The principle of operation of a gas burner

There are several different types of gas burners, but they operate on the same principle.

The burner is a hollow metal tube with several holes (nozzles). Gas is supplied into it, which burns in air forced into the combustion chamber.

As a result, a mixture of combustion products is formed (carbon monoxide, carbon dioxide, water vapor, soot - pure carbon), which is discharged outside. The gas is distributed evenly thanks to a system of nozzles, and the air is forced through natural draft (in industrial furnaces the draft is forced).

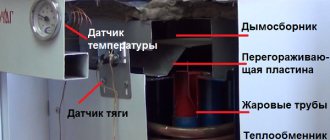

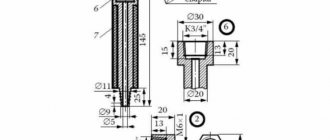

It can be represented schematically like this.

Operating principle of a gas burner (diagram)

And in a real gas boiler the burner looks like this.

Thus, if a gas boiler does not light up, this means that any of the combustion conditions are not met:

- Gas is not supplied.

- There is no draft (no air supply).

- Combustion products are not removed (as a result, they accumulate and do not allow the flame to flare up, which is why it goes out immediately after ignition).

Gas burner flame ug 20 malfunction

Its contacts must be firmly attached to the body.

There should be no oxidation on them. We check the traction sensor with a tester, measuring its resistance. We are trying to ignite. Be sure to check the draft after igniting the main burner. No heat should come out of this hole. If ignition fails, we move further along the chain. If this condition is met, we perform the following actions.

Checking the thermocouple. We ignite the igniter.

Related Posts

The solenoid valve rarely fails. Let's examine the thermocouple. It happens that the thermocouple contact disappears. This is not a reason to replace it, just solder it.

The main causes of problems with a gas boiler

You can begin to repair equipment only after the cause of the malfunction has been accurately determined. Then you can determine whether it is possible to fix it yourself or whether you will have to call a specialist.

External causes of boiler malfunction

The reasons for the extinguishing of the boiler burner can be caused by external factors:

- deterioration of the natural draft of the chimney or its overturning;

- decrease in gas pressure in the main;

- gas meter malfunction;

- gas filter clogged;

- power outage;

- lack of supply air;

- a draft in the house, creating a short-term excess of supply air;

- heating system problems.

Very rarely, sharp gusts of wind can upset the draft in vertical external chimneys or exhaust shafts built into the thickness of the wall, which is why the gas boiler can go out.

Gas boilers Siberia - What kind of breakdowns happen and the algorithm for their repair

Settings and adjustment of operating modes. Wall-mounted, double-circuit.

Repairs, adjustments and malfunctions. Settings for functions and modes. Errors and problems. Working with Xital remote control.

System control. Adjustment of work by temperature and pressure. Breakdowns and malfunctions. Operation with Logomatic control system and indirect heating boiler. Modes and functions. Components and operating functions. Programs for adjustment. Gas system. Installation and installation. Maintenance and prevention. Breakdowns and problems. Operation, maintenance. Recommendations for setting operating parameters. Lemax - repair and adjustment Models of gas floor-standing boilers Premium, Leader, Patriot.

Performance characteristics. Prime, Wise models.

Adjustment of automation Eurosit, Minisit, Sit Nova. Solid fuel boilers Forward. Operation and service. Recommendations for adjusting operating modes. Wall and floor models. Operating functions and setting up service modes. Maintenance.

Installation of an automatic pellet burner APG, 36, Call a specialist, he will find this limiter for you.

Topic in the section “Gas boilers and burners”, created by user st, Search in titles only User messages: Separate the names of participants with a comma. Newer than: Search this topic only Search this section only Display results as topics. Quick search.

Installers I know had the same garbage. Sorry for writing here, but I don’t want to create a new topic. The problem is almost the same. Automation EuroSit boiler "Danko". Therefore, there was a desire to adjust the gas flow.

Problems inside the installation

We decided not to climb in winter. The instructions and everywhere on the Internet say the same thing: 2 screws for adjusting the max and min flow must be turned. I started turning the max flow in the direction of decreasing. I reduced the max flow rate and then turned up the min flow rate a little - it’s at “1”. I tightened the screw on the igniter a little more.

Then the next day I try to turn it on, but it doesn’t work. What could be the problem? YamatoLug, Contact lost. Thermocouple power is not supplied to the solenoid valve. How can I fix it? And I don’t really believe it - yesterday it was and today it’s over? When I release the start button, I hear a faint metallic click as the flame dies out.

