Criterias of choice

If desired, it will be easy to choose a ready-made model whose parameters meet the requirements, but often home craftsmen, carried away by the ideas of inventors, make pyrolysis furnaces with their own hands. When choosing a gas generator installation option, a number of points are taken into account:

- purpose of the pyrolysis unit. To heat a barn, chicken coop, garage or other technical premises, choose a relatively compact metal or brick structure. To heat the house, the priority is to build a long-burning brick stove. For tourism purposes, choose a portable camping pyrolysis oven;

- device power. Depending on the parameters of the heated object, the required power of the gas generator is determined;

- mobility of the structure. The brick pyrolysis furnace is stationary; the device is erected at a permanent place of operation. Almost all types of metal gas generators are mobile.

For tourist purposes, choose a portable camping pyrolysis stove.

For high-quality operation of a pyrolysis stove, the presence of solid fuel of a certain humidity is required, the reserves of which are stored in a utility room.

Fuel requirements

Pyrolysis stoves for home use, using briquettes, can be fully automated and the comfort of their maintenance in this case is comparable to gas stoves. The fuel for them is waste compressed under high pressure without chemical binders. This technology makes it possible to produce relatively dry briquettes with a high calorific value. Their properties, however, may be different.

Pyrolysis furnaces and boilers operate on a wide variety of fuels

Most of them are not destroyed during combustion in the firebox, while others can only be used in a mixture with lump wood or brown coal. Small briquettes are fed using screw conveyors and are therefore used in automated systems; larger briquettes are only suitable for manually operated long-burning pyrolysis ovens. Wood pellets intended for automatic installations are obtained in the same way as conventional briquettes. Their only significant difference is size. White pellets made of soft wood without bark are considered the highest quality.

For wood-fired pyrolysis stoves, the size and type of feedstock can significantly influence performance—more wood surface area results in more gas being released per unit time. Hard rocks gasify more slowly.

Advantages and disadvantages of units

Among the wide variety of heating units, there are two main groups based on the principle of heat transfer, these are:

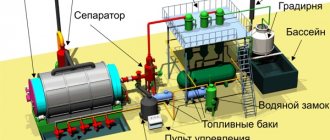

- Furnaces with a water circuit. In such units, water is heated, which releases heat into the environment for a long time, thereby ensuring long-term maintenance of a high temperature in the room. Among the advantages of such heating systems are their profitability and relatively low costs. However, there is a high risk of the colorimeter freezing, and the cost of additional plumbing work with such a unit may unpleasantly surprise the owner.

- Furnaces with different options for placing heat exchangers. In this case, the firebox is located above or below the air chamber. In the first case, it is necessary to install special smoke exhausters and fans. They create forced draft. If the firebox is under the air chamber, then natural draft works here.

Material selection

For the manufacture of wood chip stoves, acid-resistant and heat-resistant steel grades are used, because they not only tolerate high temperatures well, but are also resistant to condensation that forms during ignition.

This metal is used for the internal lining of furnaces and boilers, as well as for the manufacture of drums and internal casings of washing machines.

It is also necessary to choose the thickness of the metal correctly. After all, the thinner the part, the less rigid and durable it will be (even if it weighs less), but at the same time it is noticeably easier to process. And the thicker it is, the stronger the structure will be, but the greater its weight, and the processing will be noticeably more difficult.

Therefore, most often for home-made stoves, stainless steel with a thickness of 1–1.5 mm is used, although both thinner and thicker metal can be used.

As a basis for the manufacture of round heating devices, you can use spoon dryers of various diameters, made of food grade stainless steel.

Such dryers can be bought on AliExpress and other sites for a low price. Metal thermoses are well suited for creating pyrolysis stoves, because they are also made of stainless steel.

However, they are quite difficult to drill due to their round shape and the inability to use a drilling machine, and for complete pyrolysis, the air flow in the combustion zone should be minimal, and in the afterburning zone located above the combustion zone, maximum.

Often, various steel containers are used to make wood chips, such as:

- saucepans;

- mugs;

- pots;

- banks.

