The best price for assembly and piping of the boiler room!

Promotion! When ordering installation of a heating system and water floors, assembly and piping of the boiler room are free!

Individual heating of a cottage means freedom from both the whims of nature and the whims of public utilities. Most boiler houses in private homes today run on natural gas. Safety requirements for the installation of gas equipment are strict and high. They are due to the explosiveness and toxicity of the gas. carries out assembly, installation and piping of the boiler room using only certified specialists and guarantees full compliance with the requirements of SNiP and TB.

Prices for installation and piping of the boiler room

Turnkey boiler room installation and piping

| Name of works | Cost of work |

| Turnkey boiler room installation - 1 boiler (power up to 50 kW) | from 40,000 rub. |

| Turnkey boiler room installation - 1 boiler (power up to 100 kW) | from 53,000 rub. |

| Turnkey boiler room installation - 1 boiler (power up to 200 kW) | from 67,000 rub. |

| Turnkey boiler room installation - 1 boiler (power up to 300 kW) | from 77,000 rub. |

| Turnkey boiler room installation (power from 300 kW) | on request |

| Surveyor's visit, consultations, estimate preparation - free of charge Call a surveyor | |

| To calculate the interior decoration of the cottage, use our calculator | |

Installation work and piping of boiler equipment

| Name of works | Cost of work |

| Boiler (electric, gas, liquid and solid fuel) | 3000 RUR/piece |

| Expansion tank (heating systems) | 2500 RUR/piece |

| Setting up a security group | 2400 RUR/piece |

| Heating make-up unit | 1250 RUR/piece |

| Distribution manifold (comb) | 1400 RUR/output |

| Hydraulic separator | 2500 RUR/piece |

| Installation of an internal chimney | from 550 rub./linear m |

| Installation of an external chimney | from 900 rub./linear m |

| Installation of brackets for chimney support | 1800 RUR/piece |

| Commissioning works | 7% of installation |

| Defects and pressure testing of heating, hot water and cold water supply systems | 4300 RUR/piece |

| Draining the heating system | 2500 RUR/piece |

| Filling the heating system | 2500 RUR/piece |

| Complete price list for installation of boiler equipment | |

| Prices for installation of water heated floors | |

| Surveyor's visit, consultations, estimate preparation - free of charge | |

Gas boiler room: composition

Installing a gas boiler room may require the installation of quite a large amount of equipment. Each element or group of elements performs its own function in the operation of the heating system and is calculated individually at the design stage. Specific products of the appropriate standard size, power, and throughput are selected in accordance with the project, based on the optimal ratio of price, quality and safety margin (cycles, standard hours, etc.).

Approximate list of individual boiler room equipment:

- Gas boiler for heating the coolant and boiler;

- Boiler automation for controlling the operation of heating systems, hot water supply, water heated floors;

- Make-up system for timely compensation when pressure drops;

- Boiler for DHW system;

- Safety groups for the boiler and boiler perform protective functions;

- Collector-mixing unit for distributing coolant through heating circuits (hydraulic arrows, collectors, circulation pumps);

- Expansion tanks for heating and hot water supply systems to compensate for increased pressure in the systems;

- Chimney for removing gas combustion products outside;

- Piping a boiler room, in particular a heating boiler.

| Description: installation of a floor-standing boiler (electric, gas, liquid and solid fuel). Price: from 3000 rub./piece |

| Description: installation of a wall-mounted boiler (electric, gas, liquid and solid fuel). Price: from 5000 rub./piece |

| Description: boiler piping. Price: from 5000 rub./piece |

| Description: installation and connection of the expansion tank. Price: 2500 rub./pcs. |

| Description: installation and piping of the boiler Price: from 5000 rub./piece |

| Description: installation of security groups. Price: 2400 RUR/piece |

| Description: installation of a collector-mixing unit for distributing coolant through heating circuits. Price: from 1400 rub./output |

| Description: installation of internal and external chimney. Price: from 550 rub./linear m |

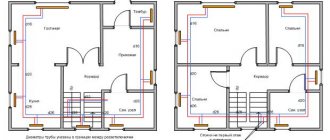

Boiler room plan with gas boiler

Using natural gas as a coolant is an economical and productive solution, but carries a high risk due to the risk of explosion. For this reason, the arrangement of a room for a gas boiler has strict requirements set out in SNiP.

This type of fuel, even in small quantities, can have harmful effects on health, so one of the important principles for the safe use of gas is good ventilation. The lack of high-quality hood entails less heat transfer at the same consumption.

The layout of the boiler room equipment of a private house depends on its power and the operating state of the gas. The liquefied form categorically does not allow the installation of a heat supply source in the basement. The specific gravity of such a carrier is much greater than air; in case of leaks, it is concentrated in the lower reaches of the building, where it can initiate an explosion.

There is no need to look for or build a separate corner for devices with a power rating of up to 60 kW. Installation in the kitchen, attic, pantry, etc. is quite possible if they meet the following conditions:

- the presence of a window with a window;

- volume of at least 15 cubic meters and on top 0.2 cubic meters for each allocated kilowatt;

- height minimum 2.5 m.

