Heating a frame house

Options for heating a frame house can be different, due to good heat-saving characteristics; any coolant can be used in such structures. Basically, the choice of a heating device depends on the preferences of residents and the financial resources that they are willing to spend on the installation and maintenance of such equipment.

Pipes and radiators.

Heat in a frame house can be obtained through:

- Combustion of natural or liquefied gas, diesel fuel.

- Solid fuel boiler.

- Systems operating on electrical energy.

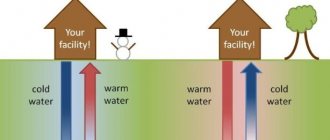

- Modern technologies for obtaining energy from the subsoil and the sun.

It is considered the most optimal when heating in a frame house is done with your own hands using a combined system. It is easy to install without additional effort or tools, and allows you to heat a frame house regardless of environmental conditions.

A combined scheme may include the following options for heating devices: an electric boiler, a solid fuel fireplace, air heating of a frame house and solar panels on the roof. At night, the house will be heated by heating water in an electric boiler and heated floors, the payment for electricity will be calculated at the night tariff, in the evening for heating you can use a regular solid fuel boiler, in clear weather - solar energy.

On a note

The main advantage of this system is the many ways it can be implemented. Thus, heated floors can be replaced with conventional radiators, and a gas unit can be installed instead of an electric boiler.

Features of heating installation

Installation of heating in a frame house begins with choosing the most suitable scheme. At the next stage, a plan must be drawn up for the placement of all elements of the heating system in the house, then the necessary equipment is purchased and direct installation is carried out.

Due to the housing design, heating pipes in a frame house can be laid already at the final stage. However, in order not to disassemble the panels, it is worth taking care of heating at the stage of working with the walls.

DIY pipe installation.

Most often, pipes are placed either on top of the frame structure and interior decoration, sometimes they are hidden between the wall and the facing plasterboard. It is best to choose the external installation option; not only will you not need to manipulate the frame, but in the event of a breakdown or leak, you will be able to quickly gain access to the problem area.

If a combined heating boiler is installed, a special foundation is poured. This stage is necessary due to the fact that the equipment is heavy. The boiler is also insulated, and a combustion product removal system is organized. It is worth noting that it is the combination boiler that causes the most trouble.

Stove heating

Modern stove heating is suitable for frame houses with seasonal and year-round use. Compact steel stoves that do not require a powerful foundation are ideal for krasniks

Solid fuel boiler for heating a frame house

There are several types of solid fuel boilers that can be used for stove heating of a frame house:

- natural combustion boilers;

- automatic solid fuel boilers;

- pyrolysis boilers, the operating principle of which is based on long-term combustion of fuel;

- solid fuel boilers, which supply secondary air to the firebox during operation;

- long-burning furnaces in the upper layer.

If previously solid fuel boilers were primitive, now they are more complex than gas and electric ones. Modern installations extract maximum efficiency from firewood, leaving little ash in the end. There are boilers that require a forced supply of air masses . Then you need to additionally install a smoke exhauster and various devices for controlling the device and monitoring it.

When choosing a solid fuel boiler, you need to pay special attention to what type of firewood should be used to operate it. For example, pyrolysis boilers use firewood whose thickness is over 10 cm and whose humidity is less than 20 percent. To achieve such humidity, you need to store firewood for two years in a specially equipped dry room where there is intense air circulation, or purchase already prepared firewood.

The boiler must be loaded completely - if the firebox is partially filled, all systems will not work properly. You can install a combined solid fuel boiler, in which, in addition to wood heating, gas heating can also be used - this is very convenient and practical.

Useful: Stove in a frame house

Solid fuel boilers have the following advantages:

- small expenses for the operation of the system;

- environmental friendliness, minimal harm to the environment;

- Possibility of use anywhere in the world where there are no communications.

For small houses, heating and cooking stoves , combining a boiler and a stove with or without an oven.

Fireplace for heating

Usually a fireplace is installed in order to create a certain cozy atmosphere, but it can also be a full-fledged source of heat and energy in the house. It will not be enough to heat a large building. If we are talking about a small dacha that is visited occasionally, you can get by with just one fireplace. Also, a fireplace can serve as a source of additional thermal energy if there is a full-fledged heating system.

Based on the type of firebox, modern fireplaces can be divided into two groups:

- short burning;

- long burning.

So, in short-term fireboxes, thermal energy is released very quickly, but the firewood burns out in 5-8 hours. And in long-lasting fireboxes, wood burns for more than 8 hours, but the room warms up slowly. You can change the intensity of air blowing, the power of the fireplace and other characteristics. You can calculate the required power of a fireplace to heat a room as follows: for every 10 sq. m requires 1 kW of heating power.

What to look for when choosing a heating type

The main problem of heat conservation in frame houses is the occurrence of voids in the frame and losses through the floor.

Voids

They can be caused by:

- non-compliance with construction technology;

- design errors;

- caking and settling of the filler under the influence of gravity during many years of operation of the house.

Large detected voids are filled with additional filler, small ones are blown out with polyurethane foam.

