How to select the power and type of radiator switching

Before installing central heating in a private house, you need to decide on the number of sections and dimensions of the panel radiator.

In order for these calculations to be optimal, you need to know the amount of heat. How to determine it has already been said above, but a couple of points require clarification. For example, the heat transfer of a section is indicated by the manufacturer for conditions when the temperature difference between the coolant and the air in the room is 70 degrees. This is achieved only when the water in the system is heated to +90 degrees, and this is not common. It turns out that the actual thermal power will be noticeably inferior to that indicated in the passport. For this reason, for normal heating of a home, radiators with one and a half heat transfer margin are used. For example, when a room needs 2 kW of heat, heating devices with a capacity of at least 2 x 1.5 = 3 kW will be required.

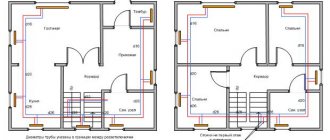

Several methods are used to connect radiators with risers:

- lateral one-sided;

- diagonal scalene;

- lower.

Single pipe system

And the most common of those myths is about the single-pipe heating scheme. The coolant is directed to the radiators and back through one pipe, and many people believe that this is an ideal option for a small house, as it is cheaper to maintain than other variations. But that's not true.

Due to the fact that all the batteries are connected to one pipe, the efficiency drops noticeably, and the radiator at the end of the chain differs significantly in temperature from those at the beginning. This leads to a forced increase in boiler power and, as a consequence, to an increase in fuel consumption.

However, this scheme remains popular due to the low cost of the installation itself. A small number of structural elements allows you to save on materials, and in small rooms, temperature losses at the extreme points of the circuit are not so important; they are leveled out by natural air circulation.

Circuit mounting options

The main pipeline transporting the coolant can not only have different configurations, called wiring, but also be installed differently.

When choosing an installation option, you should take into account aesthetic, energy and economic feasibility.

The installation of the highway can be done in two ways: open or hidden:

- The open installation method is simpler and cheaper - the circuit is laid in accordance with the selected wiring diagram, and the only additional work required is to secure the pipes to prevent their deformation. In addition, in this case, the main line, in addition to transporting the coolant, also performs a heat transfer function, that is, it additionally heats the premises. At the same time, a pipeline left in sight spoils the interior, it is not protected from external damage and is itself a source of danger: you can get burned on it, flammable materials left nearby can ignite, and if the pipeline ruptures, not only damage to the external and internal decoration of the room, but also there is a risk of injury.

- Installing a pipeline in a hidden way involves laying pipes in channels made in the wall, floor, under the baseboard or behind the suspended ceiling. A simplified option is to make a false wall or use boxes and various pipe covers. Concealed installation ensures safety and looks more aesthetically pleasing.

Fuel container

Heating with diesel fuel involves storing fuel. Therefore, the issue of capacity for this purpose is also an important point. The first question is where to store this container. And regardless of whether the tank is located in the boiler room or near the house - in any case, there must be access to a refueling machine.

As stated in “Design of autonomous heat supply sources” (SP 41–104–2000), the capacity of the tank in the boiler room should not be more than 0.8 cubic meters. But such a volume is unlikely to be enough to fully heat the building.

So, you will not need to run a hose into the house when refueling; in the event of a fuel spill, this will add safety, and will also increase the area of the boiler room due to the lack of large tanks.

Diesel fuel containers

Those users who use diesel fuel to heat a country house usually install vertical tanks with a volume of 800-2000 liters; they are considered the most common. If necessary, a fuel storage facility is created on the basis of such tanks - the tanks are connected to each other by a fuel piping. Thanks to this, the period of operation of the boiler room at one gas station increases.

As for the material used to make tanks used to heat a country house with diesel fuel, they can be made of plastic, metal, or fiberglass. There are also tanks for underground storage of diesel fuel. If the volumes are small - do not exceed 2000 liters, then it is not necessary to bury the container in the ground. Remember that if you store the tank outside, it needs to be insulated to protect it from freezing.

Diesel fuel storage tank components

We also note that if your home heating with diesel fuel uses a tank outside the premises, then you should provide an additional pump to pump diesel fuel into the boiler room. In the boiler room, a small tank is made, about 200 liters, which will store fuel for some time.

Storing diesel fuel: overview of options

The main task for the owner of a house with diesel heating is organizing fuel storage. The operation of a diesel boiler requires high energy consumption. Therefore, it is necessary to provide appropriate conditions for the safe maintenance of the optimal amount of fuel. To do this, you can use two types of containers - open and closed installation.

