In apartments and private houses, designers often use zoning. The living room and kitchen combine well. Two rooms connected to each other look spacious, and this layout will make the space cozy.

You can update the design, implement interesting ideas, or repeat a design seen in a magazine, TV show, or photo on the Internet. The style in the living room-kitchen can be different, and choosing it can turn into a fun experience.

Before combining rooms, designers advise taking into account the basic rules, creating a project, and choosing colors.

Zoning

Designers do not advise giving in to fashion trends and copying design ideas without taking into account dimensions, location and other nuances. Before planning and arranging furniture, every detail is thought through.

There are several simple rules that experts advise you to follow:

- Let the room have natural light. To do this, remove excess walls (except for load-bearing ones).

- If the rooms in the apartment are small (12 sq. m or 16 sq. m), the layout of the kitchen combined with the dining room will be the right solution.

- If the ventilation system is not designed correctly, the smell of food will spread throughout the apartment.

Partitions

The interior of the kitchen and living room begins to be thought out from the junction of the two zones.

- Here are some of the ways and objects that delimit space:

- installation of a bar counter;

- kitchen island;

- big table;

- installation of a low partition.

Designers advise installing a wide counter, since you can sit at it like at a regular table, and high chairs are quite suitable for the whole family.

However, in small rooms (16 sq m), narrow counters are installed. Kitchen islands are convenient to use, but are only suitable for large kitchen-dining rooms (25 sq m or 30 sq m). Capital low partitions are installed only if it has been decided in advance what they will be used for (for example, as a TV stand).

Finishing

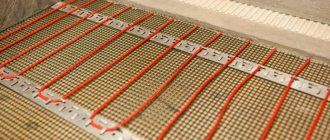

If the kitchen combined with the living room has the same floor covering, then there are no special rules for carrying out the work. When combining different materials, take into account in advance where they will be joined.

For example, laminate flooring creates unsightly joints with tiles. The main thing is that the floor is flat without curved joints, as they will be noticeable.

Kitchen cabinets that are mounted on the walls should reach the ceilings. In some cases, craftsmen “lower” the ceiling with plasterboard.

Furniture items

A few examples of furnishing a kitchen combined with a living room:

- 1. Sofa. It becomes an object that zones space. The sofa is placed with its back facing the place where food is prepared. In small rooms (less than 20 sq m) a corner is placed, which is placed against a wall installed perpendicular or parallel to the kitchen.

- 2. Set. According to designers, minimalist models without elaborate details look modern. The service, vases or glasses are placed on an open shelf. You can buy a fashionable display case for them. Furniture is placed near the wall. If the space is large (20 sq. m, 25 sq. m or 30 sq. m), then in the central part you can install an island, which also has sections for kitchen appliances.

- 3. Furniture set. The style should be combined with the design of both rooms. In small rooms, a compact table and chairs made of transparent material or painted in light colors look good. You can add a table with a round top to your living room interior. In spacious rooms, the kit is installed near the wall or in the central part. An elongated rectangular dining table would look good here.

Elements and components

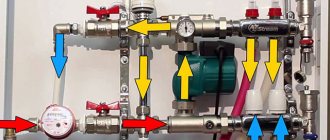

To create all the described schemes, a certain amount of shut-off and control valves and components are used. Some elements are mandatory, such as a circulation pump, while others are used if necessary. In general, most manufactured units use:

- circulation pump of the required capacity;

- control valve (2 or 3 way) with thermal head or thermostatic valve;

- supply and return thermometers (optional);

- bypass, balancing and shut-off valves;

- Ball Valves;

- air vents.

The main elements are control valves and a pump, the operation of which allows the coolant to be obtained at the required temperature in the required quantity.

Valves and taps

The water mixing unit for a heated floor necessarily includes valve taps. Let's look at the features and scope of some of them:

A 3-way valve is a device that is used to mix, separate, or switch flows of water or other coolant among themselves. When applied to mixing units, their main task is to create a mixture with the required temperature for supplying underfloor heating to the network using the hot flow from the boiler and the cooled coolant from the return pipeline.

3-way valve with thermal head.

A two-way valve is capable of changing the coolant flow from one source. That is, when using it, the flow is regulated. When the valve cross-section is reduced, the volume of coolant passing through it decreases, and the amount of water required for pump operation is taken from another pipeline.

2 way valve.

