpaper.

The process of preparing a cabinet for installing a hood

We make holes in the other shelves in the same way. By the way, they may no longer be round, but rectangular - it depends on the cross-section of the air duct you have chosen.

After this, all the shelves are installed in place, the cabinet is hung and secured. A built-in hood is attached to it with screws through holes in the body. Next is the process of connecting the air duct.

How to install a built-in hood in a kitchen cabinet yourself?

Unlike a dome hood, the characteristic umbrella of which we notice when entering the kitchen, a built-in hood is mounted inside a kitchen cabinet .

In addition, the exhaust panel can be installed on a retractable mechanism, which makes it completely hidden.

We will consider the installation option without the “pull out/push in” function as it requires more skills from the performer.

Four steps to installing a built-in hood:

- You need to assemble the cabinet itself into which the hood will be built. You can use an existing one, but it will have to be slightly rebuilt.

IMPORTANT! The cabinet needs to be made and install taking into account the parameters of the kitchen and the height of the exhaust device from the stove.The bottom of the future cabinet needs to be raised exactly to the height of the hood itself. The exhaust device will subsequently be attached directly to it. The side walls must be securely attached to the cabinet lid, and the bottom must be secured with Euroscrews.

- We make a slot for the air duct. Usually it is cut from above using a hacksaw or jigsaw.

- Attach the hood body. We remove the bottom of the cabinet and transfer to it the diagram of all the necessary holes for the mounting bolts and corrugations. We drill and cut out holes and attach the body to the bottom. Now you need to securely fasten the entire structure and put it in place.

- All that remains is to stretch the air duct and secure it securely and hermetically. Pull the cable to a pre-prepared socket and test the unit.

In the same way, you can easily install a telescopic hood, which in its essence is a regular built-in hood, with some design features that do not relate to installation issues.

In the video below you can see an example of how a built-in hood is installed in the kitchen:

How to connect the hood to electricity

Since the power consumption of kitchen hoods rarely exceeds 1 kW, they can be connected to regular sockets. It is desirable that they be grounded. This requirement must be met if you want the warranty to be valid.

If the wiring in the apartment is old, you can install the grounding or grounding wire yourself. Just don’t attach it to water supply or heating pipes. This threatens the possibility of electrical injury or even death for you, members of your group or neighbors.

To reach the ground wire, on the shield, find a busbar with wires attached to it or a pipe to which a stranded wire is welded/screwed. You can also connect your own stranded wire to these devices (without discarding those that are already there). For it to work properly, the cross-section must be 2.5 mm, the conductor must be stranded copper, and a non-flammable sheath is desirable.

Connect the hood via Vago terminal blocks

Some hoods come with a plug at the end. There are no problems with connecting such models - just plug into the outlet and that’s it. But there are models in which the cord ends with wires. This is not because of the greed of the manufacturer, but so that the consumer himself can decide how best to connect the equipment. If you want, you can connect a plug. This option is not suitable - take the terminal block and connect through it. Another option is Wago terminal blocks. You need to take three of them - according to the number of wires. In one terminal block, identical wires from the hood and from the panel are connected - phase to phase (the colors may be different here), zero (blue or dark blue) to zero, ground (yellow-green) to ground.

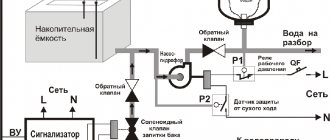

Air duct for kitchen hood

One of the stages of installing a hood is the selection and installation of air ducts. Air at room temperature is removed from the kitchen, so there are no special requirements for air ducts and any can be used. Three types are usually used:

- Aluminum corrugated sleeve. It is good because it is easy to give it the desired shape - it can easily bend at any angle. Simply take a piece of the desired length and give it the desired shape. Disadvantage: the operation of the hood will be noisy, since the air flow causes noise and resonance. The second negative point is that the surface is ribbed, which creates additional difficulties for air flow. Well, one more drawback is that it is difficult to care for: soot and dust get stuck in the grooves, and it is difficult to clean.