In addition to voids, heat loss occurs through frame elements - profiled beams.

Foundation

Insulation of any type of foundation will be ineffective if it comes into contact with groundwater. It is necessary to install a drainage system that drains groundwater below the freezing depth. The thermal insulation of the side faces of the foundation is covered with a layer of gravel of at least 50 cm to reduce seasonal soil pressure.

Tape

The strip foundation is simple in design and inexpensive to construct. However, it serves as a good conductor of frost. To reduce heat loss through the floor, it should be insulated by laying sheets of dense foam plastic or penoplex under the foundation strip and covering it with the same sheets on the outside.

Pile

Metal or concrete piles driven into frozen soil also work as cold bridges. Therefore, the frame beams of the house must be laid on them through a heat-insulating gasket. Decorative cladding of the space under the house will prevent the wind from blowing on the base - another powerful cooling factor.

Plate

The concrete slab poured under the entire house also needs high-quality thermal insulation. The base of the slab should be protected from frost by laying a layer of polystyrene foam or high-density foam. The side edges of the slab are also insulated, otherwise they will become conductors of cold.

Prefabricated frame boiler room (options)

The claimed variants of the utility model relate to installations for providing heat to heating, ventilation, hot water supply and process heat supply systems. In general, a boiler room contains at least one boiler and a burner. Additionally, a system of pumping and heat exchange equipment is located on a portable supporting frame. The frame is non-contactly placed relative to the enclosing structures and/or ceilings and is horizontally oriented along the length of the boiler room. All equipment is located on the frame in order to ensure full access to it along the perimeter of the frame. The collector of the pumping and heat exchange equipment system, which distributes the coolant, is laid along the top of the supporting frame. The created options make it possible to increase the functionality of modular heat supply units.

The claimed variants of the utility model relate to installations for providing heat to heating, ventilation, hot water supply and process heat supply systems, operating on low, medium or high pressure natural gas and (or) light (light) as well as dark (heavy) grades of petroleum products.

Heat supply installations are well known in the form of boiler installations, consisting of a set of devices designed to produce hot water under pressure (see, for example, the Great Soviet Encyclopedia). Boiler installations (hereinafter referred to as boiler rooms/boiler rooms), located in separate buildings and/or built-in premises, are a combination of a boiler, burner and auxiliary equipment located throughout the entire area of the premises used. The boiler room, in addition to the boiler and burner, may include draft devices, gas and air ducts, water and fuel pipelines, fittings, automation, control and protection instruments and devices, as well as water treatment equipment and a chimney related to the boiler. However, the construction of any stationary boiler house is associated with a number of difficulties that the construction and installation organization has to overcome. Often, the difficulty lies in organizing and coordinating work on the construction of a boiler house building, determining the composition, selection and supply of technological equipment, the need to fasten equipment and pipelines to the walls of premises when installing it inside a newly constructed building, and carrying out this type of work requires significant time and material costs .

Such disadvantages are amplified many times over if there is a need to build a boiler house in remote and hard-to-reach areas, which, as a rule, do not have a developed infrastructure and/or are unable to provide the proper level of organization of construction and installation work. Taking them into account, block-modular boiler systems were developed and implemented, the design of which allows them to be transported by all known means of transport and used for heating and hot water supply to household and household facilities. Such installations include block boiler installations of the BKU series (see website https://gazovik-gaz.ru/catalogue/tku/001/), proposed as the closest analogue. Known installations are designed to produce hot water used as a coolant in heating and hot water supply systems for various purposes. The layout of known installations includes a water heating boiler, a burner, a feed pump, a water treatment device and an expansion tank installed in a transportable container.

In general, the disadvantages of both the closest and other analogues of similar installations include the need for individual selection of equipment composition, without the possibility of its subsequent change, the need for individual planning of equipment placement indoors, as well as the inability to supply a mobile boiler installation on a platform without enclosing structures or individual units for the purpose of placement in the premises of an existing or newly constructed building.

Taking into account the above, the author of the claimed utility model set the task of creating variants of a modular heat supply installation that are devoid of the indicated disadvantages inherent in known modular installations. The achieved technical result in the implementation of variants of the declared utility model is to increase the functionality of modular heat supply units, the possibility of equipping with additional equipment throughout their entire service life, standardization of the placement of technological equipment, as well as their versatility, compactness and mobility.

To realize this result, a prefabricated frame boiler room is proposed, which in general contains at least the following fully ready-to-use equipment systems installed with the possibility of interaction:

a boiler equipment system comprising at least one boiler with shut-off, control and safety valves installed on it;

a burner equipment system consisting of at least one burner with fuel fittings installed in front of it, necessary for safe operation;

a system of pumping and heat exchange equipment consisting of at least one circulation pump that ensures the circulation of the coolant of heating supply systems (in addition, the system of pumping and heat exchange equipment may contain equipment for hydraulic coupling of the intra-boiler circuit with heating networks, equipment for the hot water supply system, including heat exchange equipment and flow metering equipment thermal energy).