Surface plastic barrels

Plastic containers for storing diesel fuel

They are structures made of polyethylene or PVC. The maximum recommended volume for heating with diesel fuel with your own hands is up to 1000 liters. Be sure to be equipped with a float level, a sealed lid and a fuel intake.

Such containers are used to store small amounts of fuel. Most often - in country cottages or houses with a relatively small area.

Underground tanks

Underground tank for storing diesel fuel

Designed to store up to 20 thousand liters of fuel. Until recently, they were made only from galvanized iron. But the advent of chemically resistant plastic made it possible to make lighter and more affordable structures.

The plastic barrel is installed in a special pit at a distance of at least 5 meters from the foundation of the building. In this way, heating a private house with diesel fuel will not only be effective, but also safe. Unlike small tanks, underground storage is equipped with a pumping station.

In addition to level sensors, fuel leak indicators must be present. To fill the barrel, delivery of diesel fuel for heating is required, carried out by specialized companies selling fuels and lubricants.

Advantages of liquid fuel boilers

- There are quite obvious advantages of liquid fuel boilers used in industries related to fuels and lubricants. For private homes, the advantages of boilers of this type may raise questions:

- Liquid fuel boilers have a high efficiency of 86 to 98%. This is a good indicator, and it is very close to the indicators of gas boilers;

- An undoubted advantage of diesel boilers, unlike gas boilers, is that you do not need permits (approvals) to install the boiler. Although the combustion room will still have to be equipped;

- Diesel boilers are produced in the most autonomous configurations. Automation of boilers and automatic fuel supply allow minimizing the presence of a person for maintenance;

- Another plus is the ability to quickly and easily, by changing the boiler burner, switch to working with natural gas;

- Although there are no omnivorous boilers, diesel boilers can operate on alternative types of liquid fuel, as indicated in the documentation for the boiler;

- Liquid fuel boilers can fit into any heating system and can work with any coolant (water and antifreeze).

Criteria for choosing a heating boiler using diesel fuel

When choosing a diesel heat generator, special attention should be paid to the following aspects:

Thermal power of a diesel boiler. In general, it is generally accepted that to effectively heat an area of 10 m2 in the middle zone, 1 kW/h of thermal energy is required; in cold regions this figure can be 1.3 – 1.4 kW/h.

Possibility of temperature control. There are three main types of liquid fuel installations:

With a single-stage burner, constantly operating at maximum mode;

With a two-stage burner, providing the ability to operate in 50 and 100% modes:

With an adjustable burner that allows settings over a wide range, which significantly reduces energy consumption.

Fuel consumption. It is this indicator that determines the economic feasibility of using a diesel unit; in addition, based on these data, it is possible to prepare in advance the necessary fuel supply for the entire heating season.

In addition, one should take into account the possibility of creating a hot water supply circuit and converting the installation to use natural gas, in the case of a centralized pipeline supply.

Efficient boilers for space heating

For each type of fuel there is equipment that works best.

Condensing gas

Cheap heating in the presence of a gas main can be performed using condensing-type boilers.

Fuel savings in such a boiler are 30-35%. This occurs due to double heat extraction in the heat exchanger and condenser.

The following types of boilers are produced:

- wall-mounted – for small areas of apartments, houses and cottages;

- floor-mounted – heat apartment buildings, industrial facilities, large offices;

- single-circuit – for heating only;

- double-circuit – heating and hot water.

In addition to all the advantages, the installations also have disadvantages:

- Higher price compared to equipment of outdated designs.

- The boiler must be connected to a sewer system to drain condensate.

- The device is sensitive to air quality.

- Energy dependence.

Pyrolysis

Pyrolysis heat generators operate on solid fuel. These are relatively economical boilers for a private home.

The principle of their operation is based on the process of pyrolysis - the release of gas from wood during its smoldering. The coolant is heated by combustion of gas, which enters the chamber from the loading compartment, and subsequent combustion of charcoal.

Pyrolysis-type systems are made with forced ventilation, powered by an electrical network, or natural, created by a high chimney.

Before starting such a boiler, it must be preheated to +500...+800˚С. After which the fuel is loaded, the pyrolysis mode is started, and the smoke exhauster is turned on.

Black coal burns the longest in the installation - 10 hours, followed by brown coal - 8 hours, hard wood - 6, soft wood - 5 hours.

Solid fuel

In addition to pyrolysis systems, which cost 2-3 times more than classic ones, do not operate on damp fuel, and have smoke contaminated with ash, automated versions of standard solid fuel boilers are used to heat the house.

To select the right equipment, you need to determine what type of fuel is most available in your region of residence.

If there are nightly electricity tariffs, then combined systems can be used, for example, wood and electricity, coal and electricity.

