Added by: Dmitry Schwartz March 8

The main advantage of solid fuel boilers is energy autonomy. To operate, they do not need anything other than the fuel itself - firewood, peat, sawdust, coal, etc. Installing such a unit is a real way to reduce the cost of heating and hot water supply for a country house, cottage or even a small enterprise. At the same time, you can start saving at the installation and connection stage, simply by doing it yourself. But to do this, you will have to take into account that the requirements for the placement, installation and connection of solid fuel boilers differ from the installation standards for gas and electric heat generators. This means that you will have to arrange the boiler room, the area where the equipment will be located, and the piping in a special way.

- 2 Installation standards

2.1 Connecting a solid fuel boiler from different angles in the photo

Basic requirements for the boiler room

Domestic solid fuel heat generators are installed in separate dry rooms, outbuildings or separate buildings. The dimensions of the boiler room are determined by the dimensions of the unit, as well as the features of its maintenance, however, the smallest allowable area is 7 square meters. In this case, it is necessary to provide a place protected from atmospheric influences for storing the fuel supply - it must be dry before loading.

3D diagram of a heating system with a solid fuel boiler

If the walls of the boiler room are made of flammable materials, they must be covered with a 2.5-3 cm layer of plaster or thermal insulation in the form of an 8 mm layer of asbestos and sheet iron. If there is no fire protection for the ceiling, the distance from it to the boiler body must be at least 120 cm.

The normal operation of a solid fuel boiler is ensured by a stable air flow. Therefore, it is necessary to provide supply and exhaust ventilation in the boiler room. The first channel, measuring 30x30 cm, should go to the bottom of the wall opposite the chimney, and the exhaust hole, whose dimensions should be 40x40 cm, should be located no more than 40 cm from the ceiling. The boiler room ventilation must ensure normal draft. If there is a shortage of it, the boiler’s performance drops, and if there is an excess, it becomes difficult to regulate the fuel combustion process.

Supply and exhaust ventilation and smoke removal in the boiler room

The solid fuel boiler must be installed on a strictly horizontal fireproof (concrete or brick) platform about 7 cm thick. On a wooden floor, such equipment can only be installed with an intermediate brick layer covered with a 3-4 mm metal sheet or at least 5 cm cement screed . The base of a solid fuel boiler should be 10-20 cm wider than the external dimensions of the body, but the sides of the firebox should be additionally equipped with a safety zone at least 40 cm wide.

Installation standards

Requirements for the installation of solid fuel heating boilers are regulated by Fire Safety Standards (FSN) and Construction Norms and Regulations (SNiP). It is very important to follow the provisions of these regulations, since not only the efficiency of the heating system being installed, but also the safety of the residents of your home directly depends on this.

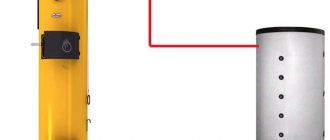

General connection diagram for a solid fuel boiler

Basic standards for installing solid fuel boilers:

- the distance from the heating boiler body to the walls of the boiler room must be at least 0.5 m;

- there should be no gaps between the bottom of the boiler and the screed;

- the distance from the firebox door to the opposite wall of the boiler room must be at least 1.3 m;

- if the heating system is designed for natural circulation of coolant, the boiler should be placed so that its heat exchanger is lower than radiators and other heating devices;

- the first meter of the inlet and outlet pipes is made of steel pipe;

- the internal walls of the chimney are protected by stainless steel sheets;

3 options for arranging a chimney for a solid fuel boiler - the cross-section of the pipe through which flue gases are discharged from the boiler must be no less than the cross-section of the chimney;

- the vacuum at the boiler outlet is regulated by the height and configuration of the chimney - it should be 10-80 Pa;

- the joint between the smoke outlet pipe and the chimney is compacted and sealed;

- the chimney must have a minimum number of bends;

- the temperature of the water entering the heat exchanger from the heating system must be at least 60°C;

- when equipping the heat exchanger with a heating element, grounding the boiler is mandatory;

- the connection between the boiler smoke exhaust pipe and the chimney must be removable;

- if the roof of the building is made of flammable materials, the chimney must be equipped with a spark arrester;

- the chimney duct must be equipped with valves, as well as a hatch for cleaning soot.

Connecting a solid fuel boiler from different angles in the photo

Necessary conditions for the correct connection of a solid fuel boiler to the heating system

- A separate room for the boiler room is selected. The area is about 7m2. A boiler room in a separate building is ideal. Loading fuel into the boiler room can be made easier. It is enough to install a so-called chute in the area of the receiving bunker on the outside where, for example, coal will be unloaded. Having unloaded the fuel into the receiving hopper, the coal is poured down the slope into the boiler room on its own.