The pumping and heat exchange equipment system is horizontally oriented along the entire length of the central part of the boiler room, and all its equipment is placed on a support-bearing frame (made with the possibility of contactless placement with the enclosing structures and/or ceilings of the boiler room) with an upper location of the collector that distributes the coolant of the heating systems throughout vertical pipelines displaced in the radial direction, in order to ensure full access to the equipment along the perimeter of the frame from any side convenient for maintenance. In this case, the circulation pump is located within the supporting frame above, if used, horizontally located heat exchange equipment.

The second of the announced options is distinguished by the placement of boiler room equipment systems in a transportable block module. It should be noted that with this design, the support-bearing frames of each of the systems, equipped with technological equipment, are attached only to the floor without additional supports on the enclosing structures of the module and are connected to the centrally located system of pumping and heat exchange equipment using connecting elements.

The third of the stated options involves the location (fixation) of all boiler installation equipment systems on the platform in assembled form and ready for connecting communications, while the platform does not involve the use of enclosing structures and ceilings.

The fourth of the stated options involves the use of all elements completely ready for operation, and the design of the boiler room itself assumes the possibility of its assembly from elements in the premises of an existing or newly constructed building (boiler plant equipment systems, which have their own supporting frames, are supplied separately for the possibility of subsequent installation and assembly in the premises of an existing or newly constructed building by joining interacting elements).

Additionally, each of the implementation options may contain additional equipment systems in the form of the following, designed to interact with each other and the main equipment of the boiler room, completely ready for operation systems:

a fuel equipment system, consisting of fuel fittings and fuel consumption metering equipment required for safe operation, both general and unit-by-unit;

a pressure maintenance equipment system consisting of at least one expansion tank used to maintain pressure in heating systems;

an automatic boiler room control equipment system, consisting of at least one cabinet that provides power supply to the main and auxiliary equipment and control of the boiler plant;

a water treatment equipment system, which includes feedwater treatment equipment;

an auxiliary equipment system consisting of equipment for maintaining pressure in the internal boiler circuit, equipment for the heating system of the boiler room, equipment for cooling emergency wastewater and equipment for emergency power supply.

Each of the boiler room equipment systems has a fixed permanent location within the area planned for the installation of technological equipment, while with a change in the number of additional equipment systems, only the length of the boiler room changes, and the location of the main equipment systems remains unchanged, just as the placement of the pump-heat exchange system remains unchanged equipment in the center of the boiler room. Like the pump-heat exchange system, each of the additional equipment systems has a completely ready-to-use form and provides for the placement of process equipment on separate portable support-bearing frames under the conditions of placing equipment elements in close proximity to each other and access to the working parts of the elements from any convenient location. for serving side.

In general, the claimed utility model consists of a set of main and additional equipment systems and, if necessary, enclosing structures and/or floors.

The structural composition of the main equipment systems is generally known, since it is determined by the general requirements for the composition of any boiler installations. Such elements include a hot water boiler, a burner and a circulation pump, piping connecting the corresponding elements with shut-off and control valves, as well as control and safety system equipment. The number of listed elements, their technical characteristics, and the type of burner power supply (natural gas or liquid fuel) can be different and determined both by the initial operating conditions of the installation and the required amount of supplied thermal energy.

As additional equipment, the claimed utility model can be equipped, if necessary, with fully ready-to-use systems with equipment for maintaining pressure in the heating circuit, hot water supply equipment (including heat exchange equipment), means for metering fuel consumption and thermal energy, equipment for preparing feedwater, etc. d.

A distinctive feature of the claimed utility model from existing boiler houses is the ease of retrofitting it with additional equipment without changing the design and location of the main equipment systems, by supplementing the boiler installation with standard systems of additional equipment located in clearly defined places in the space allocated for installation of technological equipment, on both sides of centrally located system of pumping and heat exchange equipment.

The advantages of the claimed utility model also include the compactness of the solutions used for the installation of main and additional equipment, due to the placement of technological equipment on portable support frames in close proximity to each other and access to the working parts of the elements from any side convenient for maintenance. Support-bearing frames of the main and additional equipment systems do not require fastenings to the enclosing structures of boiler rooms (i.e., the frames are placed without contact with such enclosing structures and/or ceilings, in other words, they do not have fastenings to such elements), and for greater compactness the distances between process equipment do not exceed the minimum possible necessary to ensure general safety requirements, and the space between the equipment is used only for the location of piping.

It should also be noted that to simplify access to the equipment of the installation during its operation (for the purposes of repair, prevention, maintenance, etc.), passages are provided between the structural elements of the equipment systems, providing access to the working parts along the entire length of the technological systems.

Essentially, the declared options represent a boiler installation that is completely ready for operation, assembled on a turnkey basis from systems of primary and additional equipment that are completely ready for operation, both at the manufacturer and at the place of its operation. At the same time, the composition of additional equipment can be changed at any time during the operation of the boiler room without changing the design and location of the main equipment systems, which significantly reduces both time and financial costs for the reconstruction of the installation.

Preparing a boiler room for operation essentially only involves placing it in a module, platform or other room with subsequent connection to external piping systems, as well as power supply and security systems.

