Here you will learn:

- Is it worth taking on the repairs yourself?

- Methods for self-diagnosis of faults

- Causes of gas boiler breakdowns

- Possible malfunctions and DIY repair methods

- Performing major repairs of a gas boiler

- Seasonal service

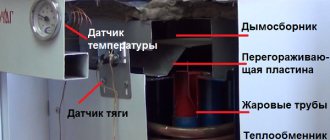

A gas heater is a rather complex unit. Its structure is based on the following components and systems:

- a furnace in which fuel combustion occurs;

- air supply and combustion product removal systems;

- a heat exchanger in which a flame heats water or coolant;

- automation systems;

- security systems.

The firebox, or combustion chamber, can be open or closed. In the first case, the air required for fuel oxidation enters the firebox through the air intake on the body from the room in which the unit is installed. Combustion products are removed through a traditional chimney that rises above the roof. The craving is formed naturally.

In a closed chamber, there is no exchange of air between the interior spaces and the heater. Air enters from the street, and exhaust gases are removed back through a horizontal coaxial chimney passing through the wall of the building. A fan is used to create draft.

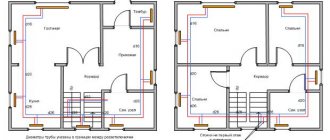

The heat exchanger may have one or two circuits. The first, closed circuit is connected to the heating system; the coolant circulates in it using a pump. A second circuit can also be installed on a gas boiler; water from the water supply system passes through it and is heated. This circuit is open; water is supplied due to the pressure created by the pumping station.

Automation and safety systems maintain the specified coolant temperature and monitor trouble-free operation of the device. In modern models they are combined into a common computerized control system.

The security group includes the following subsystems:

- draft sensor, when draft falls below a set level, it turns off the gas supply;

- an additional draft sensor in the exhaust channel protects against combustion products entering the room;

- the flame controller monitors the operation of the burner and turns off the supply when the torch goes out;

- an emergency valve relieves coolant pressure if it exceeds a preset value;

- The pressure sensor stops the unit if the pressure and flow rate of the coolant drops below a set value, for example, due to a leak.

Automation and safety systems on boilers with an open chamber and natural circulation of coolant can be mechanical - then the boiler does not require electricity to operate. More advanced and economical boilers require a constant power supply to operate the fan, circulation pump and control system

Is it worth taking on the repairs yourself?

In a typical gas boiler, all structural elements are conventionally combined into three groups:

- burner;

- blocks that are responsible for safety;

- a heat exchange unit equipped with a fan, circulation pump, and many other elements.

During repairs, the main safety risk arises from possible gas leaks. The reason for this may be improper repair, dismantling or installation of equipment with fuel supply functions.

Because of this, it is better to have these structural parts repaired by a specialist. In addition, it is not allowed to independently troubleshoot faults in the electronic equipment of a gas boiler. The automatic system is quite specific, and unless you have the appropriate qualifications, it is impossible to correctly restore this type of equipment in practice.

And yet, if you do not have enough experience, it is better to entrust the maintenance of heating boilers and the repair of geysers to professionals.

What can you repair yourself?

All other elements can be repaired yourself, for example:

- The heat exchanger is washed manually (to do this, the unit is dismantled, after which it must be correctly put back in place). You can perform this work without dismantling - using pumps.

- Chimney cleaning will be needed in cases where there is a problem with draft (mechanical or chemical removal of blockages is carried out).

- Repair of the boost fan by lubricating its bearings with technical oil.

In fact, you can repair a gas boiler yourself only in cases where there are mechanical damages or blockages that can be easily identified visually (or by smell).

Other breakdowns are considered more serious, so they are repaired with the help of a specialist, and not with your own hands.

Is it possible or impossible to repair a gas boiler without a specialist?

A typical gas boiler consists of many elements, which can mainly be combined into 3 groups:

- Burner.

- Security blocks.

- A heat exchange unit equipped with several additional devices, which include a fan, circulation pump and many others.

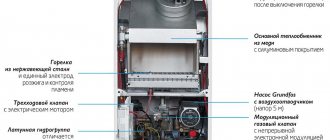

A simplified structure of this mechanism can be represented as follows.

If you detail the picture, you can find about 2 dozen different elements in the device.

The main danger during repairs is a possible gas leak. This can happen due to improper repair, dismantling or installation of equipment related to the fuel supply.

Therefore, it is better to entrust the repair of these parts of the structure to a specialist. Also, you should not troubleshoot electronic equipment in gas boilers yourself. Automation is a specific device, therefore, without the appropriate qualifications, it is almost impossible to correctly carry out restoration work and repair such equipment yourself.

What can you repair yourself?