Any of the valves described is simply a locking mechanism, the regulation of which is possible by certain methods. The simplest is manual, when the flow is blocked using a valve. But this is practically not used for mixing units in heated floors, since the autonomy of such a system is questionable.

Most often, thermal heads are used, which automatically regulate the degree of valve opening depending on the readings of a temperature sensor, which is attached to the supply or return pipeline. It is also possible to use servos.

There are also thermostatic three-way valves, to which two branches with different temperatures are connected and from which coolant leaves at a pre-selected temperature. In such a valve, temperature regulation is carried out by sensors built into the body of the device. Unlike a remote sensor, as in thermal heads with a 3-way valve.

Thermostatic three way valve

When choosing either a 3-way or a 2-way valve, it is important to have an idea of such characteristics as capacity (Kvs, Kv). It means what maximum coolant flow is capable of passing through the valve in the fully open position at a pressure drop of 1 bar. Kvs of the valve is standardized and is indicated in the characteristics - 1.0, 1.6, 2.5, 4.0, 6.3, 10...

In general, Kvs depends on the fluid flow and pressure drop across the valve. To do this, use the formula Kvs=G-√dp, where dp is the root of the pressure drop across the valve, G is the water flow.

As an example, we can say that for a heated floor with an area of approximately 50 m² with a pressure loss of about 8 kPa, a valve with Kvs 1.6 is usually sufficient. With a similar system of 150 m² and 10 kPa, the use of a three-way valve with Kvs 4.0 is already necessary.

Pump

A mandatory element of the mixing unit is a pump group for a heated floor, which is selected in such a way as to ensure the supply of the calculated amount of coolant to the heated floor. When choosing, the pressure loss in the longest heated floor loop is also taken into account. Losses depend on the length of the branch, the presence of taps and valves, turns and other elements that create resistance to the movement of the coolant. For calculations, it is convenient to use special programs that are developed by manufacturers of heated floors or use formulas from reference books.

The calculation of the coolant in the heated floor circuit can be calculated using the following formula:

Q=3600⋅P/s⋅(tп-to), where P is the power of all underfloor heating loops; c – heat capacity (for the coolant – water, it is 4.2 kJ/kg); tп and to – calculated temperature of the supply and return pipelines. Typically, the difference should not exceed 10 °C.

For example, at a temperature of the supply and return pipelines of 35 and 25 °C, and a system power of 8 kW, the coolant flow will be: G=3600⋅8/4.2⋅(10) = 685 l/h (0.685 m³/h).

Based on the found flow rate and pre-calculated pressure losses in the network using pump nomograms, we select the model of the required performance.

Pump selection according to the nomogram.

To take into account pressure losses, it is necessary to carry out a hydraulic calculation of the heated floor. To do this, many parameters are taken into account - the length of the loops, the diameter, the number and characteristics of all local resistances (branches, valves, turns, etc.). To simplify the calculation, many manufacturers provide special programs.

Total losses include:

- Pressure loss in the pipeline. They depend on the length of the longest loop of the heated floor, the speed of water movement in it and the diameter and material of the pipe. Above we found the total coolant flow rate passing through the pump. The amount in each loop may vary depending on manifold characteristics, control valve settings, etc., but a value of 0.04 l/min can be used as a rough estimate. That is, if you have a branch 50 m long, then the flow rate for it should be approximately 2 l/min. Using this value and the pressure loss per meter of the pipeline used, we find the total pressure loss in the loop. Specific pressure losses per 1 meter of pipeline are determined according to the loss nomogram for a specific pipe, which can be found in the documentation for the product. If a specific loss of 1 Pa is indicated for a pipe, then at 50 m there will be 50 Pa. In the same way, we take into account the losses on each section of the direct pipeline included in the most loaded loop.

- Pressure loss at each resistance of the design section. They are found by the formula dP=S⋅(V²/2) ⋅r. Where dP is the pressure loss at all local resistances, S is the sum of the local resistance coefficients, V is the coolant velocity, r is the coolant density. The local resistance coefficient for each fitting is indicated in its documentation or in the reference literature. You need to take into account all valves, tees, and other elements.

Total pressure losses consist of the sum of losses in pipelines and local resistances. After all these parameters are calculated for a specific network, the total losses will be found, which serve as the basis for choosing a pump. It must be borne in mind that several units are used for pressure, each of which can be indicated in the nomogram, and sometimes several at once, for example, kilopascals (kPa), meters of water column (N). If necessary, they can be converted using the formula - 1 meter of water column = 9.8 kPa.

