The advantage of heated floors

- Does not take up additional space, which allows you to implement design ideas.

- Guarantee that there are no drafts in the house. The heat evenly rises by 2-2.5 meters, which is ideal for warming up the apartment.

- Electric models are equipped with a heat regulator, which allows you to control the temperature according to the outside temperature.

- The air does not dry out and the optimal humidity of the room is maintained.

- Compared to traditional heaters, it warms up the room faster.

- Heating systems are hidden from prying eyes, which does not spoil the external style of the room.

Which cable is best to choose for underfloor heating: characteristics

When choosing, it is important to consider the following nuances:

- The price of the product should not be very low, because such a cable can quickly fail. Therefore, it is better not to skimp, but to take a trusted manufacturer that will last longer.

- Consider installation costs. The resistive option requires additional investment in the purchase of a temperature controller. When choosing a self-regulating option, purchasing such a regulator is not required. For a large room, it is recommended to select a resistive type wire. If in the future a rug will be placed on the floor, then it is worth purchasing a self-regulating wire to prevent local overheating.

- To decide on a cable for a heated floor, it is worth considering the functionality that will be assigned to it. For direct heating, a two-core or single-core cable or a heat mat is suitable. Before installing the floor covering, such products are laid in a thin layer of screed. This approach allows you to warm up the room in a short time. If the function is to accumulate heat, then it is worth using a self-regulating or two-core resistive cable. In this case, the system can cope with heating concrete with a thickness of 5 cm.

When choosing a cable, it is important to take into account many nuances, because this is the only way to achieve high-quality system operation.

Two-core

One core is used to generate heat, the second to provide electric current. The installation process does not require installing the two ends of the cable at one point. The two-core model has a return core and an additional insulating coating, which guarantees safety during cable operation.

Single core cables

Provides heat transfer along the entire length. The disadvantage of such a cable is a possible overheating point. Some areas of the flooring will be too hot. When installing, you must ensure that both ends are at the same point.

Alternative heating methods

If for some reason the arrangement of cables is impossible, then the house can be equipped with electrical mats. Such heating devices are very convenient for arranging heated floors, and they require minimal financial costs. If the cost of one meter of self-regulating wire is in the range of 5-10 dollars, then electric mats are much cheaper, and their efficiency is not inferior to a heating cable.

You can find carbon and cable mats on the market. They differ from each other in technical parameters, installation method, production material and operating principle. They are similar to each other only in appearance. Each of the mats is a long thin track that can be easily rolled into a roll.

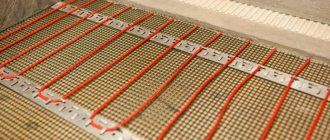

Cable mats

If you carefully consider how the cable mat is designed, you can understand that it is, in fact, a single-core cable. The only difference is that it is attached to a special mesh like a “snake”. The required distance is maintained between each turn. This kind of heater is best suited for tile coverings, since its entire thickness does not exceed 3 cm.

This heating mat is placed on the floor. The area underneath should be free of bumps and debris. This requirement is due to the fact that the mat is fixed through a special adhesive base located on the underside of the mat. The roll is rolled out, starting with the temperature controller. When it is necessary to rotate the mat, it is allowed to cut the reinforcing mesh, but the wire must not be touched under any circumstances. It can only be rotated at the required angle.

After this, the temperature controller is installed, the wires are laid and the base is glued. Then the system is checked for functionality, after which the film is glued to the floor and covered with tiles or laminate.

Carbon version

A carbon mat assumes the presence of rod heating elements connected to each other like a rope ladder. They have special coatings that, when electrical voltage passes through them, make it possible to emit infrared radiation, which is thermal energy.

Each element of this chain works independently and is not influenced by other rods. The undoubted advantage of this system is that if one of the elements fails, this will not affect the operation of the others. In addition, such a device, like a self-regulating cable for underfloor heating, is capable of autonomously monitoring the external temperature of the situation and responding adequately to it. At the same time, the cost of such devices is much cheaper, and their service life is no less.

There are many options for organizing electric floor heating. Of course, in each case, the selection of a heating element is made individually, taking into account the characteristics of the floor, its external covering, the complexity of installing the system and financial capabilities.

What wire gauge is needed?

The maximum current for thermostats is 16 A, the load is 3.5 kW. If the floor is connected to one thermostat and the total power of the system does not exceed 3.5 kW, then a pickup point with a cross-section of 1.5 mm2 is suitable for operation. If this figure is higher, then you should pay attention to models with a larger cross-section. So a model with a cross section of 2.5 mm2 can withstand a load of 25A.

If you still find it difficult to choose a section, it is recommended to pay attention to the data in the table.

Recommendations and installation rules

Useful advice from professionals in this case will never be superfluous. It is worth eliminating the intersection of the cable and the formation of loops. The arcuate contour resembles a path from beginning to end.

