Types of heated floors

Room heating systems of the “warm floor” type are classified into groups according to the type of coolant used and the method of heating control, as well as into subgroups according to design differences.

By coolant type:

- Mermen. Water is used as a source of thermal energy (from the hot water supply system in an apartment or from a heating boiler in a private house). With a wooden floor as a base.

- Using concrete screed.

- Without using a screed.

- Cable.

For temperature control:

- With manual or mechanical control. The temperature regime is set by turning the mechanical thermostat knob or turning on the key for a certain operating mode.

- With digital temperature control. Using a special heated floor sensor, you can press a key to set the required temperature, which will be maintained while the heater is operating.

- With software control. A special program allows you to set the temperature for several days or weeks in advance. The controller will automatically set the temperature in accordance with the parameters recorded in it by the user.

Infrared heated floor

Device and principle of operation

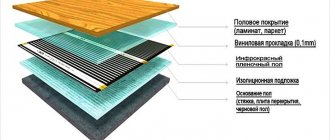

The heating system, which is based on the effect of infrared radiation, is made of ultra-thin heating film. The heating element consists of many conductive strips located at a distance of 15 millimeters from each other. The conductors are hermetically coated on top with a layer of heat-resistant polymer coating. The infrared emitter is connected to the electrical network using a cable passing through the power unit of the temperature controller.

Application of infrared emitters

Infrared film is designed for installation under any surface in the house (under the floor, ceiling, wall), the main condition is that the device does not come into contact with open air and the radiation is directed towards the area that needs to be heated.

Due to the peculiarities of its design, the heating film is ideal for use both in industrial facilities and in residential premises (houses, apartments) or in the garage. An original way to use the film is to heat large containers by wrapping it around them.

The film emitter can be safely installed under any type of floor covering (linoleum, carpet, laminate or parquet board).

Installation features

Infrared film can be laid under laminate (all preparatory work involves laying waterproofing film), under linoleum or carpet.

When calculating a “warm floor” system, two basic rules should be taken into account:

- To avoid overheating of the infrared coating, you should not place it on those areas of the floor that will be occupied by furniture or other massive objects.

- To achieve the maximum possible thermal effect, infrared film must occupy at least 70% of the room area.

Sequence of installation operations

- It is necessary to draw up a plan of the room, which will show the places for installing the heating film and the placement of furniture.

- The concrete screed must be leveled and have differences in height of no more than 1 millimeter per 2 linear meters. If the floor is wooden, it is leveled with sheets of plywood or OSB.

See also: Water heated floor

- To prevent heat loss, a thermal insulating substrate made of foamed polypropylene (3-4 mm thick) and covered on one side with a layer of metal foil is laid on the floor.

- Pieces of thermal insulation are laid end-to-end, and the joints are glued together with special adhesive tape coated with aluminum.

- The infrared film is cut into strips in accordance with the drawing drawn up before the start of work. The cut should be made along specially marked lines on the canvas.

temperature sensor

- The contact points of individual film plates should be insulated with special bitumen insulation supplied with the heated floor.

- The heating elements are connected to the power supply in a parallel circuit.

- The thermostat sensor is located in a groove in the floor, 1-2 cm deep, lined with a thermal insulation substrate, at a distance of 20-25 cm from the intended installation location of the thermostat itself (mounted in the wall).

After completing all installation work, the underfloor heating elements must be checked and only then can laminate or linoleum be laid.

Price

The average price of infrared film is 1000 rubles per 1 m2. The thermostat will cost 2000 - 3000 rubles. If you are not confident in your ability to do the installation yourself, then you should call a specialist. Payment for his services will be approximately 500 rubles per 1 m2 of coverage.

Electrical system

The general operating system of an electric floor differs from standard room heating using a radiator. The fact is that a warm floor warms the air within a range of two meters from the surface. The set temperature of +24 °C allows you to feel comfortable and saves heat inside the house. The radiation that occurs when the coating is heated is also completely safe for health. Moreover, it occurs only in the operation of single-core cables. However, it is worth considering that after installing electrically heated floors, the payment of the utility bill will most likely increase.

The electric type of heated floor is suitable for installation in any apartment, including a kitchen or bathroom. It is easier and cheaper to install than a water one. However, it is more logical to carry out installation work in a new apartment, when the finishing of the house has not yet begun. Today there are three types of electric floors: cable (regular), with heating mats and infrared. Regardless of the specifics of each type, it is worth noting that an electric floor has a number of tangible advantages compared to a water floor. It can be turned on even in summer if necessary, it has an easy control system. The service life is about 50 years.

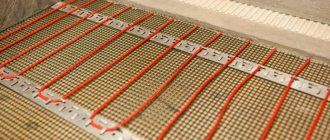

Cable floor

In this case, the floor is made on the basis of a resist cable, which heats up. It is sold both on a reel and in the form of individual sections. The heating element is laid out in the form of a snake or in a spiral in a concrete screed, and then a thermostat is mounted. The gap between the cables should be about 6-12 cm. The thickness of the concrete screed itself is 5-7 cm, and the top layer should be of the wet type. The result is a whole system consisting of separate sections with shielded cables insulated with 2 layers. It is as safe as possible, even in conditions of frequent dampness.

