Long burning pellet boilers

As a fuel, pellets can also be used for long-burning boilers - a new type of solid fuel boiler.

Their peculiarity is that the combustion process is organized from top to bottom, and not from bottom to top, like classic ones. Therefore, the combustion process is slow, and with a sufficiently large firebox it can last several days. Such boilers have a somewhat limited ability to automate their work, but the time of active operation is calculated in days without human intervention. The loaded fuel burns out like a candle, the ash is unloaded, new fuel is loaded, and the process is repeated. Loading …

Features of installing a pellet boiler

If you do not have special skills, it is best to contact qualified specialists to install a heating boiler. Gross errors made during the connection process can lead to equipment breakdown, and as a result, you may lose the opportunity to receive warranty service.

It should be borne in mind that each boiler model has its own characteristics, so do not neglect the technical documentation. In addition, when installing pellet boilers, you must be guided by the standards that apply to all solid fuel equipment:

- The ceiling height should be less than 2.2 m, and the area should be from 12 m².

- The presence of natural and forced ventilation is mandatory.

- For cladding walls and floors, you need to use non-combustible materials - ceramic tiles, plaster.

- The requirements for the base for the boiler depend on the weight of the specific model. In some cases, pouring the foundation is necessary.

- When choosing a location for the boiler, you should immediately think about the possibility of access to the main components of the unit that require inspection and maintenance.

- A prerequisite is the presence of natural light.

During operation, you should also observe the following rules:

- do not store more fuel in the boiler room than is needed for one load;

- remove flammable and explosive materials and rags from the premises;

- a non-combustible partition should be built between the boiler and the silo (pellet storage);

- The distance from the fuel hopper to the burner must be at least 1 m.

How to organize continuous power supply

When installing the structure, it is worth considering that pellet boilers require constant access to electricity, which means they are subject to the general rules for connecting electrical installations:

- the connection of the pellet boiler must be carried out by an electrician with the appropriate permission to work at this level;

- The station is powered directly from the switchboard, while cut-off circuit breakers are installed outside the boiler room;

- An RCD must be installed;

- metal parts of the structure are grounded;

- For long-burning boilers using pellets, it is necessary to install a stabilizer, since equipment of this type is very sensitive to voltage drops.

Some important design components - smoke removal system, auto-ignition, sensors, automatic systems, electric drive - operate only when electricity is available. To ensure constant operation of the system, even during a power outage, it is necessary to install an uninterruptible power supply (UPS), which operates on the basis of high-capacity rechargeable batteries. Depending on the model, the UPS can ensure autonomous operation of the boiler for up to 2-3 days.

Chimney requirements for pellet boilers

Due to some design features of boilers operating on pellet fuel, the chimney must meet a number of parameters:

- The chimney connected to the boiler must withstand an operating temperature of about 450-550 °C and maximum heating for a short period of time up to 1000 °C.

- The cross-section of the pipe is oval or round; the exact dimensions of the minimum pipe diameter are indicated in the technical documentation.

- The chimney must also provide stable draft in the pipe.

For Teplodar boilers, all chimney elements are purchased separately from the main structure.

To select the necessary elements for installation of the structure, you can contact the managers of our online store. Heating boiler with pellet burner Teplodar

Principle of operation

So, to properly understand the operating principle of a pellet device, you should understand its design. It is quite simple and consists of 3 main parts: the boiler itself with a burner, a conveyor for feeding pellets and a fuel hopper. The functioning of the boiler is ensured as follows:

- Pellets are loaded into the fuel bunker.

- The pellets are supplied by a screw conveyor.

- In the process of burning pellets, they heat up the coolant.

The principle of combustion occurs “from top to bottom”. Such combustion occurs more slowly than when the fuel burns “from the bottom up,” so that the circulating gas flows involve the upper layers of the fuel in the combustion process. The rate of fuel combustion can be controlled by moving the fire zone downward. Thus, soot and ash are formed in minimal quantities, and efficiency increases up to 96%. Pellet boilers can operate on one bed for more than a day - quite convenient for use in domestic conditions.

Combined (with several combustion chambers)

If you need to use two completely different types of fuel (for example, pellets and coal), you should consider models with multiple fireboxes.

They have their drawbacks:

- they are more expensive than usual;

- they are more bulky;

- loading coal into a small boiler is difficult to automate - you will have to load it with a shovel; in this case, the person actually turns into a fireman and is forced to frequently load coal into the boiler;

- When coal burns, a lot of soot is formed - the boiler walls and smoke channels will have to be cleaned frequently, otherwise the efficiency of the boiler will decrease;

- after coal combustion, a lot of ash is formed - it must be removed and then disposed of;

- more space is required for fuel storage - coal is usually purchased by machine.

Design and principle of operation

The design of a firebox for pellets is absolutely identical and no different from the firebox of a boiler for one type of fuel. The coal combustion chamber is larger, it holds a large amount of coal - so that it can be heated all day long; and is adapted for manual loading of fuel. The unit is larger and requires more space for installation. This boiler has no other features.

The operating principle of a pellet firebox is no different from the operating principle of a specialized unit’s firebox. The coal furnace operates according to the same scheme, but there is no automation of fuel loading.

