The circulation pump hums, but the impeller does not rotate

Users often wonder: why is the heating circulation pump humming and what to do in this situation?

Often, pump noise and complete immobility of the impeller occur due to oxidation of the drive motor shaft. p, blockquote 11,0,0,0,0 –>

This situation can happen due to the fact that the hydraulic machine has not functioned for a long time. In order to repair the pump with your own hands, you need to perform the following sequence of actions:

p, blockquote 12,0,0,0,0 –>

- Initially you must turn off the electrical power;

- then it is necessary to drain all the liquid from the pump and the adjacent pipeline;

- after this, you need to unscrew the screws and dismantle the drive motor together with the rotor;

- and the last thing you should do is to move the pump from a dead center, to do this you need to rest your hand or a screwdriver on the working notch of the rotor.

Components of the circulation pump

The pump will make noise, but will not function even if some foreign object gets inside the structure, which will interfere with the rotation of the wheel. Here you need to check the heating circulation pump, find the extra part and resort to repairing the circulation pump:

p, blockquote 13,0,0,0,0 –>

- the power supply is initially turned off;

- then the water is drained from the pump and pipeline,

- after which you need to disassemble the circulation pump as shown in the diagram in the figure;

- next you need to remove the foreign object;

- and at the final stage, a mesh filter is installed on the inlet pipe.

p, blockquote 11,0,0,0,0 –>

Operating rules

The service life of heating equipment depends on proper operation. By following some simple rules, you will protect your property from damage:

- operation of the heating unit with zero supply is prohibited;

- if there is no liquid in the pipeline, the pump must not be turned on;

- The smooth operation of the device depends on how low or high the flow is. If the supply is interrupted, the device may become unusable;

- To prevent oxidation and blocking of the shaft during downtime, you need to turn on the pump once a month for a quarter of an hour. This will extend the life of moving parts;

- Monitor the temperature of the water in the water supply pipeline. The ideal indicator is +65º. Exceeding the norm leads to the precipitation of hard salts and rapid damage to technical equipment.

From time to time (preferably at least once a month), pay attention to maintenance. Such a precautionary step ensures smooth operation of the system and will prevent untimely breakdown and, accordingly, repair of the heating circulation pump.

Check the equipment regularly for proper operation. The verification scheme includes a visual inspection and quality indicators of the system:

- After turning on the heating unit, make sure that there are no unusual noises or vibrations in the system;

- check whether the water pressure corresponds to that stated in the specifications (technical passport);

- check the heating of the device, it should not be excessive;

- check if there is grounding between the equipment housing and the terminal;

- pay attention to whether there are leaks in the places where the equipment connects to the pipeline. Tighten connections and replace gaskets if necessary;

- Check the condition of the wires in the terminal box; there should also be no moisture in it.

Many typical heating equipment malfunctions can be repaired on your own. It is enough to have an idea of the design of the pump, a set of tools and minimal knowledge in the field of repair. It is also important to know how to disassemble a heating circulation pump. Before repairing damage, check the power supply. The voltage must correspond to that stated in the technical data sheet.

Troubleshooting

Based on how the pump operates, sound, vibration or changes in pressure, outlet pressure, it is necessary to accurately determine the malfunction and eliminate the cause.

The main elements in the pump control unit are:

Causes and troubleshooting

- the pump turns on, but the rotor does not work. If the main element of the circulation equipment refuses to rotate, then the most obvious reason is a problem with the power supply. For example, if power surges frequently occur in the network, the fuse in the pump begins to melt, thereby breaking the electrical circuit. The solution to the problem in this case consists of two steps. First, get your network working. Secondly, replace the fuse with a new one. If everything is fine with it initially, then carefully inspect the remaining elements responsible for receiving power to the device. If damage is found to the wire or switch, they should also be replaced. It is strictly forbidden to use them if they are broken, as this can lead to complete breakdown of the equipment and harm to the health of the owners. Another point that should be checked is the condition of the electric motor winding. What is important here is the resistance indicator, which is measured using a multimeter. For some rotor models it should be from 10 to 15 ohms, for others - from 35 to 40 ohms. This depends on the specific equipment. The resistance inherent in a normally operating winding is usually indicated in the technical documentation supplied with the device. If, when tested, the multimeter displays infinity or something near zero, then this means that the winding is faulty and this element will have to be replaced;