To obtain hot water, you will have to purchase a double-circuit boiler or use indirect heating of a boiler connected to single-circuit equipment.

Electric boiler

Economical heating of a private house without gas can be done at the lowest cost using boilers that run on electricity.

If the device power is up to 9 kW, then there is no need to coordinate with electricity suppliers.

Budget equipment that uses heating elements as a heating element occupies 90% of the market, but is less economical and convenient to use.

Modern induction-type boilers do not have a number of disadvantages (the heating element does not come into contact with water), but at the same time they take up a lot of space and have a high price.

You can save on electricity if:

- monitor the condition of the coolant;

- periodically clean the heating elements;

- use night tariffs for electricity costs;

- install a boiler with multi-stage power control, which operates depending on weather conditions.

https://youtube.com/watch?v=q8Y0J-3dKUY

Reviews of diesel heating boilers for private homes

1. To heat the country house, we decided to purchase a diesel heat generator, since there is no gas supply in the village and is not expected in the near future. The price of a diesel boiler at the time of purchase was approximately 35 thousand rubles, which is quite commensurate with our budget. I installed the boiler myself and there were no significant difficulties. Now, for two years now, the house has been warm and cozy, we are very happy with the purchase.

2. Since our village does not have a centralized gas supply, we had to look for alternative options. Electric boilers were no longer needed, since power outages are not uncommon in our country. Of the remaining options, we settled on the Navien LFA 21K double-circuit diesel boiler. As time has shown, the choice was absolutely correct; for 4 years now there have been no problems with heat or hot water.

3. It’s very good that when installing a diesel boiler in a house, it is not necessary to install a special chimney! We installed the unit in a separate extension next to the house, and ran a sandwich pipe through the wall to the street. The turbine copes well with removing gases and we do not notice any unpleasant odors. In terms of performance, the unit provides enough heat, and in addition, there are no interruptions in hot water.

4. The year before last we installed an ACVNmini diesel boiler. In general, there are no significant complaints, except for the noise. This year I will make sound insulation from plasterboard with a mineral wool lining and then it will be absolutely good.

The use of units running on liquid fuel as a heat generator is quite justified in the absence of a centralized gas supply. In addition, unlike solid fuel boilers, the duration of operation of a diesel boiler in autonomous mode is limited solely by the capacity of the fuel tank.

Recommendations for calculating the heating system of a private house

Before assembling a heating system in a private home, you will need information about the exact amount of thermal energy. There are two methods of calculation - simple approximate and exact calculation. The first option, due to its simplicity and ensuring the correct result, is usually used by heating equipment distributors. In this case, to calculate the thermal power, parameters of the area of the premises that need to be heated are necessary.

A separate room is taken, its area is calculated, after which the result is multiplied by 100 W. Having determined the parameter for each room in this way, all indicators are ultimately summed up to obtain a total value.

For a more accurate calculation, additional indicators are used:

- To multiply by 100 W, the parameters of rooms with one wall in contact with the street and having one window opening are taken.

- Corner rooms with one window are multiplied by 120 watts.

- The area of a room with two external walls and two or more windows should be multiplied by 130 W.

If an approximate method is used to calculate the required power of a home heating system, this may lead to a shortage of home heating for residents of the northern regions. At the same time, residents of the southern regions with this approach to calculation will overpay for overly powerful devices. The second (calculation) method is usually used by design specialists. Thanks to greater accuracy, it allows you to determine the level of heat loss through the walls of a building.

Before starting the calculation, measure the house, calculating the area of walls, windows and doors. Next, the thickness of each of the building materials used for the construction of walls, floors and ceilings is determined. Each of these materials has a certain thermal conductivity coefficient, expressed in units of W/(m · ºС). It is substituted into the formula for calculating the thermal resistance R (m2 ºС / W): R = δ / λ, here δ is the thickness of the wall material in meters.

To calculate the amount of heat loss through external walls, use the formula QТП = 1/R x (tв – tн) x S, where:

- QТП – amount of heat loss, W;

- S – room area, m2;

- tв – expected internal temperature;

- tн – street temperature in the coldest period

The calculation procedure is carried out individually for each room in the house, for which the thermal resistance and area indicators for the outer wall, window, door, floors and roof are substituted into the formula in turn. Next, all the obtained parameters must be added up, which will make it possible to obtain the overall heat loss indicator. In this case, internal partitions are not taken into account.

Alternatives

Do they exist in cases where there is no main gas nearby, and the electrical power is limited to a relatively small value?

Let's first decide what is important to us in a heating installation.

- Minimum operating costs.

- Maximum autonomy.

