How and by what parameters to choose

Deciding on the project

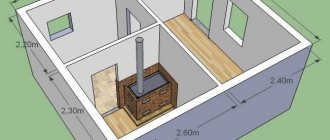

As I wrote above, I would like a bathhouse with an attic. This is the first requirement. Initially, I planned to build a bathhouse with a 6x6 attic. But due to the requirement to build structures on the site no closer than 3 meters to the fence, such a bathhouse size would leave little space on the site (I also have a house, a garage, garden beds and a playground). However, in contrast to this I would like to have in the bath:

- spacious lounge

spacious attic

- separate shower room

- steam room

- separate hallway

Choosing a foundation

It all depends on the soil and the weight of the structure. For most soils and buildings, the choice of a shallow strip foundation made of monolithic reinforced concrete will be universal. It is also possible to choose the most reliable slab reinforced concrete foundation or the more economical screw piles. I settled on a universal tape.

Second tip

:

Selecting wall material

There are the following types of bath walls:

- from rounded logs

from laminated veneer lumber

- from profiled timber

- using frame-panel technology

Roof selection

In fact, it's a matter of taste. I chose metal tiles because of the price-beauty ratio. A more budget option is roofing felt. More expensive, but aesthetically pleasing - soft roofing. Fourth tip

:

Metal tiles

Budget

This is probably the most decisive factor. Everyone should decide how to save on building a bathhouse. In my version, a turnkey bathhouse with electricity, plumbing and heating connections cost around 900,000 – 1,000,000 rubles

! Not bad. What can you save on?

- Foundation – strip – pour it yourself/hire people. Piling – screw in piles with a friend. Savings from 100,000 rubles.

It will be difficult to install the walls of the log house yourself, so you can only save on the type of material. Frame and rounded logs are the most economical options. Savings from 150,000 rubles.

- Roofing - if you are interested in the roofing budget, then roofing felt will cost about 50,000 rubles, ondulin - 120,000 rubles, metal tiles - 130,000, soft roofing - 150,000 - 200,000 rubles. The choice is yours. For me, metal tiles are a universal option.

Therefore, I still settled on the average choice of the 6x5 project.

As you can see, everything is there. Therefore the first advice

for choosing a log bathhouse project:

Personally, I didn’t doubt it for a second - the bathhouse should be made of rounded logs. Glued laminated timber is expensive, frame-panel technology is not for baths. The bathhouse must “breathe”. Profiled timber is a matter of taste. I wanted a log house (or rather, a log house). Third tip

Rounded log

Total, according to my calculations, you can save from 200,000 to 400,000 rubles

.

Fifth tip

:

Look for ways to save money.

So, decide for yourself how to choose a bathhouse. I gave you the main factors using my example. Good luck!

Waiting room

If you plan to place one dressing room in this room, then it is better that the size of the area per person is 1.2 square meters. meters. But if possible, the dressing room can also be made into a relaxation room.

Stove heating is always located in the dressing room, so there must be enough space for fuel material. Based on this, the dimensions of the room need to be increased from the minimum allowable size of 3.44 square meters. meters by 25–30%.

About the rules for harvesting logs for the construction of a log house

Harvesting is the most important process on which the condition of the log house will depend for many years. Coniferous wood is selected for the log house; rot and wormholes are not allowed. The wood should be even, preferably of equal thickness. Harvesting is carried out only in winter, at the beginning. At this moment, the moisture content of the wood is minimal, and the content of natural resin and essential oils, which are natural antiseptics, is the highest. Such a forest is much less susceptible to wood diseases.

The diameter of the logs is important when logging, minimum 220 mm, the largest is considered the best.

After harvesting, the timber is transported as quickly as possible to the place where debarking will be done.

When debarking, it is also important not to damage the top layer of the log, under the bark and bast. The inner loose layer is more exposed to the environment, and drying occurs too quickly

Because of this, the surface of such logs may end up with cracks. Carpenters say that deep centimeter cracks appear only in logs that were processed mechanically, with milling cutters or electric jointers.

After the bark is removed, it is collected and burned, since tree beetles and other unnecessary company usually live in the bark.

If trees are cut down at the beginning of winter, they can be kept without removing the bark until spring. During summer felling - no more than 15 days. The fungal disease, noticeable to the eye as the blue discoloration of the trunks, begins to progress when the air warms above 10⁰C. When selling timber, they always tell buyers about the complete harmlessness and ubiquity of “blue stain”, but it is still a disease, and it is better to do without it.