The main selection conditions are:

- heat resistance;

- acid resistance;

- compliance with the size and shape of the water container that will be installed on top.

Furnace fuel

Since these stoves are universal in relation to the combustion products used, craftsmen use a variety of fuel options for their units. However, most modern boilers operate using solid fuel. Such heating devices operate on wood and pellets.

It is important to consider that solid fuel for a pyrolysis boiler must be sufficiently dry, and its humidity on average reaches no more than 12%.

The following types of fuel are distinguished:

- Firewood. Firewood is prepared from various species and types of trees. For example, birch trees and conifers have the greatest heat transfer. Also, oak firewood is quite heat-intensive, but its wood is quite expensive, and most of these trees are listed in the Red Book due to uncontrolled logging. In addition to the trees listed above, firewood from alder, ash and hazel is often used.

- Pellets. They are compressed plant materials in the form of separate small cylinders. Straw, husks and branches are used as raw materials for the production of pellets.

- Coal. Such raw materials are used to maintain heat in industrial premises.

- Eurodrova. Their more common name is “fuel briquettes”. Unlike pellets, they are large in size, however, the raw materials for their production remain the same.

Types of pyrolysis furnaces

The following types of pyrolysis furnaces can be distinguished:

- Single-circuit devices. Single circuit furnaces have two combustion chambers that are separated by a fireproof partition.

- Dual-circuit devices. These gas generator furnaces have the same design, but they have an additional circuit that heats the liquid for hot water supply.

Also, based on the material used to make the heat exchanger, the following types of pyrolysis furnaces are distinguished:

- Devices with a cast iron heat exchanger. The service life is at least two decades, but the unit is sensitive to sudden temperature changes in the combustion chamber. In such aggressive conditions, a cast iron pyrolysis furnace gradually becomes unusable.

- Devices with a steel heat exchanger. Service life is at least 13 years. The equipment is susceptible to corrosion processes, but is not afraid of temperature changes.

A pyrolysis furnace with a water circuit is able to heat a small volume of liquid in a short period of time.

For property owners who do not want to purchase a pyrolysis combustion furnace in specialized stores, but to construct the device with their own hands, a mini pyrolysis furnace will come in handy. This is the same stove, but small in size, installed in garages, bathhouses or other small rooms.

The operating features of a mini pyrolysis oven are presented in the video.

https://youtube.com/watch?v=jzprMcjGF6Y

The essence of pyrolysis ovens

You can correctly read the drawing of a long-burning furnace and use it to make high-quality heating equipment if you understand the whole essence of the processes that occur during the pyrolysis decomposition of fuel. It is vaguely reminiscent of oil cracking, but is performed with solid fuels in a slightly different temperature range.

Pyrolysis of solid fuel takes place at a temperature of 450°C and in conditions of lack of oxygen. The result is a gas consisting of wood fractions. Its ignition temperature is significantly higher compared to the energy released when burning solid fuel. This determines the high efficiency of heating equipment (80-85%).

Stages of energy conversion.

The operating principle of a long-burning furnace is based on the following stages of solid fuel pyrolysis:

- drying the energy carrier;

- direct pyrolysis;

- combustion of the light, volatile fraction and parallel carbonization of the fuel;

- decomposition of heavy fractions to a volatile state;

- reduction reaction at +400°C.

As a result of the last reaction, pure hydrogen and carbon monoxide are obtained. It is as a result of their oxidation that a large amount of heat is released. However, the design of a long-burning furnace must be organized in such a way that the temperature in it does not fall below +250°C. Otherwise, carbon monoxide and hydrogen will not oxidize, but will go outside without giving up their heat.

Operating principle of a pyrolysis furnace

What is the operating principle of this stove? The processes occurring in it are unfamiliar to many, so it is necessary to study in more detail the principle of operation of a pyrolysis furnace.

A distinctive feature of a do-it-yourself pyrolysis furnace from a conventional one is that the fuel in it burns when there is a lack of oxygen. And this is surprising, because in conventional designs the fuel burns if there is a large amount of oxygen and this ensures the normal functioning of the entire heating system.