- If possible, make a small initial investment.

What can the modern market offer in equipment that satisfies all three conditions?

Top combustion boilers

The Lithuanian company Stropuva began producing them about a decade and a half ago. The concept, however, is so simple that it immediately gained a massive following around the world.

The operating scheme is based on a simple idea: a large volume firebox is filled with wood or coal, after which the fuel is ignited from above and burns ONLY in the top layer. There, a movable and heat-resistant air duct organizes the supply of air for combustion.

A massive metal disk separates the area where the fuel smolders from the upper chamber, where the products of incomplete combustion are burned. The ash is carried away by hot furnace gases.

How long does it take to burn one bookmark with this scheme? A boiler can operate with wood for up to one and a half days, and with coal - up to five. After this, however, the firebox will have to be cleaned and a new portion of fuel loaded.

The great advantage of the scheme is that heating with coal is two to three times cheaper than the same amount of thermal energy extracted from burning diesel fuel. However, we are not talking about complete autonomy.

Top combustion boiler design.

Heat pumps

These devices have already been mentioned. Heating pumps for the home have become widespread in the last 15-20 years. In essence, what we have in front of us is a refrigerator turned inside out, pumping thermal energy from a low-potential (cold) source to a high-potential recipient.

Without going into technical details, we can distinguish three main sources of low-grade heat.

- Geothermal pumps take advantage of the fact that below the freezing point the soil does not cool below 8-12C. Pumps of this type will provide heat to both you and your children; however, both the devices themselves and their installation with well drilling are quite expensive.

- It is cheaper to use water energy. If there is an ice-free river or lake near you, just immerse the heat exchanger in them - and you have an unlimited source of free heat at your disposal.

Let us remind you: approximately 30% of the thermal power will still be taken from the outlet. This electricity, to be precise, will go to power the compressor.

- Finally, for climate zones where the average January temperature is above zero, an excellent solution is to use the heat of the surrounding air. The cheapest solution of this type is a conventional inverter air conditioner, providing 3 kW of thermal power at a cost of 600 watts and a cost of 22 thousand rubles (a typical example is [email protected] CH-S09FTXS).

All heat pumps are completely autonomous. All of them are 3-4 times more economical than solar boilers. Finally, they are the most promising: electricity is rising in price several times slower than fossil fuels.

Expected dynamics of price growth in the coming years.

What will fuel consumption depend on?

There are a number of factors (including various loads) that influence the performance of heating equipment. But first of all this:

- area of the heated room;

- quality of thermal insulation of the building.

Of course, the larger the room itself, the greater the diesel fuel consumption will be. As for the efficiency of the equipment described, in most cases it varies between 90 and 95 percent. But, which is typical, to achieve this result, the speed during operation of the boiler must be maximum. Therefore, when choosing a heating device, you should not purchase a model whose power has a small reserve. This way you will be able to avoid unnecessary expenses, since here the liquid fuel boiler will consume less diesel fuel.

Calculation of fuel consumption for a diesel boiler

Knowing the power of the equipment and the area of the house, as well as some other technical parameters, you can calculate how much fuel you will need to store in order to be prepared for even the most severe cold weather. The consumption of a diesel heating boiler depends not only on the equipment itself, but also on the insulation of the house, ceiling height, installed plastic windows and some other parameters.

Much depends on the weather conditions of the region. On average, to heat a large house with an area of 200 square meters. m, it will take up to 6 liters of fuel at a temperature of -5 degrees and more than 20 liters at 30 degrees below zero.

When making calculations, you can rely not only on your own weather observations, but also on research conducted by specialists. At an average Russian winter temperature of -20 degrees, consumption will be about 16 liters; in more severe cold weather or with insufficient insulation, this figure reaches 20 liters.

If you choose a diesel heating boiler, fuel consumption can be reduced using automation capabilities. There are many models with automatic mode switching; in addition, you can install a thermostat that will maintain a constant temperature in the rooms. Programming equipment to heat up only at certain times when family members are at home can significantly reduce costs.

Can used car oil be used to heat your home? It is possible, but this requires a special boiler, which itself is very expensive.

Although he will save money in the future, the costs of purchasing it will be prohibitive, and it is better to just buy high-quality diesel fuel. In addition, the work will have to be collected and transported home, which will require additional costs and time.

Alternatives to gas heating

As I already mentioned, gas heating is the most convenient for permanent residences; gasification of a home is the ultimate dream. However, the total cost of gasifying a home forces us to look for an alternative to gas.