More powerful units should be placed in separate cabins on any floor, while the basement should be considered last. Free-standing boiler rooms must have their own foundation with a certain proportion of sand in it. The point where the apparatus is heated must be brought into compliance with the standards:

- windows from 0.5 sq.m.,

- doorway width from 0.8m,

- sheathing with fireproof material with a fire resistance limit of at least 45 minutes,

- availability of free space around the heat generator with a radius of 0.7 m or more.

Set of technical equipment for a gas boiler room

The use of gas for heating is carried out with the participation of:

- heating boiler;

- a boiler, heated by gas equipment, providing housing with hot water;

- a distribution manifold, which includes a circulation pump, a hydraulic distributor and a comb;

- an expansion tank that serves as a neutralizer for increasing pressure due to an increase in the temperature of the medium;

- safety groups complete with pressure gauge, safety valve and air vent;

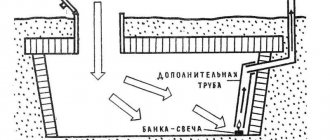

- a smoke exhaust pipe with an effective diameter and a height above the roof ridge of at least 5 m with an additional channel for cleaning;

- an organized drainage complex in case of device downtime;

- navigation in the form of electronic automation;

- fire removal and fire extinguishing system.

Boiler types

According to the operating principle

There are single-circuit and double-circuit boilers. In the first case, only one circuit is powered from the boiler - the heating circuit, and water for domestic needs is heated in the boiler. This design can be compared to a storage water heater. In the second case, the hot water supply system is powered from the heat exchanger included in the boiler, and operates on the same principle as flow-type water heating devices.

A system with a single-circuit boiler and boiler allows you to create a supply of hot water and use it regardless of heating operation. In double-circuit boilers, the supply of hot water to the house is a priority, and during its consumption the heating is turned off. As a rule, double-circuit boilers are installed in small houses where hot water supply is small (house up to 150 m2 with one or two bathrooms), or in dachas not used for living in the cold season.

By type of design

There are floor-mounted and wall-mounted boilers.

- The floor-standing boiler

is installed on a podium in a room specially designated for the boiler room (boiler room). It is possible to erect a separate building. The boiler can be steel or cast iron. The latter is more durable, its service life can reach 50 years. The boiler room itself is subject to strict SNiP requirements, failure to comply with which makes it impossible to put the boiler room into operation. - The wall-mounted boiler

is made of steel and can be installed in any room of the cottage with the exception of the bathroom. This is a modern compact device, the package of which already includes a hydraulic pump, an expansion tank, and the necessary set of automation that can ensure comfortable operation of the heating system. Wall-mounted boilers have only two drawbacks: a relatively short service life (compared to floor-mounted ones) and low power (12 - 25 kW). They are installed in houses with an area of up to 150 m2 and apartments with autonomous heating. Today you can find boilers of higher power - up to 40 kW, which can heat areas up to 400 m2, but they are very expensive.

Details

The main elements of the boiler room in the house

Installation of heating in a private house (even if it is small), as well as hot water supply, can be solved with one small double-circuit boiler, which is “powered” by gas.

But in most cases this will not be enough, and you will also need a large complex of devices, which can be made from a set of such elements:

- The boiler is the heart of the entire boiler room. It is he who will be responsible for heating the water for the heating system. Heat can be produced by burning various types of fuel - gaseous, liquid or solid. Electric boilers will be a special case. In special cases, they even install two boilers to ensure complete energy independence for a private home.

- Boiler. If a single-circuit boiler is used, then to heat the water in the hot water supply system, you will need to use a boiler.

- Expansion tank. Water from the heating system will enter such a container if the pressure in it increases. Thus, radiators and pipes will be protected from breakthroughs.

Heat accumulator. Interestingly, it is not always installed, even though it is a very useful element. In such a container, superheated coolant will accumulate, as well as “excess heat”, which can then be supplied to the system. This will significantly save resources and increase security. This is especially true for solid fuel boilers, even if there are two boilers of different types.

- Distribution type collector. It is required for the correct distribution of the coolant throughout the system, and will also regulate the temperature level.

- Pump for circulating coolant. Required only for those systems in which the coolant will circulate in forced mode.

- Chimney. Required to remove combustion products outside the house. A chimney may not be required only for electric boilers.

- The control and safety group presents a set of instruments that will monitor the temperature and pressure in the system and boiler. Sensors that can monitor the state of the air inside the boiler room may also be suitable here.

- The automation will receive commands from the user regarding the required temperature level, and also collects data from the security group and makes it possible to correctly adjust the main system parameters.

- Shut-off valves are required in order to control the flow of coolant.

- Pipes through which water will flow from the boiler to the heating radiators.

