Most car owners prefer to have a garage with a concrete block basement. In such a garage you can store food, spare parts and equipment. In order to feel safe while in the garage, some basic conditions should be observed when constructing a cellar. When arranging a basement, the main attention should be paid to the design of the ceiling of the cellar. It can be varied and depend on the size of the garage, the size of the basement and the number of cars left in the garage. It is best to include a basement in the plan before starting construction of the garage. Then, during the organization of the work sequence, all design requirements can be optimally fulfilled. When arranging a cellar after the garage is built, inconveniences arise that require time and effort.

Scheme of a cellar in a garage.

The main focus should be on the strength of the concrete slabs above the basement. Its strength is greatly influenced by the support of this floor. When constructing a complex garage with a basement, standard concrete slabs are most often used as a floor. In this option, the walls of the cellar turn out to be a load-bearing foundation for the entire garage and at the same time a support on which the ceiling is placed. During operation, horizontal forces from the surrounding soil begin to act on the basement walls. These forces tend to deform the basement walls. Therefore, the thickness of the walls should increase in proportion to the depth of the basement. The bottom of the dug pit is covered with a 10 cm layer of crushed stone and 5 cm of sand. Then a strip foundation is made. The garage, the walls of the cellar and the ceiling will act on this foundation with all its weight. It is better to build the basement walls from concrete blocks. But if this is a bit expensive, then instead of concrete blocks you can make the walls concrete using sliding formwork.

Layout of the cellar in the garage.

If everything is done properly, then you need to order survey work at the construction site. This will allow you to find out if there are underground communications below, for example, an electric or telephone cable, or nearby groundwater. If the garage is located on soil saturated with moisture, then you need to make a circular drainage system to remove moisture from the area adjacent to the garage. In any case, you need to waterproof the foundation and basement blocks from the outside. If the construction is on dry ground, then coating the outside of the blocks with hot bitumen in two layers is sufficient. If the soil is wet, then the blocks need to be covered with roofing felt on bitumen mastic. Expanded polystyrene is a good insulating and at the same time waterproof material. This material is highly resistant to mold and rot. Installation of such insulation is done by simply gluing the blocks on the outside. The size of the plates must be carefully adjusted to each other. The joints are also taped.

Cellar in a built garage

Basement layout.

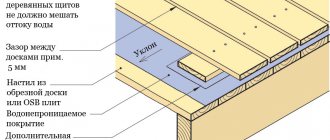

If the basement is being built in a built garage, then it is impossible to use standard concrete slabs as a floor, because they are installed by a crane. The overlap is done by laying load-bearing beams. It is best to use I-beams. Motorists use pieces of railway rails purchased at scrap metal collection points for this purpose. The mine rails for the load-bearing beam will be rather weak. They can be used as transverse elements laid perpendicular to load-bearing beams. For the ends of the load-bearing beams, beds are provided on the basement walls. In general, the basement walls serve as the foundation for the entire garage. Reinforcement is placed in the space between the load-bearing beams. The lower formwork is installed on which the concrete is laid. The result is a homemade reinforced concrete slab.

Insulating the floor above a heated basement

If the basement is heated, all its walls are insulated, and the temperature difference between rooms located above each other does not exceed a couple of degrees, then insulating the basement floor is done in the same way as insulating interfloor floors. And since it is easier and cheaper to lay insulation on the floor than on the basement ceiling, the work is carried out in this way.

Related article: Why the faucet hums when you turn on the water, what to do

Helpful advice: when installing a screed on top of insulation, you should give preference to a rigid thermal insulation material - expanded polystyrene, polystyrene foam or high-density basalt wool.

If low-density mineral wool or polystyrene foam with a density of no more than 15% is chosen as insulation, then it is better to install wooden logs, place insulation between them, and lay a subfloor. And then lay the finished floor covering.

Insulation of ceilings, walls and blocks

Cellar floor insulation scheme.

The ceiling of the cellar can be insulated in several ways. One of them is that pipes with a diameter of 25 mm are installed horizontally 15 cm from the ceiling with a fastening pitch of about 60 cm. These pipes can be attached to the walls or the ceiling. Reinforcing bars made of wire with a diameter of 8-10 mm are attached perpendicular to the pipes. They are secured with soft wire. It is better to paint the entire structure with chromium oxide, red lead or other waterproof paint. Polyethylene bags are placed in the space between the ceiling and the resulting structure. First, forest moss or chopped straw is placed in the bags and sealed with an iron. The bags are placed without a gap on top of each other and tightly together. Galvanized iron sheets, waterproof plywood or plastic film are laid on top. They are used as an umbrella, from which condensate should flow through pre-arranged grooves into a bucket or some other container.

You can use a mortar with the addition of cement and sawdust to insulate the ceiling. The layer of such a solution can reach 20 cm. After complete drying, a plaster solution is applied in a few days. The same method can be used to insulate basement walls. The floor is insulated using glass wool or other insulation placed between the joists under the finishing coating. If the groundwater level is high, then a drainage system should be installed around the garage. The bottom of the cellar is deepened 30 cm from the expected floor level. A layer of crushed stone of about 10 cm is poured onto the leveled soil. Sand is poured onto the crushed stone in a layer of 5 cm. All layers are compacted. The cover of the entrance to the basement is made with a lattice or mesh so that ventilation is better and small animals cannot enter. For the winter, the lid is closed with insulation.

Cellar insulation scheme.

