What are hot water boilers used for?

These units are intended for heating buildings with a small area, private houses and town houses. As a rule, such boilers are installed in those settlements where there is no central heating, or, alternatively, the installation of a boiler room is impractical. Be that as it may, the concept of “hot water boilers”, and regardless of the specific design and model, means devices capable of generating thermal energy (due to their technical parameters) when burning a particular fuel, and then directing it to the working fluid (coolant ), which is usually water. And when this water, accordingly, circulates through the heating circuit pipeline, the temperature in the house rises to the required value.

Purpose of hot water boilers

The main purpose of KV hot water boilers is heating and hot water supply of residential, administrative buildings and industrial enterprises, industrial premises and work in the ventilation system, for example for mines. They are installed in stationary, attached heating boiler houses or purchased for operation in block-modular boiler houses MKU and BMK.

Steel hot water boilers are designed to operate in closed and open heat supply systems with forced water circulation. The operating parameters of heat generators are water heating temperature 115 degrees, pressure from 0.3 to 0.6 MPa.

Design features, classification by temperature and method of execution

The hot water boilers found on the shelves today have a relatively identical design. Significant differences lie in specific manufacturers (they are both foreign and Russian), as well as in the maximum power of the equipment.

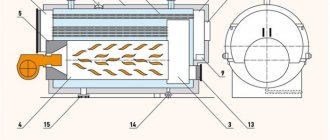

If we talk specifically about design features, then from this point of view, boilers can be gas-tube (or, as they are also called, fire-tube) and water-tube. Let's take a closer look at each of the categories.

- Fire tube models. Their distinctive feature can be considered the presence of special tubes through which heated combustion products of energy carriers move. As for the operating principle of such equipment, it is based on the use of automated burners equipped with blower fans. Thanks to the smoke tubes, the water outside them is heated. It is worth noting that such models are almost never used in everyday life.

- Water tube models. They are characterized by special boiling tubes through which the coolant moves. And fuel combustion products are used to heat these tubes. Water-tube boilers warm up quickly enough, you can easily adjust them if the loads change. In addition, the operation of this equipment also involves the possibility of serious overloads. As for the explosion hazard of these boilers, it is at a fairly low level.

Note! All hot water heating devices are also divided according to their temperature level. Thus, the maximum permissible temperature for low-temperature models is 115 degrees, while hot water boilers that overheat water can “boast” a higher figure - about 150 degrees or more.

Note that the low-temperature operating mode provides for fairly economical fuel consumption, but at the same time condensation appears on the surface of the device, which can negatively affect materials in contact with the products of combustion of energy resources. For this reason, extremely stringent requirements are placed on the materials used in the production of boilers.

Units that generate superheated water are characterized by a long service life and high reliability. During operation, they make virtually no noise, and waste emissions are minimal. These units are also equipped with convenient and simple control systems. They are installed quickly and do not require labor-intensive maintenance.

Types of heating boilers

Most hot water boilers are designed the same way; They differ mainly in power and manufacturer (for example, domestic and foreign). However, according to their design, they can be classified into:

- fire tube;

- water tube

The first are distinguished by the presence of special tubes through which heated fuel combustion products move. Such units use special automatic burners equipped with blower fans.

Water tube boilers have boiling tubes through which water is already moving. The energy carrier is burned and heats the water. All this contributes to the fact that the device warms up quite quickly, and the heating is easy to regulate. In addition, such structures provide for the possibility of strong overloads, which significantly reduces the likelihood of their explosion.

Hot water boiler

Hot water boilers usually have one or two circuits. In the second case, the heated coolant can be supplied to the water supply network or to the heated floor. Sometimes such boilers are already equipped with expansion tanks and circulators, which provide intensive water circulation.

Water heating boilers are classified according to the type of fuel used into:

- solid fuel devices in which the energy carrier is wood, sawdust or coal. Such boilers can be installed in a country house, in a bathhouse or sauna, because they require enough space;

- Liquid fuel boilers operate on machine oil, fuel oil or diesel fuel. They are used for heating cottages and private houses;

- Recently, the market for central heating boilers has been flooded with gas devices using natural or liquefied gas as fuel. Such units are suitable not only for a house or town house, but also for an apartment;

- Due to their compactness, electric water heating devices are perfect for both a private home and a city apartment.