- A filter is required to purify the water before it enters the boiler or boiler. If the water in the region is saturated with salts and also contains mechanical impurities, then you definitely cannot do without a filtration channel, since otherwise the equipment may fail very quickly.

It is not necessary to apply all the described elements to the system, and their set will also depend on a large number of factors. Before this, the area of the house and the type of fuel.

Boiler types

Most of the nuances of arranging a room such as a boiler room will depend on what type of boiler will be used. Depending on the type of fuel used, boilers can be:

- Gas engines, which operate from liquefied or natural gas, are also characterized by high efficiency and ease of control. They can be transferred from one type of gas to a second. This is an ideal choice for many country houses.

- Solid fuels (firewood, coal, briquettes and peat) are more economical in terms of use, but you will need to constantly monitor the system and also add fuel.

- Liquid fuel (diesel). Installation of a boiler room in a private house using a boiler running on liquid fuel is used in cases where it is not possible to use natural gas or supply liquefied gas. If, after some time, a gas pipeline is installed in the area, then such a boiler can be converted to operate on gas.

- Electric boilers are the safest, most convenient, and also silent, but they are also the most expensive. It will not be profitable to heat the whole house, but they are perfect as a backup heat source.

Depending on the installation method, boilers can be wall-mounted or floor-mounted. The first type in compact cases contains all the necessary elements, such as automation, sensors, expansion tank, etc. Boilers with a power of up to 60 kW are produced in this design. If the boiler power is no more than 35 kW, it can be placed in the hallway or kitchen. Wall-mounted models are often more sensitive to water conditions. Floor-standing models can be of different power, and they are also indispensable for heating a room with a large area.

What power does the boiler require? The calculation should be trusted to specialists who know that many parameters should be taken into account. To roughly understand how much power equipment may be required, you should use the rule that for every 10 square meters of house area you will need 1 kW of equipment power. If it is used in a hot water supply system, then another 10% is required to be added to the calculated power. To prevent the boiler from working at its limit, add another 20% to this value.

Combustion chambers and chimneys

The combustion chamber of the boiler can be open or closed. Operating a boiler with an open combustion chamber involves taking air directly from the room and having a chimney with natural removal of combustion products. Such a chimney has a strictly vertical location and, according to safety rules, must end above the ridge of the roof to ensure sufficient draft.

A closed combustion chamber is typical for wall-mounted boilers. A coaxial chimney “pipe in pipe” with a forced smoke exhaust system is installed for them. A fan is installed in the ventilation pipe, which can be positioned horizontally and exit through the wall. Through the internal chimney pipe with a smaller diameter, it draws smoke from the boiler outside, and fresh air is supplied from the street through a larger diameter pipe.

Coolant circulation

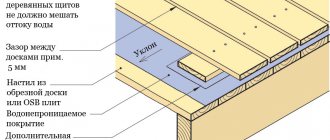

Coolant circulation in autonomous heating systems is of two types:

- Natural - is carried out due to the difference in the density and mass of the hot and cold working environment, as well as the creation of the necessary slope of the pipes during the installation process.

- Forced - carried out using one or more (depending on the configuration and size of the system) circulation pumps.

The second option is characterized by greater efficiency and allows you to save fuel. The disadvantage is the dependence on the availability of electrical power to operate the pump.

The complexity of the work when installing a boiler room lies in ensuring a reliable connection of system elements, debugging their interaction and the functioning of the automation. It is equally important to wisely choose the technology for connecting pipes, fittings and equipment if, during the installation process, you have to connect elements made of different materials - for example, copper and steel, steel and polypropylene.

It is clear that compliance with SNiP and TB will be checked by a gas service inspector upon delivery of the facility. But the task of real professionals working in is not only to obtain an acceptance certificate, but also to ensure many years of proper and safe operation of heating and hot water supply systems in clients’ homes. So that comfort and safety come to your cottage along with warmth and hot water, order the assembly, installation and piping of the boiler room from our company. A long-term warranty is provided, it is possible to conclude service contracts and carry out routine maintenance.

The value of a heat accumulator in a boiler room

Thermal accumulators, otherwise called buffer tanks, are most effective in boiler rooms of private houses with solid fuel boilers. Their use allows you to create contours with natural circulation. These are the paths along which the coolant moves during a power outage, and, as a result, the pump stops working.

The operating principle of a heat generator with a heat accumulator is as follows:

- simultaneously with the supply of heat to the heating system, the heat supply heats the medium in the buffer tank;

- after turning off the TT boiler, the temperature sensor signals the pump, which initiates the supply of the media accumulated in the heat accumulator tank to the network;

- When the required temperature is reached, the sensor sends a signal to turn off and the heat supply stops.

Cooling of the coolant occurs slowly, thanks to good thermal insulation. Cycles of starting and stopping the pump occur many times until the water in the heat accumulator cools down.

When tying with heating equipment, a large number of turns and bends should be avoided. The diameter of the pipes must correspond to the boiler pipes.

Buffer capacity value:

- improved safety;

- economic benefit;

- creating more comfortable conditions.