- Infrared film heated floor

- Infrared film heated floor: pros and cons

- Types of infrared films

- Features of carbon and bimetallic IR films

- Technical characteristics and operational scope of film flooring

- Film heated floors Caleo

- Infrared film floors from the Rexva brand

- Features of IR films from Heat Plus

- Warm floor infrared film Monocrystal

- Infrared heated floors: consumer

- Drawing up a connection diagram for a film heated floor

- Preparing the base for laying infrared film

- Features of laying film heated floors under laminate

- Installation of infrared heated floors under tiles

- Features of installing film heated floors under linoleum

- Infrared warm film floor: prices

- Video: installation of heated floors under laminate and linoleum

Infrared film heated floor

Infrared film heated floor: photos, review of models, prices and installation. Previously, installing infrared flooring was considered a luxury, however, today this method of heating rooms has gained wide popularity. Warm infrared film flooring is a modern and practical option for organizing primary or additional heating in a room. In this article we will look at the benefits of installing infrared film, its types and compatibility with floor coverings.

Thanks to infrared film heaters, an economical and efficient underfloor heating system can be built in a matter of hours

Infrared film heated floor: pros and cons

Heating using IR film has many advantages over other types of similar heating. Let's consider the main advantages of this heating design:

- such a system cannot fail at the same time, since it is connected in parallel;

- possibility of installation on any type of surface - both horizontal and vertical, as well as on elements that are located at an angle;

The film does not contain components hazardous to human health, does not produce unpleasant odors or toxic fumes

- The design features of the infrared floor make it possible to achieve uniform heating of the room. This is especially important if laminate is used as a floor covering;

- another advantage of such a system is ease of installation;

- possibility of disassembly if necessary;

- this film is suitable for installation in rooms where the humidity level exceeds the permissible parameters;

- compatibility with different flooring options;

- installation of such a system is allowed not only in enclosed spaces, but also in open conditions (for example, on a veranda);

- high heat transfer coefficient, which reaches 97%;

- The efficiency of film infrared flooring is approximately 30% higher than that of other underfloor heating systems. The prices of film heated floors fully correspond to their effectiveness.

Note! When choosing IR film for organizing floor heating, you need to take into account one very important parameter - the height of the ceilings. The lower the ceiling height, the more efficient the heating of the room.

However, this design also has some disadvantages, among which are the following:

- the need to follow clear rules when connecting;

Unlike other heating systems, infrared floors act directly on the surfaces of heated objects and do not dry out the air in the room at all

- high inertia, due to which heating and cooling occur very quickly;

- poor resistance to mechanical stress in comparison with a tubular structure that uses water as a coolant.

The film system is generally not suitable for installation as the main heating system. It is recommended to use an infrared design for additional heating.

Pros and cons of infrared film flooring

There are many advantages of infrared heated floors:

- low price of installation materials, which includes the film itself, thermostat and cables;

- ease of installation, which can be done independently; no special knowledge or skills are required;

- the ability to very quickly (in a few hours) install a heating system, and alone, without assistants;

- warm film can be used as the only source of heating and abandon all other heating systems that are expensive to install and maintain;

- Experts say that infrared heat has a beneficial effect on human health.

Film flooring has few disadvantages:

- quite high energy consumption, which is felt over large areas: for example, in a room of 20 square meters. m. this system will consume 1.5 kW/h;

- unlike, for example, a water circuit with coolant, infrared floors cool down almost immediately when the system is turned off;

Types of infrared films

From a design point of view, all IR films are similar and have a common operating principle. However, for various types of premises and operating conditions, it is customary to use certain options for film heated floors. The differences between ICs are primarily due to the fact that they are produced by different companies.