Coal-pellet boiler

Features of the pellet stove device

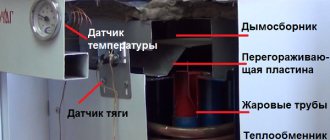

The unit, operating on fuel pellets, includes three main sections:

- furnace;

- convective;

- ash pit.

Furnace department. It is represented by a chamber in which solid fuel pellets are burned. It is equipped with a torch or retort gas burner and has two doors (inspection and cleaning).

Convective department. Has a built-in heat exchanger. Depending on the location, there are three types of heat exchangers: vertical, horizontal, and combined. In this department, the coolant (water) is heated with hot air, which is released during the processing of fuel pellets. The design of the heat exchanger can be either tubular or plate.

Pellet boilers are in most cases used only for heating purposes and have one circuit. However, there are units on the market with two circuits: heating and water heating.

Standard pellet boiler design

Ash pan. This section of the furnace is necessary to collect waste that is generated during the processing of pellets. After this, they are removed through the cleaning door.

The above structural elements of a pellet solid fuel boiler

represent its main part. But for the stove to operate, another important component is needed, namely: the APT attachment (automatic fuel supply).

Let's look at what devices are included in the APT set-top box:

- bunker;

- screw;

- fan.

A bunker is a metal container into which fuel is poured for processing. From this container, fuel flows in parts into the combustion section. Depending on the location, there are two types of bunkers: internal (built-in) and external. The auger is an important element of the APT and is necessary for portion feeding of pellets. It is driven by a special device - a gearbox.

Diagram of a pellet boiler with a hopper

The pellet stove also includes a control panel. It is necessary in order to set the parameters of the solid fuel processing process and maintain the required temperature.

Pellet solid fuel boiler

To operate a pellet heating boiler, fuel is loaded directly into the combustion chamber. The loading of pellets into the firebox and their supply to the combustion section is fully automatic. In the stove itself, the fuel burns as in a conventional solid fuel boiler or in a fire.

A pellet boiler, as the name suggests, requires a special fuel for its operation - pellets. They burn using a special pellet burner, which they enter through a special screw mechanism. The main advantage of a pellet boiler is the ability to operate without maintenance for a long time.

Depending on the capacity of the bunker, the oven will maintain the temperature for a week, or even longer. Compared to conventional boilers that require daily maintenance, this is quite convenient. Pellet solid fuel boilers, despite the complex automation system, are considered quite reliable and do not require constant repairs. However, the automatic fuel loading process has certain disadvantages.

Specifications

The operational characteristics, dimensions and parameters of Turbo series boilers are presented in the table below. It is clearly seen that the series of floor-standing diesel boilers covers a power range from 10 to 35 kW, which is quite enough to heat houses up to 250-275 square meters. Part of the heat will be used to prepare hot water, which must be taken into account in the calculations.

All Kuturami double-circuit boilers and heat exchangers, by the way, are ideally designed specifically for these tasks.

| Boiler model | Unit change | TURBO-9R | TURBO-13R | TURBO-17R | TURBO-21R | TURBO-30R |

| Power | kcal/hour | 9000 | 13000 | 17000 | 21000 | 30000 |

| Power | kW | 10,5 | 15,1 | 19,8 | 24,4 | 34,9 |

| Fuel consumption | liter/hour | 1,13÷1,5 | 1,6÷1,97 | 1,87÷2,15 | 2,28÷2,80 | 3,75÷4,30 |

| Efficiency | % | 92 | 92 | 92.2 | 92.4 | 91.8 |

| DHW consumption | Δt=25ºC | 6,0 | 9,7 | 11,3 | 14,0 | 23,3 |

| Δt=40ºC | 3,8 | 6,1 | 7,1 | 8,7 | 14,6 | |

| Heating supply and return | mm | 25 | 25 | 25 | 25 | 25 |

| Hot water inlet/outlet | mm | 15 | 15 | 15 | 15 | 15 |

| Chimney diameter | mm | 80 | ||||

| Power supply | V/Hz | 220/50(60) | ||||

| Energy consumption | W | 80 | 160 | |||

| External size | w×d×h | 325×600×835 | 365×650×930 | |||

| Weight | kg | 60 | 79 | 85 | 85 | 85 |

Fuel consumption

Fuel consumption is indicated in the table with technical requirements. However, please remember that actual consumption depends on individual settings. Based on the actual power required to heat the house, an appropriate nozzle is selected from the set offered by the manufacturer.

Thermal power, fuel consumption and fuel combustion mode are set. The parameter indicated in the table displays factory presets sufficient to ensure proper performance provided that only high-quality fuel is used, more often this means diesel fuel with winter additives that do not allow it to thicken or separate paraffin in excess of the norm.

In a real situation, for a boiler model with a power of up to 15 kW, you can expect fuel consumption at the level of 8 liters per day, taking into account the frequency of burner operation and the optimal temperature regime in the house. However, this is not the limit.

The right approach to choosing a heating mode, as well as installing a controller with variable temperature conditions, for example, depending on the time of day and day of the week, can reduce consumption even more.

Chimney

Cuturami boilers, gas, diesel, floor-mounted or wall-mounted, are mostly equipped with a closed combustion chamber and, accordingly, a forced exhaust gas removal system. The Turbo series we are currently reviewing is no exception.