We recommend: Features of repair of heating boilers

Depending on the installation method, the units can be either wall-mounted or floor-mounted.

What about the number of contours?

Most of the boilers described in the article (both fire- and water-tube) are double-circuit, but there are also quite a lot of single-circuit units. If the unit has two circuits, then the liquid heated by it will be supplied not only to the heating network, but also to the water supply (after this, of course, it can be used for domestic purposes). Note also that the design of some devices includes special circulators designed to intensify water circulation. Finally, expansion tanks (those of the membrane type) may also be present.

Other differences may relate to the possibility of using different fuels - coal, wood, gas, electric or liquid fuel. Universal units that can truly be called “omnivorous” are becoming increasingly popular today. Regardless of the type of fuel used, any boiler must be equipped with a system that supports combustion processes in automatic mode.

Fire tube hot water boilers

KV fire tube boilers produced by KZ "REP" can operate in both steam and hot water modes. To transfer the KP steam fire-tube boiler to hot water mode, changes are made to the boiler piping. Fire-tube water heating boilers produced by Kotelny are available in three modifications - natural gas, diesel fuel and solid fuel. In the boiler model for burning solid fuel, a fixed grate is installed; in gas and liquid fuel boiler models, Ecoflam and UNIGAS burners are installed.

The KV fire tube boiler is a single-fire horizontal design. Two cylinders of different diameters are inserted into one another and connected to each other by flanges. There is a steam collector on top. In the front part of the flame tube there is a firebox, and in the rear part there is a convective bundle of pipes. A cast iron front plate is attached to the front side of the fire tube boiler, which has a mount for installing a fan, which serves to force air into the grate space and speed up the combustion process, or a plate with a hole and mount for installing a burner and burning gas or liquid fuel.

Hot water fire tube boilers KV - KV-300 (0.22 MW), KV-500 (0.37 MW), KV-700 (0.52 MW), KV-1000 (0.74 MW).

Main types of hot water boilers

There are many classifications, but often such boilers are divided by purpose, type of fuel used and, of course, by installation method. Let's take a closer look at each of the classifications.

Classification of hot water boilers by type of fuel used

In this regard, devices are divided into four groups, which are given below.

- Solid fuel models. As the name suggests, they use solid energy carriers as fuel - coal, wood, pellets, waste from the wood processing industry, etc. As a rule, they are intended for use in bathhouses and private homes, since they require a sufficiently large area for installation (including space for storing that same solid fuel).

- Liquid fuel models (this can be waste fuel, that is, used engine oil, diesel fuel or fuel oil). As for the application, such water heating boilers are used primarily for heating private houses, and for the same reasons as units of the previous category. The difference is that liquid fuel, in accordance with GOST, must be stored at a certain distance from the heating device so that explosive situations do not arise.

- Gas models. They use liquefied or natural gas as an energy carrier. Typically, they can be used not only in country houses, but also in townhouses and city apartments.

- Electric models. They are usually installed in apartments and not very spacious cottages.

Classification by purpose

Here all devices are divided into only two categories.

- Domestic hot water boilers. Their power can be low or medium (which is much less than that of industrial models, which we will talk about later). They are used in domestic premises that have a small area.

- Industrial hot water boilers. High-power devices in which steam acts as a coolant. That is why they are also called steam boilers. Power is measured in megawatts and averages from 5 to 40 megawatts, which allows you to simply cope with huge volumes of work. Typically, such boilers must be constantly monitored by a specialized operator who has operating charts, as well as detailed instructions for self-repair. In addition, the operator must switch the unit to one or another operating mode, check all elements, etc.

Classification according to the method of heating water

There are also only two varieties, let’s get acquainted with them.

- Boilers with storage tanks. In this case, the water is heated thanks to storage tanks, which, in turn, are filled as it (the water) is used.