Let's consider the types of IR film based on maximum heating temperature and their compatibility with various floor coverings:

- high-temperature infrared heated floors under tiles. The maximum heating temperature of such systems reaches 50°C. They are incompatible with floor coverings that are more susceptible to heat (linoleum, laminate);

In their structure and principle of operation, all infrared films are similar to each other, the main difference is the maximum heating temperature

- low-temperature infrared heated floors for linoleum and laminate. Such systems can heat up to 27°C;

- universal IR systems that are compatible with all types of floor coverings.

The second parameter by which IR films are classified is the type of heating element. Today, there are two main types of infrared floors, depending on the heating element:

- carbon;

- bimetallic.

The power density of the infrared floor is the last indicator, which is very important when choosing heating. Let's consider three main types of IR films, depending on this parameter:

- with low power (130–160 W/m²) - used in cases where it is necessary to organize heating of a room with a small area. Compatible with “light” floor coverings;

Infrared films from different manufacturers may differ in appearance and technical parameters

- with average power (from 170 to 220 W/m²) - installed in more spacious rooms. Perfect for the following flooring options: porcelain stoneware, tiles;

- with high power (above 220 W/m²) – installed in industrial buildings. They are also used for floor heating in saunas and various workshops.

If necessary, you can always contact specialists who will help you choose the necessary system for a particular case. It is also recommended that before purchasing, read the relevant reviews on specialized forums. Film heated floors are an innovative solution for any room, allowing you to achieve maximum comfort.

Features of carbon and bimetallic IR films

Carbon films used for underfloor heating are more expensive. The heating elements in such a system are made of a special carbon material, which has a fibrous structure. In some cases, they are equipped with a protective layer of graphite. Spraying of this material helps to increase the strength characteristics of the system and also affects the length of its service life.

The basis of the material is represented by lavsan film. Carbon infrared film flooring

Scheme of bimetallic infrared film for heating

Helpful information! When installing carbon film for a heated floor, the choice of connection diagram is very important. In such a situation, experts recommend using a parallel connection option.

Bimetallic IR film differs from carbon film in that it has heating elements consisting of two metal layers (aluminum and copper). The material is based on double polyurethane film, which has good elasticity.

The installation of a bimetallic system is complicated by the fact that a ground electrode cannot be connected to the system. Also, the bimetallic structure is incompatible with ceramic flooring. It belongs to the low-temperature variety, so its recommended heating level does not exceed 27°C.

Technical characteristics and operational scope of film flooring

Before purchasing IR film, it is imperative to study all its main technical characteristics. This knowledge will help you select the required type of system and calculate it for a specific room. Let's consider the characteristics of such heating structures:

- IR film is produced and sold in rolls, the length of which reaches up to 100 m. The width of the roll can be different (from 50 to 100 cm), and its weight is approximately 55 kg;

Rolls of IR film come in different widths - from 50 cm to 1 m, their thickness can be from several microns to several millimeters

- the finished structure is powered from the electrical network, the voltage of which is standard 220V;

- per day, the IR floor consumes approximately 20 to 70 W/m²;

- the speed of heating the film to the maximum temperature is quite high (about 2 minutes);

- surface temperature can reach 50°C.

If you decide to use such a film as the main heat source, then you need to remember that it must cover at least 70% of the floor area. In regions with cold climates, film electric heated floors can only be used as additional heating.

Where is the infrared film floor system used?

- The use of film electric infrared flooring is designed primarily for areas where the climate is mild and during the off-season, when the street temperature level is average.

- Despite the fact that the main area of application of the floor system is residential and public premises, it is also installed in commercial buildings. The objects are garages, greenhouses or buildings that require heating, but do not have the opportunity to obtain it in a centralized manner.

- The widespread use of infrared film in the construction of heated floors is used in agriculture. The installation sites are incubators and nurseries for raising young animals.

- On a larger scale, the IR film floor system is used at airfields as an element of de-icing of runways, in parking lots and outdoor sports fields.

Such floors are used in many industries

Film heated floors Caleo

Caleo has a wide range of infrared films for underfloor heating, making it easy to choose the right system for a specific situation. The products of this brand are represented by both simple options and ultra-modern film coatings, the operation of which is as automated as possible.