All other elements can be repaired yourself, for example:

- The heat exchanger is washed manually (to do this, the unit is dismantled, after which it must be correctly put back in place). You can perform this work without dismantling - using pumps.

- Chimney cleaning will be needed in cases where there is a problem with draft (mechanical or chemical removal of blockages is carried out).

- Repair of the boost fan by lubricating its bearings with technical oil.

In fact, you can repair a gas boiler yourself only in cases where there are mechanical damages or blockages that can be easily identified visually (or by smell).

Other breakdowns are considered more serious, so they are repaired with the help of a specialist, and not with your own hands.

Methods for self-diagnosis of faults

Often the user is in a situation where he is not sure what exactly is broken in the gas boiler. In such cases, there is no need to rush to remove and repair anything. It's risky and dangerous. Before work, you should diagnose the equipment and identify the exact causes of malfunctions.

Modern gas boilers are equipped with various sensors that reflect a number of important functional indicators of the unit. They monitor changes in temperature, pressure and other parameters. In the event of a malfunction, modern boiler models provide automatic shutdown of the device.

The source of the breakdown is identified by the consequences it causes. For example, you can visually see fumes, leaks, and sparks. You can smell a gas leak or short circuit by smell. From the changed sound of the gas boiler, it becomes clear that the unit has malfunctioned.

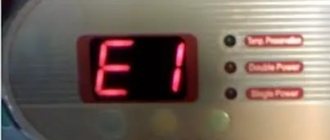

The instructions included with the purchase of the device describe the most common faults in the boiler model being purchased and how to detect, diagnose, and eliminate them. It also indicates what a specific error code and blinking lights on the dashboard mean.

So the light can blink in different modes: fast or slow. Or burn constantly. The color of the light bulb can be red, green or yellow.

The manufacturer's instructions indicate all possible error codes that may appear on the display. It also explains how to troubleshoot the problem.

You should not throw away the instructions from the device, as they may be useful to the gas technician you called to fix the problem. It indicates the characteristic features of the gas boiler model, the dimensions and location of components and parts.

Causes of gas boiler breakdowns

First of all, it is necessary to establish why any malfunctions may occur in the operation of gas heating boilers. A number of different factors can lead to problems.

Poor water quality

This reason is relevant for double-circuit boilers that supply hot water to the local water supply system. Mineral deposits and rust gradually accumulate in the tubes of the secondary circuit heat exchanger, reducing their cross-section and causing corrosion, up to complete blocking. When water circulation decreases, the heat exchanger connections become overheated and may fail. To prevent such a situation, you should install a mechanical cleaning filter at the inlet of the circuit and periodically change the filter element in it.

Poor water quality is a possible cause of gas boiler failure

Power supply quality

Voltage drops, phase surges, periodic power outages and other manifestations of poor quality power supply lead to the operation of the heater's electrical equipment with overloads, and its components are subject to accelerated wear. Particularly strong voltage surges can lead to their complete failure. To combat low quality power supply, the following methods are used:

- installing a stabilizer will eliminate voltage surges;

- connecting an uninterruptible power supply to a battery will allow you to survive short-term power outages;

- An electric generator with an internal combustion engine will provide power in case of long-term outages.

You should assess the quality of the network in advance, purchase and connect the necessary devices in advance

Incorrect installation of equipment

If the unit was installed by an amateur, not all requirements of the installation instructions may be met:

- Lack of grounding (or improper grounding) of the device leads to the accumulation of static charges on the body and chassis and can damage the electronic control system;

- there are air pockets in the heating system, this leads to overheating and damage to heat exchangers and pipelines, the circulation pump may also fail;

- incorrect connection of inlet and outlet pipes, neglect of emergency valves or blocking of their valves can lead to overheating of the coolant and failure of the pipeline system

There are also errors in the installation of a coaxial chimney, as a result it begins to freeze and the draft sensor turns off the boiler.

Failure to comply with operating conditions

often occurs among those owners who incorrectly calculated the boiler power and did not provide a 20% reserve for extreme weather conditions. In such houses, during severe frosts or winds, the device operates at maximum power for a long time. The automation will periodically turn off the gas. In addition, such operation leads to its accelerated wear and failure in the midst of cold weather.

Types and designs

A gas boiler is a device designed to heat water by using the energy generated by the combustion of gaseous fuel. In this capacity, gas of natural origin is most often used - methane or propane-butane, but there are models that run on liquefied gas.

The geyser is used to heat water with gas.

The water supply system is connected to this device, resulting in the supply of hot water or heating of the room. First of all, gas devices differ in the installation method and are of wall and floor type.

