Building a bathhouse from expanded clay concrete blocks with your own hands is one of the most economical and functional options today. Relatively low cost, ease of use, ability to hold temperature well and exposure to high humidity - all this makes the material an ideal choice for the construction of utility and residential buildings of any size, shape, or structure.

When constructing buildings from the material, it is necessary to follow all technical requirements and know some nuances in order to ensure the structure’s strength, reliability, compliance with all standards and other properties. It is better to purchase the material from a trusted supplier, where large construction companies fulfill orders.

Bathhouse projects

Number of projects 681

- 1 room

- 1 bathroom

Project of log bathhouse 4x6 m

- To favorites

- 60² Total area

- 6 x 4m Construction area

from 225,000 rub.

Construction time individually

- 1 room

- 2 bathrooms

Project Baths 5B-B

- To favorites

- 18.55² Total area

- 5 x 5m Building area

from RUB 300,159

Construction period 17 days

- 1 room

- 2 bathrooms

Project Baths Mercury

- To favorites

- 37² Total area

- 8 x 7m Construction area

from 499,500 rub.

Construction period 27 days

- 1 room

- 2 bathrooms

Bath Rafaella project

- To favorites

- 84² Total area

- 10 x 7m Construction area

from 1,134,000 rub.

Construction period 40 days

- 2 rooms

- 2 bathrooms

Project AS-2272

- To favorites

- 79² Total area

from 1,066,500 rub.

Construction time individually

Project of Log House Baths 4x5 m

- To favorites

- 20² Total area

- 4 x 5m Building area

from 245,000 rub.

Construction time individually

- 1 room

- 1 bathroom

Bani Anapa-5 project

- To favorites

- 30² Total area

- 6 x 6m Construction area

from 405,000 rub.

Construction time individually

- 1 room

- 1 bathroom

Antalya Baths Project

- To favorites

- 74.5² Total area

- 11 x 11m Construction area

from 1,005,750 rub.

Construction period 40 days

- 1 bathroom

Sanduny Baths-2 project

- To favorites

- 48² Total area

- 6 x 9m Construction area

from 587,012 rub.

Construction time individually

- 5 rooms

- 3 bathrooms

Bani Opus Project

- To favorites

- 159² Total area

- 13 x 10m Construction area

from 2,146,500 rub.

Construction time 82 days

Quad bathhouse project "Mega-2"

- To favorites

- 2 x 5m Building area

from 244,900 rub.

Construction time 1 day

- 1 room

- 1 bathroom

Bathhouse project No. 25-11

- To favorites

- 19.26² Total area

- 4 x 5m Building area

from 260,010 rub.

Construction time individually

- 1 room

- 2 bathrooms

Bathhouse project "Anthea"

- To favorites

- 43.2² Total area

- 8 x 7m Construction area

from 1,030,000 rub.

Construction time individually

- 1 room

- 1 bathroom

Bathhouse Ivanovo project

- To favorites

- 93² Total area

- 9 x 9m Construction area

from 1,255,500 rub.

Construction period 52 days

- 1 bathroom

Barrel sauna project 6m

- To favorites

- 13.2² Total area

- 6 x 2m Building area

from 259,000 rub.

Construction time individually

- 3 rooms

- 2 bathrooms

Bathhouse Parkhochevo project

- To favorites

- 146² Total area

- 9 x 12m Construction area

from 3,500,000 rub.

Construction time individually

- 1 room

- 1 bathroom

Project of a garden house-bath "Sanduny"

- To favorites

- 24.2² Total area

- 6 x 5m Construction area

from 326,700 rub.

Construction time individually

Project Hozblok made of timber “Light”

- To favorites

- 18² Total area

- 6 x 3m Building area

from RUB 143,550

Construction time 1 day

- 2 bathrooms

Bani South project

- To favorites

- 62² Total area

- 9 x 8m Construction area

from 994,000 rub.

Construction time individually

- 1 room

- 2 bathrooms

Bani Cricket 2 project

- To favorites

- 62.68² Total area

- 6 x 9m Construction area

from 846,180 rub.

Construction period 38 days

View all projects

Many owners of country houses and cottages build a bathhouse on their property, which is often not just a luxury, but a necessity. After all, you can relax in it after a hard day, relieve stress, and also improve your well-being. Recently, a bathhouse made of expanded clay concrete blocks has become very popular. This option differs from others in its low cost and good characteristics. All the features, advantages and disadvantages of such extensions are discussed in detail below.

Bathhouse made of expanded clay concrete blocks Source vosaduly.ru

What is expanded clay concrete?

Expanded clay concrete is a type of building material. It is monolithic and hardens naturally. It consists of expanded clay, cement, sand, as well as special air-entraining additives. It differs from traditional concrete by its lightweight filler – expanded clay.