Today this company produces 4 main modifications of infrared film systems.

Caleo IR film is sold complete with an installation kit: contacts and bitumen insulation, some also include connecting wires

LINE. An inexpensive system that is perfect for installation in small spaces.

GRID. A product belonging to the middle price segment. A special feature of the GRID infrared floor is the presence of an anti-spark mesh, which is made of silver.

Note! Caleo warm floors have their own characteristics. For example, their installation should be done only using the “dry” method. They are also not suitable for installation under ceramic floor coverings.

GOLD. As in the previous case, anti-spark mesh technology is used here. And also such films can self-regulate, which allows reducing energy consumption by up to 20%.

PLATINUM. The most expensive option for infrared flooring. It is distinguished by energy-saving qualities that can reduce electrical energy consumption by 5-6 times. IR flooring PLATINUM can be installed under areas that are covered by furniture, without the danger of overheating.

All of the above models have a remote control function. Installation of Caleo heated floors is carried out without the necessary organization of screed or special adhesive coating.

Caleo infrared film can be used as a main and additional heating system in almost all types of premises

Infrared film floors from the Rexva brand

Rexva IR films occupy second position in the ranking of heated floors. This company produces ultra-thin film communications that can be installed on various types of surfaces (vertical, horizontal and even on the ceiling). The Rexva range of heated floors is represented not only by systems with a standard power range.

For heating residential and industrial premises, this company offers infrared films, the power of which reaches 400 W/m². As a rule, such models are used to organize heating in saunas. They are characterized by a high level of water resistance, as they have a special double-sided coating located on top of the main lamination.

Products from the Rexva brand are highly durable and resistant to high pressure. Their operational scope is quite wide - from small rooms to gyms. The price of the Rexva infrared floor fully corresponds to good quality and reliability.

New film floors from RexVa have appeared on the market with a self-regulating effect, that is, with local overheating, it changes its own heat transfer in this area

Features of IR films from Heat Plus

The Heat Plus brand produces heated floors (including infrared). The peculiarity of the models manufactured by this company is that they can have different film shapes, namely:

- striped;

- solid.

Features of the IR floor production technology from this company make it possible to avoid the presence of unheated zones. The production of such film systems involves uniform application of carbon material on a polyester base, which allows achieving a high level of efficiency of heating communications.

Let's look at other advantages of Heat Plus IR floors:

- ease of installation;

- wear resistance;

Infrared film Heat Plus consists of safe and environmentally friendly materials and is a coating with a thickness of 0.338-2 mm, consisting of 5-9 technological layers

- reliability.

The service life of such products can reach 15 years under normal use. If desired, organizing such a system takes no more than one day, which is very convenient.

Note! The price of IR floor Heat Plus is several times higher than the standard one. However, products from this brand pay for themselves in 1-2 years.

What are the advantages and disadvantages of infrared flooring?

Heating film has many advantages, thanks to which it is in demand everywhere and is used not only in apartments and private houses. The advantages include ease of installation, since there is no need to lay a concrete screed.

It is important to have a minimum amount of time to install the structure, since literally a couple of hours is enough.

The advantages include the ability to combine a heated floor system with any type of flooring, for example, ceramic tiles and even carpeting, with a minimum film thickness that will not affect the floor level.

The main advantage of infrared flooring is that it is easy to install

There are also advantages:

- Low heating inertia, due to which rapid heating of both the film and the room occurs.

- Wear resistance to increased loads on the finish.

- Uniform heating of the room.

- Wear resistance to sudden temperature changes.

- Optimal cost.

- Opportunities to significantly reduce electricity consumption when heating a room by 30%.

- Possibility to install heating on the wall.

- Low intensity electromagnetic field.