The above, clearly, allows us to draw a conclusion about the significant advantages of the declared utility model, since a clear definition of the locations of the main and additional equipment systems, coupled with the compact design of the process equipment systems, can significantly reduce the costs of technological re-equipment of the boiler plant, while reducing the requirements to the size of the area allocated for its construction. In this case, the second design option for a prefabricated frame boiler house essentially makes it possible to place it outdoors, without requiring the presence or construction of special premises.

The advantages of prefabricated frame boiler houses also include the fact that during their operation the presence of service personnel is possible only in specially designated passages, which makes it impossible for them to stay in the spaces between the process equipment and, in turn, ensures an increase in the level of labor safety during operation boiler installations.

In conclusion, it should be noted that the declared model, if it is necessary to use it in the premises of existing or newly constructed buildings, guarantees a reduction in the costs of organizing and performing construction and installation work, which is undoubtedly its additional advantage.

The declared prefabricated frame boiler houses, which have both their own enclosing structures and those built into existing or newly constructed buildings, are divided according to their purpose into:

- heating - to provide heat to heating, ventilation and hot water supply systems;

— heating and production — to provide heat for heating, ventilation, hot water supply and process heat supply systems;

- production - for process heat supply.

1. Prefabricated frame boiler house containing at least one boiler and burner and a system of pumping and heat exchange equipment located on a portable support frame, horizontally oriented along the length of the boiler room so as to ensure full access to it along the perimeter of the frame and the absence of fastenings to the enclosing structures walls and/or ceilings, and the collector of the pumping and heat exchange equipment system, distributing the coolant, is laid along the top of the supporting frame.

2. The boiler room according to claim 1, additionally containing fully ready-to-use additional equipment systems in the form of at least one of the following elements: a fuel equipment system, including fuel fittings and fuel consumption metering equipment required for safe operation, a pressure maintenance equipment system, including at least one expansion tank, an automatic control equipment system, including at least one power supply and control cabinet, a water treatment equipment system, an auxiliary equipment system, including equipment for maintaining pressure in the internal boiler circuit, equipment for the heating system of the boiler room, emergency waste water cooling equipment and equipment emergency power supply, located on portable support-bearing frames that do not require fastenings to the enclosing structures of walls and ceilings, on both sides of the centrally located system of pumping and heat exchange equipment, and designed to interact both with each other and with the systems of the main equipment boiler room by connecting to the pumping and heat exchange equipment system.

3. Prefabricated frame boiler house containing at least one boiler and burner and a system of pumping and heat exchange equipment located on a portable support frame, horizontally oriented along the length of the boiler room so as to ensure full access to it along the perimeter of the frame and the absence of fastenings to the enclosing structures walls and/or ceilings, the collector of the pumping and heat exchange equipment system, distributing the coolant, is laid along the top of the supporting frame, while all the elements of the boiler room are located inside the transportable block module.

4. The boiler room according to claim 3, additionally containing fully ready-to-use additional equipment systems in the form of at least one of the following elements: a fuel equipment system, including fuel fittings and fuel consumption metering equipment required for safe operation, a pressure maintenance equipment system, including at least one expansion tank, an automatic control equipment system, including at least one power supply and control cabinet, a water treatment equipment system, an auxiliary equipment system, including equipment for maintaining pressure in the internal boiler circuit, equipment for the heating system of the boiler room, emergency waste water cooling equipment and equipment emergency power supply, located on portable support-bearing frames that do not require fastenings to the enclosing structures of walls and ceilings, on both sides of the centrally located system of pumping and heat exchange equipment, and designed to interact both with each other and with the systems of the main equipment boiler room by connecting to the pumping and heat exchange equipment system.

5. Prefabricated frame boiler house containing at least one boiler and burner and a system of pumping and heat exchange equipment located on a portable support frame, horizontally oriented along the length of the boiler room so as to ensure full access to it along the perimeter of the frame and the absence of fastenings to the enclosing structures walls and/or ceilings, the collector of the pumping and heat exchange equipment system, distributing the coolant, is laid along the top of the supporting frame, while all the elements of the boiler room are located on a platform that does not have enclosing structures of walls and ceilings.

6. The boiler room according to claim 5, additionally containing fully ready-to-use additional equipment systems in the form of at least one of the following elements: a fuel equipment system, including fuel fittings and fuel consumption metering equipment required for safe operation, a pressure maintenance equipment system, including at least one expansion tank, an automatic control equipment system, including at least one power supply and control cabinet, a water treatment equipment system, an auxiliary equipment system, including equipment for maintaining pressure in the internal boiler circuit, equipment for the heating system of the boiler room, equipment for cooling emergency effluents and emergency power supply equipment located on portable supporting frames that do not require fastenings to the enclosing structures of walls and ceilings, on both sides of the centrally located system of pumping and heat exchange equipment, and designed to interact both with each other and with the systems of the main boiler room equipment by connecting to the pumping and heat exchange equipment system.