Electricity

Electricity itself is an excellent alternative to gas, if only it weren’t so expensive. Practice shows that over 7 months of the heating season, using only electric heating, you will have to spend 50-60 thousand rubles, and this is with a good setup of the heating boiler.

Using electricity, you can heat your house using:

- Electric heating boiler (100 meters of house = 10 kW boiler).

- Electric convectors (cheap installation, but requires new wiring).

- Film infrared heating (rarely used as the main heating due to the high cost of installation and operation).

In addition to electricity, alternatives to gas can be:

Diesel fuel. There are a lot of disadvantages: expensive equipment, you need a special place for the container, you need to constantly replenish fuel. Cost of diesel fuel: 2-3 rubles per 1 kW of heat.

Firewood. Wood heating is not easy. On the one hand, they are accessible. If you prepare them yourself, they are quite cheap. This is probably why all of rural Finland is heated with wood. In Russia, the cost of purchased firewood is slightly more expensive than gas, but cheaper than all other types of fuel. Gas - 20-30 kopecks per 1 kW, firewood - 70 kopecks, coal 1.3 -1.5 rubles, electricity - 3±1 ruble per 1 kW.

Sun. If you don't live in a sunny area, the sun can be considered a source of heating for your home. Typically, solar collectors can only act as an additional source, for example, of charging the batteries of an uninterruptible power supply system or gas boilers.

BIO fuel. Today, BIO fuel is difficult to consider as a real alternative to other heat sources.

Expenses

How to calculate diesel fuel consumption for heating during the season and, most importantly, your costs?

- For the center of the country, with good insulation of the house, you can take the approximate need for thermal energy as 1 kW per 10 m2. Yes, such a scheme is greatly simplified and gives rather mediocre accuracy; but an accurate calculation of the heat requirement is still beyond the scope of the article.

- As practice shows, burning a liter of diesel fuel produces about 10 kilowatt-hours of thermal energy. To provide heat to a house of 100 square meters during the peak of cold weather, we need to burn a liter every hour.

- Again, turning to practice - a correctly calculated heating installation ON AVERAGE operates at half the rated power. That is, if calculations showed that we need a 10-kilowatt boiler, then half the time it will operate at full power and half the time it will be idle. Therefore, in practice, the average fuel consumption will be halved and amount to 1/2 liter per hour.

A month is, as you can easily calculate, 720 hours. The instructions for further calculation are quite simple: we multiply hourly consumption by 720 and get 360 liters of diesel fuel per month, which at current prices will result in 32.5*360=11,700 rubles at the rate of 32.5 rubles per liter.

It is easy to judge the immediate prospects from the table of world fuel prices. We are still moving towards a market economy, which implies leveling prices at the general level.

Types of water heating systems

Before installing heating in a private home, in order to avoid installation errors, you need to understand the principle of its operation. It is based on the movement of heated liquid through pipes. Along the way, it gives off heat to the room. The system can be arranged in various configurations. Let us consider in detail the device of each.

Organization of the heating system

Water system “Warm floor”

The installation of a heated floor can be made either as an addition to the radiators or as an independent installation.

Combined floor heating system with radiator

The main advantage of this configuration is the ability to set different temperature conditions for each floor, since cold air rises and warm air remains below.

The temperature in the system can be lowered to +55°C, which is recommended by design standards. Pipe distribution is arranged over the entire floor area, this is effective for uniform heating of the room.

The main disadvantages of heated floors include:

- complexity of installation;

- Possibility of installation only at the construction stage;

- difficulty during repairs.

Connecting heated floor heating

Baseboard heating systems

They perfectly replace conventional radiators and underfloor heating systems. The pipes are installed at the level of the baseboards, and the room is heated sequentially. Manufacturers offer a variety of shades of pipes for installation “under the baseboard”; you can choose the color to match the interior or diversify it.

Installation of baseboard systemwarm water baseboard

Radiator

Radiators are a more familiar system. Manufacturers produce interesting models both in configuration and in cost. You can choose a completely budget product. Currently, radiators are made from:

- cast iron:

- become;

- aluminum

Aluminum radiator in the interior

Heating system of a one-story house with natural circulation

Natural coolant circulation is possible only in one-story houses. A liquid in a hot and cooled state has different densities. At their difference, flows move. The warm coolant rises, the cooled coolant flows down. The flow movement is continuous.

The main advantage of the system is simple and affordable installation. In addition, the heating system can operate without a pump, which significantly saves money.

The disadvantages include installation of pipes at a certain slope. It is necessary to strictly adhere to the calculated parameters during installation. In addition, it is necessary to install an expansion tank in the attic or roof.