Multi-level floor

To zone the space, craftsmen install floors at different levels. They advise installing a podium to separate the kitchen and dining room. This option is considered one of the most practical because, among other things, the owners have additional free space where they can hide something.

It is convenient to use boxes or crates for this. Wicker baskets will look good. But such space can remain free.

For podiums, reliable materials are selected that can withstand heavy loads. Usually builders make wooden or metal podiums.

However, such a design should not be made if there are small children in the family, since the podium can become an obstacle for him. In addition, various floor coverings can be used.

They will zone the space between the living room and the kitchen and protect the podium from damage. For example, tiles are laid in the kitchen area, and laminate flooring in the dining room. The main thing is to choose colors and textures and combine the finishes correctly.

Styles

There are many current trends and design ideas. The kitchen-living room in a modern style looks simple and minimalistic.

At the same time, it is not necessary to strictly adhere to any style; you can take its main idea as a basis and cleverly play with it with accessories and other details.

Main goals

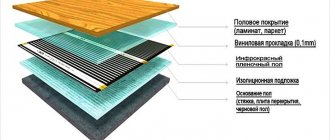

Conventional heating systems are considered high temperature. Most water heating boilers are designed for radiators and convectors that can withstand heating up to 90°C. In this case, the average temperature in the system is usually maintained at 75°C.

This is too much for water heating of the floor covering for the following reasons.

- This temperature will be uncomfortable. It will simply be unpleasant to walk on the floor. Its heating should not exceed 30°C.

- No floor covering can withstand high temperatures for a long time. Over time, it will swell, begin to crack and lose its original appearance.

- Excessive heating negatively affects the concrete screed into which the pipes are laid. It is destroyed.

- To create an optimal microclimate in the house, water heating of the floor covering does not require elevated temperatures.

Modern heating boilers are able to maintain heating of the coolant within a certain range. Installing a separate boiler is not economically profitable. Typically, a heated floor system is connected to a pipeline common with radiators.

How to make a manifold for a heated floor with your own hands:

In this case, the only reasonable solution would be to install a pump unit for a heated floor. It will allow you to mix hot water with the coolant, which has already given off most of the thermal energy. This way you can regulate the required temperature of the floor covering.

People do the same thing manually in the bathroom and kitchen when they turn on the hot and cold taps to get water at the required temperature. Naturally, the mixing unit for heating has a more complex structure than a mixer in the kitchen. Its main task is to ensure balanced water circulation in the system circuits. He must also accurately select the required amount of coolant from the pipes and, if necessary, close the flow into a ring. A good unit should independently adjust its operation so that a person does not have to adjust the heating level manually.

A device that meets such requirements must be complex, so most people buy ready-made solutions in stores. Such units look excellent and function just as well, but their prices are too high. Because of this, there are still people who, after studying all the available information, assemble a mixing unit for a heated floor with their own hands. It turns out that this is not such a difficult task.

Scandinavian

This style came into fashion several years ago, but still does not lose its relevance. Its practicality and European elegance are well suited for a living room in a city apartment or house. You can add bright accents, for example, textiles of different shades.

The basis for the Scandinavian style is white and gray finishing, wooden details. To decorate the space, pink, blue or ocher elements are suitable.

Principle of operation

All mixing units operate on the same principle. The flow of heated water passes through the circuit and is stopped by a safety valve located in the distribution manifold. The valve is connected to a thermostat or sensor that takes temperature readings.

Thanks to the pumping and mixing units, the underfloor heating system operates evenly

If the coolant temperature is too high, the valve opens the damper to allow cold liquid to enter the system. It is mixed with hot water. At low temperatures the reverse process occurs. When the set temperature is reached, the valve closes and the flow of heated coolant stops.

The mixing unit not only controls the temperature of the liquid, but also regulates its circulation in the system. The fulfillment of these two functions is ensured by 2 main elements: a safety valve and a circulation pump. The latter is a key element of the system. It is thanks to him that the floor warms up evenly.

More information about the pumping and mixing unit for heated floors:

Minor elements include:

- bypass;

- air vents;

- shut-off and drain valves.

The presence of one or another element is determined by the tasks and goals of the system. The node is always installed before entering the common circuit. However, its exact location is not regulated.

Loft

This year the style remains in demand. It is often used to equip kitchens combined with a living room. This combination gives more free space, which will only emphasize all the details of the loft.