7. Prefabricated frame boiler room containing at least one boiler and burner and a system of pumping and heat exchange equipment located on a portable supporting frame, horizontally oriented along the length of the boiler room so as to ensure full access to it along the perimeter of the frame and the absence of fastenings to the enclosing structures walls and/or ceilings, a collector of the pumping-heat-exchange equipment system, distributing the coolant, is laid on top of the support-bearing frame, while the above elements are completely ready for operation, and the boiler room is made with the possibility of assembly from such elements in the premises of an existing or newly constructed building.

8. The boiler room according to claim 7, additionally containing fully ready-to-use additional equipment systems in the form of at least one of the following elements: a fuel equipment system, including fuel fittings and fuel consumption metering equipment required for safe operation, a pressure maintenance equipment system, including at least one expansion tank, an automatic control equipment system, including at least one power supply and control cabinet, a water treatment equipment system, an auxiliary equipment system, including equipment for maintaining pressure in the internal boiler circuit, equipment for the heating system of the boiler room, emergency waste water cooling equipment and equipment emergency power supply, located on portable support-bearing frames that do not require fastenings to the enclosing structures of walls and ceilings, on both sides of the centrally located system of pumping and heat exchange equipment, and designed to interact both with each other and with the systems of the main equipment boiler room by connecting to the pumping and heat exchange equipment system.

Advantages of gas heating compared to electric.

- Low heating costs over a long period of time.

- There are no restrictions on the power of heating devices. Electric heating is usually limited to a total power of 15 kW.

Comparative table of the cost of gas and electric heating for a house of 100 square meters. meters

| Expenses | Gas heating | Electric heating |

| Boiler room equipment | from 120,000 rubles with installation (licenses required) | 12,000-40,000 rubles depending on the equipment, we take 20,000 rubles |

| Connecting to networks | 150,000-500,000 rubles and above, let’s say 250,000. | By default, the house is connected to the power grid |

| Annual heating costs (at the rate of 35,000 kW/h, with normal insulation of the house) | 20,562 rubles (in other regions the cost may be slightly different) | 75000 (including rural areas and night rate) |

| Service costs per year (taking into account equipment depreciation over 15 years) | 8000 rubles | 1000 rubles |

| Total expenses for 15 years | 798430 rubles | 1,165,000 rubles |

When considering these two tables, you should keep in mind that for your area, your prices, your home, the situation may be different. The main rule is that in order to make an informed decision about choosing a heating system, you need to carefully calculate everything. For example, the presence of a gas pipeline at the border of the site plus the choice of gas heating, and the distance from gas pipelines, as a rule, closes this topic altogether.

Comparative table of the cost of gas and electric heating for a house of 70 square meters. meters

With even smaller house sizes, installing gas heating becomes unprofitable compared to electric heating. At the same time, electric heating has a number of undoubted advantages compared to gas heating, which makes us think about its use even in houses larger than 70 square meters:

Heating a house without gas using electricity

Quite often, owners of country houses are faced with the serious question of how to cheaply heat a house without gas. The most common heating method is the one that uses electricity.

Depending on your financial capabilities, you can choose installations and equipment that will be able to provide maximum heating.

Electrical units are available in the following varieties: fireplaces, fan heaters, underfloor heating systems, infrared heating, and convectors. Popular “warm floor” systems are often used to supply heat to residential premises if there is a need to heat the house without using gas. They are installed not only on the floor, but also on the surface of the walls, as well as the ceiling. For a country house, the most relevant solution would be fan heaters, which raise the indoor temperature to an acceptable level within a short time.

A highlight worth noting

How does a frame house differ from, for example, a brick house? According to the technology, a “skeleton” is first built - a frame that is “overgrown” with several sound, moisture and heat insulating layers. The wall becomes like a multi-layered sandwich.

"Sandwich" in section

The layers consist of:

- from expanded polystyrene;

- polyurethane foam;

- mineral wool;

- stone wool;

- vapor barrier film;

- various decorative facing materials.

If heating in a frame house works well, then ventilation and humidity remain a problem. Multilayer walls have poor thermal conductivity or, in other words, the heat inside the house remains there.

The internal space is hermetically sealed in a state-of-the-art impenetrable shell. A frame house, unlike its brick counterpart, will not quickly freeze out, and heating savings reach up to 30%!

What is included in the turnkey frame house construction service?

Turnkey frame houses are a new, interesting and sustainable trend in suburban construction. This is a worthy replacement for traditional capital buildings, characterized by lightness, warmth and durability. In addition, frame house projects are much cheaper, are implemented faster, and the finished houses have excellent performance characteristics. From a technical point of view, a frame frame is a structure based on a load-bearing frame made of durable profiles, filled with insulation and sheathed with certain wall materials depending on the wishes of the customer. This is an effective technology for modern suburban construction in any climate zone, has many advantages, and is widespread in many countries. The advantages of building frame houses are largely determined by the activities of the construction industry; there is sufficient experience not only in assembling, but also in designing houses.

