Yes, in some topic, someone wrote the workshop’s telephone number, but then there was no need - I didn’t write it down. You need to search by topic.

Sorry for being specific.

Gagarina, 96 “Gaztekhnika”: t. 336 - 13 - 76 - single reference; Mon. - Fri: 9 - 19 Sat: 10 - 17 Sun: 10 - 16 No lunch.

Service center: t.202 -12 - 00. Mon - Fri: 9 - 17 (no lunch) Sat., Sun. - vyhi.

I had the same thing, the buttons stopped working after a while. I replaced them with others, soldered them out from somewhere (I think from a Chinese alarm clock). Their contacts oxidize, cleaning these contacts gives results, but only for a few days, it’s difficult to disassemble them, they are small . Therefore it is better to change. It's a cheap thing, for those who are comfortable with a soldering iron.

If I find more buttons, I can help. I only changed 2 pieces on my remote control, the others will also have to be changed soon!

Tell me, what are the main error codes that Navien boilers produce?

Brief description of errors and malfunctions:

01E - boiler overheating. 02E - low RH level. 03E - no signal about the presence of a flame or an open circuit of the flame sensor. 04E - false signal about the presence of a flame or a short circuit in the flame sensor circuit. 05E - open circuit of the exhaust temperature sensor. 06E - short circuit of the exciter temperature sensor circuit. 07E - hot water supply temperature sensor circuit open. 08E - Short circuit of the hot water temperature sensor circuit. 09E - fan malfunction. 10E - malfunction of the smoke removal system. 12E - flame goes out during boiler operation. 13E - short circuit of the OM flow sensor. 15E - malfunction or control board malfunction. 16E - boiler overheating. 17E - DIP switch setting error. 18E - smoke exhaust sensor overheating. 27E - open or short circuit of the APS air pressure sensor.

I have Navien 24k. For some reason there is a knock, as if someone is opening the door. Recently the indicator turned red and showed 10. The display jumps back and forth. What's the matter? Please tell me. One person came and said that there was scale and the radiator needed to be changed. It happened that when I came home and turned on a higher temperature, dirty water came out. Maybe the radiator is just clogged with rust? and can it be washed rather than replaced?

If you have a knocking sound in the lower right part of the boiler, then the three-way valve needs to be changed. If in the upper part (as if the kettle is boiling), then flush the heating circuit. And dirty water is already a water circuit. Either wash it or just look at the filter, and then draw conclusions.

A Navien 12 boiler is installed; when the burner is turned off, the pressure drops to zero, and when turned on, it rises to normal, and so on continuously. Could the expander diaphragm be torn?

when the boiler is zero, drain the heating water from it (glory below the pump). And check the pressure in the expansion tank. It should be 1.0 atm.

We turned off the lights and now the Navien Ace Coaxial boiler does not turn on at all, even the remote control does not turn on! what to do?

Try to close the wires at the output of the control unit; it should work at full speed; just close it at the output of the boiler and do not confuse it with the 220 power supply.

Please tell me where the Navien boiler is located. After turning off the hot water tap, the water boils and makes noise for a long time. In this case, no error is generated. I set the temperature to 30-36 for hot water, when it heats up it rises to 63 and automatically turns off. after min. 2 the burner lights up again and this continues until I fill the bath.

This is how it should be: a radiator with water is heated in the boiler, in which water is circulated in order to cool it faster after heating. To set up a bath, set the hot water supply to maximum, and mix the bath with cold water, either separately or through a mixer.

My ACE 30KN boiler does not have hot water. it's cold. I changed the secondary heat exchanger - without any effect. Am I right in thinking that the problem is in the three-way valve, taking into account the fact that during heating the water in the pipes is hot! Is it worth dismantling it, cleaning it and installing it back?!

That’s right, it’s a three-way thing. Cleaning will not help, only replacement.

I have a wall-mounted Navien. Can you please tell me how to set the temperature correctly? My batteries are at 80 temp and my house is 20 temp, is this correct or should I set the temperature to one thing?