After the logs are debarked, they are stored in stacks with ventilated intervals of 4-5 cm for ventilation and drying. The stacks are assembled on scraps of logs or thick boards with wedge stops at the ends to prevent the logs from rolling out. Under the stack you need waterproofing - a layer of thick polyethylene film or any other rolled material.

The logs in the bottom row are preferably of the same diameter. The next row of logs is laid on boards attached to the logs of the bottom row. The boards should be no thinner than 80 mm. The stack structure must be rigid and fixed in both directions. A gable roof is installed on top of the stack to protect from rain and snow. To make it more convenient to take logs to the log house in the future, thin logs are placed below, and the thickest ones are placed in the top row.

After laying the stack, all log cuts are coated with bitumen, PVA glue or clay so that drying occurs evenly along the entire length of the trunk.

If you plan to make a log house without compaction between the crowns in order to disassemble and re-arrange it permanently in six months or a year, then you can start cutting from undried logs. But if you are cutting a log house for a permanent place, immediately with inter-crown seals, then you need to take logs that have dried in a stack for at least 1 year.

Everyone understands that if you cut it from a damp forest, and in order to avoid the problem of mold and mildew, do a copious antiseptic treatment, there will be no particular benefit from such a tree. In addition, it may not help, since the wood, which has moisture inside, cannot be saturated with an antiseptic; it will only affect the top layer of the log. Even worse is to varnish raw wood, even with antiseptic treatment. This is a sure way to create conditions for the rapid spread of rot in the inner layers of the tree. The service life of such a log house can be approximately estimated at 15-20 years, in conditions of constant deterioration in environmental friendliness and safety. Drying logs to “equilibrium” moisture content should take at least two years, this is the traditional technology. And if you follow it, then you will not see cracks in the walls, strong shrinkage of the house and various cracks in the corners in your house, as well as wood diseases. A wooden frame can last more than 100 years; this has been proven over centuries of construction practice. Will serve both children and grandchildren.

The next topic is about the design of the log house and cutting methods.

Choosing material

Building a bathhouse from timber is the best option. The price of such a steam room is much cheaper than construction from any other material. Of course, brick and stone are famous for their durability, but preference should still be given to wood, since it is an environmentally friendly material and creates the right atmosphere during bath procedures.

Note! The timber must be well dried, since its operation will take place at high temperatures and humidity.

What kind of timber to build a bathhouse from? The wood should be from coniferous species, since the resin it contains has water-repellent properties, which are so necessary for the steam room. In addition, at high temperatures, logs emit a delicate aroma that soothes and relaxes.

Pine is an excellent product for building a bathhouse

So, timber is the most suitable material in terms of quality and price; when building a steam room with your own hands, this is what you should use.

What we will need during construction:

- Wooden beam.

- Flooring material.

- Lining.

- Lags.

- Hammer.

- Master OK.

- Brick.

- Columns.

- Wooden formwork.

Pouring the foundation

Now we will look at how to properly build a bathhouse from timber and what kind of foundation is needed for this. If the terrain on your site is clayey or rocky, and the groundwater is deep, the best option would be to fill the foundation with a columnar type. Support pillars must be made of brick or concrete.

Columnar foundation

These pillars need to be dug approximately 50 cm into the ground and then concreted. We will waterproof them using bitumen. But do not forget that the distance from pillar to pillar should not exceed 1 m. And the height above ground level is about 30 cm, and you need to make sure that the top of the pillars is level everywhere.

In case of soft soil or shallow groundwater, it would be correct to use a strip foundation for a bathhouse. You will need to dig a trench, insert formwork into it and fill it with concrete.

Ready foundation - strip

Construction of walls and floors

Before you start laying the floor with your own hands, make a slope of 4 degrees. It will be needed so that moisture does not collect, but runs to a predetermined place. It is necessary to attach the logs from the timber to the foundation, attaching them to the lower frame, having previously soaked them with any antiseptic, to prevent rotting of the future lower part of the wall.

When installing logs, do not forget that you still need to leave space for water drainage and the stove. The floor itself must be laid from well-dried pine boards, the thickness of which is 20-22 mm.

It is important to know:

- There should be no gaps between the floor boards.

- The boards must be perfectly dried.

- The floor must be laid on a slope.

- The walls need to be treated with an antiseptic.

- Use paint and varnish products from reliable manufacturers.

Bath walls are erected after the foundation has completely hardened.

Then you need to start building walls using square beams. Select the material carefully, making sure there are no knots or cracks on it. The most common sizes of beams when building a bathhouse are 150 x 150 mm.