Our commercial offer for projects and construction of frame houses includes:

- Individual home design;

- Extensive catalog of standard projects;

- Adaptation of the project to the site, capabilities and wishes of the client;

- Turnkey house construction;

- Development of an interior design project;

- Development of landscape design;

- Internal and external finishing works;

- Installation of engineering communications;

- Technical Supervision;

- Legal support.

General requirements for a boiler room in a wooden house

First, let's look at the list of general requirements for the arrangement of a boiler room, and only then we will highlight and discuss the most significant of them. This does not mean that the points not touched upon are not important. No. They are simply obvious, and in most cases they will not be violated.

The general requirements for arranging a boiler room in a wooden house include the following points:

- The boiler room must be located in a separately equipped room, and under no circumstances in a residential one.

- The dimensions of the boiler room must comply with the standards established by SNiPs.

- The room with heating equipment must have properly equipped and efficient ventilation.

- The boiler is selected in accordance with the required thermal output.

- The installed boiler must be provided with normal, unobstructed access not only for setup and operation, but also for service and major repairs without dismantling.

- It is prohibited to store fuel in the boiler room of a wooden house.

- In wooden houses, special standards regarding the arrangement of the chimney system must be observed.

- In wooden houses, automatic fire extinguishing systems and means must be provided directly in the boiler room.

- When using atmospheric heating units, it is necessary to ensure access of fresh air into the room in sufficient quantities.

- Wooden boiler room walls must be properly screened.

Let us dwell in more detail only on some points that are of particular importance when arranging boiler rooms in wooden houses.

Communications in a frame house. Electrics

The power supply system of a frame house consists of an external and internal electrical network. The internal one, in turn, consists of a panel, sockets, switches and current consumers. In our area, the current is usually connected from a pole through the air, after which the input node into the house must be grounded again, even if grounding has already been done at the pole. First, we decide on the layout, then we think through all future consumers (household appliances, appliances, etc.) in our layout. It is especially necessary to determine precisely the “special” consumers (stove, refrigerator, hob, boiler). These consumers are special, they either have their own special automatic machine or they must be placed on a special non-disconnected line, etc. This is not your headache, but headache for the designer of your future shield (I wouldn’t dare to design the shield myself, there are a lot of subtleties in this matter). It is best to find a craftsman whom you trust. As with the design of a frame house, it is better to trust this matter to an experienced designer, and not to a company - one-day event.

Primary requirements

The boiler unit (depending on the size and type) can be installed in a separate room on the ground floor, in the basement of the house or in the attic (but this must be provided for by the layout of the house, determined at the design stage).

It is also possible to use an autonomous module (container with a mini-boiler room), erect a special extension or a separate building. As a separate structure, a ready-made mobile boiler room can be used, mounted from sandwich panels and finished with non-combustible materials.

The heating unit can be solid fuel, liquid fuel or gas. Depending on the type of heating unit, the requirements for a boiler room in a private house have some differences.

The design standards for a boiler room in a private house provide

:

- compliance with requirements regarding room size;

- installation of no more than two boiler units in one room;

- absence of flammable materials in the finishing of surfaces and roofing;

- the presence of doors to the street and to the house (for an extension);

- competent selection and installation of doors: they must be included in the fire category and open outward, like the door of an adjacent room in the house;

- unobstructed access to all heating equipment;

- installing a window with a window for natural light and emergency ventilation, the window sashes should swing outward, and the glass area should correspond to the volume of the room (0.03 m2 per 1 cubic meter);

- the presence of natural or forced ventilation, which is calculated as follows: (room width x ceiling height x room length) x 3. As a result, we get the volume of air that needs to be replaced in one hour;

- the presence of a chimney, if required by the type of boiler (for units with a power of less than 30 kW, the chimney pipe is allowed to exit through the wall);

- connecting the water supply (for filling and recharging the heating circuit) and sewerage (for draining water from the system);

- installation of a separate foundation for boilers weighing more than 200 kg (installation of lighter models on a reinforced concrete floor is allowed).

For wooden walls of built-in and attached boiler rooms (which are common with the rest of the house) a non-combustible finish is needed that can increase the fire resistance limit of structures to 0.75 hours. To build an extension, it is recommended to use bricks, blocks and other non-combustible materials.

Boiler room plan in a private house

Basic standards regarding room dimensions

:

- ceiling height: should be from 2.5 m with a heating unit power over 30 kW, for less powerful boilers the figure is at least 2.2 m;

- boiler room volume: from 15 m 3 (if the heating unit is planned to be installed in the basement, then when calculating the volume of the room you need to add 0.2 m 2 for each kW of boiler power);

- The boiler room area must be at least 6 m2.

The minimum area makes it possible to ensure the safe operation of the equipment, but for ease of installation and maintenance of the heating system, it is still recommended to equip more spacious boiler rooms.

In the boiler room of a private house, the layout of which is developed taking into account the characteristics of the selected unit, it is necessary to provide free access to the boiler piping elements, control valves, and electrical equipment.

Electric heating

Most often, heating a frame house with electricity surpasses other options in popularity. Installation of electrical appliances does not require additional permits, they do not depend on environmental conditions, and do not require additional consumables.

Electrical heating circuit.