The first type of device is compact and low-power . They have a high coefficient of efficiency (COP) and are mounted on brackets to the wall. Based on the type of combustion chamber, they are divided into open and closed. Floor-standing devices, depending on the operating principle of the burner, are available in two types: atmospheric and inflatable.

The latter type is often called replaceable, or ventilator . It has high efficiency and cost. Atmospheric burners are easier to restore when repairing heating gas boilers due to the simplicity of their design, and they are also quieter.

This video will tell you how to choose the right gas boiler:

Principle of operation

The principle of operation of gas heaters, regardless of the variety and design features, is almost the same. The automation equipment used in the equipment ensures high reliability and efficiency of their operation.

At the same time they happen:

- single-circuit;

- double-circuit.

The former are used only for space heating, while the latter also provide hot water supply. During operation of the device, gas is mixed with air, forming a mixture that is subsequently ignited. The fire and the resulting combustion products heat the coolant - cold water coming from the plumbing system. After which the heated coolant, due to the created pressure, begins to flow into the circuit intended for it.

Automatic equipment makes the column safe and reliable

The design differences of a single-circuit boiler are that, unlike a double-circuit boiler, it does not have a heat exchanger. If there is a need for hot water supply, an additional coolant tank is installed. This container is nothing more than an indirect heating boiler.

A boiler with two circuits works a little differently. It uses a heat exchanger to supply heated media to the heating system. The water in it heats up to a temperature of +80ºС. As soon as the temperature in the heated object changes, the heating mode is switched on. The changes are monitored by a sensor that sends signals to the thermostat.

It is the latter that transmits the command to the controller, which, in turn, starts the pump and ignites the burner through a relay. At the same time, the boiler electronics control the heating of water and, when the desired value is reached, turns off its heating by reducing the gas supply or stopping it.

As soon as the temperature drops again, the temperature sensor again sends a signal, which leads to a greater opening of the fuel valve and ignition of the burner. The heated water, passing through the circuit, returns through the return line to the boiler. To prevent it from mixing with the second circuit, a three-way valve is used.

Since the water in the heat exchanger flows in a circle, then, unlike the hot water supply (DHW) circuit, it practically does not contain any mixture or impurities. Therefore, when repairing and servicing gas boilers, attention is first paid to the condition of the DHW circuit.

Essential elements

At its core, a gas boiler is a mini-boiler room with its own protection, control elements, pump and other parts. One of its important blocks is the smoke removal unit. Depending on the combustion chamber, it can be open or closed.

The open-type chamber is designed in such a way that all combustion products generated are removed from the room using a chimney. Combustion is supported by air coming from the surrounding space, so it is important to ensure a constant flow. If the chamber is closed, then forced ventilation is used to remove emissions. A fan is built into the design, which draws out and throws combustion products into the smoke channel.

When the chamber is closed, forced ventilation is used

The main elements of the boiler include:

- Gas burner. Its task is to mix fuel with air and then transfer the resulting mixture to the nozzles. Its main element is nozzles, which are responsible for uniform distribution of gas and ensure uniform heating.

- Heat exchanger. This is a device that divides the system into two parts. In its manufacture, plates are used, stamped in such a way that the heat transfer area is increased. The plates are installed on a base in which there are pipes for supplying and dispensing water.

- Circulation pump. Not used on all models. You cannot do without it if the pressure in the supply circuit is low. It provides forced circulation and creates the required pressure.

- Expansion tank. Used as a protection element. In case of excess liquid arising from thermal expansion, its excess flows into it.

- Control block. Responsible for all operating modes, from water supply to activation of protection in the event of emergency situations. This is a very important unit, the repair of which is carried out followed by testing at a special stand.

- Self-diagnosis unit. Using this unit, you can carry out initial diagnostics of the device and identify possible breakdowns. Most often, when problems occur, a code corresponding to a particular error is displayed on the device screen.

In addition, device protection is an important element. It automatically closes the solenoid valve when the gas supply stops. It also includes sensors that detect overheating, weakening of traction, and gas leaks.

Possible malfunctions and DIY repair methods

Any malfunction of a gas boiler must be dealt with by a specialist. However, it is not always possible to use the services of a specialist, and the breakdowns can be trivial. Let's look at problems that can be solved independently.

The house smells like gas

Typically, the smell of gas appears when it leaks from the threaded connection of the supply hose. If there is a smell in the room where the boiler is installed, you need to open the window and turn off the boiler. Then follow the instructions:

- Prepare the necessary things: soap solution, FUM tape, open-end or adjustable wrench.

- Apply the solution to all threaded connections. If bubbles begin to inflate, the leak has been identified.

- Close the gas valve.

- Use the key to open the connection. Wrap FUM tape around the external thread and put everything back together.

- Reapply the solution and resume gas supply.