- Flow models. In them, the water is heated while passing to a certain temperature from the heating element.

Classification by method of execution (installation)

Water heating devices can be installed on the wall or on the floor.

- Floor models. They are stationary, and differ in that they can operate on any type of fuel.

- Wall models. Wall-mounted devices, as the name suggests, are hung on walls and can operate on gas or electric energy.

Let's look at each of the design options in more detail.

Advantages and disadvantages

As mentioned above, this type of water heater is in great demand today. This can be explained by the following advantages:

- The device is completely autonomous, that is, its operation does not depend on the functioning of any centralized power supply network.

- Fuel is cheaper than gas, especially if waste from the wood processing industry or agriculture is used.

- To install a solid fuel hot water boiler, you do not need to obtain a permit and invite specialists, as is the case with a gas boiler.

- Compared to conventional solid fuel boilers, hot water boilers are lightweight, and the requirements placed on them are more lenient.

- Such devices are rarely equipped with automation, so failures almost never occur.

- Boiler maintenance consists of very simple actions (removing soot and ash), so it does not require any special knowledge or high qualifications.

- Durability. The hot water boiler can be used for decades, which is confirmed by the warranty provided by the manufacturer: it is usually 15 years.

- The cost is more than affordable.

At the same time, the potential user should know in advance about the characteristic disadvantages:

- The operation of the water heater cannot be automated. The user himself has to add fuel and monitor the temperature of the water in the tank.

- Since they strive to make the hot water boiler extremely simple and cheap, no measures are provided to increase its efficiency. Accordingly, it is very voracious and will require a fairly large supply of fuel.

In order to correctly connect the boiler to the heating system, you need to know some nuances. Wiring of a solid fuel heating boiler - diagram and additional circuits.

We'll tell you what an inverter is used for for heating boilers here.

Owners of gas boilers must know how this equipment works in order to be able to carry out simple repairs without calling a specialist for every reason. For more information about the design of a gas boiler, see this page.

Features of floor-standing units

The fuel in this case can be gas, coal, wood or diesel. Boilers must be placed only in a separate, specially equipped room, and if the fuel is liquid/solid, an additional room will be needed for its storage (and with fire-fighting equipment, which are provided for by the provisions of SNiP).

Note! This type of devices can be equipped with automation and control elements. There may also be automatic systems for adjusting water heating, which provides additional convenience. Such systems analyze the temperature inside and outside the room.

In addition, there are special software devices that put the equipment into operating mode based on a preset program.

Technical characteristics of hot water boilers

- The power of hot water boilers is from 0.15 MW to 4 MW;

- Type of fuel - gas, diesel, fuel oil (grade KBa), solid fuel - stone, brown coal, firewood in the layer (grade KVR, KVM), sawdust, husks;

- Water heating temperature of hot water boilers is 115 or 95 °C;

- Load control range 50-100%;

- Operating pressure of boilers is 0.6 (6.0) MPa (kgf/cm);

- Type of combustion device - burner (KVA brand), manual grate firebox (KVR brand), semi-mechanical firebox, mechanical firebox (KVM brand);

- Craving is natural, forced, balanced;

Characteristics of hot water boilers according to the degree of automation of the combustion process:

- manual solid fuel boilers of the KVR brand - supply of fuel to the boiler room and boiler, removal of slag is carried out using the physical labor of a fireman;

- semi-mechanical with RPK and ZP RPK firebox - fuel is supplied to the firebox automatically, slag is unloaded manually;

- mechanical hot water boilers - fuel supply, regulation of the combustion process and removal of slag from the boiler room is carried out by mechanisms.

- automatic boilers - for the operation of these models, you only need to set the operating parameters on the control panel; ignition processes, combustion regulation, and removal of combustion products are carried out and provided by automation. These characteristics are typical for hot water boilers running on gas, liquid fuel and sawdust.

Features of wall-mounted units

If representatives of the previous category require a specially equipped room/extension, then wall-mounted models can easily be installed in the kitchen, bathroom, and so on. Which room to use depends on the specific energy source and convenience considerations. In other words, you yourself must decide where it will be most convenient to use the boiler.