An electric boiler is installed in accordance with the rules for installing other electrical equipment: all wiring in a frame house is calculated according to the power of the device with a reserve and is reliably insulated.

The following types of electric heating can be used in a frame house:

Warm floor

Warm floors in a frame house are installed on the subfloor. The surface must be covered with a vapor barrier material. It will protect the flooring from high humidity. Reflective material is placed on the prepared surface, which will prevent heat dissipation; thermal mats are placed above. The floor is finished and all system controls are installed.

Installation of a warm house.

The main advantage of a heated floor is air heating of a frame house; warm air rises evenly from the floor and is distributed over the entire surface, while cold air gradually falls down, where it is also heated.

Electric boiler

Installation of an electric boiler can be carried out without the involvement of specialists, but the following must be observed:

- Wire cross-section, according to the technical documentation of the equipment.

- The switch is located in the same room as the boiler.

- If a boiler is used, it is mounted above the electric boiler.

- All electrical wiring in a frame house is laid in advance.

- During installation, the necessary safety rules are observed to avoid electric shock.

During operation of the electric boiler, monitoring is constantly carried out for the absence of leaks and poor insulation.

ELECTRICAL SYSTEM

Heating a frame house with electricity provides three options:

- convection heating;

- warm floor;

- electric boiler;

electric heating system

Each of them has its own advantages and disadvantages. The first method is more expensive in terms of energy consumption. The second is more economical, but in severe frosts one such source will not be enough to heat the entire house.

Convector heating

The number of convectors should be calculated on the basis that one heating element serves an area of 20 m². Installation costs are quite small, but if you take into account the constantly growing cost of electricity, heating a frame house with convectors will be quite expensive.

Warm floor

This type can be used for any floor covering - ceramic tiles, laminate, parquet, linoleum. To heat a room with an area of 20 m², it is sufficient to lay heating pipes in a frame house on an area of 15 m². Only the free space of the room is used; there is no need to install a heating system under the furniture.

Laying features

The correct layout of pipes is carried out according to project diagrams or the drawing is carried out independently. Setting up electric heating for a frame house is not particularly difficult, but in order to get a high-quality coating, it is advisable to adhere to the following recommendations:

- The film is laid on a clean floor plane. It serves as a vapor barrier and is also needed to protect the floor from the cement mixture.

- The next layer is a special mesh. It serves as a reinforced base in the arrangement of a heated floor.

- The mesh is being fixed. You can attach it to the floor using self-tapping screws.

- Pipe elements are laid according to the chosen scheme.

- The heating pipe in the frame house is being fixed. Fastening to the floor is carried out with special electrical devices - clamps.

- Next, you need to perform general assembly of the entire line and install the collector. Additionally, balancing valves are installed. They will regulate the flow in each pipe loop.

- A sand-cement mixture is prepared, with the addition of crushed stone manually or using a concrete mixer.

- The beacons are placed and the screed is poured.

- After pouring, the floor is covered with plastic film. All windows and doors in the room must be closed. This is necessary so that the screed hardens evenly.

- After hardening, the beacons must be removed and their installation sites covered with new mortar. (you can read what drilling fluids are here)

So, a frame house is heated, the video will clearly demonstrate all the details.

electric boiler for heating a frame house

Electric boiler

The use of home heating based on an electric boiler is more popular than others. The main element in them is the heating element, which allows you to convert electrical energy into heat. Compared to heating with convectors, heating a frame house with an electric boiler will be very economical in terms of energy consumption.

When installing heating in a frame house , be sure to comply with electrical safety requirements:

- the selection of cross-section and connection of wires should be carried out only according to the manufacturer’s recommendations;

- all wiring must be pre-installed before starting installation work;

Before starting installation work, you must make sure that the walls can support the weight of the boiler. Also, so that there is easy access to it during possible repair work.

Heating a frame house with gas

Heating a frame house with gas is one of the popular options for heating a room. It is the gas boiler that has been used for many years as a reliable way to obtain heat.

On a note

When choosing gas heating, it is worth remembering that it is not so easy to supply gas to a frame house: it will take several months to go through various authorities and obtain all permits.

Gas heating of a frame house also requires specialized equipment, which is quite expensive. Carrying out all the work on installation, installation and startup will cost a pretty penny, so it is much easier to give preference to electric heating.

A gas boiler.

But in the long term, gas heating will be more profitable than other types of heating for a frame house. Due to the low price of gas, it will cover all costs for installation and gas equipment. And in just a few years you will be able to save on heating a frame house with gas.

Fan heaters

The most affordable devices for heating with electricity are fan heaters. According to the principle of operation, these devices are similar to convectors, but fan heaters provide forced air circulation, due to which the room is heated more evenly and faster.

The fan heater itself does not heat the air, but passes it through heating elements - heating elements. For example, spirals or a heat exchanger with hot water.

Due to the high energy consumption, this heating method is considered extreme. It is more suitable for cases when you need quick heating of an entire frame house or a separate room.