Chimney installation diagram

The chimney for boilers is coaxial to simultaneously supply fresh air from the street and remove exhaust gases. Since the exhaust temperature after passing through the heat exchangers is no longer high, the requirements for the heat resistance of the chimney are reduced, and the list of acceptable materials is expanded.

In the best case, a steel coaxial chimney is still used, but a ceramic vertical chimney with a group of internal separate channels for supplying air, removing gases from the combustion chamber and ventilating the boiler room can be effectively used in the same capacity.

The size of the chimney is strictly indicated in the boiler specification and operating instructions. For the entire Turbo series it is 80 mm.

If desired, you can make a chimney with a slightly larger diameter, but no more than 50% above the specified value, that is, up to 120 mm.

Under no circumstances should the size and cross-section be reduced. Even though the removal of combustion products is forced, the resistance of the chimney will greatly affect the combustion mode and the quality of fuel combustion.

Cost of different types of boilers

A big plus is that all the necessary elements are included in the package. Other companies often sell parts such as a thermostat and control unit separately, which increases the cost of the assembled product.

Cost of solid fuel models (in rubles):

- KF-35A - 127,199;

- KRP 20A - 270 799;

- KRP 50A - 318,499.

Bi-fuel heat generators are also represented by 3 devices.

Prices for them (in rubles):

- KRM-30 - 137,999;

- KRM-70 - 218,599;

- KRH-35A - 168,099.

Prices for diesel boilers

The cost of production directly depends on the power of the device and its efficiency. The higher these indicators are, the more expensive it will cost to purchase the unit. Other parameters influence pricing indirectly.

Other factors:

- area of the heated room;

- fuel consumption;

- materials used;

- DHW performance;

- security level: presence of sensors and safety devices.

The comparative cost of liquid fuel units is indicated in the table.

Prices for gas units

Kiturami Eco Condensing condensing units have 3 standard sizes.

Prices (in rubles):

- 16r - 52,360;

- 20r - 57,800;

- 25r - 59,440.

The TGB line includes one model: 30R. You can purchase it for 61,613 rubles.

The cost of traditional type gas appliances is presented in the table.

inexpensive kiturami heating boilers from South Korea

Kiturami boilers from an official dealer. One of the major players in the heating equipment production market is the Kiturami company. It has more than 40 years of successful work not only in its homeland in South Korea, but also in Europe, America, Russia and many other countries. Even in the polar Andera, Kiturami double-circuit boilers are used to provide heating for important public buildings. The company has a lot to be proud of; it has more than 560 patents and development rights. It consists of 16 production, research and financial and investment divisions. And in 1993, the company received the prestigious New Technology certificate in South Korea, as a company with promising and innovative products. In Russia, the Kiturami company has all the necessary documents and GOST certificates.

Kiturami boiler boilers have gained popularity due to their efficiency and reliability. A chip is built into the boilers, which ensures that the boiler operates when voltage surges occur, which significantly extends the “life” of the boiler. It is worth paying attention to the unusual system for protecting pipes from freezing in winter; the boiler does not allow pipes to freeze and automatically maintains their operation if the temperature drops below 5 degrees. All parts of South Korean boilers are manufactured and assembled into a single unit in factories in Korea and Japan. In the manufacture of all components, Kiturami uses only high-quality stainless steel.

Kiturami are double-circuit boilers, which allows owners of this equipment not only to heat the room, but to have hot water supply in the house thanks to only one device. When you open a hot water tap, the boiler automatically switches from heating mode to heating and water supply mode. The modulating burner heats the water evenly. The two circulation rings operate independently of each other, allowing operation in different temperature ranges. Then the boiler switches back to heating mode or goes into standby mode.

Even a child can operate the Kiturami boiler, because smart automation itself will provide the most economical and efficient operating mode. A person only needs to indicate the comfort temperature for the room or the ideal temperature for heating water, the Kiturami boiler will do the rest itself.

Kiturami produces a full range of boiler equipment - these include gas boilers, which in turn are divided into wall-mounted gas, floor-standing gas, floor-standing diesel, bi-fuel (solid fuel and diesel fuel) and pellet. With such variety, the main thing is to make the right choice. All Kiturami boilers are double-circuit and have a remote control panel.

Installation, delivery

Popular Kiturami models

The history of the largest South Korean manufacturer of gas equipment Kiturami begins in 1962 - since then, Kiturami gas boilers have been the standard of the highest quality.

To date, the company has patented more than 560 innovations. It is part of 16 financial, production, and research associations. The production of high-tech equipment and the constant introduction of new developments is ensured by the presence of a powerful production and research base.

The high quality of Kiturami boilers allowed the company to achieve the honorary title of New Technology in 1993, awarded for the production of innovative products.

The products have the necessary international certificates, thanks to which they have been successfully sold for a long time in Europe, Asia and the Russian Federation, having managed to win the recognition of buyers.

The Kiturami brand has been present in Russia for more than 10 years; units of this brand operate successfully in all climatic zones of the country

An important advantage that distinguishes Korean gas heaters is their low cost and large selection of models offered

Price range

The range of Kiturami gas boilers is very wide. The cost of household models (for a private home) is in the range of 30-60 thousand rubles, but there are also more powerful models that will cost 100-800 thousand.