How does the pyrolysis process occur? When hydrocarbon fuels are burned, a process of oxidation and heat generation begins. Fuel under the influence of high temperature does not burn completely, releasing a large amount of various gases. The higher the temperature with a lack of oxygen, the more intense these gases begin to be released.

Thus, the principle of operation of a do-it-yourself pyrolysis oven is to burn these gases. That is why such furnaces are also called gas generators. Pyrolysis is the process of decomposing fuel into its component parts when heated, followed by their combustion and release of heat.

How does this boiler work? The boiler consists of the following elements:

- Gasification chamber

- Afterburner

- Air supply system (primary, secondary)

- Water jacket

- Grate

Boiler elements

The operating principle is as follows:

- Fuel is loaded into the gasification chamber and ignited.

- Gas begins to be produced from the fuel.

- Primary air is supplied to the chamber, and due to excess pressure, gas begins to flow into the lower afterburning chamber.

- Secondary air is supplied to the afterburning chamber, and the resulting mixture burns at a high temperature.

- The water in the water jacket of the boiler is heated and supplied to the heating system, while at the same time return water is supplied to the inlet part of the jacket.

- The coolant used also serves as a boiler cooler.

This is the basic principle of operation. But for proper functioning, strict proportions of the air-fuel mixture must be observed. Otherwise, combustion will proceed unevenly, with increased smoke. So, to the question whether it is possible to make pyrolysis ovens with your own hands, we will answer positively. But it’s worth making a reservation right away:

- To manufacture such a unit, it is not enough to have good welding skills or to have working drawings of the unit in hand.

- It is necessary to use high-quality materials, many of which are expensive.

- This primarily applies to metal. For manufacturing you will need good alloy steel.

- Appropriate electronics will be required. Unless, of course, you plan to hire a stove technician to constantly monitor the boiler.

There is no need to talk about using such a boiler for the main heating of a home. To make a pyrolysis boiler, you can, of course, take old barrels, pieces of pipes and other iron trash, which is also used to build an iron furnace. But we must understand that the processes occurring in this unit require compliance with certain conditions for its normal operation.

Operating principle of furnaces

Pyrolysis of organic raw materials is the heating of biomass to a high temperature without air access.

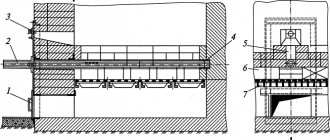

Detailed structure of a pyrolysis furnace

Under these conditions, the fuel is converted into a mixture of three types:

- coal (solid);

- organic gases (gaseous);

- oils (liquids).

Depending on temperature fluctuations and the speed of ongoing processes, the percentage of charcoal, gas and oils changes.

The advantages of this type of wood burning compared to traditional ones:

- greater efficiency with the same amount of raw materials;

- minor negative impact on the environment (for example, in terms of a parameter such as CO2);

- slight formation of solid unburned particles (ash).

Most household pyrolysis stoves and boilers operate on wood or briquettes. High-quality installations are capable of operating on mixed raw materials (cuttings, bark, shavings, sawdust, logs). Regardless of the type of fuel, three processes occur in them:

- Drying and heating wood material in a bunker, releasing gaseous components.

- Combustion of gaseous products.

- Combustion of solid components (charcoal).

A pyrolysis furnace is perfect for a summer residence

. Each of these stages requires different conditions, so the correct distribution of temperature and other factors affecting the chemistry of the processes is the basis for the effective operation of the installation. The wood is dried at temperatures below 200°C. The pyrolysis process begins around 300°C. At this temperature, cellulose, as the main component of wood, breaks down to form light compounds. Closer to the nozzle, the temperature in the pyrolysis combustion furnace rises to 200-700°C. There the biomass is freed from volatile compounds and converted into charcoal.

The released gases are forced into the combustion chamber, where they gain access to the required amount of combustion air, burn and release heat. Charcoal is burned on a grate. Unburned residues fall into the ash collector.

More information about the pyrolysis oven:

Mechanism of action of a pyrolysis oven

Internals of a pyrolysis furnace

All existing pyrolysis furnaces, and brick ones are no exception, operate on the same and extremely simple principle.