As a constant source of heating, using a fan heater will be ruinous for the budget. In addition, such devices are noisy, they fail faster than convectors, and due to the formation of dust on the coils, an unpleasant odor appears. Therefore, experts advise using fan heaters to heat a home only during the construction phase.

Electric heating

Heating of a frame house with electricity is carried out using various electric heaters.

Warm floor

The heating cable or electric heated floor mats are also laid inside the cement screed layer.

Cable or mats

What to choose? The energy efficiency of the two types of heating is the same. Mats are much more convenient to lay; they do not require reinforcement mesh. However, the cable can be laid in a heating zone of any shape, and the mats can only be laid in a rectangular one.

Infrared film

This type of electric heated floor does not require a cement screed and does not reduce the height of the room. A thin film that emits infrared rays is placed directly under the floor covering.

It is significantly more efficient than cables and mats, since there are no losses due to heating of the screed. The disadvantage of IR film is its high price.

Features of surface preparation

Before installing a cement screed or laying a film, it is necessary to carefully level the subfloor. the protrusions need to be sanded, the depressions and cracks need to be sealed with putty. After sanding, vacuum and degrease the surface.

Use of vapor barrier and waterproofing

It is imperative to lay a layer of waterproofing under the screed. It will protect it from absorbing moisture. Next, you need to place a layer of thermal insulation, especially if there is a cold room below. A vapor barrier membrane is placed above the screed, removing water vapor from the cement layer.

Thermostats

The simplest thermostats control the power of the heater. Improved models can maintain a constant temperature. For this purpose, they are equipped with a built-in or remote temperature sensor.

Devices with a built-in sensor measure the temperature at the height of their placement. Devices with a remote sensor can be placed where it is convenient, and the sensor can be installed at the height at which the set temperature needs to be maintained.

Power calculation

The electrical power of any underfloor heating element is indicated on the packaging. The efficiency of its conversion into thermal power will depend on compliance with installation recommendations. For heating cables and mats it can reach 90%, for infrared films - 99%.

Energy consumption

The energy consumption of a heated floor system can be reduced in the following ways:

- improved thermal insulation of the subfloor;

- installing a heat-reflecting layer on top of the insulation;

- use of an automated control system.

Such systems allow you to programmatically reduce the heating power while no one is home, and quickly warm up the room before the residents return.

Electric convectors

The heating element is housed in a lightweight casing with wide slots at the top and bottom for air flow in and out. The air flows around the heater and is heated by it. The casing has a low temperature and protects the inhabitants of the house from possible burns.

How to choose the right power

What power should I buy a heater? The formula for assessing power is similar to that used for the water circuit: for every 10 m2 - 1 kilowatt of thermal power.

The efficiency of electric convectors reaches 95%. So, to heat a room of 18 m2, a 2 kW convector is theoretically sufficient. In practice, they always make a 20-30% power reserve for extreme weather conditions.

Installation options

Wall mounted

Convectors are attached to the wall using brackets. They have permanent hidden wiring and are controlled using a thermostat installed in a convenient location.

Floor-standing

Such convectors are installed on the floor and connected via a network cable to the nearest outlet. To increase modularity, they are equipped with wheels and a handle. Such devices are used to temporarily warm up the required areas. Their energy efficiency is lower than that of wall-mounted

Is it possible to make a single system using thermostats?

To do this, you will have to select a thermostat of sufficient power and connect to it in parallel several convectors installed in the same or adjacent rooms. The cable cross-section must withstand a current corresponding to the maximum total load.

Warm floor

The underfloor heating system is installed on subfloors. It is first necessary to install a vapor barrier on the surface to protect the floor from moisture. Next, heat-reflecting material is laid to prevent heat dissipation, after which heating mats are laid. Finally, finishing and installation of heated floor control systems are carried out.

The advantage of the solution is that warm air rises up from the surface of the floors and is distributed throughout the entire space of the room, and cold air falls to the bottom, where it also warms up.

Air heating

If desired, a frame house can also be heated with air heating. The advantages of such a system include:

- Fast response to temperature changes

- Fast warm-up

- No heating devices on the walls

Disadvantages of air heating of a frame house:

- The system is expensive

- Constant noise during operation

- Often takes up extra height under the ceiling

Our recommendation will still be that it is better to use water heating for a frame house.

Application of electric boiler

Electricity in frame houses is used mainly when there is no access to the main gas pipeline, and the use of liquefied bottled gas is approximately 10 times more expensive. Electric boilers are a fairly new invention that actually convert electricity into heat. The method has its advantages:

- Easy to use

- Convenience

- Small size and great appearance

- Maximum efficiency rate

- Relatively low costs

- Possibility to vary tariffs and choose the most optimal one

Use of solid fuel boilers

When deciding how to heat a private house without gas, you may prefer a solid fuel boiler. This heating option has become especially popular in European countries. This type of solid fuel units can provide economical heating, as well as ease of operation. Such devices operate not only on wood, but also on pellets, coal, and peat. Heat will be supplied through the pipeline thanks to water, which acts as a coolant. This heating method allows you to maintain the required temperature inside the premises for a long time, all this is ensured thanks to a sufficiently long burning of fuel in just one load.