Also relevant is the absence of a detrimental effect on human health, the ability to eliminate unpleasant odors from the room, and the elimination of dry air in the room, which allows you to create an optimal microclimate. Installation, connection and dismantling is easy, simple and quick, and therefore there is no need to contact qualified specialists.

Related article: How to properly cover a sofa with your own hands?

Warm floor infrared film Monocrystal

The Monocrystal company is located in Ukraine and is the only manufacturer of IR floors in the CIS. Thanks to South Korean technologies used in the manufacturing process of IR films, products from this brand have taken a confident position in the construction market.

The main difference between Monocrystal models is that they do not contain silver paste. To achieve the necessary electrical contact, products from the Ukrainian brand are equipped with a thicker layer of carbon paste. In this way, stabilization is achieved between the copper busbar and the heating device.

Let's look at the main technical characteristics of Monocrystal IR floors:

- film width – from 30 to 60 cm;

Special graphite film for tiles - produced by the Ukrainian company Monocrystal

- step – 20–25 cm;

- powered by an electrical network with standard voltage (220V);

- maximum power indicator – up to 200 W/m²;

- The maximum heating temperature of the material reaches 50°C.

The service life of IR film from the manufacturer Monocrystal is 10 years. The model range includes the following varieties: linear, perforated, solid. Perforation is arranged for compatibility with tile flooring. Film heated floors under tiles are widely popular among buyers.

What is infrared heated flooring and how does it work?

The operation of infrared heated floors is based on the principle of the passage of weak currents through a semiconductor. In our case, carbon plays the role of a semiconductor—more precisely, its thinnest sputtering.

So, if we looked at the work through an atomic microscope, we would see the following - when voltage is applied to the contacts, the directed movement of charged particles, that is, the flow of electrons, begins to excite carbon atoms, which were previously static.

Carbon atoms, having received excitation, begin to heat up from the “attack”. And this happens because in them the electrons in all orbitals begin to move - and not just move, but like a “train” run from one atom to another. With all this atomic chaos, a large amount of heat is released in the form of long-wave radiation.

And the thing is that this movement causes not just heat, but the radiation of a stream of photons - like sunlight, but without the sun. This radiation does not affect airspace, but only physical objects.

This type of heating can be performed in two variations: film and rod.

Rod - is a bunch of carbon rods enclosed in insulation that is resistant to temperature and moisture. These tubes are connected to each other by a high-strength conductor that can be exposed to heat for a long time without losing its mechanical and electrical properties. The structure is extremely durable and is made specifically for installation into the thickness of the screed layer. It is supplied in the form of rolls - usually the dimensions of such a roll are 1x3 meters.

Film is the most widely used heating method. It is a film on which a carbon conductor is applied by sputtering, in strips or some kind of honeycomb. From the very manufacture, the ends of the conductor have a rigid connection with two tires, which are located on opposite edges of the film. All conductors are laminated with a high-strength, temperature-resistant film that is not afraid of long-term heating, moisture and static loads.

This heater is produced in three versions - 50, 80 and 100 cm. It comes in a variety of power: from 50 W/m2 for additional heating to 200 W/m2 for independent heating.

Related Posts

- Electric heated floor in a private country house: installation features in a wooden and frame house

- Warm floors on a balcony or loggia

- Warm floor under laminate on concrete floor

- Calculation of underfloor heating power

- Optimal temperature for heated floors

- Electric heated floor under laminate

- Water floor in a private house connected to the heating system

- How to make a heated floor from a stove in a bathhouse

- Installation of an electric heated floor: types, diagrams, do-it-yourself installation

- "penoplex" under a warm water floor, the advantages of the material, methods and technology for its installation

- Installation of heated floor heating mats under tiles

- Heated floor consumption, how much electricity is needed

- Step-by-step technology for pouring self-leveling floors

- Electric heated floor under linoleum

- Installation of a warm water floor

- We make a water heated floor from a gas boiler

- Electric heated floor under carpet: pros and cons

- Infrared film for heated floors: power calculation and installation

- Insulation of a veranda in a wooden house

- How long should a floor screed dry?