Comparison of systems with natural and artificial circulation

Systems with forced circulation of coolant

Forced transfer of coolant occurs thanks to pumping equipment. This is a more efficient system, thanks to which the heated liquid reaches the most remote points

This is important for 2-storey houses. The efficiency of such a system is one third higher than natural

The advantages include the installation of a pipe system without a slope, which greatly simplifies installation. Expansion tanks are also not installed. Instead, pumped storage tanks are used.

Negative features of the system include the need to install fittings on pipes. It acts to protect against emergency situations associated with increased coolant pressure. In addition, it is necessary to install safety valves on both sides of the circulation pump equipment.

Pump connection diagram

What are combi boilers

In some cases, diesel heating can be used not as the main method, but as an additional method. On sale today you can find combination boilers that run on both diesel and gas fuel or diesel and coal. Such equipment is more expensive, but in the future it will be possible to spend much less on heating, and the risk of being left without heat altogether in the event of any network problems will disappear.

On normal days, you can use gas heating for your home, and if there are changes in the gas supply, a diesel burner is put into operation. In this case, fuel consumption will not be too high, and the home owner will be able to prevent the heating system from freezing without unnecessary expenses.

Modern combination boilers can combine not two, but more fuel options, and this will allow you to choose the most cost-effective solution in the future. But such boilers themselves will be very expensive, so installing and connecting the system will require large expenses.

In addition, connecting to the gas pipeline will still require drawing up a project and obtaining an official permit, and the work will have to be carried out by a specialist. It will not be easy for a massive, bulky boiler to find a suitable place in the house; the boiler room must comply with all fire safety rules.

Should you choose diesel heating for your home? This issue will remain controversial for a long time, since such fuel has both pros and cons.

In Russia it still remains insufficiently in demand, although with the advent of new economical models the situation has begun to change. Diesel heating is expensive, but very reliable, and your home will be reliably protected from the cold throughout the entire heating season.

Andrey Levchenko

Author of publications on 1Drevo.ru with the topics: Windows for the attic | Rounded fence | Five-wall log house | Repair of a cylinder house | Production of cylinders | House layout | Rounded dacha | Induction electric boiler | Solar panels | Canadian log house | Log bathhouse | Wall insulation | Cottage - laminated timber, etc.

Was this publication useful to you?

Bookmark it on social networks!

Total score: 2Votes: 5

Brick stove with water heating boiler

Log houses made of rounded logs - construction of cottages

We recommend! — Encyclopedia Wooden Houses — NEW

You can find out detailed and expanded information on the topic of the article from the book “Wooden Houses,” which reflects all stages of building a house, from laying the foundation to installing the roof. Book price = 77 rubles.

You may also be interested in other BOOKS on building houses from wood with your own hands.

We recommend other posts on this topic:

Stoves for water heating in a private home

Review of alternative heating systems for a private home

Electric heating for a private home - how to save money

Heating and cooking stove made of brick with a water circuit

Pellet boilers for heating a private home - advantages

Induction electric boiler for heating a private house

What determines the fuel consumption of diesel heating boilers?

If you decide to install a heating boiler, you need to decide what type of boiler you need and what its power should be. It is a little difficult to imagine that a city dweller, accustomed to comfort, would choose a solid fuel boiler. Undoubtedly, it will be gas. What if the gas line is so far away that connecting to it would cost huge amounts of money? Then choose the most optimal option in this situation - heating a country house with diesel fuel. All that remains is to find out what the fuel consumption of diesel heating boilers is.

Choosing a diesel heating boiler has an important advantage: its autonomy, which, in addition to ease of control, also saves on diesel fuel. This is certainly a more economical option than, say, electricity

Installation of this boiler does not require special permission.

Of course, they also have certain disadvantages. First of all, the need for a special container in which the fuel will be stored, a room with an exhaust hood for installing the boiler.

Combustible fuel will need to be stored in special bunkers, steel or plastic fuel containers. Their volume depends on the volume of the heated premises, as well as the required level of their thermal protection. On average, the volumes of these containers range from 4 to 10 tons.

They can be installed in an isolated room inside or outside the building. According to fire safety rules, containers, if hydrogeological conditions allow, must be buried in the ground. They should also be buried because if there is groundwater nearby, half-empty tanks may, as they say, float to the surface in the spring. and also, at lower temperatures, the viscosity of the fuel increases, which increases the load on the fuel pump, therefore, more electricity is consumed to pump fuel.

You can roughly calculate the diesel fuel consumption based on the following ratio: you can get a boiler thermal power of 10 kW with a diesel fuel consumption of 1 kg/hour.

You can calculate the consumption of diesel fuel required for heating as follows: multiplying the burner power by a factor of 0.1. The resulting figure will show the amount of diesel fuel (in kilograms) consumed in 1 hour.