- the pump overheats. Normally, the temperatures of this device and the pipe should match. If you find that the pump is significantly hotter than necessary, there could be several reasons for this. The first of them is incorrect installation. In this case, you will observe overheating as soon as you install the new pump. The only way to fix this is to disassemble everything again and reassemble it the way it should be. The second reason may be that the device is clogged. Most often, this is typical for heating systems that use elements susceptible to corrosive processes - for example, low-quality steel pipes. Particles of rust that form on the inner walls sometimes fall off, and the coolant carries them wherever it goes - including to the circulation pump. If the latter becomes clogged, then it has to apply more effort to ensure normal fluid flow, hence overheating occurs. The problem is solved by cleaning the filter installed inside the device, as well as all elements of the equipment where dirt has clogged. The third possible cause of overheating is insufficient or complete absence of lubricant on the bearings. This leads to a deterioration in their performance and abrasion of the elements. The solution to the problem is obvious - you need to lubricate the parts again. And the fourth reason for overheating, which is worth mentioning, is too low voltage in the electrical network. In order for the pump to work normally, it needs 220 V. If you find that the voltage in your network is less, then it is useless to deal with the circulation equipment - adjust the power supply;

- The coolant circulates with insufficient pressure. This also indicates some kind of malfunction in the operation of the equipment. As with overheating, clogging of structural elements can play an important role here. The fix method is still the same - cleaning. Also, if your network voltage is not 220 V, but 380 V, be sure to check that the pump is connected correctly. It often happens that the electrical wire is connected to the wrong phase, hence problems with the power of the equipment.

circulation pump inspection

By the way, you can make your life much easier if you initially purchase equipment with overheating and dry-running sensors. They will monitor the state of affairs and if problems arise, immediately turn off the pump, thereby signaling you about problems. This approach will help to avoid serious repair work, because the earlier a malfunction is detected, the less damage will be caused to the equipment.

We are confident that now you can easily cope with both disassembling and repairing the circulation pump. To consolidate the information, also watch the video, the link to which is located below. Good luck!

How to disassemble Grundfos

When you are absolutely sure that the cause of the problem is some internal problem in the mechanism, you should begin disassembling the pump.

Before this, it should be disconnected from the power supply and the water should be drained from the internal cavities and tubes. You should start disassembling the device from the junction box, after which a visual inspection of the internal components is carried out. In this way, you can find a burnt or failed part. In a situation where all the components in this part of the device are in working order, you should continue disassembling.

Grundfos deep-well pumps are disassembled as follows:

- The body is firmly clamped in a vice. This is best done using two halves of a steel pipe of the appropriate diameter. This eliminates the possibility of deformation of the device body.

- If you cannot unscrew the lid by hand, the threaded seam should be lubricated with a special liquid. Often, silt and dirt accumulate at the junction of the cover and the body itself, making it difficult to turn the thread.

- After removing the cover, remove the rotor from the working chamber.

When disassembling, the pump motor must be in a vertical position. In this case, the leakage of lubricating oil from it can be avoided.

How can you eliminate typical circulation faults?

Let's see exactly how they can be expressed and what the user should do in a given situation.

So, the main malfunctions of circulation pumps and ways to eliminate them.

In this case, the first suspect is the fuse, if your model has one, of course. It reacts sensitively to power surges, which, alas, are not uncommon in suburban areas, and at the slightest threat to the engine it melts, opening the electrical circuit. After replacing the fuse, the pump will return to operating condition.

If the fuse is intact, you should “ring” the power cord and electrical wiring, and also check the condition of the fuse or circuit breaker in the junction box. Perhaps it or some section of the wire needs to be replaced.

If everything is in order with the wiring, the electric motor winding may have burned out. Its condition is checked by measuring the resistance (using a multimeter). When connected to the contacts of the working winding, the device should show 10 - 15 Ohms.

Some pumps, in addition to the working one, also have a starting winding. Its resistance should be 35 - 40 Ohms.