- Insulation under laminate. From what and for what?

- Level the floor with your own hands: instructions on how to level a wooden floor in an apartment

- How to insulate the underground floor in a wooden house from the inside

- How to update old tiles in the bathroom

- Subfloor in a wooden house: making a strong joist base for the finishing coating

Read with this

- Electric heated floor in a private country house: installation features in a wooden and frame house

- Warm floors on a balcony or loggia

- Warm floor under laminate on concrete floor

- Calculation of underfloor heating power

- Optimal temperature for heated floors

- Electric heated floor under laminate

- Water floor in a private house connected to the heating system

- How to make a heated floor from a stove in a bathhouse

- Installation of an electric heated floor: types, diagrams, do-it-yourself installation

- "penoplex" under a warm water floor, the advantages of the material, methods and technology for its installation

Infrared heated floors: consumer reviews

Today, many home craftsmen refuse to install water-heated floors and give their preference to infrared floors. This is primarily due to the fact that a water system requires a longer installation time. And also its use is possible only after the screed has completely hardened. On many construction forums, consumers recommend infrared film heated floors. Reviews about these models are mostly positive.

The infrared energy emitted by carbon elements is completely identical to that emanating from the Sun, which is why it is so comfortable to be in a room with such heating

Consumers also pay attention to the efficiency that manifests itself in the process of using such heating systems. Studying various comments, you can see that many people point to savings in energy consumption with film heated floors. Reviews talk about saving electrical energy when using such systems by up to 20%.

Helpful information! Some IR systems take no more than 3 hours to install and can be used immediately after installation.

Such heating communications are considered completely safe and are repairable. If individual segments of the IR system are damaged, it does not fail completely. In addition, they can be easily replaced and continued operation of the system, which is often indicated in reviews. Warm floors under laminate are in great demand and usually cost the most.

Negative comments are much less common and, as a rule, indicate that when replacing the system, it becomes necessary to dismantle the floor covering. Most often, infrared heated floors are installed under laminate. Negative reviews in this case tell us that this floor covering cools down very quickly and the heating system cannot be used as the main one.

Laying and connecting film IR heaters does not require special training and can be done by hand

Where is warm film flooring used?

To install heating film in their apartment, many pay attention to such features as the level of radiation, cost, recommendations of specialists, and scope of application of the equipment. Before looking for reasons why warm film will be the best option for your own home, you should pay attention to the parameters of the product.

You can use warm film flooring for heating in almost any room.

Namely, the film has:

- 0.5-1 m wide;

- Roll length 50 m;

- The thickness of the material is 0.2-0.4 mm.

Related article: Choosing a substrate for linoleum on a wooden floor

The power consumption level is 25-80 W/h, and the average operating temperature of the heating elements is 30-50 ᵒC. Film flooring can be quite successfully used as the main heating system in an apartment or private house.

For space heating, and not for heating, it will be necessary for almost the entire area of the room to be covered with such material (at least 70%).

Unfortunately, in the harsh climate of the northern regions it is impossible to get by with this type of heating alone, and therefore it is used mainly as an addition to create comfort and save fuel when it comes to a private home. In addition, an infrared floor can become an emergency or backup heating system, for example, in the event of a pipe break, boiler breakdown, or central heating shutdowns that occur in apartment buildings with the onset of spring.

Drawing up a connection diagram for a film heated floor

In order to avoid installation errors and other surprises, experts advise choosing a connection diagram and drawing up a project plan before installing IR film. An elementary diagram will help not only to correctly calculate the amount of material needed in a particular case, but also to select the film required in terms of power.