- Plastic (PVC) round air duct. Easy to use round polymer pipes. The air duct of the required configuration is assembled from shaped elements - curves, bends, adapters, couplings. They are connected to the pipe due to the presence of extensions on the shaped elements. To prevent the elements from becoming separated during operation, the joints can be coated with glue (liquid nails or Moment). Another option is to fasten with self-tapping screws - three or four for each connection. The advantage of PVC air ducts for exhaust is that they are “quiet”, the smooth inner walls do not interfere with air movement, and the outer walls are easy to clean. The disadvantage is that the assembly process is more complex (compared to aluminum corrugation).

Types of air ducts for kitchen hoods - Plastic square air duct. Also made from polyvinyl chloride (PVC), but has a rectangular cross-section. All other characteristics are the same. Rectangular air ducts are used if it is necessary to save space - they are well hidden behind plasterboard partitions, behind stretch or suspended ceilings.

There is also a difference between plastic and corrugated air duct - price. Polymer ones are more expensive. Despite this, if you have the opportunity to install a hood using PVC, install them. With an equal cross-section, they provide more efficient air removal and are also less noisy.

The cross-section of the pipes for the air duct is determined by the size of the outlet opening on the hood. In the case of rectangular pipes, an adapter is used.

Air duct sizes for hoods

Round ducts are available in three sizes: 100 mm, 125 mm and 150 mm. This is the diameter of plastic pipes and corrugated hoses. There are more sections of flat air ducts and they are presented in the table.

Dimensions of flat PVC air ducts for hoods

How to choose the size? In the case of round pipes, their diameter must match the diameter of the hood outlet. It is very undesirable to install an adapter at the outlet and then use an air duct of a smaller diameter - this will reduce the speed of air purification. And even if the hood is very powerful, it will not cope with air purification.

When choosing the cross-section of a rectangular air duct, its cross-sectional area should not be less than the cross-sectional area of the outlet pipe. And the connection occurs through a suitable adapter.

How to attach corrugation to the hood and ventilation

If you decide to install a hood and use aluminum corrugation for the air duct, you will need to think about how to attach it to the body and to the ventilation. To do this, you will need clamps of the appropriate size. They can be metal or plastic.

To connect the hood to the ventilation system, you will also need a special ventilation grille. It has a hole in the upper part for connecting the air duct pipe. There are holes in the lower part to remove air from the kitchen using natural circulation when the hood is not working.

Attaching the corrugation to the grid on the wall

A grate with a protrusion is suitable for attaching the corrugation - around the hole there is a side of several centimeters, onto which the corrugation is placed, after which it is secured using a clamp of a suitable size.

The corrugated air duct is attached to the hood using the same principle. It has a protrusion on which the corrugation is put. The connection is tightened using a clamp.

How to attach an air duct to walls

For plastic air ducts there are special fastenings in the form of latches. They are first mounted on the wall using dowels. The installation step depends on the curvature of the route, but on average, 1 fastening per 50-60 cm is sufficient. Pipes are inserted into these latches during installation with little effort.

If the air duct needs to be fixed to the ceiling, you can use the same fasteners. But if you need to maintain a certain distance from the ceiling, this type of installation will not work. In such cases, take perforated plasterboard hangers, attach them to the ceiling, and then use small PVC screws to attach an exhaust duct to them.

Methods for attaching corrugations

Corrugated air ducts are attached to the walls using clamps or large plastic ties. If necessary, they are also mounted to the ceiling using perforated aluminum hangers.

Where and how to remove the air duct

Most often, the air duct from the kitchen hood is connected to a ventilation hole through which natural ventilation occurs (due to draft). This is incorrect, since in this case most of the grille is closed by the air duct, and air exchange through the remaining accessible holes will be clearly insufficient.

A significant part of the ventilation grille is closed and ventilation in the apartment will be insufficient

Correctly connect the air duct to a separate ventilation duct. In this case, the same grille as in the photo above is installed on the hole.

If there is no separate ventilation duct, but there is an external wall nearby, you can take the pipe to the street by placing a grille outside. These are two ways to have normal ventilation and ensure normal operation of the hood.