Note! Windows in a steam bath must be installed small to avoid heat loss.

For good structural strength, you can make grooves, and use dowels for reliable fixation. When building walls, lay the beams on top of each other as shown in the photo, laying a layer of felt between them to increase thermal insulation.

We build walls

When choosing the height of the walls, build them so that a person of average height feels quite comfortable inside the bathhouse. Be aware that if the internal size of the steam room is large, it will be more difficult to warm it up.

Advice! To insulate walls from steam, use polymer membranes and protective films.

Bathhouse roof installation

Depending on your wishes, you can install a gable or single-pitched roof. A pitched roof is made up of transverse joists, which are installed at a slight angle to ensure water drainage. Roofing material is placed on the boards, which is then screwed to the joists.

We build the roof

A gable roof is assembled from rafters and sheathing on the ground, then raised to the top. This design looks quite aesthetically pleasing, but it will take more time to install. It is better to use slate or metal tiles as a roof for a bathhouse.

All materials and tools that we will need at all stages of work:

- Wooden beam;

- Crushed stone;

- Cement;

- Sand;

- Metal tiles or slate;

- Bulgarian;

- Chainsaw;

- Waterproofing.

Stove installation

The principle of the furnace

If you have instructions, a little experience and drawings, then you can start building a stove inside the bathhouse. The best option is to build a sauna stove from brick, since it has low thermal conductivity, which is very important for a sauna.

Follow these rules:

- The stove must be at least 50 cm away from the wooden parts of the steam room.

- Install the chimney correctly.

- Fire protection is needed between the roof and the chimney.

- The brick for the stove needs fireproof.

Choose a place for it so that it is at least 50 cm away from the wooden walls of the steam room. Use high-quality fired brick with sand-clay mortar for masonry. Each brick must be immersed in water before laying.

When work on the stove is finished, you need to give it a certain time to dry, preferably several days. To remove residual moisture, the stove needs to be heated with dry wood, but it should not be heated too much so that the brick does not crack.

Finishing inside the bath

Interior decoration with clapboard

Upon completion of the construction of the bathhouse, you can start decorating its interior. It is recommended to use unvarnished wood for these purposes.

For the steam room itself, preference should be given to boards made from the following wood species:

- Aspen.

- Linden.

- Birch.

Near the floor, the plinth should be at least 10 cm high.

General description of a log bathhouse

Information.

A log bathhouse is good because its walls heat up faster, breathe, and absorb moisture. It is easier to maintain the desired microclimate in a log structure.

The logs of adjacent crowns are joined along a semi-cylindrical surface 12–14 cm wide. The joints are closed from moisture, since the groove is selected from the underside of the log. Carefully caulked, they do not become bridges for heat escape. The connections of crowns in bathhouses made of chopped logs are insulated with moss, linen tow, jute tape, felt).

The log must be a construction log (for construction), and not a saw log (for creating lumber). For a bathhouse, a “twenty” log is often chosen, less often a 24-centimeter log.

Regular timber: pros and cons

The main advantage of conventional edged timber is its affordable price.

The surface of this material is rough, so it will need to be sharpened and sanded before starting construction. The inside of the timber can be coated with regular varnish. Also, the walls will require exterior finishing for aesthetic reasons.

Ordinary timber with natural moisture causes significant shrinkage. For a bathhouse, due to the lack of interior decoration, this is not as critical as for a residential building - however, the height of the room can be reduced by up to 10%.

Shrinkage of ordinary timber leads to deformation of the finished object and to the appearance of cracks in the walls, which will have to be caulked. A traditional Russian bathhouse does not provide for insulation, so for the sake of maximum heat retention, you should choose the thickest possible timber. If the bathhouse is intended for year-round use, the thickness of the timber should be at least 150 mm. If the bathhouse is made of thick timber and still does not retain heat well, it is permissible to use clapboard, blockhouse or other types of lumber that do not contain chemical impurities and glue for interior decoration.

Protection of log walls

They place a log bathhouse on (with a base half a meter high) or on screw piles.

To protect the logs from getting wet, the foundation is made ventilated - vents are installed on all sides (they are closed for the winter). They don’t skimp on roof overhangs. The larger the overhangs, the better. And the higher the bathhouse, the longer the overhangs will be required.

It is worth remembering that the distances between buildings are the distances between their projections on the ground.