Let's consider the points that need to be taken into account when drawing up a connection diagram:

- cutting of infrared fabric is carried out strictly in those places that were marked by the manufacturer;

- It is strictly forbidden to cut at any angles and try to form shaped elements from the canvas;

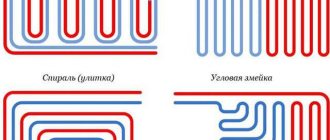

- installation of the film is carried out in parallel strips;

- the strips must be laid in such a way that they do not overlap each other;

- It is important to remember that the gap between the film sheet and the furniture should not be less than 3 cm. The same distance must be maintained between the edge of the infrared sheet and the wall;

- copper bars of adjacent panels should not touch. The minimum distance between them is 1 cm;

- the number of connection points should be kept to a minimum;

Connection diagram for infrared film heater

- the best option for locating the connection points is on the side of the wall on which the thermostat will be installed;

- the diagram must be drawn up in such a way that the main part of the wiring is hidden behind the baseboards;

- when using short film sections (up to 100 cm), it is necessary to take care of additional insulation and purchase additional terminal clamps.

Helpful information! The individual panels are joined together using adhesive tape.

The thermostat must be selected in advance, before installing the electric heated floor. Reviews about these devices can be easily studied on specialized forums on the Internet. If the area that needs to be heated is quite large, then you need to purchase additional temperature sensors.

Preparing the base for laying infrared film

After choosing a laying scheme and purchasing material, you can begin pre-installation preparatory work. A very important point is preparing the base for laying the infrared floor. If the old concrete screed is not even, then it must be dismantled. However, if everything is in order with the screed, it is enough to simply clean it of debris and remove dust.

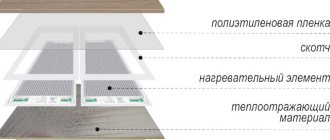

To prevent heating towards neighbors living on the floor below, it is necessary to lay heat-reflecting material for infrared heated floors

In most cases, the base has many small cracks and chips before laying the film. Experts advise eliminating these defects using cement mortar or any other suitable composition. In some situations, owners discover that the screed has begun to peel off from the subfloor. This situation requires the removal of the old screed and the organization of a new one.

The joints that form from connecting the walls to the floor must be carefully leveled and sealed if they have cracks. If this is not done, then the film floor will lose heat through them.

After preparing the base, it is necessary to lay thermal insulation material on the screed. As a rule, a reflector made of foamed polyethylene is used for these purposes. The joints of the individual insulator sheets are glued with mounting tape, and this is where the process of preparation for installation of the infrared heated floor ends.

How does a film heated floor system work?

A warm floor in the form of a film is quite complex; you cannot make such a system at home. The heating element is a unique nanostructure made of carbon materials in which carbon atoms form a hexagonal lattice. This material has the ability to generate infrared radiation invisible to the human eye.

The heating element is placed between two layers of dense polymer material. These strips, which are approximately 15 mm wide, are connected by special conductive copper bars protected by a silver coating.

The polymer layer protects the heating element from moisture, mechanical stress, fire and other negative factors, but at the same time perfectly transmits infrared rays.

Features of laying film heated floors under laminate

After completing the preparation process, you can proceed directly to installing the IR film. The installation algorithm for a heated film floor under a laminate is as follows:

- First of all, it is necessary to cut the material. The length of the strip should not be more than 8 m;

Before laying the infrared film under the laminate, it must be cut correctly

- At the second stage, the strips are laid. In order to reduce the number of joints, experts recommend laying sheets of infrared material along a long wall. The distance from the edge of the film to the wall should be at least 10 cm, and the distance between adjacent panels should be at least 5 cm. Installation of film heated floors is best done using the parallel method;

- Next you need to connect the wires and insulate unused contacts. The wires are connected using special clamps - terminals. And for insulation, a special bitumen tape is used, which has a high sealing coefficient;

- then the infrared floor wires are connected under the laminate. To do this, you need to connect the wire to the terminal and insulate it;

- At this stage, the temperature sensor(s) are installed. Experts advise placing these elements under the second canvas (closer to the midpoint). The sensor is installed in this way: it must be glued to the underside of the canvas on the black strip;

- Next, the infrared heated floors are connected to the thermoregulatory device. To do this, you need to connect the wires from the film and the temperature sensor to it. The connection itself is made through an RCD;

When installing IR film, you should use only special types of laminate that are designed specifically for such systems

- Next, you need to check how the installed communication functions. To do this, a trial run is carried out;

- The last stage of installing an infrared floor involves laying the appropriate floor covering on top of it, which in this case is represented by a laminate.