- It is preferable to place the heating boiler below the 0 floor level. This boiler installation option ensures ideal coolant circulation in the heating system without the use of a circulation pump.

- The base for the boiler must be made of a concrete pad with an even top layer. The thickness of the concrete screed is 10 cm. The area of the base under the boiler should be 20 cm larger than the dimensions of the connected boiler. On the furnace side 40-50 cm.

- According to SNiP standards and fire safety requirements, the distance between the boiler and the wall is 50 cm. From the side of the combustion opening, firebox, to the opposite wall the distance is at least 1.3 m.

- The installed heating boiler should not have gaps between the base and the body.

- The boiler must be connected to the heating system with a steel pipe at least 1 meter long at the inlet and outlet of the pipeline. It is incorrect to connect the boiler to the heating system with copper and polymer pipes.

Below is a diagram of the correct connection of a solid fuel boiler.

There are many connection methods. Let's consider one of the simple and reliable connection methods.

A safety group is installed from the boiler on the direct pipeline. After the safety group, a tee for the bypass is installed. Next, the supply is connected to the heating system wiring. Having given up its heat in the heating system, the coolant returns to the boiler through the return pipe. To avoid the main disease in the operation of solid fuel boilers, condensation, which negatively affects the integrity of the boiler, a thermostatic three-way valve is installed, connected to the return line on the bypass, set to a temperature of 50-60°C. When heated, the coolant circulates through a small circuit through a three-way valve. A temperature of 55°C prevents the formation of condensation on the inner walls of the boiler. A circulation pump is installed after the three-way thermostatic valve. As soon as the return temperature reaches 55°C, the three-way valve opens and the heated coolant flows into the heating circuit to the radiators.

What do you need to install a solid fuel boiler yourself?

If you are not going to involve specialists to install a solid fuel boiler, you will have to prepare for the work yourself.

First of all, you will need special clothing and tools:

- overalls, leggings and welding mask;

- welding machine;

- circular saw with cutting discs for metal;

- building level and square;

- set of open-end wrenches;

- adjustable wrenches;

- screwdriver with a set of various attachments;

Locksmith tool - tape measure and marker;

- sealant gun.

To connect the boiler to the heating system you need to additionally purchase:

- 2 ball valves with drive and double-sided (external and external) thread with a diameter of 50 mm;

- safety group (pressure gauge, safety valve, automatic air vent and a pair of ball valves with a diameter of 15 mm);

- 3 steel couplings with a diameter of 50 mm;

- steel adapters 57-32 mm;

- steel bends with a diameter of 50 mm;

- chimney with gate valve;

- metal pipes for connecting the boiler;

- heat-protected sealant;

- plumbing winding;

- circulation pump (installed on the return line and provides forced circulation of the coolant in case of difficulty in natural circulation).

Diagram of a heating system based on a solid fuel heat generator

The most important thing when installing a heat generator is to follow the manufacturer's instructions. Before starting installation work, it is necessary to assemble the heating system and check it for leaks, as well as organize ventilation and a smoke removal system in the boiler room.

Heating systems based on solid fuel boilers must be equipped with open expansion tanks, the function of which is to protect communications from rupture due to overheating of the coolant.

Subtleties of installing solid fuel boilers

The boiler piping scheme is adopted in accordance with the characteristics of the heated object.

You can implement it using one of the following options:

- boiler in an open heating system with natural circulation and radiators;

- boiler in a closed system with forced circulation and radiators;

- boiler with thermal accumulator in a closed forced system with radiators;

- boiler with thermal accumulator in a closed system with forced circulation and heated floors;

- boiler with radiators and heated floors as part of a forced circulation system.

The piping of a solid fuel boiler must be equipped with a safety system. The latter includes:

- heat accumulator or buffer tank;

- three-way valve for adding cold water;

- thermostat in the control system.

The safety group of a solid fuel boiler is installed at the outlet, i.e. on the hot water supply line.

Solid fuel boiler safety group

Immediately before installing a solid fuel boiler, it is necessary to carry out a visual inspection and test firing in the open air for about 1 hour at maximum load of the combustion chamber.

According to the requirements of SNiP, after connecting the boiler, a hydraulic pressure test of the system should be carried out for 24 hours.

To do this you need:

- connect the water, open all taps and shut-off valves;

- increase the pressure in the system to 1.3 atm (with a control valve);

- make sure there are no leaks, especially at welded and threaded connections.