If the meter display shows “infinity” instead of the indicated numbers, then the winding under test has burned out. If the multimeter readings, on the contrary, tend to zero, then there is an interturn short circuit. In this case, when you try to turn on the pump, the fuses in the panel will trip.

The cause of the pump “strike” may also be a breakdown of the non-polar capacitor present in the starting winding circuit. In good condition, it has a capacity ranging from 10 to 40 μF. If the meter readings differ from normal, the part must be replaced.

You can undertake electrical repairs yourself if you have sufficient experience in this matter. In most cases, you have to trust specialists.

The pump hums, but the shaft with the impeller does not rotate

In such a situation, the pump must be turned off, otherwise the motor winding may burn out. There may be several reasons for such a breakdown:

- As already mentioned, the shaft may become stuck due to prolonged inactivity. Also, an impeller that does not work for a long time can stick to the housing. In such a situation, you need to disassemble the pump and force the shaft to rotate. To allow the user to do this, there is a notch on the shaft that can be grabbed with a screwdriver. If you were unable to find it, disassemble the discharge mechanism and turn the shaft, holding the impeller itself.

- The impeller may become stuck due to a foreign object entering the chamber. By removing it, you will resume system operation.

To prevent this from happening in the future, install a dirt filter at the pump inlet.

The operation of the pump began to be accompanied by an unusual noise

This is exactly how air accumulated in the system can manifest itself. To remove it, it is most rational to equip the heating circuit with an automatic air vent. In the meantime, you will have to bleed the air manually. Immediately after this, the pump will stop making noise.

The pump vibrates a lot during operation

If you observe such a phenomenon, it makes sense to check the condition of the bearing.

Most likely it is worn out and needs to be replaced. Bearings are always installed on the shaft and in the mounting hole with interference, in other words, they are pressed.

In factories and workshops, a special tool is used for this - a puller.

Home craftsmen who do not have such a contraption knock out the bearings with careful blows of a wooden hammer or make a primitive puller themselves. It consists of a pair of plates with holes into which two studs with nuts are threaded. One plate rests against the end of the shaft, the other against the bearing (it is put on the shaft, for which a hole of the appropriate diameter is made in it), after which it is necessary to tighten the nuts on the studs one by one and very gradually.

Pump vibration can also be caused by excessive cavitation. To solve this problem, it is necessary to increase the pressure at the inlet to the unit by raising the coolant level in the circuit.

Troubleshooting

Based on how the pump operates, sound, vibration or changes in pressure, outlet pressure, it is necessary to accurately determine the malfunction and eliminate the cause.

| Symptom of malfunction | Probable Cause | Repair |

| The pump makes sounds after switching on, but the shaft does not rotate | Shaft oxidation due to prolonged inactivity | Unscrew the protective cap from the end of the shaft on the motor housing and manually turn the motor shaft using a slotted screwdriver. |

| Blocking by a foreign object | Disassemble the pump block with the impeller and clean it, check the condition of the coarse filter installed in front of the pump | |

| Power problems | Check the voltage rating in the network and correct the problem if necessary. | |

| After applying voltage, the pump does not start and does not make any sounds. | No actual voltage on power line | Check the power line and the condition of the circuit breakers |

| The fuse in the control unit has tripped | Replace fuse | |

| The pump turns off after a short period of operation | Limescale deposits in the stator cup | Clean the stator cup and motor rotor |

| Strong extraneous noise when the pump is running | Dry running, presence of air in pipes | Release the air. Drain the pump shell and fill with water. |

| Cavitation | Increase the pressure in the supply line. | |

| Pump vibration | Support bearing wear | Replacing bearings |

| Reduction of pressure and flow in comparison with the passport data | Abnormality in the power supply to the pump, phase change, resulting in a decrease in pump power or a change in the direction of rotation of the impeller | For three-phase motors, the quality of all phases is checked. For single-phase power supply, check the capacitor and replace if necessary |

| High hydraulic resistance of the circulation circuit | Check the filters, increase the cross-section of the pipes, check the condition of the shut-off valves. | |

| Triggering of external protection on the pump power line | Problems with the electrical part of the pump | Check the condition of the terminals for short circuits, check the capacitor and the control unit. Check the stator windings. Their resistance should not be lower than the rated value. |

Basic malfunctions of the heating circulation pump

Components of the circulation pump

Many typical heating equipment malfunctions can be repaired on your own. It is enough to have an idea of the pump design, a set of tools and minimal knowledge in the field of repair

It is also important to know how to disassemble a heating circulation pump. Before repairing damage, check the power supply

The voltage must correspond to that stated in the technical data sheet.