Helpful information! The wire belonging to the sensor can be placed in corrugated protection. This will simplify the repair procedure if necessary.

It is recommended to keep it in the room for 2-3 days before laying the laminate flooring. This is necessary so that it acquires the appropriate temperature, which will further prevent its expansion. To become familiar with the features of using IR film in this case, it is recommended to read reviews on specialized websites. Film heated floors under laminate are the most common today.

Installation of infrared heated floors under tiles

Laying an infrared floor under ceramic tiles can be done in two ways: “dry” and “wet”. In the first case, the heating elements of the film do not come into contact with the cement screed. In turn, the “wet” method of installing IR film is done by pouring cement mortar over the system.

Two schemes for connecting film heated floors under tiles

Let's consider the algorithm of the method:

- Installation of the film sheet, which is carried out according to the same rules as in the case of organizing infrared heating under the laminate.

- Next, a protective layer is installed, which is often used as a polyethylene film.

- At this stage, it is necessary to install a base under the screed on top of the film. Plasterboard sheets (GKL) are excellent for such purposes. When fixing the sheets, special care must be taken, as there is a risk of damage to the heating elements of the infrared floor.

- Then a thin layer of screed is poured over the substrate.

- The last step is to lay the tiles. For this, standard tile adhesive is used.

In turn, laying infrared heated floors using the “wet” method is more profitable from a financial point of view. It includes the following steps:

- First of all, it is necessary to install the heating elements of the IR floor;

Laying the infrared film sheet under the tiles is carried out according to the same rules as under other coatings

- Next, a protective polyethylene film is laid. This stage is the most important in the entire procedure of the “wet” method of installing IR. Experts recommend laying protective polyethylene film in 2-3 layers;

- At the third stage, reinforcement is installed. As a rule, a metal masonry mark is used for these purposes;

- then the screed is poured;

- Finally, ceramic tiles must be laid.

Note! The thickness of the screed should not be more than 10 mm, otherwise the efficiency of such heating will be significantly reduced.

Thus, the installation of film heated floors under tiles can be done by hand. The only thing that is necessary for this is strict adherence to the sequence of work.

Two methods of laying infrared film under ceramic tiles: “dry” and “wet” methods

Rod infrared heated floor: installation

Rod infrared heated floors got their name due to the shape created by the heating elements. The system is self-regulating, since the design consists of an insulating rod that contains a composite material of carbon, silver and graphite. IR rods connect insulated copper wires. The heating elements are connected in parallel. That is, if damage is caused to even one element, the system will stop functioning. This is considered to be a disadvantage for this type of heated floor. But this is compensated by increased savings in operation, unlike other designs.

A flat base is required for a rod heated floor. As in the case of film flooring, thermal insulation is arranged in the same way. The main mats are rolled out and placed at intervals of 15-20 cm from the walls. When rolling, make sure that the wires do not intertwine. The fastening of the rods is similar to the film type. The difference is the cutting of windows in the heat insulator to connect the laid top screed with the rough base. The arrangement is staggered. The total percentage of windows is up to 25% of the entire thermally insulated surface area.

When installing a rod floor, the base must be level

Features of installing film heated floors under linoleum

Installing an infrared floor under linoleum has its own characteristics. Let's look at this process step by step:

- First, the thermal insulation material is laid.

- Next, you need to cut the IR fabric into pieces of the required length.

- At the third stage, film heated floors are installed. It is important to remember that they must be laid with the copper elements facing down.