Let's calculate the approximate consumption of diesel fuel for heating a house with an area of 150 square meters. m. The boiler power required to heat such a house is 15 kW.

Let's perform simple mathematical calculations:

It turned out that at full burner power, the boiler burns 1.5 kg of diesel fuel in 1 hour, and the daily consumption, accordingly, is 24 x 1.5 = 36 kg.

If we take into account that during the entire heating season the boiler operates for about 100 days at full power, and another 100 at half power, in the end we get: (100 x 36) + (100 x 18) = 5200 kg, i.e. a little more than 5 tons of diesel fuel.

With proper operation of a diesel boiler, it can last about 50 years.

Advantages

Let's start right away by considering the winning aspects (we'll discuss those that aren't so good later) that characterize heating a country house with diesel fuel. This question is relevant for many owners of private housing, because diesel fuel is not cheap; frankly speaking, a lot of it is required for the heating season.

The rating of this equipment in European countries is quite high, thanks to its advantages. Let's list the main ones.

The efficiency of the equipment under discussion is high, reaching 95% under the following conditions:

- correct installation of the boiler;

- furnace installations in accordance with all rules and regulations;

- high-quality insulation of the house;

- installation of double-glazed windows;

- proper storage of fuel reserves;

- using high-quality fuel;

- timely maintenance;

- competent choice of equipment power, manufacturer, model.

The efficiency can reach up to 98% when using a condensing type boiler, but more on that later.

- Wide range of model range, manufacturers, power characteristics, etc.

- Economical consumption of electrical energy.

- Environmental friendliness, which is a fairly current trend in modern European society. When burned, almost no harmful substances or gases are formed.

- High level of safety compared to gas boilers.

- Autonomous, automatic operation that does not require constant human intervention.

- Inertia is not typical for the design of diesel boilers (unlike solid fuel analogues). Productivity decreases immediately.

- Liquid fuel takes up much less storage space than solid fuel (peat, firewood, coal).

- Possibility to use used engine oils, which are cheaper. At the same time, the issue of recycling waste material, which is completely burned in a diesel unit, is resolved. Again, a reference to environmental friendliness.

Design and types of diesel boilers

Modern diesel heating boilers for dachas and cottages are made in the form of a floor structure. Which allows you not only to heat water for the heating system, but also transfers heat through its walls to the boiler room.

The latest modern models have a special outer casing - a protective coating. It guarantees no burns if you accidentally touch a hot boiler.

According to the type of heating of the coolant, all boilers can be divided into three groups:

- with one circuit (single-circuit) - will provide exclusively heating of rooms;

- with two circuits (double-circuit) - in addition to heating, due to the presence of a flow-through heater, they are capable of heating water for hot water supply or a warm water floor;

- with two circuits plus a built-in boiler - a unit that will provide heat, hot water in sufficient volume for consumption by the whole family and heated water for the pool.

Boilers differ according to the method of exhaust gas extraction:

- with natural draft - a regular vertical chimney;

- and with forced draft - models with a closed firebox and a built-in chimney.

In fact, the most important device in a diesel boiler is its fan burner. It pumps and regulates air flow, and therefore oxygen, in the firebox. The burner controls the volume of fuel supplied to the combustion chamber. The injected air guarantees complete combustion of the fuel, which ensures the high efficiency of such a boiler.

The burner is an undoubted advantage of a diesel boiler, but it is also its indisputable disadvantage. The noise from its operation discourages many who want to purchase one. Manufacturers are trying to reduce its noise by any means, but it is still recommended to make noise insulation in the boiler room.

The second most important component of a diesel heating boiler for a summer residence is the heat exchanger. It is made of steel or cast iron. The first one is lighter and is much smaller in size and weight. But cast iron can last up to half a century, since its thick walls are much more resistant to corrosion.

Power and required fuel volumes for winter

For convenience, it is believed that for comfort in a house, 1 kW of heater power is needed for every ten square meters. Then the resulting figure is multiplied with a correction factor of 0.6 - 2. It depends on the climatic zone of residence. In the southern regions - 0.6, and in the far north up to 2.

Fuel consumption per hour of operation, which can be calculated by multiplying the power by 0.1, does not operate at full capacity during the winter. It is believed that the heating season lasts 200 days. Half of them he works at full capacity, and half at half capacity. The result is another coefficient - 0.75.

As a result, averaged over the winter for heating a house of 250 square meters, it will be burned = 250 * 0.1 (needed power) * 0.1 (consumption per hour) * 24 (hours in a day) * 200 * 0.75 (heating season) = 9000 kg of diesel. That is, in the warm south you will need a little more than 5, and in the north about 18 tons.