If the boiler operates at temp. in the room (like yours is 20 degrees), then before this you need to set the temperature of the coolant (battery) to 75-80 degrees as much as possible. Otherwise, if, for example, the coolant temp. costs 50g, the boiler will heat up to 50g. and turn off, after a few seconds turn on. and off again. etc. And room temperature (in this case 20 degrees) may not be achieved.

Tell me I have an ace boiler. First it showed error 03 (no signal about the presence of a flame or an open circuit of the flame sensor), then 10 (malfunction of the smoke removal system) and finally 15 (malfunction or malfunction of the control board), and after opening the lid, water drips from the combustion chamber and there is also water in the fan!!

The main heat exchanger is covered.

I bought and installed Navien 16K today. And after launch, the problem is almost the same as in Nikolai’s previous question. I set, say, room temperature to 23 degrees. The boiler runs for 25 seconds, then turns off, after 30 seconds it turns on and so on constantly, and the temperature. on the remote control only 21 gr.

I set the temperature. according to the coolant, let's say 60 g. The boiler runs for about 40 seconds and reaches 61-62g. and turns off. In 15-20 seconds the temp. drops to 51 gr. and it turns on again and so on constantly. The pump runs all the time. There is suspicion about the three-way valve because... The DHW heat exchanger is hot, but the boiler is new. There are no problems with the hot water supply, when I turn it on and the heating pipes do not heat up. Maybe there are other settings that need to be made.

if there is no error on the display, then the reasons for such operation of the boiler (in addition to setting the temperature) are: the three-way valve does not work properly, the system is clogged somewhere, the pump does not work or does not push water, having lost power, the temperature sensor is fooling, the air is in system, the main heat exchanger is clogged. Well, in other cases an error should light up.

I am redoing the heating system, at first the water in the shower was normal, after two days the water stopped heating up altogether, it gives error 02 (low pressure in the heating system), heating will continue for three more days, what to do with warm water, can it be turned on?

Localizing the problem of boiler malfunction

With the development of modern low-rise construction and gas networks, the boiler has become a common household appliance in every house or apartment. Basically, after installation, the boiler does not cause users any trouble. Modern boilers operate completely autonomously and require only regular maintenance or inspection. In our opinion, the average operating time of units before the first breakdown is from 4 to 6 years. Some users encounter problems even after 9 years, and some, on the contrary, earlier. In this material I will tell you what can be done if the boiler simply does not turn on, and I will also consider the most common malfunctions of gas boilers. The concept of “does not turn on” can mean completely different problems:

There is no indication (the display is not lit)

The boiler does not light up

The boiler does not operate in any particular mode

Therefore, these different situations should be considered separately in detail. Please note that to eliminate some malfunctions, user intervention is sufficient, but in some cases it is necessary to call a qualified specialist.

Design Features

The boilers are designed for domestic needs; they are perfect for heating country houses or apartments. They perfectly warm up the heating system and heat water for home use. All inscriptions and the attached instructions are in Russian, which prevents confusion when operating and setting up the device.

There are gas and water pressure supply sensors, and this helps to significantly save on gas and ensure the stability of its operation. A small device regulates the supply of the required gas pressure entering the burner and promotes complete combustion without the formation of soot.

The built-in fan ensures uniform combustion, while providing air access for complete combustion of the fuel.

Equipment:

- Circular pump;

- Separate heat exchange equipment;

- Storage capacity;

- Automatic thermal equipment;

- Functional timer device.

Heating equipment can operate in two modes - natural and liquefied gas, depending on capabilities. The thermometer allows you to set a convenient heating mode, for example, set it to operate for half an hour, that is, it will turn on and off every 30 minutes, and additionally setting the mode to number 4 will set the boiler to operate for 4 hours. This is convenient if you are going to leave the house and there is no need to heat it.

A dual-circuit system allows you to heat the house and separately process water, and some designs can operate in secondary circuit mode when hot water for household needs is needed, for example, in the warm season, but heating is not.

Some models can only be started by opening a strong flow of water into the system, while others have their own tank that is heated and supplied to supply the body.