Below are common heating pump malfunctions, their causes and methods for solving problems.

Problem #1. The heating pump is noisy

| Causes: | Elimination methods: |

| 1. The pump has been idle for a long time and the motor shaft has oxidized | ● disassembling the heating pump begins with turning off the power supply;● free the pump and adjacent pipelines from residual coolant;● remove the screws securing the pump housing and the motor;● disassemble the electric motor and rotor; |

● it is necessary, resting against the working notch, to turn the rotor by hand.

2. A foreign object is blocking the wheel ● turn off the heater; ● remove the coolant from the pump and adjacent pipelines; ● remove the screws securing the housing and the motor; ● remove the foreign body;

● insert a mesh filter to protect the inlet pipe from dirt and scale.

Problem #2. The equipment does not rotate and does not make characteristic sounds

Use a tester to check the power supply and voltage at the terminals, and also correctly connect the device to the power supply. Many models have a fuse that quickly blows due to power surges. The solution to the problem is to replace the fuse.

Problem #3. The circulation pump is noisy when turned on

When air accumulates in the pipeline, an uncharacteristic noise appears. The solution to the problem is to bleed the air out of the pipes. If an automatic unit is installed at the top of the pipeline, the air will be released automatically.

Problem #4. Heating equipment does not turn on

There is a problem with the power supply. Check phases and fuses. If the inspection does not correct the situation, most likely the drive winding has burned out. In this case, independent repair is impossible.

Problem #5. The pump turns on but turns off after a couple of minutes of operation

If the wires are connected incorrectly, then you need to repair the circulation pump yourself. Look into the terminal box and check the connection of the wires in phases. Also, if the contact of your fuse is weak, you need to remove it and clean all the slagged elements.

Problem #6. Strong pump vibration

The most common reason for repairing a heating pump with your own hands is bearing depreciation. Replacing the part eliminates the problem.

Problem #7. Insufficient pump pressure

| Cause: | Elimination methods: |

| The wheel and blades are rotating in the wrong direction | check the correct phase connection |

| Water viscosity due to filter clogging | wash the filter, remove dirt and scale |

Cleaning the Flow Sensor

It is important to keep the flow sensor clean. Sludge and rust change the sensitivity and characteristics of the sensor, resulting in reduced pump performance. If the sensor is heavily contaminated, the pump may shut down completely. Therefore, when cleaning the pump parts, do not forget to clean the sensor as well.

flow and temperature sensor

How to remove the sensor from the circulation pump? To do this, remove the cover from the control unit and disassemble the pump housing into two halves. Next, use the wrench that comes with the pump to unscrew the screws and the sensor can be easily removed. If the sensor cannot be removed due to accumulated dirt, pry it off with a screwdriver. The sensor body is made of plastic, so when cleaning it, do not use aggressive chemicals or abrasives - use a regular toothbrush.

Prevention and Maintenance

Long service life and trouble-free operation are possible only if proper operating conditions and regular maintenance of the pump are observed. Maintenance means periodic inspection and cleaning of the pump. Inspection for abnormalities in operation should be carried out at least once a quarter, that is, twice during the heating season. It is advisable to perform cleaning every two to three years, depending on the quality of the water and the conditions in which the pump operates.

During the entire period of operation, it is advisable to periodically check the operation of the pump:

- Connections are checked for leaks. If identified, gaskets and seals (tow, FUM tape, etc.) are replaced.

- The presence and condition of grounding is visually checked.

- The sound of a running engine should not be accompanied by clangs, knocks, or extraneous sounds.

- The engine should not vibrate much.

- The pressure in the line is checked and its compliance with the nominal one.