Important! The minimum possible distances between buildings and trees are calculated by specialists and specified in regulations. Their compliance is checked by public services and local authorities

The aspect of fire safety has rightly received special attention. The most important thing is to maintain the distances between wooden structures (or if at least one of them is wooden).

There are distance standards that apply specifically to bathhouses, regardless of the material (for example, from a bathhouse to a poultry house). The maximum of all values must be observed.

A log bathhouse is treated with an antiseptic and fire retardant. The floor, the joists for its flooring, and the lower crown - under the floor - are especially carefully protected.

After using the bathhouse for its intended purpose, it is well ventilated.

Profiled timber 140x90 mm

The size of the profiled timber 140x90 mm, which is included in the cost of our bathhouse projects, is more intended for summer use of the bathhouse, regardless of the amount of insulation. The wall thickness in this case is 90 mm (9 cm). It is better to assemble this beam on wooden dowels, which will save the relatively thin beam from excessive curvature during its shrinkage and operation. Also, the use in construction of profiled timber with a section of 90x140 may be justified in the case of further finishing of the bathhouse from the outside through additional insulation (finishing with siding (plastic panels) or brick lining). In this case, the timber is made not with the profile of a round log (block house) from the outside, but with a straight profile.

Which log house is better for a bathhouse?

Log buildings vary in total area and number of floors. For a bathhouse, they often prefer a small one-story log house with a terrace, the area of one floor is 30–50 m2.

Logs for log houses can be hewn (planed) or galvanized (with the outer layer cut to a given diameter).

In what ways does it lose to hewn:

- cracks appear earlier and larger;

- the log house looks unnatural;

- processing technology removes the densest sapwood;

- wood quality indicators visible on the outer layer are hidden;

- processing technique - with a miter saw, a milling cutter - makes the wood more vulnerable, the log rots and collapses more quickly (an ax and a plane do not saw, but chop, not “shaggy”, but flattening the fibers);

- requires more impregnation consumption;

The main advantage of logs that have gone through a rounding machine is the speed and ease of erecting walls.

Semicircular joints of the same width are not blown through and make the wall more stable.

As a result, the owner receives a beautiful log bathhouse, which does not require additional wall cladding.

But the performance qualities of a log house are much higher if the cambium of individual logs is manually trimmed (the layer immediately under the bark, hygroscopic and attractive to bugs).

In this case, only 1-2 annual rings of the sapwood (the layer between the core and the cambium) should be captured, and the surface should be well sanded.

Information.

The plane removes too thick a layer of wood. A scraper is a more gentle tool designed specifically for this operation.

Wash room size

If the washing compartment does not have a shower, then its area should be at least 1.8 x 1.8 square meters. meters.

When planning a shower room without a pool, you need to take into account that its size should be half that of the steam room. A small bathhouse with shelves, designed for two people, can have an area of 9.6 square meters. meters.

If we take into account the equipment for a small bathhouse in the country, then there is approximately 0.9 square meters left for one person. meter of free space. This place should be occupied by a shower stall or tray, as well as 1-2 benches.

The occupied area of equipment in the washing department of the bath should be 2.25 square meters. meters. If the bathhouse is planned for 3-4 people, then you need to leave about 4.25 square meters. meters.

How to choose a log house for a bath

The construction of a log house is possible from forest materials of coniferous and deciduous species. The types of wood allowed for use and the parameters of building materials made from it are prescribed by state standards.

Conifers

The buildings are erected from pine, spruce, fir and larch logs of grades 1 and 2, average thickness - 14–24 cm, length 3–6.5 m. You can often find a wild log bathhouse - this is when the logs can vary greatly in diameter from crown to top crown, the projections of logs from the walls may also differ. All this creates a picture of the chaotic nature of the construction of the log house, but at the same time it makes the construction more natural, more natural.

It is impossible to build a log bathhouse from cedar due to the fact that when heated, this tree releases substances hazardous to health into the air!

Traditionally, resinous, soft, warm species are used for a coniferous log bathhouse - pine and spruce. One or two lower crowns are made of larch - harder, denser and more durable. (Larch also goes on beams - under the floor and under the rafters).

Information.

It is more pleasant to steam in a spruce bath, and healthier in a pine one. Spruce removes excess moisture well, while pine breathes better. In terms of durability, one is not inferior to the other.

Building a bathhouse from larch will cost more (due to the higher price of the material and labor - larch is difficult to process). The walls of the bathhouse will be colder (almost a third) and heavier. The smell of this wood when heated is not to everyone's taste.