This price difference is due to the power level and capabilities of the boiler, its purpose and design features.

As a rule, users choose units of lower power and, accordingly, cost.

Before purchasing, you should check the terms of delivery. Boilers in the basic configuration do not have a chimney, so you need to immediately decide which type is needed and order it. You should also immediately acquire filters and a voltage stabilizer.

Wood and pellet boiler

In case of interruptions in the supply of pellets, it is worth considering alternative heating options. There is solid fuel equipment into which you can load firewood or briquettes.

Device

Units that can be heated with wood or briquettes for some time do not differ in design from conventional ones. Only the shape and size of the firebox differs.

Principle of operation

The operating principle is almost the same as the basic model, but there are several differences:

- Firewood or briquettes are loaded manually and last for several hours; you have to frequently load fuel into the firebox.

- There is no automated loading of fuel into the firebox.

- Firewood and briquettes do not burn completely.

- More ash and soot are formed.

The principle of operation of a boiler using pellets and wood

This heating option is temporary, as a last resort.

Diesel boilers from the manufacturer

All diesel fuel boilers from the Kiturami company are double-circuit and are manufactured in several series, let’s get acquainted with them.

- Kiturami Turbo are devices whose power can reach 35 kilowatts. The power, as we see, is insignificant, but there is a turbocyclone burner, and the cost is low. All models are intended for use in private homes or cottages, the area of which does not exceed 350 square meters

| Specifications | Unit change | Kiturami Turbo-13R | Kiturami Turbo-17R | Kiturami Turbo-21R | Kiturami Turbo-30R |

| Power | kW/hour | 15 | 19.8 | 24.5 | 35 |

| Heated area | m2 | up to 150 | up to 200 | up to 250 | up to 350 |

| Efficiency | % | 92.8 | 92.9 | 92.8 | 92.7 |

| Average heat consumption | l/day | 4.9-6.8 | 6.1-8.6 | 7.3-10.4 | 10.0-14.5 |

| DHW performance | l/min at T=40C | 5.2 | 6.5 | 8.2 | 13.0 |

| Heat exchanger area | m2 | 0.78 | 0.92 | 1.03 | 1.03 |

| Heat exchanger capacity | l | 23 | 32 | 29 | 29 |

| Boiler dimensions WxLxH | mm | 310x580x835 | 360x640x920 | 360x640x920 | 360x640x920 |

| Boiler weight | kg | 64 | 75 | 85 | 88 |

| Electrical consumption energy | W/hour | 120 | 170 | 200 | 280 |

Table of technical characteristics of boilers of the Kiturami Turbo model

Kiturami STS are similar devices, differing in that they are made of stainless steel.

| Model | Power | Heating area | DHW at dT 25 C | HxWxD-mm | Weight |

| Kiturami STS 13 OIL | 16.9 kW | 160 sq.m | 6.2 l/min | 700x325x602 | 30 kg |

| Kiturami STS 17 OIL | 19.8 kW | 190 sq.m | 6.7 l/min | 700x325x602 | 30 kg |

| Kiturami STS 21 OIL | 24.4 kW | 240 sq.m | 8.3 l/min | 700x325x602 | 32 kg |

| Kiturami STS 25 OIL | 29.1 kW | 290 sq.m | 10.4 l/min | 930x365x650 | 48 kg |

| Kiturami STS 30 OIL | 34.9 kW | 340 sq.m | 12.5 l/min | 930x365x650 | 48 kg |

Table of technical characteristics of boilers of the Kiturami STS model

Kiturami KSOG are high-power devices (up to 465 kilowatts) of a two-cylinder type, also consuming diesel fuel. These Kiturami diesel boilers have a built-in turbocyclone burner and are intended for use in industrial facilities with an area of up to 4650 square meters, as well as for supplying hot water.

Note! All mentioned boilers have an electronic control unit, which is equipped with numerous functions. In addition, the manufacturer provides the possibility of installing a room thermostat, which allows you to control the room temperature directly on site

Table - Comparison of models and prices of Kiturami heat generators

| The lineup | Name | Power, in kilowatts | Cost, in rubles |

| Kiturami KSOG | 50R | 58 | 95.5 thousand |

| 200R | 230 | 304 thousand | |

| 150R | 175 | 246 thousand | |

| 100R | 116 | 166.6 thousand | |

| 70R | 81 | 104 thousand | |

| Kiturami STS | 30R | 35 | 63 thousand |

| 25R | 29 | 55 thousand | |

| 21R | 24 | 50 thousand | |

| 17R | 19 | 42 thousand | |

| 13R | 16 | 41 thousand | |

| Kiturami Turbo | 30R | 34 | 52 thousand |

| 21R | 24 | 50 thousand | |

| 17R | 19 | 40.6 thousand | |

| 13R | 15 | 38 thousand |

Wall-mounted gas boilers Kiturami

There are three series of heaters:

- Twin alpha;

- World plus;

- Hi fin.

Each series has its own characteristics and equipment, which, accordingly, determines the price of the heater. Let's consider each type of boiler separately.