Repair consultations are only online via Q&A. Over the years of uninterrupted operation of gas heating equipment, you have probably become accustomed to warmth and comfort. But suddenly the boiler stopped turning on, the burner did not light, and meanwhile the room quickly cooled down. We have to look for the reasons for the failure in order to restore the operation of the equipment. Our recommendations will help you find the problem and fix it on your own.

Question for the Eurosit specialists - with normal settings, should the automatic system increase power linearly when turning larger increments? I finally figured out my boiler. The reason is the traction sensor. A very capricious thing. Just touch the wires a little or the wind blows, the contact may blink and the boiler will go out.

I soldered the wires to the sensor; there were removable contacts and fixed the appropriate wires so that the sensor did not fall out of its place. Thanks to everyone who helped me with their tips.

What you can do yourself

The sequence of first actions is the same in all cases:

- The boiler is disconnected from the power supply, and the gas tap is completely closed.

- A visual inspection is carried out to check for possible blockages and mechanical damage.

- If the combustion chamber is open, you can simply light a match or lighter and hold the flame near the holes through which air is supplied to the burner. If the draft is not clogged, the tongue will immediately deflect towards the holes, and the flame will burn evenly. If the flame deflects weakly, then there are large blockages.

- You can also draw conclusions based on the operation of the boiler. If it hums quite loudly, and the color of the flame is closer to colorless, then the draft is too strong - it needs to be reduced.

Using a gas burner with piezo ignition

The classic burner with piezo ignition is especially popular among tourists who willingly use such a simple device as an alternative to a fire.

With its help, you can quickly boil water or cook food, and unlike a fire, the device allows you to regulate the strength of the flame, and at the same time, control gas consumption. In addition, modern portable burners are equipped with a windproof function, a holder for utensils and other “devices”.

The piezo ignition function allows you to light the burner in a matter of seconds with just one press of a button, without using matches.

This burner with piezo ignition is also actively used in dachas, where there is no need to supply gas to the house. The device will greatly simplify your task of cooking, for which even a small gas canister will be enough for you. In addition, gas burners are often used for soldering and heating metal parts.

The popularity of burners with piezo ignition is quite justified, since the user does not have to worry about the presence of matches, but only until the device breaks. It is the presence of piezo ignition - an additionally inserted element that produces a spark - that often causes the problem of frequent breakdowns of the gas burner.

Diagnostics of a gas burner with piezo ignition

Often the reason for the malfunction of such a device lies in the breakdown of the piezoelectric element, after replacing which the burner works again without any problems.

However, in some cases, the operation of the device can be restored by simply cleaning the nozzle or sprayer, which can become clogged from time to time, as a result of which the gas in the burner simply does not ignite.

If the gas burner stops working due to a faulty piezoelectric element, then it can be replaced with an identical part removed from the most ordinary lighter

The cost of repairing a gas burner with piezo ignition can be equal to the cost of a new device, so there is no more profitable option than fixing it yourself. To identify the cause of the breakdown, you will need to diagnose the gas burner, during which you can understand why it stopped working.

When disassembling the burner, special attention should be paid to whether a spark appears when you press the button. The presence of a spark indicates the serviceability of the piezoelectric element, which means that the cause of the device failure lies in the contamination of individual parts of the burner.

If, even though there is a spark, the burner still does not ignite, then most likely the problem is that dirt has gotten inside the atomizer - a small hole through which gas enters.

Often, a gas burner can leak gas into a can, which indicates wear of one of the rubber gaskets inside the device. Also, the device may not work due to contamination of the mesh on the back of the sprayer. In this case, it is recommended to wash this element with alcohol or gasoline.

If the piezoelectric element is in good condition, a spark will be supplied, but due to oxidation of the wire through which it is supplied, the gas may not be ignited. If the wire insulation has melted, then you will need to clean it with a file or sandpaper, and, in general, the problem will be solved.

To avoid spinning the burner again, it is better to immediately clean all the listed parts, even if at first glance they do not look dirty

It is important to understand that the absence of a spark means only one thing - the piezoelectric element has failed, which means it requires urgent replacement. You can do this yourself, relying on simple instructions, and you don’t even have to look for a long time for a new piece.

Instructions for replacing the piezoelectric element

Despite the external differences of many burners, everything inside is arranged according to the same principle, and all parts have standard sizes, which makes it easy to choose a replacement for a broken element. Since the piezoelectric element is the most vulnerable part of the device, it is not at all surprising that in most cases it is its breakdown that causes the entire burner to stop working.

The piezoelectric element can fail either as a result of a strong impact or as a result of water or any other liquid entering the burner. To replace the piezo element, you will need to prepare all the necessary bits for the screwdriver, a new lighter from which the new piezo element will be removed, as well as heat shrink to connect the two wires.