Before laying the cable, you should put a mesh on the soft insulation. It is this that ensures the rigidity of the entire structure and prevents the heating elements from sinking into the screed. The cables themselves are attached to the mesh and must not be crossed with each other.

Installing heated floors in the shower room

Typically, cables with one or two cores are fastened together with hermetically sealed couplings, which also connect the elements to the electrical system. By the way, it needs to be installed close to the thermostat, at the level of the cables themselves. The self-regulating cable is much more advanced than other constant heating models, since it is made from a durable polymer matrix. With its help, you can set the required power for each room. In the kitchen, 120 watts per square meter is usually enough, and in the bathroom, 140 watts per square meter. The coupling is not used when installing such a warm floor. Regardless of the cable model you choose, you need to ask the seller for a certificate that guarantees the environmental friendliness of the production process.

Among the significant advantages of this coating, users also name:

- Elimination of the possibility of overheating;

- Long service life;

- Low cost of consumables;

- Availability of installation for different floor coverings;

- Possibility of using the cable as an anti-icing system.

The disadvantages of cable flooring include the complexity of installation. In particular, it is almost impossible to make a screed yourself, and the work of a specialist requires some time. It is necessary not only to follow the technology of pouring concrete, but also to wait until it dries. The cable itself can only be installed in a month. When laying it, it is important to take into account the size of the loops, the absence of cuts and connections of the two ends in the main. Thus, it is very difficult to select the cable length in advance. You also need to take into account that in the presence of electricity, electromagnetic radiation also appears, which does not have a very good effect on the physiological parameters of some people.

Infrared floor

This type of coating is also called film and is sold mainly in rolls. Such a floor heats the room using a very thin system based on long infrared waves. Thermal film is made from special strips of carbon or graphite, which are held together by a copper busbar, silver paste and contacts. If you choose an expensive infrared heating model, graphite or carbon paste can be applied in a continuous layer. The film floor is especially good because all its elements are laminated on both sides with electrical-type polyester, which creates a protective environment and adds waterproof properties. The temperature of floors of this type in working condition is 25-45 °C.

The copper terminal of each strip on the film is clamped with pliers during installation. The system is connected to a cable that leads to the thermostat. The installed heated floor is not only durable and flexible, but also heat-resistant. When current passes through the strips, the formation of waves is triggered, heating not the air, but objects. Thus, there are no harmful electromagnetic emissions. If necessary, the film floor can be covered with a dry type screed. In general, after laying this coating, the floor level changes slightly, since the thickness of any of the elements in this system does not exceed 0.5 mm. The voltage of such a film is 12-24 volts, so any building with such a floor will be protected from system overload.

The film type of coating is used when floor heating is needed in a room without stationary heating or during the off-season. The film can also be used to warm the walls of the house and the ceiling. Today this is a very popular option for heated floors in kindergartens, hospitals and hotels. The fact is that infrared radiation is considered useful, as it stimulates many intracellular processes in the body.

The main advantages of infrared flooring are:

- Easy to install in a few hours;

- No screed;

- Cost-effective installation and operation;

- Availability of fastening to different surfaces, including carpets;

- Resistance to mechanical damage;

- No air dehumidification;

The main disadvantage of infrared film is its high cost. Carbon samples are especially expensive, but they are much more reliable than graphite ones. Film flooring should also not be installed in damp areas. It should also be taken into account that before installation, you need to check the quality and operation of all components of the floor and ensure that they are not damaged during installation. When installing a film floor yourself, you will need special tools, for example, a flat-type press. If the infrared coating is placed under the tiles, an adhesive will be required. It is laid at least 1.5 cm thick.

Heating mats

This coating option is the cheapest electric-type heated floor. The mats are produced in rolls and are self-adhesive. The design consists of a synthetic polymer mesh and a cable, the installed pitch of which already meets all safety standards. The heating cable is usually two-core and quite thin (no more than 3 mm). The mesh with cable is placed over a thin screed directly into the glue solution.

Heating mats can be installed even under old tiles, porcelain stoneware or natural stone in the house. A floor with a heating mat is suitable for those apartments where a multilayer cable system cannot be installed. This especially applies to rooms with ceramic surfaces: bathroom, kitchen, toilet. Today, heating mats are produced for houses where the floor cannot be raised by more than 0.5-1 cm. After purchasing a roll, the material can be cut into the required number of pieces without endangering the integrity of the heating element itself.

The undoubted advantages of this type of electric floor include:

- Possibility of self-installation;

- Speed of installation;

- Work in the most inaccessible and remote corners of the house.

Unfortunately, warm floors with mats cannot be installed where large furniture is placed and there are no ventilation pockets. Otherwise, the element will overheat very quickly and the coating will fail.