- The housing must be clean and dry. If this is not the case, then you should carry out external cleaning, check the electronic unit for flooding and eliminate the reason why the pump is wet.

Approximately every two to three years, it is advisable to clean the pump, including all its elements. This only applies to models that can be disassembled. There are pumps with a pressed or solid, welded casing that does not require repair or disassembly. Such units fail and are then replaced with a new assembly. It is advisable to entrust this work to a service center. However, if you have the skills and tools, you can do everything yourself

- hex wrench;

- slotted screwdriver (flat) 4 and 8 mm;

- Phillips screwdriver.

Before disassembling the pump, drain the water from the system or drain a separate area in which the pump is involved, dismantle it and then begin disassembly.

- Using a hex wrench or Phillips screwdriver, unscrew 4-6 bolts around the perimeter of the engine housing at the junction with the shell of the pump part.

- Remove the shell, leaving the impeller on the rotor shaft along with the engine.

- Locate four drainage holes around the perimeter. Using a narrow slotted screwdriver, pry the jacket of the engine compartment under the impeller little by little around the perimeter. As a result, the shaft with the rotor and impeller will come out of the grooves and stator shell. You can help yourself by unscrewing the protective plug on the outside of the pump, inserting a screwdriver into the slot at the end of the shaft and lightly knocking the shaft out of the support bearing.

The analysis is now complete. Now you should clean the surface of the rotor, impeller and the inner surface of the shell from plaque and scale, if any, without damaging the surface of the parts. It is not permissible to use a coarse abrasive. It is better to use a brush with hard polymer bristles. Cleaning products containing a weak solution of hydrochloric acid can help. As a last resort, the finest sandpaper is used - “zero”.

For wet rotor pumps, it is important to check the cleanliness of the channel inside the shaft and the drainage holes located in the protective jacket separating the area of the pump part and the motor. The fluid enters the rotor precisely through these holes and then returns through the internal channel; if they are clogged, engine cooling suffers.

For pumps with a dry rotor, waterproofing the support bearing is important. If a leak is detected from the pump block to the stator block, then all gaskets and seals inside the device should be completely replaced.

The condition of the bearings on which the shaft rests is checked. If they are already quite broken, they will need to be replaced, which is extremely difficult to do at home; you will have to contact a service center.

All seals and gaskets inside the pump should be checked for wear and replaced with new ones if necessary. Once all elements have been cleaned and checked, reassembly is carried out in reverse order.

Circulation pump needs cleaning

Pump device

Appearance.

Grundfos.

Wilo.

If you don’t know the workings of the heating system, then you won’t make repairs. The design of the device includes:

- body, which is made of stainless steel or non-ferrous alloys;

- Electrical engine;

- a rotor on which a wheel with blades is installed.

In the context.

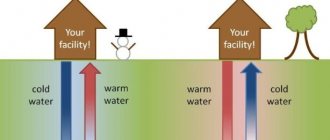

The devices are divided into two types: with a wet rotor and a dry one. For private homes, wet-type units are better suited. In this case, the rotor is constantly in the liquid. Thanks to this, the moving elements are lubricated and cooled in a timely manner. And also the advantages of the equipment include: low noise level, ease of installation. It is better to install devices with a dry rotor in separate boiler rooms. They are suitable for heating large areas.

In any case, the operating life of the equipment depends on proper operation. If you follow the rules, you will protect the system from various types of damage:

- it is prohibited to turn on the unit with zero supply;

- and also if there is no liquid in the pipes, it is strictly forbidden to turn on the pump;

- consider the feed level. If anything is broken, the device will become faulty;

- control the water temperature in the pipes.

The best option is +60 - +65 degrees. If it is higher, then salts will precipitate, and the equipment will then be damaged.

Design

Almost all circulation pumps are centrifugal type. They have an impeller mounted on the motor shaft and placed in a special “shell” chamber. The entrance to the shell is located in the center, while the exit is the outer edge of the shell with a channel extending around the circumference in the direction of movement of the impeller. The engine spins the impeller, and water, under the influence of centripetal force, rushes from the center to the edges of the sink from inlet to outlet.

Pump structural elements:

- pump part, sink and impeller mounted on the shaft;

- electric motor;

- electronic control unit.