Advantages and disadvantages:

- The device remains operational even at low temperatures. Installed frost protection keeps the boiler in working condition;

- The circulation pump device operates in automatic mode; it starts the device when the temperature drops to 10 degrees Celsius, which will not allow the water to freeze and destroy all heating equipment;

- When the coolant temperature drops to 6 degrees, the combustion system is automatically activated and provides heating to approximately 20 degrees;

- The device does not require additional insulation measures, so it can be installed in completely unheated rooms (basements, outbuildings);

- When the temperature drops to a set value, the burner automatically turns on, ensuring uniform heating of the heating systems of the house;

- Significant fuel savings are achieved by starting the reverse stroke, which allows you to use the gas supply wisely and keep all the main components of the boiler operational for a long time, thanks to the smart adjustment of the start-up and shutdown cycles. They have performed well in low pressure conditions;

- The fan device regulates the supply of the required amount of air, which increases the efficiency of the boiler due to the complete combustion of the supplied fuel and the reduction of heat loss by the device.

All boilers of this brand are made using heat-resistant materials, and heat exchange equipment is made of alloyed stainless steel.

The boiler does not turn on - there is no indication

Almost all modern gas boilers are equipped with a control board and an information panel with a liquid crystal display or LED indicators. If there is no indication, first of all you need to make sure that power is supplied to the boiler. Typically, the electrical connection of the boiler is carried out through a separate “automatic machine” - check whether it is turned on or not.

The surest way to make sure that power is supplied to the boiler is to check with a multimeter in voltmeter mode the presence of 220V at the connection point to the boiler board. If there is no voltage, it is necessary to localize and eliminate the problem. In real life, it happens that someone in the household simply pulls the plug from the socket.

Safety fuses

It is also worth paying attention to the location of the fuses. In some boilers, depending on the model (for example, Ariston, Buderus, Vaillant), the fuses are located on the board itself, and in some, before they are connected to the board. If there are no problems with the electrical connection to the boiler, you should check the integrity of the fuses (with the same multitester in the “continuity” mode).

If the fuses are intact and there is 220 volts at the control points, it is likely that the boiler does not turn on due to a malfunction of the control electronics.

If during the inspection it turns out that the fuses have blown, then there was at least a problem with the power supply. In this case, it would be correct to first conduct research on the actuators (fan, pump, priority valve) and boiler wiring for a short circuit. However, in practice, even representatives of specialized organizations simply replace the fuses with good ones and check the boiler in operation. If the fuses blow again, then sequentially turn off the high-voltage parts of the boiler to identify the problem area (this is not a recommendation for action! This approach is not entirely correct).

Several spare fuses are usually supplied with the boiler.

If the fuses blow due to damage to one of the actuators, it must be replaced (or the cause of the short circuit must be eliminated). In the case where it is proven that the mechanisms (and wiring) are in good working order, the control board itself remains. Blown fuses indicate that there was an unacceptable load on the electronics (thunderstorm, pulsed power surge in the network), so the cause of the malfunction may also be a short circuit on the board itself.

Water (moisture) getting on the board

Water ingress is one of the most unpleasant situations. Although the board is in a protective case, water may get inside due to leakage or condensation. Often it gets into the box through the wires. Water ingress almost always causes damage to the board, in most cases irreparable. Characteristic stains and oxidation will be visible on the board due to water.

Varistor and power supply

Often, if the boiler board is damaged, burnt or charred elements can be visually detected on it. A varistor is a protective element of the board that is installed at the input of the circuit. In most cases, this is a blue round part (but not necessarily). When the rated load is exceeded, the varistor is destroyed and opens the circuit. In some cases, if the varistor helped prevent damage to the electronics, biting it out is enough to eliminate the gap in the circuit. Important! Although the board circuit will work without a varistor, it should be remembered that the varistor is a protective device and the correct solution would be to replace it. The power supply is a microcircuit that is also damaged primarily by pulsed power surges or during a thunderstorm. If cracks or damage are visible, the boiler board will likely need to be diagnosed and repaired.

Display board

For some boiler models (Vaillant, Ariston, Navien), the control unit consists of a main board and an information board (display board). The boiler may also not turn on if the display board is broken. The display board, unlike the main one, is cheaper, but most often cannot be repaired. In this case, the fault can only be identified by replacing a known good part.