Expanded clay concrete block Source beton-house.com

Finishing

Interior and exterior finishing are separate stages of construction work. Expanded clay concrete blocks are a universal material, since different decorative options can be used to cover them.

Internal

Materials that can be used for interior decoration of a bathhouse differ depending on the room:

- steam room - lining made of different types of wood;

- shower room - lining, plastic panels, decorative stone.

For the dressing room and recreation area, you can use any finishing material.

Decorative stone (Photo: Instagram / dekor_kamen.kzn)

External

For exterior decoration you can use:

- lining, wooden panels;

- decorative brick;

- plastic and metal siding.

You can also cover the walls with dry finishing compounds.

Pros and cons of expanded clay concrete baths

For a properly constructed bathhouse made of expanded clay concrete blocks, the pros and cons are dictated by the characteristics of the material. When choosing expanded clay concrete for the construction of a bathhouse, it is necessary to take into account all the features so that in the future the extension will serve for a long time, and its owner will not regret the previously made choice.

The main advantages of objects made from this building material include:

- Installation work is completed in a short time because there is no need for a technological break in the process of working on the structure: for example, when using foam or aerated concrete, you need to wait three to six months.

- Sufficiently large parameters of the blocks ensure ease of working with them. In addition, despite such dimensions, the material is easy to install, so there is no need to use special equipment.

- The construction of a bathhouse from expanded clay concrete blocks occurs without the use of special masonry mortars, because an ordinary concrete mixture or adhesive foam is prepared for fastening the building materials.

- Quite low cost of expanded clay concrete blocks.

- The walls of the structure are very smooth. In addition, their surface is easily amenable not only to plastering, but also to other methods of wall cladding.

- Long service life of the bath.

- No additional vapor barrier of the walls is required, which also helps to save on the construction of a bathhouse.

- Quite low moisture absorption coefficient.

Expanded clay concrete blocks are smooth and easy to lay Source stroim-dv.com

However, in addition to the advantages, there are also several disadvantages that should not be neglected:

- This material should not be chosen if the project involves the construction of a two-story bathhouse with an attic.

- Expanded clay concrete blocks are characterized by increased fragility, which is why they can collapse even from a slight impact or mechanical damage.

- Also, many experts call a significant drawback the need for mandatory cladding of both external and internal walls, and the use of cladding materials, accordingly, increases the cost of money for construction work.

- You need to build a strong and stable foundation.

Building from blocks has both pros and cons, but the number of advantages outweighs the number of disadvantages. In addition, thanks to the right architectural solutions, even the slightest defects can be easily eliminated. For this reason, you can safely order a bathhouse project made from expanded clay blocks, and it is better to turn to professionals for such a service.

Ventilation

Some argue that ventilation is not required in the steam room, since heat escapes through it. However, this only happens in the absence of air exchange control. The steam room will be very stuffy, and your feet will start to freeze.

During bath procedures, the air must be renewed every 2 hours, which requires proper ventilation. As a rule, the inlet is made near the boiler, and the exhaust hole is made under the ceiling on the opposite side. During warming up, the exhaust vent is closed. After opening it, warm air masses begin to escape, which leads to cooling of the room.

It is better to make the inlet hole behind the stove, and a couple of exhaust holes in the opposite corner. One exhaust hole should be lower than the other. This allows half-cooled air to escape. The lower ventilation window is opened to ventilate the steam room.

Ventilation should be not only in the steam room, but also in every room. To eliminate unwanted heat loss, the openings can be closed manually when there is no need for ventilation.

How to choose the right blocks?

To begin construction of the facility, you need to purchase expanded clay concrete blocks. After all, the performance properties of the finished structure directly depend on the quality of materials.

It is better to purchase blocks from a trusted supplier Source ufasnab.ru

See also: Contacts of construction companies that offer the service of building a bathhouse from expanded clay concrete blocks.

First of all, you need to find a trusted supplier who guarantees high quality products - this will allow you to purchase good material with suitable performance characteristics. When choosing blocks, you should carefully check them for chips, microcracks, and deep scratches. In addition, you need to make sure that they are reliable and durable so that they do not crack even from the slightest blow. An important factor is the color of expanded clay concrete blocks, because, for example, dark gray colored products are made from a mixture with a high concentration of cement - they are stronger and more durable.

Construction technology

Compliance with construction technology is the key to the longevity of the bathhouse Source openoblokah.ru

In order for a bathhouse built from expanded clay concrete blocks to serve for a long time, you must strictly follow the rules of the technological process:

- Special beacons are installed at the corners of the intended area;

- a strong rope is stretched between them, around the perimeter of which the blocks are laid (before this, it is necessary to clear the entire area of various debris to prevent deformation of the structure being constructed);

- It is best to remove the remaining mortar used to attach the blocks immediately before it dries;

- reinforcing mesh should be laid every two rows;

- to erect a single-pitched or gable roof, the support beams are fastened with anchor bolts, and then the roofing material is laid;

- In order for the bathhouse to be used during the cold season, it must be insulated with mineral wool, which has water-repellent and heat-insulating properties. It is secured from inside the building;

- the outer surface of the walls is covered with waterproofing and protective material;

- Wood or tiles are used as finishing materials indoors, and wood is most often chosen for exterior finishing.