Kiturami Twin alpha series

Twin alpha series.

According to reviews, Kiturami gas boilers operate almost silently. The units are equipped with a system to protect against gas leaks and prevent water hammer; if the wind blows out the flame, the boiler restarts automatically. The Twin alpha series is represented by five heaters with different powers: 15, 19, 24, 29 and 35 kW (rounded to whole numbers). The main heat exchanger for heating is flow-through, and for hot water supply it is plate-type.

The combustion chamber of all models is closed. To operate the boiler, a coaxial chimney of 75/100 mm or 60/100 mm is required. The energy carrier can be natural or liquefied gas. Design of Kiturami heating boilers of the Twin alpha series:

- 2 heat exchangers;

- burner;

- fan for coaxial chimney;

- Control block;

- gas leak sensor;

- seismic sensor - against water hammer;

- gas valve;

- pump;

- expanzomat.

The average efficiency is 92%. The working pressure in CO is no more than 2.5 atmospheres, and in the DHW system – up to 6 atmospheres. The maximum coolant temperature is 85 degrees. The heater only operates in forced circulation circuits. The cost varies between 30-37 thousand rubles depending on the power.

Kiturami World plus series

World plus series.

High technical characteristics of Kiturami gas boilers of the World plus series are ensured by the introduction of capacitive heat exchangers made of copper and burners with internal combustion. This allows you to increase the service life of the heater, increase its corrosion resistance, and ensure complete burnout of the energy carrier (natural and liquefied gas).

The closed combustion chamber operates in tandem with a 60/100 coaxial chimney, which is not included. The World plus series is represented by 5 units, the power gradation of which is the same as in the Twin alpha series. Characteristics:

- Efficiency 92.5%;

- working pressure of natural gas 20 mbar, liquefied gas – 28 mbar;

- maximum pressure of a high-temperature heating system is 2.5 atmospheres, hot water supply – 10 atmospheres;

- coolant temperature adjustable (45-85 degrees);

- The volume of the expansion tank is 7 liters.

The weight of the heater ranges from 33 to 39 kg. This is a power-dependent device that consumes 230 W/hour. The cost varies from 42 to 52 thousand rubles.

Kiturami Hi Fin Series

Hi-fin series.

A special feature of the Hi fin series is a burner with double-sided gas combustion and a capacitive heat exchanger. Heaters of this line can produce one and a half times more hot water for the domestic hot water system. The series is represented by 6 units. Minimum power 11.7 kW, maximum – 34.9 kW.

Hi fin line equipment:

- expanzomat with built-in DHW heat exchangers;

- Control block;

- 2 seismic sensors – one;

- dual combustion burner;

- circulation pump;

- fan;

- CO heat exchanger;

- proportional gas valve.

The efficiency of Kiturami boilers according to the instructions is within 92.5%. The cost ranges from 38 to 42 thousand rubles.

Assembly Guide

A self-assembled pellet stove is a unit consisting of a burner, a housing with a heat exchanger, a firebox, a hopper and a screw mechanism (it is used to supply pressed fuel to the boiler)

Burner

The burner used in furnaces may have a different design; drawings are drawn up for them separately, since the technical characteristics and operating principles will also differ. The volumetric burner is installed during self-assembly directly into the firebox of the heating device. The main burner materials are steel and cast iron.

Pellet burner design

It must be remembered that a homemade pellet burner for a boiler will not meet safety requirements without prior control by a specialist, since an ordinary person may not know all the intricacies of the work. The burner must be installed in strict accordance with the regulations.

Also, a burner for a pellet boiler assembled by yourself can be supplemented with an ignition system. It can be manual or automatic. If automatic is selected, you will need to additionally install an electric fan. The torch burner differs from other options in its low power and has compact dimensions convenient for use at home.

The retort burner has the shape of a bowl. It is filled from below. The fan supplies air to the combustion zone, which enters the burner through special small holes.

Methods of supplying fuel to the burner

Purchase

A burner assembled in production conditions will require serious investment. The average cost of a finished product is about 75,000 rubles. The cost is affected by:

- Manufacturer.

- Materials used.

- Dimensions.

- Ignition type.

In order to save money, it is proposed to create a burner with your own hands according to existing diagrams and drawings.

DIY making

A homemade pellet boiler, the drawings of which are selected for work, must correspond to the type of burner. You can also make it yourself. The burner operating in the unit is fireproof. The service life with proper assembly is at least 10-15 years (production options can work up to 20 years). All the tools and components that the burner requires can be purchased at a regular store.

Pellet burner diagram

The parameters should be calculated using a specialist or a special calculator. Video on installation work related to the burner:

Housing and heat exchanger

It is recommended to make the body from fireclay bricks (resistant to high temperatures, overheating and temperature changes). Cast iron is also suitable for this element.

The heat exchanger is created from pipes. They must have a square cross-section. It is necessary to make holes in order to later bring round pipes. The material is sheet steel, the thickness is 4-6 mm. There should be technical doors in the front and rear walls (required for maintenance of the unit). Tools – welding machine and drill.

The heat exchanger, according to the available diagrams, is located inside the boiler body.

Design example

Firebox

Pellets are poured here and fall into the burner.