- Then, using pliers, clamp terminals are mounted on the copper wire elements of the film.

- At this stage, the strips are fixed with double-sided tape. This is necessary in order to avoid their free movement.

- Next, you need to complete the procedure for connecting the heated film floor to the electrical network.

- After connecting the IR floor, you need to check its functionality.

- Then a protective polyethylene film is placed on the heating elements, which is fixed with tape.

- The penultimate stage takes into account the installation of the base under the linoleum. Fiberboard sheets can be used as a base.

- At the last stage, the linoleum is laid.

The packaging with a roll of linoleum must have a pictogram indicating the possibility of using it in combination with heated floors

Thus, a film heated floor is installed under linoleum. If you are not confident in your own skills, then it is recommended to contact the masters who will do all the work efficiently and in a matter of hours.

Features of “warm floor” on walls

Heating installed on a wall surface has the following features:

- When placing this type of heating on wall surfaces, keep in mind that hanging pictures, clocks or other decorative elements on warm walls is unsafe, as there is a possibility of a nail getting into the cable.

- When using this design, the external decoration of the walls will not last long; sometimes, even after the first heating season, the wallpaper may lag behind.

- When heating a room vertically, dust does not spread throughout the room.

- Infrared rays do not heat the air, but the surface of adjacent objects. After the surrounding objects have heated up, excess heat is released into the environment, thereby warming the air in the room.

- Installing heated floors on the walls promotes uniform heat distribution.

Important! Infrared film is even installed outdoors when insulating gazebos.

Warm walls combined with heated floors

Infrared warm film floor: prices

Today you can find various options for IR floors of carbon or bimetallic type. Their cost varies from 300 to 1700 rubles. per 1 m², depending on the manufacturer and technical characteristics. Some carbon models may have a special protective coating of graphite and cost up to 2000 rubles.

The dependence of the price on the company that produces IR floors can be seen with the naked eye. For example, the price of a Caleo infrared film heated floor can exceed 2,000 rubles. for 1 m², while the Rexva company sells some high-quality models for only 300–400 rubles. The price of film heated floors under laminate is the highest, which is due to high demand.

Note! If the cost of IR is indicated for a whole roll at once, then it is recommended to recalculate the cost of 1 m2 yourself. Some companies use this method to increase the price of products.

The cost of IR film for floor heating directly depends on its manufacturer

The price of a heat-reflecting base ranges from 80 to 200 rubles. The simplest thermostat model will cost approximately 1,200 rubles, and more expensive devices equipped with touch programming will cost 2,500 rubles. The cost of installation services also differs and can vary from 200 to 400 rubles. for 1 m².

Where can I buy film heated floors? You can purchase these heating systems at any specialized store or construction hypermarket. You can also buy infrared film heated floors via the Internet. To do this, you need to go to the website that sells this product and place an order.

Characteristics of infrared heating film

An incredible amount of products such as heating polyethylene film goes on sale, the selection of which is carried out according to such parameters as size, power, efficiency, cost, manufacturer.

In general, the choice of such products is very wide, and the price directly depends on the amount of film in the roll, as well as what type and quality it is. These parameters depend on the brand and product configuration.

When choosing infrared film for floor heating, you should pay attention to its quality and characteristics

The most popular film is European-made film from Pask, as it is manufactured in accordance with all established standards and GOSTs, and also comes complete. By purchasing such products, you can avoid problems during installation and operation, but the cost of such products will be far from cheap. If we consider a more economical option, then we should give preference to Korean-made models with a power of 150-220 W per 1 m2.

They are installed in rooms where there is an increased level of heat loss, for example, on:

- Balcony;

- Loggias;

- Floor in the vestibule and more.

Such products are manufactured in almost every country and in incredible quantities, and therefore choosing an option for floor heating according to your own preferences is not too difficult, you just need to pay attention to a number of the above nuances and recommendations.

Related article: Heated floor sensor: how to connect a thermostat