- If the leak is fixed and the smell of gas has disappeared, remove the remaining solution.

Attention! When the leak cannot be found, turn off the gas and call a specialist.

Fan doesn't work

If during operation of the boiler the sound produced by the turbine disappears or decreases, this indicates a malfunction of the blower fan. For repair you will need: a screwdriver, a new bearing, a cloth, and grease.

- It is necessary to turn off the boiler and turn off the gas.

- Remove the turbine.

- Use a cloth to clean dust and carbon deposits from the turbine blades.

- Inspect the electric fan coil for blackening. If everything is ok, move on or replace the fan.

- Disassemble the fan housing. There is a bearing installed inside the turbine shaft; it needs to be replaced. Some fans have a bushing instead of a bearing. In this case, it needs to be lubricated.

The turbine may also not work due to low mains voltage or a faulty control board. The first can be eliminated with the help of a stabilizer, but the second can only be eliminated by calling a specialist.

High temperatures

Overheating of the boiler is associated with contamination of the heat exchanger. To clean the device you will need: a special solution of hydrochloric acid, an adjustable wrench, FUM tape, a metal brush. Then follow the instructions:

- Turn off the boiler, turn off the gas and water.

- Remove the heat exchanger using an adjustable wrench.

- Clean it with a brush.

- Pour the acid solution into the heat exchanger through the pipe. If foam appears, it means there is a lot of scale inside.

- Pour out the solution and repeat the procedure.

- Rinse.

- Reinstall, having previously wrapped all threaded connections with FUM tape.

Sensor malfunction

Problems usually arise with the combustion electrode. If the burner flame goes out after a few seconds and the boiler gives an error, then the problem is in the combustion sensor. Turn off the boiler and turn off the gas.

To repair the electrode, you will need sandpaper, which can be used to clean the sensor probes without removing it. If the damage remains, the sensor is replaced.

The chimney of a floor-standing boiler is clogged

Problems with the chimney occur only with floor-standing boilers. This is due to its size and vertical position. Mounted units do not require chimney cleaning.

The chimney, consisting of metal parts, is cleaned with a metal brush. It needs to be disassembled and the accumulated soot mechanically removed. A solid chimney is cleaned with special vacuum cleaners or chemicals. But for this you need to call a professional.

Three ways to arrange a chimney for a floor-standing gas boiler. The first option is the most difficult to clean.

Self-shutdown

There are two problems that lead to spontaneous shutdown of the boiler. The combustion sensor is broken or the chimney is clogged. Repair of both faults is described above in the article.

Performing major repairs of a gas boiler

After the expiration of the operational period specified in the product passport, the gas boiler is subject to technical diagnostics. The main task of engineering activities is to determine the possibility of further safe operation of the equipment.

Major repairs are carried out to restore the technical characteristics of gas heating equipment. As necessary, worn parts and functional units are replaced.

In addition to diagnostics, as part of a major service the following is performed:

- Flushing the heat exchanger.

- Comprehensive inspection and cleaning of all closed boiler components.

A properly carried out set of measures guarantees the proper operation of gas equipment during the subsequent period of operation.

Scaling that forms in the heat exchanger coil due to improper maintenance leads to a gradual deterioration in the efficiency of the equipment

The heat exchanger is cleaned from scale after the first five years from the date of commissioning of the boiler unit. Although most service organizations recommend carrying out preventive flushing once every two years.

A simple procedure for flushing the boiler heat exchanger can eliminate the problem at the stage of scale formation.

To carry out major cleaning, remove the device casing and disassemble all removable parts of the unit. Separately, dismantle the heat exchanger and, using a pumping station, thoroughly wash it with chemical reagents.

This flushing allows you to remove all the scale that has formed in the pipelines and fins of the heat exchanger over several years. After this, the boiler is assembled and the system is filled with coolant.

In addition to servicing the gas boiler itself and the gas pipeline leading to it, it is important to regularly check the condition of the chimneys

Cleaning of smoke channels, designed to remove combustion products from gas appliances and create draft, is not included in the list of activities required to be performed by the master.

He can do this work for an additional fee. If desired, you can clean the chimney yourself. It is advisable to wash it at least once a year.

Self-repair of gas boilers

Before you start repairing a gas boiler yourself, you need to identify the cause of the breakdown. Various elements of heating equipment can fail. Most often, the causes of breakdowns are: violation of operating requirements, poor quality of parts, impacts.

Volatile boilers often fail due to reset. Therefore, repair of a heating unit must begin with checking the settings and the presence of open contacts. When troubleshooting, the device is turned on at full power in the “Winter” mode. Repair of heating gas boilers begins with this step.

- If the pump does not work, it may be necessary to: either replace the cable or the device itself (pro