The most susceptible to wear is the moving part of the pump - the motor shaft and impeller, as well as the bearings on which they are mounted.

Possible breakdowns and ways to eliminate them

So, if something goes wrong with your circulation pump and it refuses to work, then we’ll try to repair the unit ourselves.

If the pump makes a hum, but the impeller does not rotate

The reasons may be the following:

- Presence of a foreign object in the impeller area;

- The rotor shaft has oxidized due to long-term downtime of the unit;

- Loss of power supply to the mechanism terminals.

In the first case, you need to carefully remove the pump from the heating system and unscrew the housing in the area of the impeller. If a foreign object is found, remove it and rotate the shaft by hand. When assembling the pump in the reverse order, it is necessary to install a reliable filter on the pipe.

If there is oxidation, then clean it well, lubricate all movable elements of the working unit and reassemble the pump in the reverse order.

If there is a problem with the quality of the power supply, then you will have to check the voltage using a tester. First, completely replace the cable in all sections of the cable and if a break or fault is detected. Then, if the cable is OK, check the voltage at the terminals. If the tester shows infinity, a short circuit has occurred. If it shows less voltage, it means that the winding has broken. In both cases, the terminals are replaced.

If the unit shows no signs of life at all

This can happen if there is no voltage in the network. Using a tester, check the voltage and, if necessary, correct the problem.

By the way, it is recommended to protect the pump from surges in the network by installing a reliable stabilizer. This move will also protect the pump from the combustion of a fuse, which fails as a result of constant pressure drops in the network.

If the pump starts but then stops

The reasons may be:

- Presence of scale between the moving elements of the unit;

- Incorrect pump connection at the terminals.

In the first case, you will have to disassemble the pump and check it for scale. If detected, limescale deposits are removed and all joints between the rotor and stator are lubricated.

If there is no scale, then check the tightness of the fuse on the unit. You should remove it and thoroughly clean all the clamps. Here it is also worth checking that all wires in the terminal box are connected correctly in phases.

If the pump makes a loud noise when turned on

The reason for this is the presence of air in a closed circuit. It is necessary to release all air masses from the pipes, and install a special unit in the upper part of the pipeline to prevent the formation of air locks.

Another reason could be wear on the impeller bearing. In this case, you need to disassemble the unit housing, check the bearing and, if necessary, replace it.

If the pump is noisy and vibrates

Most likely, the issue is insufficient pressure in the system. It is necessary to add water to the pipes or increase the pressure in the area of the pump inlet.

If the pressure is still low

Here it is worth checking the direction of rotation of the working unit in the pump body. If the wheel does not spin correctly, then an error was probably made when connecting the device to the terminals in phases when using a three-phase network.

Another reason for a decrease in pressure may be too high a viscosity of the coolant. Here the impeller experiences a lot of resistance and does not cope with the assigned tasks. You will have to check the condition of the mesh filter and clean it if necessary. It would also be useful to check the cross-section of the inlet and outlet pipes and, if necessary, set the correct operating parameters of the pump.

Proper operation of the pump - so that emergency repairs are not needed

Proper handling of pumping equipment and regular maintenance eliminates the need for repair work for many years. When operating the pump, consider the following:

- Do not start the pump if the pipeline is not filled with coolant.

- Turn on the circulation equipment at least once a month for 15–20 minutes. Prolonged downtime of the pump is guaranteed to lead to malfunctions of its individual components and mechanisms.

- Follow the manufacturer's recommended volume of pumped liquid. If the device is designed for 100 liters of coolant per hour, it is prohibited to pump more water through it.

- Before the start of the heating season, check the system for leaks and the correct connection of the circulation unit to the electrical network. Carry out test runs of the pump to make sure there is no vibration or extraneous noise.

Regular maintenance is also important for the stable operation of the circulation pump. You can perform this procedure yourself. You need to make sure that the wires leading to the terminals are securely fixed, that there are no leaks in the unit, and that there is grounding between the terminal and the pump body. You also need to lubricate the threaded flanges and tighten all pump bolts every 1–3 months. Do not forget about the described preventive measures, and then the circulation unit will serve you without accidents for decades.