Gas and electricity appliances can be powerful enough to maintain the required temperature in the room, as well as to provide the house/apartment with hot water. The latter in this case is heated in two ways:

- flow-through;

- boiler

Water heating boilers of the first category are equipped with heating elements that are in direct contact with the working fluid. Representatives of the second category involve the use of a storage tank or boiler, where the water is actually heated. In this case, the container is filled as water is used.

Video - How the KVGM boiler works

Electric hot water boilers - features and reasons for popularity

Such natures are very popular in Russia. They are produced by many manufacturers - both Russian and foreign. These boilers make it possible to provide housing not only with heat, but also with heated water, regardless of whether there is a centralized hot water supply in your area.

Electric boilers have a simpler design than, for example, gas boilers and do not require regular maintenance. Moreover, they are easy to operate and cannot explode. What can we say about such an important parameter as environmental safety?

Design features of electric hot water boilers

Such devices consist of the following elements:

- heat exchanger (it is a container in which an electric heating element is built);

- automation (necessary to maintain the required temperature in the room, but without direct human participation);

- closet.

Typically, not only ordinary water, but also non-freezing liquid can act as a coolant (this option is more preferable). Such boilers can also be divided according to the type of heating element used.

- Models with tubular heating elements. Such elements are filled with a special conductor that heats up when in contact with electricity. Capable of permanently heating running liquid, but subject to connection to an electrical network. Tubular heating elements are used in cases of combined heating. Who doesn’t know, during the day such systems operate from a heating device using liquid/solid energy or gas, while at night, when the cost of electricity decreases, they keep the house warm using it.

- Models with electrodes. Electrode-type units heat the liquid through an ion flow that forms between the electrodes (this is written in the description). The main advantage is the absence of heating elements, but due to the fact that the most important component of the circuit is the coolant, it must be properly prepared. Salt must be added to the liquid in a certain amount to obtain the desired concentration.

Note! As we have already found out, the main advantage of any electric boiler is its affordable price, ease of installation and operation, small dimensions and weight, and the absence of the need to arrange a separate room.

Installation of hot water boilers

Installation of a pipe system and lining of a hot water boiler

Gas-oil water heating steel boilers KVA and solid fuel steel water heating boilers KVR, KVm are assembled from the same type of elements. Flue gases leave the furnaces through the upper openings in the rear walls and wash the convective surfaces with a flow directed from top to bottom.

KV water heating boilers have a two-block or monoblock device. All gas-oil and liquid fuel boilers are made as a monoblock; in solid fuel boilers with a power of 1 MW or more, the firebox can be made as a separate unit.

For all boiler models, the combustion space and convective part are pipes welded into the collector systems through which the coolant flows. Water heating boilers with such a device are called direct-flow, water-tube, smooth-tube. The water flow is directed through the pipe part by a system of partitions. The boiler hydraulics are calculated in such a way that the flow movement is at the same speed and uniform, to avoid stagnation zones in individual parts of the pipe system or, conversely, exceeding the boiler resistance above the optimal level. The combustion part of a water boiler is hollow; fuel is burned in it. The convective block consists of convective packets. The convective package is assembled from U-shaped panels. The pipes are arranged in a checkerboard pattern. Convective pipes are welded to vertical risers. During repairs, the panels of the KV water heating boiler can be easily dismantled even in a limited space (with the width of the passages between the boilers being one and a half meters).

Water-tube hot-water boilers are shielded by a gas-tight strip between the furnace pipes; this device ensures that there is no air suction during combustion and prevents smoke in the boiler room.

The lining device for hot water boilers is lightweight and removable. A frame is installed on the gas-tight block of the pipe system, spikes are welded onto steel strips, onto which thermal insulation boards are attached. The lining is made of galvanized or sheet steel and installed on a frame made of a profile pipe or channel.

Direct-flow water-tube boilers are easy to maintain and repair due to the presence of an access device in the lining for inspection and cleaning of the pipe system from the outside.