No contact with the rest. The distance from metal structures is at least 5 cm. Wooden ones can be located in three. The rest is up to personal requirements. Heat sources at least 50-60 cm.

The laying step is 6-10 outer diameters of the electrical wire. That is, 2.8 * 6 = 16.8 cm. In this case, the hot part is placed in insulating material. Nothing is connected directly to the network. There is a regulator for this.

It will ensure proper functioning without any third-party complications/problems. Connection using terminals. They are crimped with further insulation. For power surges, choose an uninterruptible power supply or automatic.

All this is the key to the successful functioning of the entire system. The specific choice is a matter for people in their individual situations. All advice on this matter is wrong. The exception will be safety measures for the operation of electricity in general.

- Related Posts

- How to lay cable heated flooring?

- How to make a warm floor from a heated towel rail?

- How are PEX pipes connected for heated floors?

- How to install damper tape for heated floors?

- How to lay a water-heated floor under tiles?

- What concrete is suitable for a warm water floor?

Laying wires in a screed under heated floors with your own hands

Installation of the heating cable is carried out in several stages:

- A cement-sand screed with a thickness of at least 3 cm is poured. To lay the wire that will pass to the thermostat, you will have to cut a channel, the diameter of which is within 2 cm.

- Installation of a heat-reflecting substrate layer.

- Installation of reinforcing mesh on which the cable is fixed. If you do not use a mesh, you will have to install tape. The product should not be placed under furniture.

- The wire is being laid.

- The heat sink is installed in a special corrugated tube and placed in a groove.

- A cement screed, 4 cm thick, is poured. Ohmic resistance and insulation resistance are indicators that should be established to determine the performance of the cable after pouring. Laying the floor covering is carried out after the solution has completely dried, which will not happen earlier than a month.

Taking into account nuances when choosing

Some criteria are still worth considering. The first factor, and sometimes the most important, is the price of the wire for the heated floor. Cities such as Moscow or St. Petersburg have large construction hypermarkets.

Having so many choices confuses people, not to mention sales assistants. The ideal option would be to contact installation companies. They have experience and knowledge.

Based on which you can draw your own conclusions. After all, a proven manufacturer does not always give the necessary results.

We recommend: How to install heated floors under PVC?

A resistive electric cable for underfloor heating operates only with the help of a regulator. This is a special device responsible for setting a specific temperature. This set is 100% mounted on medium and higher areas.

That is, 20 square meters and beyond. Self-regulating works without such equipment. Plus, it is more suitable for some finishing coatings followed by the placement of decorative elements.

The final choice still occurs after counting all the pros and cons. A person needs to set expectations so as not to have problems with implementation in the future. Sometimes it is possible to use mats instead of both cables.

In all cases, it will have to be covered with a concrete screed. Its thickness should not exceed 5 cm. This is enough to warm up in a short time.

It’s better to choose a cable or mat

The cable consists of one or more cores with insulation and an outer sheath. Installation of such a wire will be carried out in a screed, the thickness of which is 3 - 5 cm.

It is recommended to install the cable under:

ceramic tiles, porcelain stoneware, natural stone, self-leveling flooring, laminate, parquet boards, PVC tiles, linoleum, carpet.

This floor can be called almost universal.

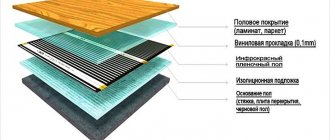

There are two types of mats on the market - convection and infrared. This cable is thinner and is fixed at the correct distance on a mesh base. Mats take up less space; a smaller screed thickness of up to 5-10 mm is required. Installation is simple and does not increase the planned height.

Simple installation often determines the choice in favor of a mat. The film is laid lengthwise on a thin layer of thermal insulation, and the floor covering is installed on top. Unlike the first option, you do not have to make a screed and fill the floor with cement. This approach allows you to use mats on a vertical surface. Having assessed the advantages of the presented materials, many prefer the latter. Such efficiency and ease of installation captivates many users, which is why the popularity of mate flooring is growing every day. It's worth watching the video once to learn the editing technology.

Warm floors are the key to comfort for home residents. It can be an auxiliary element of the heating system or replace it. The main advantage is ease of installation and significant savings in resources. But for the system to function correctly, you need to select the right cable. The selection criteria are very diverse - from the cross-section to the expected load. Be sure to decide on the functionality to be assigned to the heated floor. Then the cable selection process can be greatly simplified.

You can make a warm floor yourself using simple panels that can be installed even without pouring cement. It is worth carrying out installation procedures to evaluate the benefits of heated floors in action.

Useful video

Cable underfloor heating is a modern, practical and reliable system, suitable for both main and auxiliary heating of rooms of any type and size. It is simple and convenient in everyday use, provides exceptionally high heat transfer and does not introduce dissonance into the interior design of the home. The equipment set includes three basic components, namely:

- heating element (cable);

- thermostat;

- sensor.