Operating procedure:

It is necessary to purchase an auger with a diameter of 7.5 to 10 cm, a metal container and an electric motor. The motor is connected to the burner control unit. You can use any thick-walled casing as a metal container. An inlet pipe is connected to one part of the auger, and a corrugated tube is connected to the second. The fuel supply will pass through it.

Hopper and screw mechanism

To make your own you will need:

- auger with a diameter of 75 mm or 100 mm,

- metal casing

- a simple electric motor that connects to the burner control unit.

The bunker is best made of steel.

Video instruction:

What is a pellet boiler?

In essence, such a device is a solid fuel stove that heats the room by processing pellets. What is a pellet? These are cylindrical granules made from wood waste (shavings, sawdust, bark). In some cases, such fuel is made from peat or straw. It has high environmental performance and does not cause an allergic reaction in people.

Pellets are used as fuel, which are granules consisting of wood waste: pressed wood fragments, chips, shavings

The main difference between pellet boilers and conventional solid fuel devices is the ability to fully automate the work process. Thus, pellet structures are able to function with minimal human intervention.

Advantages and disadvantages of a pellet stove

Today, pellet units are the main competitors of gas heating equipment. Let's consider the advantages of using boilers operating on solid fuel pellets:

high efficiency (up to 97%);

Important advantages of pellet boilers are their small size, operational reliability and ease of maintenance.

- the operation of such furnaces is completely safe due to their high environmental performance;

- solid fuel water heaters of other types do not have such a burning duration;

- they are unpretentious in maintenance and have a high level of automation;

- have the ability to be equipped with remote sensors that determine temperature;

- The pellet unit can be controlled remotely, via a GSM module or a mobile application.

Like any other device, the pellet machine also has some disadvantages. Let's look at them:

- the cost per unit of heat released during the processing of compressed wood pellets is quite high;

- For autonomous operation of the boiler in a remote area outside the city, it is necessary to purchase a generator and additional technical equipment.

The monthly cost of pellet raw materials is about 1 ton, which makes it easy to calculate the total cost of heating with such a solid fuel boiler. Forums on the Internet contain a lot of additional information about the features of use, as well as the pros and cons of such equipment.

Consumers are attracted by the relatively low cost of pellet boilers, the availability of fuel material and ease of maintenance due to automation of the heating process

What you need to know about pellets?

Wood pellets used as fuel come in different sizes depending on the standards adopted by the state. Thus, pellets produced in the European Union reach a length of 30-60 mm. In Russia, where the rules have not yet been established, the granules may be longer.

Therefore, if you use such a product for a boiler manufactured in Europe, it will be difficult to configure the automation to the desired mode. As a result, overexpenditure, incorrect operation in modes specified by the owner, etc. are possible.

The bunker can be located at a significant distance (up to 10 m) from the boiler itself

Also, all heating boilers operating on pellets require that they be of sufficient quality. That is, the granules must retain their shape until they enter the firebox. Otherwise, overspending is inevitable.

The strength of pellets depends on the quality of production and humidity. It is important that it does not exceed 12%. If the norm is not observed, the calorific value will decrease, and in severe cases the granules will become completely unusable.

This type of fuel is:

- household (ash content up to 1%) - they are made from hardwood waste with minimal addition of bark;

- industrial (ash content up to 3%) - it is made from coniferous waste with the addition of bark (up to 10%);

- from agricultural waste (ash content more than 3%) - they are made from biomass of various origins (sunflower husks, straw).

Granules for household use are characterized by the highest calorific value, as they contain a small amount of dust and have low humidity. They are always white.

Cheaper ones are granules for industrial use. Low cost is their significant advantage. Their disadvantage is not the highest calorific value. In addition, the boiler will have to be cleaned much more often and this procedure will be more labor-intensive.

Industrial granules can be identified by color - they are dark brown. They are undesirable for domestic use due to their low calorific value.

There is another type of pellets made from agricultural waste. But you shouldn’t use them - they have extremely low calorific value and high ash content. This means that the boiler will become clogged often, and in this case it is quite difficult to clean it, especially with frozen ash.

You can set up the production of pellets yourself; more details about the manufacture of a special press are written in this article.

Installation and piping diagram of the Kiturami boiler

Since I have 3 sources of thermal energy (Kiturami pellet boiler, Waltek electric boiler, Laminox pellet aqua fireplace) and two consumers (indirect heating boiler and heating radiators), the wiring diagram suggested itself:

All three boilers are connected in parallel and, through a hydraulic valve, supply thermal energy to consumers through the distribution manifold.

Implemented by a compact hydraulic pump from the Italian manufacturer Stout (SDG-0015-004001), a manifold SDG-0017-004023, and pump groups SDG-0001-002501. Circulation pumps Grundfos ALPHA1 L 25-60 180.

The first small circulation pump is controlled by the Kiturami boiler. The boiler loading pump is controlled by the Tech controller. The radiator loading pump is controlled by an Auraton 1106 controller.

Sandwich chimney made of stainless steel 125, height 6m. Two angles are 90 degrees, but since the Kiturami boiler has a smoke exhauster, this is enough.

Supply ventilation is 80 since the outlet from the smoke exhauster is also 80. In case of lack of air, in the opposite part of the boiler room, in the pellet warehouse there is a window that can be opened for ventilation.