At the bottom of the convection packages there is an ash hopper with a manhole for cleaning ash deposits and inspecting the convection bundle pipes.

Water boiler safety device

To monitor operation and ensure safe operating conditions, KV hot water boilers are equipped with:

- safety and shut-off and control valves

- instrumentation

- safety devices

Shut-off valves are used to drain water from the boiler into the heating network, supply return water, drain water from the boiler, for periodic purging and removal of sludge.

Control and measuring instruments (thermometers and pressure gauges) provide measurement of pressure and temperature at the inlet and outlet of water from the boiler.

Safety devices ensure that the fuel supply is turned off when the temperature and water pressure limits in the boiler are reached.

Boiler automation is designed to control the operation of hot water boilers and prevent accidents using light and sound alarms.

The functionality of the automation allows you to manually start and automatically stop the boiler.

An emergency stop of the boiler with indication of the cause of the accident and an audible signal is performed when:

- decrease and increase in pressure at the outlet of the boiler;

- increasing temperature at the boiler outlet;

- lowering the vacuum in the boiler furnace.

Furnace design for hot water boilers

The furnaces of gas, diesel and oil-fired hot water boilers KVA are part of a pipe system in which fuel combustion occurs. The combustion process is controlled by the burner. Boilers produced by the boiler house can work with various types of burner devices of imported and domestic production; for this purpose, holes and fastenings for the selected burner are made on the front plate. Depending on the type of burner, the design of the boiler changes, taking into account the opening and length of the torch, the size of the combustion chamber of the boiler is determined.

Solid fuel water heating boilers KVR, KVM are made with various options for combustion devices, on which the design and arrangement of the pipe part depends. Types of fireboxes used:

- manual grate firebox or EUR firebox;

- semi-mechanical firebox with rotating grate RPK;

- semi-mechanical firebox with ZP spreader with rotary grate ZP RPK;

- mechanical firebox TSHPM;

- mechanical combustion chamber TLPH;

- automatic combustion chamber for burning raw sawdust and wood waste.

- It is possible to design hot water boilers for burning reserve fuel - firewood.

Review of some popular models

For clarity, let’s look at the key characteristics and approximate prices of some popular models of hot water boilers. Let us immediately make a reservation that there are quite a lot of manufacturers, and even more so the models themselves, so only a few are described below. For the convenience of site visitors, the information is presented in the form of a small table.

Table. Comparative characteristics of some water heating boiler devices.

| Name, photo | Short description | Average market value, in rubles |

| FORTE BT-S 12 kWt | A solid fuel non-volatile device weighing 115 kilograms and a power of 12 kilowatts. The efficiency is 78 percent, dimensions are 89.5x47x68 centimeters (HxWxD), heating area is from 60 to 110 square meters. | About 27000 |

| An electric water heater, which is distinguished by the presence of a “wet” heating element and a volume of 50 liters. The weight of the product is 15 kilograms. The tank is steel, with polyurethane insulation. | About 5,500 – 6,000 |

| Kospel ekco L1z 21 | An electric boiler intended for use in heating systems in tandem with an indirect heating water heater. Such hot water boilers weigh 16 kilograms, dimensions are 66x38x17.5 centimeters (HxWxD). The outlet water temperature ranges from 40 to 85 degrees, as for the voltage, it should be 380V. | 16000 |

| Solid fuel boiler equipped with a manual firebox. The power indicator (in this case, thermal) is 350 kilowatts, the model is capable of effectively heating rooms with an area of up to 9.45 cubic meters. Does not operate on coal or wood waste. | 210000 |

| The products of this brand are distinguished, first of all, by their versatility. They are not only heating and hot water, but also cooking, and they also operate on both solid fuel (wood) and electricity. | From 23890 |

| Gas-fired water heating boilers with floor-mounted installation. The kit also includes smoke pipes. Consumption is only 21 cubic meters of gas per hour, while the thermal power reaches 200 kilowatts. | From 150,000 to 185,000 |

Note! As you can see, the price spread is quite large, and the specific cost depends on the manufacturer and type of fuel used. In addition, industrial models always cost much more.