It is these positions that you should pay the main attention to when choosing and purchasing floor heating equipment.

What you need to know about the heating element of a cable heated floor

The electric cable is the basic heating element of a cable system designed for underfloor heating. When purchasing equipment, you should first find out what its power per unit length is. Various manufacturers and brands offer their customers electrical cables with a specific heat release level ranging from 17 W/m to 21 W/m. Even a minimal excess of these indicators is considered not only extremely undesirable, but also unsafe. In a cable floor heating system, two types of cable are usually used: self-regulating or resistive.

Wire for heated floor

A system with such equipment needs a fundamental element. It becomes an electrical cable. It happens:

- resistive;

- self-regulating.

The first point, in fact, consists of a two-wire radiation source. Each wire performs its own function. One carries current, the second converts it into heat. A complex design is actually a safer option. The insulating element becomes the return core.

Shielding prevents heating to a certain temperature. If installed incorrectly, a self-regulating/single-core cable will overheat at specific points.

Wire structure for heated floors

This is reflected in the finish coating and leads to malfunction of the entire system. Which one to install is a purely individual choice. A competent approach allows for option 2 even without the advantages of the first.

Thermostats

Thermoregulator (thermostat) is a device designed to control the heating system. Allows each user to control the heating temperature level, reducing or increasing it at will.

In the modern market, accessories of this type are offered in a wide range by various brands. The cost of devices largely depends on. The cheapest models are made by China; in the middle price segment, products from Belarusian and Russian enterprises predominate, and the highest prices are asked for products from Danish, Finnish and Swedish brands.

Another cost component is the type of thermoregulatory device. Simple and unpretentious devices with a minimal set of functions will cost the client significantly less than ultra-modern programmable models with an extensive package of capabilities and a memory base that allows you to set the desired heating mode for 3-7 days.

The third pricing factor is the management method. Today, mechanical, wireless, push-button and touch-sensitive thermostats are available for sale. The more complex and sophisticated the design of the device, the more money you will have to pay for it. You can find a mechanic for a fairly budget price, but a modern touch-screen version with the ability to program the system on/off several days in advance will cost a tidy sum.

Before purchasing a thermostat, the user must clearly decide which functions of the device will be used regularly and only then make a choice. There is no point in overpaying for unclaimed features.

Sensors

Thermal sensor (external or internal) is a small communication device necessary for the full functioning of underfloor heating equipment. It reads the air temperature level in the room, records the degree of heating of the floors themselves and sends the information to the thermostat processor.

- Internal temperature sensors are mounted in the floor structure, directly between the turns of the heating electric cable. Designed to control the heating of the floor system.

- External devices are most often located in the thermostat itself and monitor the air temperature in the living room.

In underfloor heating used as an auxiliary heating system, only internal temperature sensors are usually installed. If the equipment is the main and only type of heating available in an apartment or house, then the issue of ambient air temperature becomes extremely important. Therefore, it is necessary to install additional external sensors.

When cable heated floors are placed under laminate flooring, wooden parquet or any other material susceptible to overheating, there is an urgent need for an increased temperature control system. In this case, both types of sensors must be installed.

Rules for installing cable floors

You can lay an electric cable heated floor under a concrete screed, in the thickness of the screed and on the surface of the screed. Each type has its own installation features. But when providing them, you must adhere to the following rules:

- To fully heat the room, the heating system must occupy 70% of the floor area. Therefore, before starting installation work, it is necessary to draw up a diagram of the layout of the electrical heated floor cable circuits.

- To prevent additional costs, before purchasing wires, first calculate their length. This precaution is due to the fact that the circuit is made of solid wire in compliance with the permissible pitch.

- If mats are chosen as heating, it will be enough to spread them on the prepared surface. If the wires are purchased in reels, you will need certain knowledge when installing them. Therefore, before performing them, you must read the instructions.

- When installing an electric cable heated floor, deformation of the cables is not allowed. Every sharp bend and intersection between contours can lead to irreparable consequences, up to and including the failure of the system.

It is also worth mentioning that although electric flooring can be combined with almost all finishing coatings, it is not advisable to use it with combined floors. Also, without a concrete screed, it is not recommended to lay it under natural wood, otherwise, under the influence of high temperature, the floor will begin to dry out and deform.

To sum up, we can say with confidence that cable underfloor heating is indeed a new innovative system that has surpassed other types of heating models. If installed correctly, in compliance with operational restrictions, the cable floor can serve as an ideal source of heat for your premises for many years, without additional costs.

AdminAuthor of the article

Did you like the article?

Share with your friends:

Comments (1)

- Vladimir June 01, 2021 at 14:33

Recommend underfloor heating for a room of 20 m2 in a rural brick house with one window. Floor: waterproofing, sand, extruded foam 100 mm, reinforced screed 45 mm. Next is porcelain tile. Power, cable length?

Answer