The boiler control thermostat is located in the living room. The control is simple: there is a temperature in the house and there is a temperature threshold below which the boiler turns on. The threshold is set to 23 degrees.

You can also set the coolant temperature from 60 to 80 degrees. Trusting the instructions, I set it to 60 for the summer. In winter, 80 is recommended.

There is a timer and a Departure mode, when the temperature will be maintained at 8. But in case of departure, I have an electric boiler that maintains the coolant temperature at 35 degrees constantly, and with thermal heads on the radiators I maintain the temperature in vital rooms where there is water: bathrooms, boiler room, kitchen.

Product varieties

As a rule, by default, Kiturami means diesel boilers, since it is they who have created such high popularity for the brand.

However, the Kiturami model range consists of equipment of varying degrees of power and modification. Most are represented by double-circuit models, which allow not only heating the premises, but also providing the living space with hot water. Depending on the type of fuel used, heating boilers are divided into:

1. Gas boilers - most widely represented by floor-standing and wall-mounted models. This is a fairly common and economical option for suburban construction. The main distinguishing feature is the innovative technology of the “turbocyclone” burner. Thanks to this, double ignition is carried out, allowing operation even at low pressure in the gas pipeline. The heat exchanger, made of alloy steel, prevents the formation of scale, thereby increasing service life.

Kiturami gas boilers include a gas leak sensor and multiple programmable security systems. The operating mode required for a specific season and room can also be adjusted. Gas options can be either single- or double-circuit boilers, providing the house, in addition to heating, with hot water. The main series presented here are Twin Alpha, World Plus, Hi Fin, STSG, TGB and KSG, differing in power, tank volume, dimensions, external design and installation method.

2. Diesel boilers are the second most popular due to the fact that not every home has a gas pipe. They feature economical fuel consumption, approximately 6 l/day, customizable heating modes, depending on which the room temperature is switched. Diesel heating boilers are presented by the manufacturer in the Turbo, STSO, KSO lines. All of these are floor-standing structures, high-power and compact in size. As an additional equipment or when modifying the fuel line, a KR-6 pump is installed in the standard configuration, which provides the necessary pressure to the fuel at the outlet. It would be a good idea to connect the drain pipe to the fuel tank, which will make it easier to regularly clean it of accumulated sediment.

3. Solid fuel equipment is produced in two series – KF and KR. All boilers are equipped with computer remote control, remote thermostats and circulation pumps. Thanks to patented technologies, stable combustion and economical fuel consumption are achieved - one masonry can hold up to 40 kg, which is enough for more than a day. It is even possible to use damp and wet firewood.

4. Pellet boilers of the KRP series represent a separate type of solid fuel, the advantage of which is the unpretentiousness of the fuel material - these can be wood pellets, shavings, sawdust, husks, pine needles and much more

An important requirement is the lowest possible level of fuel moisture, which otherwise, according to the manufacturer, can reduce the performance and sometimes damage the screw mechanism. A 150 kg fuel tank allows autonomous operation for a week. The boilers are equipped with an automatic self-cleaning system

Thanks to a three-pass heat exchanger, hot gases ensure device efficiency of up to 92%. Kiturami pellet burners precisely dose the air supply into the chambers, thereby promoting uniform combustion of the fuel.

5. Kiturami biofuel combination devices are designed to use solid and liquid feedstocks. In this case, the combustion process automatically switches to another type of fuel when the first one is completely burned out. The efficiency is more than 92%.

A review of the model range reveals a number of shortcomings in Kiturami boilers. According to experts, some gas samples of this brand are slightly noisy. Diesel analogues are subject to high requirements regarding the quality characteristics of the fuel; they are also considered more expensive and require constant maintenance, thereby preventing fully autonomous operation.

Advantages of using pellet boilers

- Saving effort and time. Automation of the fuel supply process and the ability to set the desired temperature or even program the inclusion of different modes at certain times of the day ensures ease of use.

- Fast heating and maintaining the desired temperature. Thanks to the high efficiency of pellets and the significant power of heating devices, it is possible to quickly achieve and maintain the desired temperature regime for a long time, including in large rooms.

- Convenient storage. The main requirement for storing pellets is low humidity. Otherwise, this type of fuel is much more convenient: it does not leave a lot of dirt and dust, like coal, and is not explosive, like

- Low level of electricity consumption, which is required only for the operation of automation and the fan.

- Environmental friendliness of pellets. This type of fuel does not emit toxic substances when burned.

Boilers "Teplodar" on pellets

Teplodar pellet boilers have a well-thought-out design, small size and high power. Universal devices can be easily converted to wood or gas if necessary. The boiler body is lined with basalt cardboard, which ensures more efficient heating of the coolant and safety during operation.

Our company’s engineers have developed effective models of pellet boilers “Kupper OK” and “Kupper OVK”. The Kupper OVK model is additionally equipped with a hob, which is convenient for boiling water or heating food.

Depending on the size of the heated room, you can choose the modification you need in terms of power: boilers are designed to heat a room from 100 to 300 m². The efficiency level reaches 83-89%, which ensures economical fuel consumption.