The best insulation for floors, walls and ceilings is polyurethane foam. It is applied by spraying directly onto the insulation surface. The entire inner surface of the basement is blown with foam. The insulation fills all the cracks, penetrating into inaccessible places. During rapid hardening, a smooth surface without seams or voids is formed. Polyurethane foam has very low thermal conductivity. It is practically weightless, so it will not additionally load the supporting structures. Using this method, the basement is insulated very quickly, and the only drawback is the high price of the material.

Insulation over concrete floors

In this case, it is advisable to use rigid insulation. It is fixed to the concrete ceiling of the basement using glue and dowels. Then it is covered with a mesh and plastered.

If you prefer soft insulation, then you need to fill the ceiling with wooden slats or a galvanized profile for plasterboard (the thickness of the profile should be equal to the thickness of the insulation), cover it with a vapor barrier film, lay thermal insulation and decorate the ceiling.

Related article: Features of choosing and installing porcelain tiles for walls

We hope this information will help you decide how to insulate the ceiling above the basement and reduce heat loss in the house.

Space ventilation

Scheme of ventilation of the cellar and garage space.

Proper ventilation is a guarantee that moisture will not be retained in the basement. With good ventilation, dampness will not damage food supplies. Knowing how dangerous exhaust fumes can be in a garage, ventilation should be high and in the main area of the garage. In most cases, natural ventilation is used, in which air movement is carried out due to the difference in temperature of the incoming air and that available inside. If the air change is not done in sufficient volume, then it makes sense to install a fan. At this time of year, when the air temperature outside and inside the cellar is equalized, ventilation stops. There will be no ventilation even when the outside air temperature is higher than in the basement. Artificial and natural ventilation can be carried out through one channel. Artificial ventilation can have one hole.

Working conditions

Ventilation diagram for cellar and garage.

The opening of the supply pipe is located at a distance of 10-15 cm from the cellar floor. The suction hole should be at a height of 30-40 cm above the ground. It is equipped with a mesh to prevent the penetration of small animals. The hole must be protected by a so-called deflector. This device consists of a sheet bent in an arc and attached like a mushroom to the suction hole. The deflector is designed to protect against precipitation.

For natural ventilation to work, there must be a difference in height between the suction and outlet openings in the ventilation pipes. The minimum value of such a difference to ensure a pressure drop is 3 meters.

The supply pipe should be positioned so that it is constantly exposed to wind. The lack of natural ventilation manifests itself in severe frosts, when the pipe may become blocked with frost. To prevent this drawback, it is necessary to insulate the pipelines. Periodically, pipes should be cleared of snow and frost.

Cellar ventilation diagram.

It turns out that natural ventilation may have malfunctions and cannot cope with the work all year round. Therefore, a fan can be inserted into the exhaust pipe. It pushes exhaust air into the pipe and creates conditions for the influx of fresh air. The disadvantage is that during the cold season the basement and garage can get too cold. There are systems with fans at the inlet and outlet, and a two-speed fan is installed at the outlet. The ventilation control system is equipped with temperature and gas level sensors. When the garage is filled with exhaust gases, the second speed of the exhaust fan is turned on. Modern systems in European garages are equipped with fans based on the needs of an optimal climate in the garage. All switching and fan speeds are controlled by a computer program. We consider the simplest devices and the ordinary garage of our domestic motorist so that the garage owner has a good understanding of the impact of ventilation and takes timely measures to eliminate failures.

Practical tips for creating high-quality insulation

The quality indicator of the insulation work performed will depend not only on the type of insulator used, but also on the technique of its installation. The maximum effect when laying mineral wool can only be achieved if the following conditions are met:

- The rough coating layer, consisting of a mixture of sand and cement, must be laid as evenly as possible and compacted thoroughly.

- The material for waterproofing can be roofing felt or polyethylene film.

- If the insulation boards are located in the same horizontal plane, without noticeable gaps between them, additional sealing of the joints will not be necessary.

- It is necessary to place a thin layer of screed on top, reinforce it with a galvanized mesh and fill it again with concrete mixture. You can use foam concrete, since it has less weight compared to the standard composition.

- Laying the flooring can only be done after the concrete has completely gained strength and dried.

Thermal insulation of the floor surface located above a damp and unheated basement is a non-standard task. The room will require the creation of simultaneous protection from the penetration of moisture and cold. It is for these purposes that insulation materials were created, used in combination with other materials that provide protection from both moisture and steam. If the technology is strictly followed, living spaces will always be warm and comfortable, and the issue of possible mold in the home will be resolved once and for all.

Implementation results

Scheme of a garage with a cellar.

A garage with a cellar made of concrete blocks is a fairly reliable structure. No one denies the usefulness and functionality of such a structure. However, when installing a ceiling for a cellar in a garage, one should take into account all the nuances associated with the distribution of loads on walls made of concrete blocks, the influence of insulation and ventilation on the condition of the structure and atmosphere of the garage. When planning, you need to organize the sequence of work in such a way as to provide maximum convenience for their implementation. It is best to design a garage entirely with a concrete block basement to ensure the functionality of all devices. Neglecting insulation can damage the ceiling due to increased moisture condensation with subsequent corrosion of supporting structures.

Ventilation is also important to prevent unnecessary condensation. Insufficient waterproofing of walls and foundations, as well as the lack of a circular drainage system, can lead to basement flooding. Such a garage will turn into a breeding ground for mosquitoes with a swampy smell.