The user places fuel in the firebox, compacts it thoroughly and ignites it. After this, you need to close the furnace doors and start the smoke exhauster. Under conditions of elevated temperature and lack of air, the load begins to smolder, simultaneously releasing wood gas. This is precisely what the principle of pyrolysis is based on.

Pyrolysis oven

During the pyrolysis combustion process, the loaded fuel is separated into wood coke and a mixture of pyrolysis gases. There is also some solid residue left. The decomposition reaction is exothermic and is accompanied by the active release of a large amount of heat. Pyrolysis is a much more efficient use of fuel compared to conventional combustion.

The resulting gases pass into the second chamber of the firebox, mix there with the incoming secondary air and burn, releasing additional heat. The generated heat is used simultaneously to heat the house and dry the loaded fuel.

The main feature of the pyrolysis process is that one load of fuel is enough for at least a day when wood is used (for stoves with a medium-sized firebox). The use of coal allows you to completely forget about the need to add fuel to the stove for several days.

Principle of operation

Pyrolysis gases ignite at a temperature of at least 450 degrees. However, elevated temperature alone is not enough. It is necessary that air is supplied to the furnace in certain quantities in accordance with a pre-calculated and tested scheme. To control the volume of supplied air, the pyrolysis furnace is equipped with a fan. It, in turn, connects to the automatic control unit.

The main difference between the design of a pyrolysis furnace and an ordinary furnace unit is the presence of an additional combustion chamber for wood gases. In this case, the height of this chamber must be at least 500 mm.

It is the arrangement of the firebox that is the largest cost item when constructing a pyrolysis furnace. To achieve maximum efficiency, the firebox must be equipped with automation equipment. However, if you have a limited budget, you can do without them - with automation it is simply more convenient and, of course, more efficient.

At the same time, pyrolysis furnaces of any configuration are environmentally friendly. Pyrolysis gases actively interact with carbon dioxide. As a result of this reaction, the release of harmful products is minimized. Thanks to this, the requirements for the chimney are significantly relaxed.

What is pyrolysis

Pyrolysis is the thermal decomposition of a substance at high temperatures into smaller particles, and no additional reagents are involved in the process. Small particles in turn are concentrated in the form of gases, which are subsequently burned, releasing large amounts of thermal energy. That is, there is a double release of heat, plus complete combustion of fuel with minimal waste.

As for the above-mentioned reagents, we were mainly talking about oxygen, which supports combustion. So the pyrolysis process itself occurs in the absence of this chemical. In fact, it turns out that the fuel in the furnace does not burn, but smolders. In this case, a sufficient amount of thermal energy is released, and at the same time gases are released, which are collected in a special compartment, where they burn under the influence of high temperature, again releasing a large amount of heat.

Advantages and disadvantages of pyrolysis furnaces

Some advantages of pyrope ovens have already been mentioned.

- Efficiency reaches 90%.

- Fuel economy.

- A long burning process takes place inside the firebox, which allows one load of fuel to be used for a long time. That is, human presence is minimized.

- The pyrolysis process can be considered environmentally friendly, because when it is carried out, a minimal amount of carbon monoxide is released into the atmosphere.

- If you make a pyrolysis furnace with your own hands correctly (according to the drawings exactly), then you can guarantee the complete absence of soot, because it simply will not be formed due to maximum fuel combustion. Therefore, there is no need to clean such an oven.

- Pressed waste plant biomass is used as fuel here. This is the cheapest type of energy carrier today.

Design features

As for the shortcomings, there are some too.

- A pyrolysis oven is a fairly large unit.

- Assembling it with your own hands is not so easy. This is not an ordinary water heater or potbelly stove.

- Low-humidity fuel is used as fuel in pyrolysis furnaces. Its increase has a negative impact on the pyrolysis process itself, which will affect a decrease in efficiency, plus the appearance of tar deposits on the walls of the unit and the chimney.