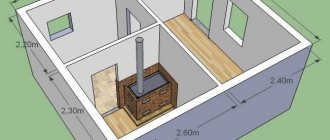

Features of bath design

Design of a bathhouse made of expanded clay concrete Source vashslesar.ru

Before starting construction work, as a rule, they draw up a project that takes into account all the features of the object and the wishes of the owner of the site:

- an accurate model of the planned structure is created;

- the area of the entire structure and the dimensions of each room are determined;

- convenient parameters are established, as well as the location of openings for doors and windows;

- the amount of building materials is determined.

Even if you plan to build a bathhouse from blocks with your own hands, it is better to order the project (photos are posted in the article).

Construction of the foundation of the object

Under a bathhouse made of expanded clay concrete blocks, it is necessary to build a foundation of crushed stone and sand. Its thickness is calculated taking into account the type of soil. The work is carried out in the following order:

- The area is completely cleared of debris.

- The top layer of soil containing plant roots is removed.

- The soil surface is leveled.

- The foundation is marked.

- A ditch is dug, the depth of which is 0.5 m.

- A sand cushion is poured, which must be compacted tightly with feet or special equipment. In this case, you need to constantly add liquid to make the surface hard and well stable.

- A layer of waterproofing is created.

Foundation for a bathhouse Source optopg.ru

After completing all the above steps, you can lay the blocks.

The seam between them should not be thinner than 1.5 cm. In order to increase the strength of the foundation, reinforcing mesh is used - it prevents the building from warping.

Preliminary work on the foundation

Basically, owners prefer to install a strip-type foundation for a bathhouse with a shallow depth. This allows you to save money, since the cost of foam blocks is considerable, and for a standard depth it will cost a little more. You can, of course, use FBS, but still the consumption of materials at a standard depth will be greater.

To begin any construction operation on the ground, it is worthwhile to carefully mark the future structure. But before that, you should remove the top layer of soil and level the area for the building.

Marking is not difficult and can be done with your own hands, carefully transferring the dimensions from the project drawing to the plot of land. You need to mark not only the corners of the building, but also the partitions, which will then be in the middle of the room. Trenches also need to be laid under the partitions so that the load on the foundation is uniform.

Once all the dimensions have been transferred to the plot of land and marked with stakes, you can begin digging trenches. The width of each trench can be made 15 cm larger than the size of the blocks used for the base. You can go only half a meter deep, although sometimes the depth can be only 40 cm.

It is necessary to calculate the depth of depth depending on the expanded clay concrete materials. The average depth for such a foundation is quite suitable. But for the use of lightweight foam blocks, the depth is 10 cm greater than usual standards.

Trenches for foundations, for which FBS slabs are taken, can be made in standard sizes. Since slabs made of such material are quite heavy, they themselves will compact the soil and cause sufficient deep settlement during the pouring and cooling of the solution.

Video description

They tell you more about insulating baths in this video:

Features of external decoration

In order for the finished structure to acquire an aesthetically attractive appearance, the external walls should be finished. For this, as a rule, various materials are used that have not only decorative, but also protective functions. Quite often, preference is given to clinker panels, special facing bricks, plaster, which is then coated with paint, and hanging facades. These materials are beautiful and affordable.

One of the inexpensive cladding options is cement plastering. For it you need to prepare a solution of cement and sand in a ratio of 1:4. The mixture is applied in one layer, and then grouted, so that the result is a smooth surface with a uniform shade. To make the walls look even more attractive, it is recommended that a day after the plaster has dried, cover them with another layer of mortar and rub it in. At the end everything is covered with paint.

Painting as an option for exterior finishing Source blog-potolok.ru

Stages of work to create a foundation for a bathhouse

When the trenches are ready, construction of the foundation of the building can begin. All construction work is divided into several stages:

- Laying a sand-gravel or sand-crushed stone cushion.

- Creation of a waterproofing layer.

- Construction of the first base layer from FBS or expanded clay concrete blocks.

- Reinforcement of the foundation with corrugated rods of medium section.

- Filling trenches with concrete solution.

It is worth remembering that the blocks must be bonded together with a solution before the main pouring.

The optimal dimensions of the seams should not be more than 1 cm. Secondary moisture insulation must be laid after the foundation tape has completely dried. This way there is a greater chance of preserving the foundation from constant dampness.