If the installation, piping and connection of the boiler are carried out correctly, there will be no pressure losses or coolant leaks. In this case, you can begin to inspect the boiler itself:

- checking the installation of grates and fireclay;

Checking fireclay and boiler grates - setting the ignition valve to the extreme position to ensure optimal traction;

- checking the quality of installation of plugs, combustion chamber doors and other elements of the boiler design.

Equipment for solid fuel boilers: buffer tank

The operation of solid fuel equipment is always associated with a certain cyclicity - peak production of thermal energy, even in excess quantities, during the main phase of fuel combustion, with a gradual decrease to almost zero during periods of inactivity.

Constantly replenishing fuel in the boiler is inconvenient for a number of reasons, it is unprofitable, and in many models it is completely technologically impossible.

Is it possible to make sure that the efficiency of the heating system does not suffer from this pronounced unevenness of energy supply, so that during the burning of the fuel fill a reserve of excess heat is created, which can then be usefully used, and not “thrown down the drain”?

Yes, this is quite possible - a similar problem is successfully solved by a buffer tank for a solid fuel boiler.

A buffer tank (heat accumulator, storage tank) is a device that accumulates and stores heat.

It looks like a huge thermos, in the form of a cylindrical tank with insulated walls. Its height is several times greater than its volume. The tank is insulated with heat-resistant foam, which helps retain and maintain heat inside the tank.

The heat accumulator is the main element in heating and heat distribution throughout the room. Its main task is to receive and accumulate thermal energy from different heat sources (solid fuel or electric boiler), and then rational distribution throughout the heating system and water supply.

The high efficiency of the buffer tank is due to the fact that it is able to accumulate and retain heat (a certain amount), and then gradually release it. In a nutshell, a buffer tank is a kind of thermos, a barrel made of metal (sometimes insulated) with a volume of 200 to 7000 liters.

The main element of the buffer tank is a thermal storage material that retains and distributes the heat supply.

Depending on the material used, the heat accumulator can be divided into several types:

- liquid;

- solid state;

- thermochemical;

- steam;

- with additional heating elements.

Let us pay attention to the operation of the heat accumulator using a solid fuel boiler.

In the pipeline between the boiler and the heat accumulator, there is a circulation pump, which starts, and this is how the system begins to work.

From the lower half of the tank, cooled water moves to the boiler, where it is heated. Once heated to the desired temperature, the liquid moves to the top of the container. Hot water is located at the top of the tank, and with the help of a pump, the liquid that is located below is pumped into the boiler.

When the circulation pump, which is installed in the return line of the system, is turned on, cold water slowly flows into the lower half of the buffer tank.

Subsequently, hot water is forced out of the tank and sent to the heating system. After the fuel boiler stops operating, heat from the buffer tank continues to be supplied to the system until cold liquid from the line fills the internal volume of the tank.

The operating time of the heat accumulator, after stopping the boiler, depends on the outside air temperature, the volume of the tank and the number of heating devices.

The buffer tank is a unique invention that provides heat to the home and helps save money.

A buffer tank is a metal barrel with insulation with a volume of 200 liters or more, installed between the source of thermal energy and the heating system of the house as a separator of thermal circuits with different temperatures and a heat storage device.

A storage tank is necessary if several different sources of thermal energy are combined into one system: gas, solid fuel, electric boilers, heat pump and solar collector.

The heat accumulator collects heat at any time during operation of each source. For example, during the day - from a solar collector, at night - from a heat pump or electric boiler, at any time when a gas or solid fuel boiler is operating.

Heat is distributed continuously. Connecting a buffer tank to the thermal energy transfer circuit increases the operating efficiency of the solid fuel boiler itself due to the collection and accumulation of heat. This allows you to eliminate idle heat energy consumption from the system.

If the temperature in the buffer tank drops, does this mean that the boiler needs to be fired up again? In the case of a system without a buffer tank, the temperature begins to drop immediately and this drop begins to be felt by a person after 0.5 - 3 hours (depending on the temperature outside, insulation of the house, etc.).

In a scheme with a buffer tank, the amount of water in the system increases (depending on the volume of the buffer from 500 liters to 2000 or more).

Accordingly, this volume of water will cool down several times slower. So it turns out that you will feel the cooling after stopping the boiler not after 0.5-3 hours, but after about 6-24 hours.

Here are the real benefits and savings. This is the time when you don’t have to heat the boiler.

Most types of solid fuel have three combustion phases - flare-up, intense combustion and decay. During intense combustion, the fuel gives off more heat than is required by the system, but the initial and final phases, on the contrary, do not provide enough heat.

When using such fuel, there are often large temperature changes in the house, and a comfortable climate for life is formed rarely and accidentally.