Cost of work and materials

Before starting the assembly process, you should calculate how much it will cost to build such a boiler. In general, it is generally accepted that making a boiler yourself is the cheapest and most economical option. However, we should not forget that in order for the system to serve uninterruptedly for a long time, it is necessary to purchase only high-quality materials.

With additional use in the house or for a bath, self-assembly of the boiler will save up to 2000 USD. However, many who want to cut costs sometimes misjudge their own strengths. Therefore, it is recommended to solve this issue not in one day, but to think and make all the required calculations.

How to make a pyrolysis oven with your own hands: step-by-step instructions

The assembly of a metal structure is carried out in stages:

- The frame is made by welding the metal elements of the racks together. Up to 1 m in height, the width is the size of the oven.

- The inner walls are installed on the brick base along the entire length and welded, and a compartment for ash is placed on the bottom.

- The main parts are welded: the afterburner with the base and with the combustion chamber.

- Stiffening ribs are attached.

- Cut out the firebox window.

- The system is connected to supply air to the stove.

- Install the top plate and outer walls.

- A steel water jacket and water tanks are installed.

- Water pipes (as a set) - heat exchanger, are welded into a flow circuit with a significant external surface to deliver the greatest heat transfer to the coolant.

- Install a fan in the pipe.

- Cleaned (pre-calcined) sand is poured between the inner and outer walls. It will accumulate heat and also protect against overheating and burnout.

- The doors are attached and sealed. A collector with water is connected to the circuits.

Assembling a brick stove is carried out in the following order:

- Prepare the materials - ordinary brick 400 pieces, fireclay brick up to 100 pieces (for the heat exchanger) and a mortar of: 8 parts sand, 1 part water and 4 parts clay.

- The solution is made in advance: the clay is mixed with water until it becomes sour cream and left overnight. Next, the solution is passed through a sieve and sand is added.

- A heat exchanger consisting of two chambers is created from brick.

- The grates are attached in a loose, light position, since they will expand when heated.

- Place a fan, chamber doors, and valves.

Important! A pyrolysis furnace requires dry fuel with a humidity of up to 20%, then the heat transfer effect will be maximum. With increased fuel humidity up to 50%, the furnace performance indicator is reduced by 2 times

Pyrolysis boiler manufacturing technology

To make a powerful boiler, you need to be able to handle an angle grinder and a welding machine, as well as understand the drawings. If you manufacture a boiler with a power above 25 kW yourself, you must do everything according to the drawing, otherwise the boiler will not meet safety requirements.

The walls of the boiler should be made of heat-resistant steel, only this will guarantee that it will last for quite a long time. If such steel cannot be found, you can use ordinary steel, only in this case the internal chambers of the boiler are lined with fireclay bricks.

Boiler manufacturing stages.

- The boiler body is made of sheet steel. Using a grinder, boiler parts are cut out of a sheet of metal, holes are made in the walls for the ash pan door and loading door, as well as for pipes and a smoke exhauster. The most important thing is to adhere to the dimensions indicated in the drawing. Using a welding machine, the parts are connected, after which the seams are cleaned of scale and ground.

- Then the pipes are welded so that there are no gaps between the seams. A pipe of the required diameter is taken and a protective heat exchanger is installed on the rear wall of the boiler. After that, they check whether the heat exchanger is leaking due to increased pressure from the compressor, and only then install the rear wall of the chamber, made of heat-resistant steel.

- Then they begin to install a partition that separates the gasification and gas combustion chambers, installing a cast iron grate. An air duct with a damper is made at the top of the gasification chamber. An air duct is also made at the bottom of the chamber and at the same time the bottom and sides are lined with fireclay bricks.

- The boiler doors are made of heat-resistant steel, and for maximum tightness they are reinforced with metal corners.

- The boiler should be installed in a non-residential area, connecting the chimney. Then a water circuit is connected to it and a smoke pump is installed.

Classification of pyrolysis devices

The design provides two compartments: the first contains solid fuel and the process of its slow oxidation occurs. When wood smolders, a large amount of flammable gases are released, which enter the compartment above and burn. To prevent the fuel from flaring up and smoldering, the supply of oxygen is strictly regulated. By and large, pyrolysis devices operate on gas, which is produced in the unit itself.