Types of hot water boilers

Types of hot water boilers depend on the type of fuel used for combustion in the boiler and the technical characteristics of the coolant.

On the hot water boiler market, the following types are distinguished by fuel grade:

- solid fuel;

- liquid fuel;

- gas;

- combined and universal.

Solid fuel types of hot water boilers are in turn divided into:

- coal;

- wood;

- combined coal-wood boilers;

- boilers using raw sawdust and wood waste.

Liquid fuel types of hot water boilers are divided into:

- diesel boilers;

- waste oil and waste oil boilers;

- oil boilers.

The classification of gas-fired hot water boilers depends on the gas pressure used in the burner device:

- boilers with low pressure gas burners;

- boilers with high pressure gas burners.

Universal and combined boilers are classified according to the types of fuel that work together:

- coal-wood boilers;

- combined firewood and sawdust;

- combined gas-diesel;

- fuel oil gas;

- diesel fuel oil.

Features of installing a hot water boiler

Let's consider the features of installing solid fuel devices, taking into account their prevalence. The procedure itself consists of several stages, and an approximate algorithm of actions is given below.

Stage one . Preparation. You need to prepare the premises (including the one in which the device will be installed). A concrete foundation must be prepared for the boiler, although there are other requirements (minimum distances to other objects, for example).

Stage two . Installation. Obviously, at this stage the boiler itself is installed in its place.

Stage three . Strapping. This stage is rightfully considered the most difficult. It is necessary to connect all communications, as well as additional elements - for example, an expansion tank.

Stage four . Chimney pipe. The next step is to install the chimney.

Stage five . Test run. When everything is ready, you need to check the equipment for functionality. The installation process is described in detail in the file below.

Installation of a hot water boiler. Download file (click on the link to open the PDF file in a new window).

We also recommend watching a video on the topic. That's all, good luck!

Classification of hot water boilers

Classification of hot water boilers is made depending on the type of combustion device or burner device.

Solid fuel hot water boilers are classified into the following types:

- manual;

- semi-mechanical;

- mechanical;

- automatic.

Manual solid fuel boilers operate on grates or fireboxes of the EUR type. Throwing solid fuel into the firebox is done manually by a fireman, and slag is also removed manually. These types of fireboxes are installed with hot water boilers with a capacity of 150, 200 kW to 1 MW. By special order, our plant produces boiler systems with manual fireboxes with a capacity of up to 2.5 MW.

Semi-mechanical fireboxes are installed on hot water boilers with a capacity of 800 kW to 3 MW. These are RPK and ZP RPK fireboxes. These types of fireboxes have a series of rotary grates, which the fireman turns as slag accumulates on the grate. The slag is poured into the slag removal channel, where a mechanical conveyor TS 2-30 removes the slag outside the boiler room. A mechanical conveyor and a caster are also installed in the ZP RPK firebox, which supply fuel to the grate firebox. Fireboxes of the ZP RPK type are installed on hot water boilers with a capacity of 1 MW or more.

Mechanical solid fuel water boilers operate with different types of mechanical fireboxes depending on the power. Hot water boilers with a power from 0.8 MW to 3 MW operate with mechanical fireboxes with a rustling strip type TShPM. Hot water boilers with a power of 1.5 MW or more operate with more complex and expensive TLPH fireboxes - with a direct-running belt grate. To operate these industrial hot water boilers, mechanical fuel supply and slag removal conveyors are also installed in the boiler room.

Classification of hot water gas and liquid fuel boilers depending on the type of burner device:

- boilers with burners operating under pressurization;

- boilers with burners operating under vacuum.

Burners operating under pressurization have a built-in fan in their design, which, under pressurization, supplies a gas mixture to the firebox. For such burners a smoke exhauster is not required. This design is usually provided for imported burners.

Boilers with burners operating under vacuum require the installation of a smoke exhauster in the boiler room. This design is usually provided in domestically produced burners.