The buffer capacity is designed to smooth out these irregularities. Thanks to it, without any effort or additional equipment, you can always see your favorite +22, +25 or any other number that is comfortable for you on the thermometer.

During the intense combustion phase, the container absorbs excess heat, and after the boiler dies out, it continues to release heat into the heating system.

This allows you not only to maintain the desired temperature in the room, but also save up to 50% of energy. The buffer tank works in exactly the same way in combination with a heat pump, only in this case it accumulates cold, not heat.

The storage tank has another important function. If you have more than one heating device installed in your system, you can connect them to one buffer tank.

Thanks to this you can:

- abandon unnecessary parts of the system;

- configure heating devices to operate according to priority;

- avoid unnecessary switching on of some devices or switching off of others.

Advantages and disadvantages of using a buffer tank

There are many reasons why you should use this design:

- Boiler operating schedule.

Solid fuel boilers must be regularly equipped with fuel. At night, such a process is completely inconvenient, and in this case the heat accumulator saves the day. Warm water is stored in a buffer tank. And then it spreads throughout the system.

Installing a heat accumulator allows you to increase the intervals between firing the boiler and will help to significantly reduce fuel consumption.

- If an electric boiler is used, savings occur at night.

Since the cost of electricity differs several times during the day and at night. Installing a buffer tank will allow you to program the boiler to operate only during night operation.

- Uneven heat supply.

Almost all boilers have three phases of operation: flare-up, intense combustion and decay. Due to this process, strong temperature changes occur. A buffer tank will help avoid this phenomenon.

During the period of intense combustion, the tank absorbs excess heat, and during extinction it gradually releases it into the heating system.

- Mechanical regulation of the boiler operation prevents the combustion of all harmful substances.

During operation of solid fuel boilers, harmful substances (acids, tar) are released. Standard boilers are equipped with an air valve, which blocks the supply of oxygen to the fuel and provokes the release of harmful substances.

By installing a buffer tank, you can not only provide your home with heat, but also maintain your health and reduce the amount of harmful emissions into the atmosphere.

- Overheat protection.

Working intensively, the boiler may overheat, which will lead to disastrous consequences (system failure, explosion). The heat accumulator reliably protects the boiler installation and heating system from overheating.

- Saving.

By installing a thermal accumulator you can save up to 30% of fuel and electricity.

The advantages of autonomous solid fuel heating systems with a heat accumulator include the following:

- The energy potential of solid fuel is used to the maximum extent possible. Accordingly, the efficiency of boiler equipment increases sharply.

- The operation of the system will require much less human intervention - from reducing the number of boiler loadings with fuel to expanding the ability to automate the control of operating modes of various heating circuits.

- The solid fuel boiler itself receives reliable protection against overheating.

- The operation of the system becomes smoother and more predictable, providing a differentiated approach to heating different rooms.

- There are ample opportunities to modernize the system, including the launch of additional sources of thermal energy, without dismantling the old ones.

- In most cases, the problem of hot water supply at home is also solved.

There are also a number of disadvantages:

- A heating system equipped with a buffer tank is characterized by very high inertia. This means that from the moment of initial ignition of the boiler until reaching the nominal operating mode it will take quite a lot of time.

This is unlikely to be justified in a country house, which in winter the owners visit only on weekends - in such situations, rapid heating is required.

- Heat accumulators are bulky and heavy (especially when filled with water) structures.

They require enough space and a well-prepared, reliable foundation. Moreover, it is close to the heating boiler.

This is not possible in every boiler room. Plus, there are difficulties with delivery and unloading, and often also with bringing the container into the room (it may not fit through the door). All this should be taken into account in advance.

- The disadvantages include the very high price of such devices, which sometimes even exceeds the cost of the boiler. This “minus”, however, brightens up the expected saving effect from more rational use of fuel.

- The heat accumulator will fully reveal its positive qualities only if the rated power of the solid fuel boiler (or the total power of other heat sources) is at least twice as high as the calculated value required for effective heating of the house.

Otherwise, purchasing a buffer capacity seems unprofitable.

First start of the heating system

Before the first heating of the boiler, the pressure in the system should be about 1 atm. Don't forget to open the damper on the chimney. The kindling material is placed on the grate, after which fuel can be loaded into the combustion chamber. After 10-15 minutes from the moment of ignition, the ignition valve should be closed. When the temperature of the coolant in the system reaches 85 ° C, you should adjust the thermostat, and then set the minimum (about 5 cm) gap between the primary damper and the firebox door.

Fire up the boiler

The dampers allow you to adjust the volume of secondary air and thus increase the efficiency of the heating boiler.