If you take a gas burner with piezo ignition on a hike, then to be on the safe side it is better to take matches or a lighter with you, since the slightest fall of the device will lead to breakage of the piezo element

First of all, you should make sure that the piezo is malfunctioning, which you will be “notified” by the absence of a spark when you press the button. Next, we disassemble the burner body using a screwdriver and the corresponding bits, which are included in any set of attachments. At the same time, we check all burner parts for contamination and, if necessary, clean them.

Having reached the piezoelectric element, using wire cutters we cut the wire connecting the piezoelectric element to the burner, and thus remove the broken piezoelectric element.

Using the same principle, we remove a working piezoelectric element from a new lighter, leaving a supply of wire for further connection with the burner wire. To do this, we use a small heat shrink, which will need to be heated with a lighter.

Next, we assemble the gas burner in the same way as we disassembled it, after which we test it. If the correct sequence of actions is performed, the operation of the device will be completely restored, which means you will not have to buy a new burner.

We also recommend reading our other article, where we described in detail how to refill a gas canister with your own hands.

If the boiler does not start at all

It may also be that the boiler does not turn on - i.e. there is no flame initially.

The reasons for this may be:

- The simplest is low voltage or other problems in the electrical network. What to do: you should once again check the connection, the integrity of the electrical wiring, and the serviceability of the outlet.

- The electronic control system does not work. Then you need to call a service technician, since it is almost impossible to fix such malfunctions yourself.

- The burner nozzles are clogged - you can carefully clean them at home. The cause of clogging is incomplete combustion of gas and soot deposition. Normally, the flame burns blue, but a blockage can be identified by the abundance of red, orange and yellow hues in the flame. How you can eliminate the cause is shown here.

- Low pressure in the gas pipeline network, fluctuations. You should clarify information about a possible accident or temporary failure by calling the service company.

What to do if the automatic ignition of a gas stove does not work?

What to do if the auto-ignition in a gas stove does not work?

When the electric ignition on a gas stove does not work, the burner can be lit with a match, otherwise it will not turn on./p>

| What's happened? | What to do? |

| Ignition doesn't work. If you try to light a flame with a match, it burns. The spark is small, flies to the side or is not there at all. | Spark plug not working:

If the ignition of the gas stove does not work for these reasons, diagnostics of the spark plug is necessary:

|

| All burners do not light. The spark is yellow, small or absent. | The automatic ignition unit, which regulates spark generation, has broken down. It needs to be replaced by a technician. |

| A switched-on burner does not produce a spark, but a flame appears from a match. | The ignition button does not work. The contacts are oxidized or damaged. The contacts need to be cleaned, and if there is damage, the button must be replaced. |

| There is no spark, but fire appears from a match. | There is a fault in the wiring on the way to the ignition unit. It is more common in private homes where mice chew through wires. And when the ignition on a gas stove does not work for this reason, it is necessary to replace part of the wiring. |

Why does the boiler go out?

To understand why the Aton boiler goes out, you need to familiarize yourself with the main reasons, of which there may be several. The gas boiler of the Ukrainian manufacturer has excellent European protection, which automatically stops the operation of the entire system in the event of the slightest malfunction. The fault that the wick goes out is more likely to lie with the gas pipeline, smoke removal system, hot water supply or electrical network, rather than with the heating device itself.

The main and most common problems associated with:

- with chimney;

- with low gas pressure.

Basic elements of heater designs

Such equipment is electric, wall radiators, the heating of which allows you not to worry about frosty days, consists of the following basic elements .

- Heating device housing . The case is in most cases made of aluminum, which allows it to withstand high temperatures under load.

- heating element . These devices are made of nichrome thread, which is enclosed in a hollow steel tube. Heating elements of this type are the most durable, safe and economical, because they eliminate the appearance of microcracks, which ensures ideal heat transfer. In some devices, the heating element may consist of two rods. This allows convectors to operate at half power. To save money on budget models, manufacturers installed tape or needle heating elements. They are a dielectric thin plate with a built-in chrome-nickel thread.

- Temperature-regulating thermostat . A mandatory device that electric wall-mounted heating radiators cannot do without is a thermostat. It works according to the selected consumer parameters and can turn itself on and off, maintaining the desired temperature. Such devices are electronic and electromechanical. A simpler electromechanical device involves manual adjustment of parameters, which can lead to quite a serious error. The error can range from half a degree to two. Electronic thermostats are more accurate and their error does not exceed 0.01 ° C.

A new generation of heating batteries has already gone on sale, which, thanks to electronics, allows you to program the temperature and operating mode for a whole week in advance.