The best pellet boilers Kiturami

In total, the line of pellet installations includes four options of low and medium power from 25 to 50 kW. The boilers are made of high-quality steel 4 mm thick and equipped with a pellet burner with a self-cleaning system.

Kiturami KRP 20A Premium

Kiturami pellet boilers are distinguished by their productivity and operating efficiency thanks to their power of 24 kW. The device is equipped with two circuits, thanks to which it can heat water and heat the room at the same time.

KRP 20A Premium

The automated equipment has a pellet burner with a feeding mechanism, as well as a control module and a pellet compartment with a volume of 225 liters. This capacity is enough for the cat to operate continuously for 5 days with a guaranteed high efficiency of 92%.

At the exit from the Kiturami solid fuel boiler, the gas temperature does not exceed 115°C, so the device can be installed in almost any room.

Specifications:

| power, kWt | 24 |

| Number of circuits | 2 |

| Water heating, l/min. | 8,3 |

| Dimensions, cm | 128x142x135 |

| Weight, kg | 230 |

| Combustion chamber type | Open |

Price 200,000 rub.

Kiturami KRP 50A

The Kiturami pellet boiler is installed on a flat, durable floor surface; it has 2 circuits and an open combustion chamber. There is a separate chimney system here. The solid fuel device has a high power of 52 kW, with an efficiency of 95%.

Kiturami KRP 50A

There is also an energy saving option, an anti-freeze system, self-diagnosis, vibration cleaning, and automated ash removal. The dimensions of the model are 1420x1200x405 mm. Price – 265,000 rubles.

Burner KRP 33

The Kiturami KRP 33 pellet burner, unlike similar models from European and domestic manufacturers, is unpretentious in terms of the quality of the fuel used. The use of pellets with a high ash content is allowed. This is achieved thanks to the presence of mechanical cleaning of the burner. As a result, the following fuel pellets can be used:

- From agro waste.

Low quality wood.

With a high content of ash and sawdust.

The design of the KRP 33 burner makes it necessary to carry out service maintenance no more than once every 7-10 days (for other models once every 2-3 days), and the service takes only a few minutes.

All models of South Korean pellet boilers of the Kiturami brand are equipped with a burner of our own invention with the function of mechanical self-cleaning and soot removal. The burner package includes a control unit and a screw transmission.

Features of operation

Pellet stations are delivered to the buyer completely ready for use. Piping the boiler room does not require the installation of additional circulation and other equipment, since it is already built into the body of the product. To begin operation, it is enough to connect the hot water supply and heating system to the boiler.

Start-up is performed automatically. Usually the controller already has factory settings. If necessary, you can program your own operating mode, including the individual preferences of the owners of the house.

One of the significant features of the operation of pellet boilers is the need to periodically clean the heat exchanger, burner and chimney from accumulated soot.

Recommendations for selection

When choosing models KRP 20A and 50A, special attention should be paid to their performance and battery life of the boiler. Power calculation is calculated using the formula 1 kW per 10 kW

m. Other nuances can be found out by contacting one of the company’s consultants for help.

Kiturami pellet stations have no analogues in their versatility among similar equipment from European manufacturers. The installation cost is approximately a third less, and the functionality is not inferior to competitors.

Advantages of pellet equipment

Today, the advantages of boilers running on pellets are significant, which makes them in demand. One of the most important advantages is high efficiency, it reaches 80-97%. It is comparable to the most recognized heating equipment - gas.

It is important that efficiency is ensured by cheap fuel - pellets are made from wood waste (shavings, sawdust of various hardwoods or softwoods), thanks to which their cost is second only to gas.

Moderate fuel prices coupled with high efficiency ensure the equipment is economical. In Russia, this is the cheapest type of heating after gas; in a number of post-Soviet countries (for example, Ukraine) it is even the most affordable.

For example, using a pellet boiler will cost 1.5 times less than similar equipment running on coal. And heating a building with an electric boiler is 2-3 times more expensive.

A pellet boiler differs from any other solid fuel boiler only in the presence of a special burner

An important advantage is autonomy in operation - it is achieved by a high level of automation. For example, the boiler itself is capable of supplying the required amount of pellets into the firebox, controlling the temperature regime set by the owner, and stopping and starting operation. Often the equipment is even able to clean itself of ash.

Autonomy ranges from 2-15 days, and if the automated boiler is provided with an uninterrupted supply of fuel, it can operate without human intervention throughout the cold season. Also, these units are independent of the presence of centralized heating and main gas pipelines.

We must not forget about environmental friendliness - pellets are compressed sawdust, they do not contain glue or other binders. This guarantees the absence of harmful substances (for example, sulfur) in the granules; their ash content is tens of times lower than that of firewood, as is the emission of carbon dioxide.

Another important advantage is safety. To ensure this, a multi-level fire protection system is used, which includes control sensors, electronics that interrupt the supply of pellets, automatic shutdown, and a number of boilers are equipped with alarm systems.

You will also be pleased with the cheap service - this is a guaranteed fact, explained by the fact that there is little work and any person who does not have special skills can cope with them

An important advantage is the simple installation - the boiler owner does not need to obtain any permission or draw up a project. Current rules allow the installation of such equipment in utility rooms, basements, corridors, and kitchens.