Today, such a definition as “classic style” is used less and less by designers. Loft - any interior design in which various technical elements are not hidden, but emphasized.

For example, stylists play with brickwork, wires or concrete walls. The photographs clearly show how successful it can look like a living room that is combined with a kitchen.

For loft, rough and heterogeneous surfaces and rough materials are selected. In apartments decorated in this style, wall lamps are installed. In this case, the light is directed along the walls.

Due to this, shadows fall so that uneven surfaces look three-dimensional. At first, loft was viewed with caution, but it quickly became popular. Designers do not hide finishing materials and even fake them. To imitate a concrete surface and smudges, decorative plaster is used.

Designs of mixing units

The diagrams discussed above show only the principle of coolant circulation in heating circuits. For each scheme, different designs of mixing units are used. Moreover, in each of the two types there is a fairly large number of different designs that use different equipment and configurations.

In general, by design, all schemes of mixing units can be divided into the following products:

- on 3-way valves;

- on 2-way valves.

Each of these structures can be made using different elements in different sequences and with different arrangements. Since sequential circuits of mixing units are more common and are more often used in self-manufacturing, we will pay more attention to them.

On 2-way valves

Parallel and series mixing circuits are also implemented on 2-way valves. An example of a node is shown in the image.

Sequential mixing circuit with 2-way valve.

The choice of valve and layout is carried out mainly based on the possible layout of the unit, its location and other characteristics of the system. It cannot be said that the 3-way valve assembly works better, or vice versa.

On three-way valves

If a mixer for a warm water floor is used based on a 3-way valve, the circuit is most often designed as a sequential one. In this case, the three-way valve can be installed both on the supply branch and on the return branch.

Sequential mixing circuit with 3-way valve.

In the first case, it works as a mixing-type valve, in which the water flow from the return pipeline is mixed with the supply pipeline and then pumped through the heated floor branches. When the valve is installed on the “return”, it acts as a flow separator.

It is possible to install a check valve on the jumper between the supply and return pipelines, which will shut off the flow if the pump stops, but with the three-way valve open. This situation is possible when implementing the function of regulating the heated floor with a pump. This valve can also be installed in circuits with a two-way valve or in a parallel mixing unit.

Parallel mixing circuit with 3-way valve.

Two different products are used for mixing and separation and are not interchangeable. The water flow pattern is indicated on the valve body for marking.

Separating and mixing valves.

Neoclassical

Even popular music has echoes of ancient motifs. The same can be said about the design, in which classic details are framed in a fashionable design.

This style is characterized by symmetrical lines, framed mirrors, arched openings, and antique accents. All this is complemented by fashionable finishing materials and accessories. Neoclassicism combines sleek modern details with traditional combinations.

Provence

The name of this destination comes from a region in the south of France. Even a small kitchen-living room, the decor of which was inspired by French aesthetics, will be filled with warmth and comfort.

The main thing is that it has a lot of daylight, textiles with romantic prints, and floral patterns. The dining room in the Provence style is designed in pastel shades. Furniture items can be vintage or artificially aged. Plain walls will contrast with large checkered curtains.

The door in the kitchen area set is sometimes replaced with curtains made from the same material as the tablecloth. A good addition would be vases and figurines, clay pots, forged metal parts and ribbons.

What does the mixing unit consist of?

The mixing unit consists of the following main elements, due to which it can not only regulate the temperature, but also circulate water in the circuit:

- Safety valve - controls the water temperature at the inlet of the heated floor structure. In this way, it feeds the heating circuit as much as necessary.

- Circulation pump - ensures regular movement of water throughout the system at the required speed. Due to this, the heat is evenly distributed along the entire perimeter of the floor.

- Bypass is a very important element when installing a mixing unit. According to the recommendations of experts, it should have a bypass valve. This will help transport water from high pressure to the return line. It is important to take into account here that the bypass for a single-pipe floor heating system must be open so that water from the coolant constantly enters the circuit. But with a two-pipe scheme, it should definitely be closed.

- Thermostatic mixer – used for installation of an automated mixer. Its functions include adjusting the internal temperature depending on climatic conditions.

- Shut-off valves are taps, which come in two types. Ball - change the mode of the mixing unit to maintain a certain temperature. Regulating - regulate the flow of the entire system.

It also includes: an air vent and shut-off valves.

Before connecting the unit, it is worth considering all its main valves.