Scheme of a pyrolysis furnace

The operation of a long-burning installation provides the maximum amount of thermal energy with significant savings in fuel resources. This is due to the fact that the fuel is processed almost completely, as a result, soot and ash are almost not formed, and there is also no smoke.

This group includes a number of designs:

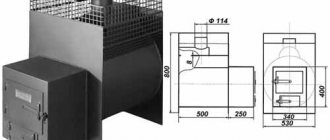

- Potbelly stove. A gas generator with an internal structure in the form of a potbelly stove is used for heating residential and technical premises. The model is also relevant for baths and saunas, used for cooking, there are outdoor options for barbecue complexes;

- Buleryan stove. This shaft-type pyrolysis structure with an efficiency of up to 75% is intended for heating both residential and non-residential premises. Cold air is sucked in through the lower ends of the pipes surrounding the boiler, which quickly heats up and is thrown upward into the room through the upper elements.

- Bubafonya stove. The invention belongs to a craftsman from Kolyma; an old gas cylinder is used as the basis for the design. The installation is relevant for heating technical premises. A bubafonya from a cylinder with a volume of 50 liters is capable of working on one stack of firewood for 6 hours, maintaining a comfortable temperature in a room of up to 70 m².

- Lachinyan stove. The installation combines the highest possible efficiency and extremely low fuel consumption. The models are actively used for heating RVs and camping tents. “Lachinyanki” are also used for heating agricultural buildings and hunting lodges. Models with a water jacket are used for heating residential premises up to 300 m². It is noteworthy that 2 buckets of coal are enough for 5-7 days of uninterrupted operation of the pyrolysis unit of Lachinyan, a famous inventor from Kazakhstan.

- Pyrolysis furnace using waste oil. An economical long-burning unit during mining is designed for heating non-residential premises. The design is as simple as possible, and most home craftsmen can make such a model.

Pyrolysis furnace Buleryan

A gas generator in the form of a brick structure - a Kuznetsov stove - is used for heating residential premises and bathhouse complexes. The device is also used for cooking. The efficiency of Kuznetsov pyrolysis furnaces is 80% and higher, the fuel in them burns almost completely. The full potential of hot gases and smoke is used to heat the brick body of the structure. High productivity of Kuznetsov gas generators is ensured by a special two-bell design.

Types of long-burning stoves

Options for furnaces of this type are classified depending on the material, method of operation and method of heat transfer. The designs differ in the type of traction and the relative position of the internal chambers. Thus, stoves are made of metal or brick.

Table: classification of pyrolysis furnaces

| material | internal structure | application |

| metal | potbelly stove | heating of residential and non-residential premises |

| for baths and saunas | ||

| cooking | ||

| for barbecue (outdoor) | ||

| Buleryan stove | heating of residential and non-residential premises | |

| Bubafonya stove | heating of non-residential premises | |

| waste oil oven | heating of non-residential premises | |

| brick | Kuznetsov furnace | heating of living space |

| for a bath | ||

| cooking |

Photo gallery: variety of heating units

Based on the method of heat transfer, the units are divided into models:

- with a water heating circuit;

- variability in the placement of heat exchangers (combustion and smoldering chambers are located in different orders). If the firebox is located at the top and the afterburning chamber is at the bottom, then forced draft is required using smoke exhausters and fans. If, on the contrary, the firebox is located below, then natural draft is triggered.

How to choose a stove option

- for what purposes is the stove needed;

- where will she stand;

- what fuel to run on?

When choosing the type of structure to DIY, consider the area and type of space. Depending on the parameters of the heated room, the size and power of the furnace are selected. It is worth considering that brick models are placed in a permanent place for future use, while metal ones are almost all mobile.

A homemade stove must meet the necessary characteristics and be safe to use

When making any furnace model, it is worth calculating the balance between the ratio of oxygen and gas. Therefore, the selection and assembly of any furnace option requires careful calculation of the parameters, power and dimensions of the product.