If the gas boiler is working, there is an indication on the display, but it does not start or produces errors, further diagnostics are required.

Boiler malfunctions

Typical problems with the operation of heating equipment:

- malfunction of the built-in pump;

- the heat exchanger is clogged;

- The three-way valve does not work.

If the boiler is working and the radiators are cold, experts recommend, first of all, assessing the technical condition of the main heating element. More specifically, determine whether the circulation pump built into the device is working. This part is an invariable attribute of modern equipment and is designed to increase the efficiency of its operation. Very often, after a long period of inactivity in the summer, the pump can become clogged or become covered with a layer of limescale. As a result, it does not remove the heated coolant from the heat exchanger in a timely manner. The boiler is boiling, but the radiators are cold.

It is strictly prohibited to independently repair such complex equipment as a boiler. In this case, either a specialist from the service center or a repairman with the appropriate certificate or permit is called to your home.

Experts do not recommend using ordinary tap water as a coolant, as it is hard. When the coolant temperature increases, dissolved salts settle on the heat exchanger. As a result, the following problem arises: the boiler is working, but the radiators are barely warm. Scale reduces the thermal conductivity of the heat exchanger, so the water in the circuit does not heat up, although the heating element constantly works with excessive energy consumption. You can fix the problem by changing the coolant and cleaning the heat exchanger. This video will help you understand how to clean the heat exchanger correctly:

A double-circuit boiler heats water, but does not heat the radiators. Here you need to pay attention to the serviceability of the three-way electric valve. It is responsible for switching the bypass from heating circuit maintenance mode to DHW and CO mode.

Before making a heating register with your own hands, familiarize yourself with the technical base.

Why can't antifreeze be used for radiators? The answer is here.

The boiler does not light up

If the gas boiler does not work, then in most cases there will be an error signal on the information panel indicating its number or code, by which you can approximately find out in which boiler system the malfunction occurred and how critical it is. All double-circuit boilers provide switching between summer and winter operating modes. In summer mode, the boiler will not turn on to heat the room (the same is true when using weather-compensated automation or thermostats).

The boiler does not work in DHW or heating mode

And finally, situations when the boiler does not operate in a particular mode. They happen much less frequently compared to others. In this case, it is likely that the boiler will need to be diagnosed by a specialist. The process of ignition and operation of the boiler in different modes is virtually the same, with the exception that different modes may have different power. In hot water preparation mode, the boiler power is usually full, but in heating mode it can be minimal. You can read about problems in the operation of the DHW mode in a separate article.

Operating principle of the Navien boiler

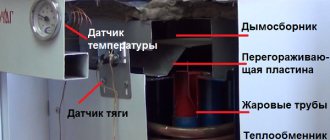

The operating principles of modern gas boilers are almost the same for all manufacturers, the only differences are in the configuration of the equipment and the internal arrangement of the actuators. The flow diagram of water in the boiler is shown in the figures. The Navien boiler works either to maintain the required temperature in the CO, when heated water from the first heat exchanger is pumped by a circulation pump in a large circle, or in the DHW preparation mode. The DHW mode is a priority, which means that if it is necessary to heat the water, a special three-way valve switches the circulation to the DHW plate heat exchanger, and the coolant flow through the heating circuit is blocked. The signal to switch the boiler to the DHW preparation mode comes from the flow sensor located on the hydraulic unit with the make-up tap.

Summary

In this article we looked at the most common cases when the boiler does not turn on or ignite. No one anywhere on the Internet will definitely tell you why your boiler won’t turn on; this requires at least an external inspection. This material will help you get acquainted with possible situations in general and is written on the basis of our statistics over several years.

If there is a malfunction, you need to determine the error and read the boiler operating manual. Also, for many boiler models, error descriptions with recommendations are available on our website. Malfunctions can be simple, which the user can fix independently, or complex, requiring qualified assistance and spare parts. We strongly do not recommend performing any actions with the boiler if you do not fully understand its structure and principles of operation, disabling protective devices or changing the boiler’s operation circuit to restore its operation. If there is a malfunction, it must be eliminated! If the cause of the malfunction is not completely clear to you, it is better to call a specialist.