How to take it outside

To install the hood and lead the air duct into the wall, you need to make a hole in it. And this is the only difficulty. Next, an air duct is inserted into this hole and sealed with mortar. From the outside, the hole is covered with a grill to prevent debris from getting in and birds and small animals from settling in.

One example of installing a hood in a kitchen with air exhaust through the wall

To prevent outside air from blowing into the room, install a check valve (in the figure above it is indicated by an oblique line). By the way, it is advisable to install it when connecting the air duct to the ventilation system - so that odors from the pipes do not enter the room.

This is what a non-return or anti-return valve for air ducts looks like

The check or anti-return air valve is a lightweight plastic or metal plate. It is movably attached in two places to the pipe - at the top and bottom, the petals are supported by a weak spring. While the hood is not working, the valve blocks access to air from outside. When the hood is turned on, the air flow bends the plate forward, pressing the spring. As soon as the hood is turned off, the plate returns to its place using springs. If you install a hood without this valve, it may be too cold in the kitchen in winter - outside air will enter the room without problems.

So that the hood does not interfere with natural ventilation in the kitchen

Using a tee and a check valve, by the way, you can install the hood so that it does not interfere with natural ventilation in the kitchen. You will need a special ventilation grille for connecting hoods, a check valve and a tee. A tee is attached to the ventilation grille, an air duct from the hood is connected to its lower entrance, and a check valve is installed on the free outlet, only so that the petals are locked when air passes from the pipe (pictured below).

Anti-return valve for normal natural ventilation in the kitchen

How does such a system work? When the hood is turned off, the petals of the check valve are bent, air from the kitchen enters the ventilation duct through the grille and the open outlet of the tee. When the hood is turned on, the air flow from it unfolds the valve plate, and the air flows into the ventilation system. When the hood is turned off, the springs again open air access through the tee.

Externally, such a system does not look very attractive and will have to be disguised in some way. But this is the only way to connect the hood to the only existing ventilation outlet and not reduce air exchange.

Hood functions in the kitchen

A hood, which can be seen in any kitchen, is a simple device, and regardless of the price and the number of bells and whistles, all hoods have the same operating principle.

Working hood in the kitchen

The hood consists of the following elements:

- Metal body;

- An engine that takes in the air flow (in some models there may be two);

- Filters that purify incoming air;

- A lamp that serves to illuminate the workplace.

According to statistics, women spend more than half of the time they are at home in the kitchen preparing food. And since the air in the kitchen, containing particles of fat and harmful combustion products, negatively affects health, a hood is simply necessary.

The hood will not help to completely get rid of foreign impurities and odors, but without it the situation would be catastrophic, and those who happened to grow up in Soviet apartments can remember that the entire entrance knew when the neighbors on the first floor were frying fish. Many nuances should be thought through in the kitchen for convenience, this also applies to water-saving faucet attachments, which can be found here.

The video shows the functions of a kitchen hood:

Please note: it is believed that in modern apartments, supply and exhaust ventilation is designed to clean the air by pulling it into the ventilation shaft. In practice, this does not happen, since the shafts very quickly become clogged with dirt and dust, so exhaust hood is the most effective way to remove burning particles and harmful substances. By the way, the corrugated exhaust pipe also discharges air into the same shaft, but due to strong injection. It is also necessary to choose the right exhaust duct.

But a hood, regardless of cost, will not work effectively if its power is not enough to work in a room of a certain size. In order not to make a mistake when choosing, you can independently calculate how much power is enough for your kitchen.

There is a formula for this:

Q=12xSxH

H – kitchen height in meters

S – kitchen area

12 – coefficient indicating that within one hour the air in the room should be completely renewed 12 times (according to sanitary standards).

Multiplying these numbers, you get the number Q: this is the number of cubic meters of air that should be renewed in your kitchen in one hour. This parameter is indicated among the characteristics of each hood, and if the device you like has Q equal to or greater than according to your calculations, you can buy it. But reviews of such a meat grinder as Mulinex can be found in this article.