But the fire resistance of larch is twice that of pine. It tolerates high humidity much better than other breeds and is not inferior to rounding. (The core of its trunk is strong and moisture-resistant, the sapwood is weaker and very narrow).

Hardwood

For a log house made of deciduous wood, 2nd grade logs with a thickness of 12–24 cm and a length of 4–6.5 m are suitable.

Moreover, if the walls of the log house are designed to be longer than 6.5 m, then the design is complicated by internal capital partitions.

Baths are built from the trunks of maple, birch, aspen, poplar, linden, willow, beech, elm, and hornbeam.

Ash is not suitable for wet areas. Oak is used for the crown molding (and floor joists).

Aspen is considered ugly and too soft (it grows quickly and does not have time to gain strength). The tree gains a thickness suitable for construction late, when the trunk begins to collapse from the inside. But if the aspen was felled healthy, it remains strong for a long time. An unsightly, but useful protective film for the wood is formed on the surface of the planed log. As a result, aspen:

- not afraid of humidity;

- flammable;

- unattractive to most pests;

- sold at a low price.

Log cabins made of aspen are common: you can buy a large amount of wood, select commercial logs, and use the rest for firewood. After sanding, the aspen log house looks decent, and the steam in the aspen steam room is “softer” than in the log bathhouse made of pine.

An aspen bathhouse does not “breathe” well; the room requires proper ventilation after its intended use.

Linden is similar in roughness and softness to aspen, but is susceptible to rotting. They build linden log cabins from logs with their own hands because of the unique aroma of wood. As a last resort, only the top crowns, or only the shelves, are made linden - they do not heat up as much as those made from dense wood.

Birch is harder than aspen and linden and less prone to rotting during growth. Birch wood warms up better.

Dimensions and calculation of the steam room

When calculating, you need to focus on the area of the steam room and other rooms.

Estimated steam room parameters for 4 people:

- The width of the steam room is 1.8 meters.

- The length of the shelves is 1.8 meters.

- The width of the shelves is 0.6 meters.

- Number of shelves – 3 pieces.

- The total width of the shelves is 1.8 meters.

- The safe space near the stove and the remaining space on the floor is 0.7 meters.

- The total area of the steam room is 1.8 x 2.4 x the number of people.

Processing logs for logs

The basic rule for building a log house is to process it exclusively with hand tools. It is clear that this rule is not always possible to follow. Nowadays, log houses are mostly not cut, but “sawing”. Not only the preparation of wood, but also the selection of a longitudinal groove and the processing of corners is done with a chainsaw. And this is understandable, the speed of construction should be as high as possible, and labor costs lower. But you need to know that with this method of processing, the capillary fibers of the wood, in which moisture accumulates, remain open. The resulting saw cuts continue to absorb and accumulate moisture. The internal moisture content of such logs will be higher than that of chopped logs. At the same time, heat loss and the risk of rotting and damage by mold and mildew increase.

When processed with hand tools - an axe, chisels, scrapers, planes and jointers, the wood capillary tubes become clogged and can no longer take in and accumulate water. As a result, the log house retains heat better and suffers significantly less. Modern craftsmen choose the best of two technologies - they save their time and labor by working with power tools and a chainsaw, but leave a few centimeters to the marks. And then they do the cutting using an ax and hand tools, closing or “plugging” the capillaries of the tree. Experts say that with this method of work, wood cuts do not differ from those processed by hand.

Modern wood materials have many advantages. Calibrated (rounded) logs, profiled and laminated veneer lumber have valuable advantages and excellent appearance. But they lack one unique property compared to a solid log. During processing, the integrity of the tree is violated, the resistant outer layers are removed and the looser inner layers are exposed. Subsequently, in order to achieve the necessary resistance to external factors, wood is periodically treated with biostability compounds, which does not make the wood more environmentally friendly, on the contrary. However, there are also folk safe and useful methods and means of processing; the only negative factor is the time factor.

A special unique property of coated wood is its high resistance to diseases.

Brick bathhouse

The least fire hazardous option is considered to be a brick building. A brick bathhouse can withstand constant loads and has a long service life.

The disadvantage is high thermal conductivity, as a result of which more time is spent heating the steam room.

The thermal conductivity of brick walls inside a built bathhouse can be reduced by using a thick layer of thermal insulation between the brick and the cladding.

Which cladding is best to use? The ideal option would be eurolining, against which bath accessories look good.

A foundation for a brick building is required if the floor does not have load-bearing capacity. To fill the foundation, a trench is dug in the ground with a depth of at least 0.3 m and a width of 0.25 m.