Dampers of a classic solid fuel boiler

Installing a solid fuel boiler is not an easy task, but it can be solved. It is important not only to comply with the requirements of regulatory documents, but also to follow elementary logic. And do not forget to use the successful experience of those who have already dealt with the organization of heating systems based on solid fuel heat generators. The most important thing is to ensure optimal operation of heating equipment. After all, its reliability and durability and, of course, the microclimate in the premises of your home directly depend on this.

Review of long-burning boiler models

There are boilers from different manufacturers on the market, and their declared characteristics are similar, so making a choice is sometimes difficult. Below is an overview of the most popular models.

Boilers Liepsnele, Lithuania

The design of the boilers is of the classic shaft type with top combustion. Liepsnele boilers are energy independent and have high efficiency - it is at least 90% in any operating mode and with any fuel.

Brief technical specifications:

| power, kWt | from 10 to 40 |

| Heated area, m² | from 70 to 400 |

| Time of continuous operation on wood | up to 48 hours |

| Continuous operation time on coal | up to 7 days |

| Firewood loading volume, kg | from 25 to 75, depending on the model |

| Firewood length, cm | from 25 to 55 |

| Coal loading volume, kg | from 75 to 220 |

| Price, rub | 102 000-123 000 |

Video: installation and connection of Liepsnele heating equipment

Boilers SWaG, Ukraine

Brief technical specifications:

| power, kWt | from 10 to 50 |

| Heated area, m² | from 120 to 550 |

| Time of continuous operation on wood | from 12 to 36 hours |

| Continuous operation time on coal | from 3 to 6 days |

| Fuel loading volume, kg | from 70 to 400, depending on the model |

| Electricity consumption per hour, W | from 83 to 100 |

| Price, rub | 27 000-110 000 |

In SWaG boilers, along with the main fuel, you can burn sawdust, straw, wood chips and other waste, mixing them with coal or firewood. Do not use dusty fine coal that is prone to caking and coking - the operation of the boiler will be unstable and ineffective.

Video: description of SwaG boilers

Boilers Stropuva, Bulgaria

Classic top-burning, shaft-type units for heating residential and industrial facilities.

Equipped with a bimetallic traction regulator, which eliminates the need to connect to the electrical network. The range of universal boilers is represented by models from 8 to 40 kW. Brief technical specifications:

| power, kWt | from 8 to 40 |

| Heated area, m² | from 30 to 400 |

| Time of continuous operation on wood | from 18 to 31 hours |

| Continuous operation time on coal | from 3 to 5 days |

| Firewood loading volume, kg | from 30 to 80 |

| Firewood length, cm | from 45 to 55 |

| Coal loading volume, kg | from 70 to 180 |

| Price, rub | 54 000-110 000 |

Stropuva boilers are distinguished by increased safety and resistance to water hammer - in case of sudden overheating, the walls of the housing are not damaged, the deformation is directed inward.

Video: Stropuva long-burning models

Boilers Nedelka, Russia

Domestic-made boilers capable of operating on one load of coal for 6-7 days. They have high efficiency - up to 92%, the boiler automation allows you to accurately regulate the temperature of the network water and the microclimate in the premises of the house.

The boiler has a rectangular shape with a loading door in the upper plane. The type of combustion in the boiler is top; for more complete heat removal, smoke circulation is provided - channels through which heated flue gases pass.

The heat exchanger of the Nedelka boiler is multi-pass, which ensures maximum heat removal from the most heated surfaces. The firebox is equipped with a grate and two cleaning doors: through one, located in the fuel chamber, combustion products are removed from the firebox, and through the second - from the ash pan.

The fuel quality requirements for Nedelka units are low: they can burn coal and firewood, pellets, wood chips, and construction waste. The greatest efficiency and duration of combustion is achieved when working on coal, the quality of which does not have any special requirements - effective pressurization can ignite any fraction of coal.

Three models of boilers are recommended for private houses: KO-60 - for a house with an area of 100 to 300 square meters, KO-90 - from 200 to 400 square meters and KO-110 - from 250 to 600 square meters. Moreover, the larger the area, the shorter the boiler’s burning time at one load, so it is better to choose a more powerful boiler.

Prices for Nedelka boilers, depending on the modification, range from 110 to 220 thousand rubles.

Nedelka boilers do not require maintenance between loads. The entire combustion process is controlled by a microprocessor unit.

Why do I choose the solid fuel boiler “Nedelka” KO-60 - Video

The correct choice of the appropriate model of solid fuel equipment will allow you to forget about daily loading, cleaning and maintenance of heating equipment. Modern boilers are reliable, safe and do not require monitoring. It is enough to clean the unit from ash and ashes once every few days and load a new batch of fuel, after which the house will be warm and comfortable all week.