The given figures are approximate, but you can already start from them when selecting the boiler power and the size of the fuel tank. In order to reduce them, you should also perform high-quality insulation of the entire home and carefully configure the automation.

Also interesting: when arranging your home, don’t forget about the yard! High-quality paving slabs https://www.cemsys.ru/ will transform your site and create the desired comfort. Good luck!

Advantages and disadvantages of diesel boilers

Liquid fuel equipment is used to heat homes in almost all countries with cold climates.

Such boilers are in demand in Belgium, Finland, Scandinavian countries, etc., in Russia they are also beginning to play an increasingly important role in the heating market. The fuel for them is diesel fuel, which can be purchased anywhere, and this is one of the advantages of such equipment.

Modern diesel heating boilers for home can be a profitable solution for several reasons:

- High efficiency, reaching 95% in modern models. This is an important factor, since in traditional wood and coal stoves the efficiency does not rise above 70-80%, which leads to additional fuel consumption. Energy-efficient liquid fuel equipment will allow you to get by with minimal heating costs all winter.

- Easy to install. Gas boilers must obtain a special permit, and connection work must be carried out only by specialists. Diesel boilers can be installed independently, and in the future there will be no problems with their maintenance. Installation is not particularly difficult.

- High degree of automation. Modern models are equipped with electronic control units that allow you to configure operating modes. This will ensure uniform heating without human intervention, and fuel refueling can be done only once every few days.

- Safety. A diesel heating boiler running on diesel fuel creates a much smaller threat to the home than heating with gas in cylinders. If the operating rules are followed, it can reliably serve your home for many years. Proper storage of fuel will be necessary to avoid fire hazards.

- Environmentally friendly. The fuel burns almost completely, without releasing carbon monoxide, and the amount of harmful emissions is kept to a minimum.

However, heating a house with a diesel boiler also has a number of important disadvantages that also need to be taken into account. Firstly, there is an unpleasant odor that will disturb the residents, so they try to install the boiler in a separate room away from the living rooms.

Secondly, the high cost of diesel fuel, which continues to rise. Gas heating, if a centralized gas pipeline is connected to the house, will be much cheaper, especially for a large building.

In addition, the fuel must be of high quality, which further increases its price. By purchasing cheaper diesel fuel, you can significantly reduce the life of the equipment, and very soon it will need repairs.

How to choose a diesel boiler

A diesel heating boiler for a private home has a fairly simple design. It includes a burner with a pump, a fan to provide oxygen flow, a fuel filter, control sensors and a control panel. The fuel enters the burner using a pump, mixes with air and ignites, and the thermal energy released during the combustion of diesel fuel is transferred to the heat exchanger.

The heated coolant enters the pipes and radiators, heating the house. The device has a minimum of components, so it will not fail very soon and will not leave your home without heat during the cold season. The heating system must also be equipped with a circulation pump and an expansion tank, as well as a set of shut-off valves.

Such a boiler should be selected according to several basic parameters:

- Power. A normally insulated house, built in accordance with SNiP, requires 1 kW of energy to heat 10 square meters. meters of area. Accordingly, the power is calculated for a specific building: for example, to heat a building of 150 square meters. m. you will need a boiler with a power of at least 15 kW.

- Heat exchanger material. Steel or cast iron can be used: the first option allows you to make the boiler lighter, but it will be less efficient.

- Method of heat generation. You can purchase a standard boiler, or you can choose a new condensing model.

- Condensing boilers use thermal energy not only from fuel combustion, but also from the resulting condensate, which is why they got their name. Such a system will make it possible to constantly save on heating, since the consumption will be less.

- Purpose. It is better to choose a single-circuit diesel boiler for heating a house for a cottage and install an additional electric boiler, otherwise the generated heat will not be enough. Double-circuit boilers provide both heating and hot water supply to the building. They are usually installed in small houses so that there is enough heat and hot water.

Cast iron takes longer to warm up, but also cools down much longer, which will save fuel when heating the coolant. Cast iron heat exchangers are offered by the most famous manufacturers, such as Viessmann, Vaillant, Dakon, Buderus and many others.

In addition, you need to pay attention to the manufacturer’s brand: European equipment may last longer, but it will require high-quality fuel, and sooner or later expensive components will be needed to repair them. In some cases, it is more profitable to purchase an inexpensive Russian boiler, which will be less demanding to use and will definitely not fail in severe frosts. If you are looking for a heating option with a diesel boiler, reviews from owners will give you an idea of the most popular models.