Brick ligation can be performed using one of the following systems:

- single-row - the masonry is strong, but more labor-intensive,

- 3-row – used for pillars and narrow partitions,

- multi-row - allows you to use bricks more efficiently.

At the dacha, for a brick bathhouse, it is better to use lightweight 0.4 m masonry. For insulation, the gap between the walls is filled with a mixture of light slag, sawdust and lime.

Additionally, you can attach tile insulation to the inside of the bathhouse, leaving an air gap between them.

The walls of a bathhouse built of brick should not come into contact with the ground, otherwise they will become saturated with moisture.

To do this, you need to organize waterproofing: coating with bitumen mastic or gluing roll-type material. For plastering brick walls, a solution consisting of cement and lime interspersed with light aggregate material (pumice, fine slag, expanded clay) is used.

Choosing wood for a log house

A real log house is made from coniferous wood harvested in winter. Pine, oak, larch and ash are rot-resistant. Cedar, fir, larch and spruce are classified as moderately resistant. Deciduous wood is classified as low-resistant and unstable; this wood is more susceptible to insects and various diseases.

In terms of cost, cedar, oak and larch are much more expensive than pine and spruce. Pine wood is plastic, and when processing it with hand tools it is easier to avoid scuffing and chipping. Pine is a strong energy donor. Many specialists in wooden architecture consider pine wood to be the best material for modern private builders, and not only because of its cost-effectiveness. Spruce is also a good option, but it is a little more difficult to process and is more susceptible to various diseases. But the heat-conducting properties of spruce wood are higher than those of pine, and a spruce log house will be warmer than a pine one at the same thickness.

Options for country baths

You can build a small bathhouse for your dacha, and if the site allows, you can build a larger structure, but first you need to decide on the choice of location:

- Place separately . The purchased separate bathhouse is very popular. Such buildings are prestigious and can be small for one person or entire complexes with swimming pools. In addition, they can be installed near a water source.

- Attach to the house . This type of bathhouse is good because it allows you to connect both parts of the building, for example, with a completed winter terrace. This reduces heating costs.

- Arrange inside the house . This is a good economical option for a bathhouse in the country, since you don’t have to spend money on communications and heating.

What type of sauna is most suitable for a summer residence? Each owner of a summer cottage must make a choice based on his material capabilities and needs.

Choosing a foundation for a bathhouse

When building a bathhouse, a columnar (cheaper) or strip foundation is more often used - this depends on the type of soil in the area. If the soil is formed by coarse-grained sand or rocks (weakly heaving soil), preference is given to a columnar foundation: at the intersection of the outer walls and in the corners of the building, supports 38 x 38 cm are placed, based on bricks or rubble stones filled with cement mortar.

Asbestos pipes filled with concrete mixture are also suitable The gaps between the supports are filled with gravel or half-brick brickwork is laid out. Or they don’t lay it out so that there is good ventilation of the bottom of the bathhouse, if it was specially raised higher, due to the high groundwater level and possible flooding.

And besides, our savvy people arrange a columnar foundation on car tires , which you can read about on the Internet, they assure that this is the most profitable way.

For those who do not want to bother themselves with excavation work and need to build a foundation as quickly as possible, in most cases screw piles are suitable, which, by the way, is no more expensive than a strip foundation.

It is better to do a strip foundation when it is really necessary (heavy bathhouse, made of stone, complex, heterogeneous soil), because it is quite expensive both in terms of labor and monetary resources.

Where is the best place to place it?

One way or another, a wooden bathhouse is considered a fire hazard . Therefore, the best place for it is a corner remote from the main capital structure. By the way, it will be great if there is some body of water nearby (but not closer than 20 m, so that there is no chance of flooding the bathhouse). And if there is no natural reservoir on the site, an artificial one can be organized. Then, after steaming, you can run out of the steam room and plunge into cool, clean water - double pleasure!

An exception may be bath houses , which are increasingly appearing in suburban areas. But this is a separate topic that requires an individual approach. If you are interested in it, read it here.

Requirements for a Russian bath

An important requirement for a bathhouse in a summer cottage is the minimum time for preparation for use. In a word, the room and water must be heated to the proper level in the shortest possible time. Usually this is no longer than an hour.

Next comes a chain of quite a few important requirements: low cost of its construction, the likelihood of quick installation and reconstruction with your own hands or with the involvement of unskilled labor, durability, reliability, economical consumption of firewood and water and ease of maintenance.