Features of heating frame houses

One of the main features of frame houses is their high energy-saving qualities.

Heating of a frame house should be arranged in such a way that the process of dissipating thermal energy from the house into the environment occurs as slowly as possible.

This requirement is dictated by a distinctive feature of frame houses - thermal inertia.

It is important to understand that such a house is neither warm nor cold.

All thermal energy used for heating is produced inside the house.

The type and characteristics of the source are not of fundamental importance.

To heat a frame house, thermal energy can be obtained as follows:

- When burning natural or liquefied gas.

- When burning diesel fuel.

- When burning solid fuel (wood, coal, pellets, etc.).

- When using electrical energy to heat water or air.

- Using modern highly efficient technologies (subsoil energy, solar energy, etc.).

Fuel combustion processes take place in special heat-generating devices - boilers. Heat supply systems (heating, hot water supply, ventilation) of a frame house may include the installation of gas, electric, solid fuel, liquid fuel or combination boilers.

Combined version of the heating device for a frame house

Below we give a detailed description of a simple and effective option that allows you to organize the heating of a frame house using a combined circuit with your own hands.

This scheme can be safely called combined, since it incorporates various technical solutions:

- Electricity, solid fuel (wood) and solar energy are used as energy sources.

- The boiler room will contain an electric boiler that heats water for the heat accumulator at a nightly rate. In the evening, a wood-heated fireplace equipped with a water jacket will be used. In clear weather, free solar energy will be used to heat water in a vacuum collector located on the roof.

- The internal heating system is made in the form of a water heated floor, arranged in a screed.

The choice of this system is due to the lack of possibility of using natural or liquefied gas. The main advantages of the described scheme are the ability to do it yourself and versatility (an electric boiler can be replaced with a gas one, and heated floors with ordinary radiators).

Air heating

If desired, a frame house can also be heated with air heating. The advantages of such a system include:

- Fast response to temperature changes

- Fast warm-up

- No heating devices on the walls

Disadvantages of air heating of a frame house:

- The system is expensive

- Constant noise during operation

- Often takes up extra height under the ceiling

Our recommendation will still be that it is better to use water heating for a frame house.

Installation of heated floors

Before installing this system, you need to purchase some installation materials: sensors, fittings, pipes. The sequence of actions will look like this.

An inexpensive vapor barrier film is laid on the subfloor (made of 18.3 mm OSB). The film is attached to the floor using a stapler, and the joints are taped.

The functions of the vapor barrier film are to create a closed loop together with the vapor barrier of walls and ceilings, to protect the flooring and insulation from seepage of cement mortar when pouring the screed.

A road mesh with parameters 200 x 200 x 4 mm is laid on the film. In the future, heated floor pipes will be mounted on this grid.

The mesh is attached to the subfloor using self-tapping screws and pieces of punched paper tape. The fact that the road mesh does not sink into the middle of the screed somewhat reduces its reinforcing properties.

However, for the operating conditions of an ordinary residential building this will be sufficient.

At the next stage, the pipe is laid out according to the preliminary diagram or design solution. The pipes are laid in a snail shape and secured to the floor using ordinary electrical clamps.

Scheme for laying heated floors in a frame house. Click to enlarge.

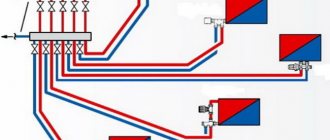

Next, the floor collector is installed and the overall system is assembled using fittings.

Before pouring the screed, beacons are installed (if necessary) and a sand-cement screed is prepared. To mix the solution, you can use a concrete mixer or shovel. During the mixing process, be sure to add crushed stone to the screed.

After pouring the screed, you do not need to cover the surface with plastic film. Simply close all windows and doors until it hardens completely. The screed filling stage is completed by removing the beacons and grouting with fresh mortar.

When installing manifolds at each stage, it is important to remember the need to install special balancing valves. These valves regulate the coolant flow depending on the temperature curve in each loop.

Heating frame (and not only) houses using heated floors is most effective with high-quality thermal insulation of all surfaces, which is quite easy to do with your own hands.

Classic fireplace design

The standard version of the fireplace consists of the following parts:

- the firebox is a place in the fireplace that is U-shaped and framed by a portal. For better combustion of combustible material, a grate or hearth is installed in its lower part;

- perval or otherwise smoke tooth is a special narrowing to the chimney that provides better draft;

- chimney - provides fairly good removal of combustion products and excellent air supply.

The modern version of the fireplace provides the most accurate non-standard heat exchange system, which increases the efficiency of the device and ensures the preservation of a certain amount of air in the room. Thus, the air under the grate is not collected from the room, but comes from outside. Special holes are formed in the floor of the room, which supply air to the channels from the back wall of the firebox. This heated air begins to move to the tubular heater a little below the pass, and only then into the room. As a result of this, the air will take heat from the combustion products and transfer it to the room and reduce the temperature of the exhaust gas.

Although, this solution does not fully compensate for the air gap from the room. For example, it is not recommended to install fireplaces in frame houses in rooms with a volume of less than 30 m2?

This is especially important for modern houses with sealed windows and doors of increased density

Foundation for a classic fireplace

The weight of a classic fireplace of 15 tons poses a significant problem for different types of foundations. All projects of frame houses with fireplaces include the installation of a special, more powerful base under the hearth or stove. If this foundation was not planned, then you can safely forget about installing a fireplace in a frame house.

The frame house itself is light in weight when compared to a brick building. Therefore, the foundation for it is usually made lighter, for example, a shallowly buried strip. A stone fireplace is another matter; under it it is necessary to install a monolithic concrete slab, around the entire perimeter 30 cm larger than the original dimensions of the fireplace. The foundation must be buried below the freezing level of the soil and ground and not connected to the foundation of the house. A strip foundation can swell when the soil freezes and thaws, but monolithic ones will not react to this in any way, which is why it is prohibited to connect them into one single system.

A more correct option would be a regular fireplace in a frame house on screw piles. Swelling when the soil freezes does not affect this foundation at all, and the base of the fireplace and walls can be connected.

In a frame house with a foundation on screw piles, additional metal sheets are laid under the fireplace, which are tied together with a channel and special sheet metal 10 mm thick.

This steel platform under the fireplace can fully withstand a certain load.

This method is used in the construction of special outdoor stoves or barbecues.

Fireplace safety

The fireplace is an open type structure, that is, access to the fire is open all the time, and this, of course, creates a characteristic threat. In order to reduce it, the fireplace is installed in compliance with a certain number of rules.

Consider these rules below:

- The walls of the fireplace and chimney should not come into contact with the frame and insulation material. The vapor barrier layer and sheathing at the joints are protected with special heat-resistant building materials.

- The fireplace is built in and mounted into the internal partition, made of sand-lime brick in this place. This is the best option.

- The fireplace sits on its own concrete base. The danger zone in front of the firebox is covered with a special fire-resistant coating, for example, brick, tile and stone, it all depends on the building material of the main flooring.

- The chimney pipe is removed in compliance with all fire safety rules: the pipe must be insulated and insulated at a certain intersection of ceilings or walls.

Electric boiler installation

When installing an electric boiler with your own hands, you should pay special attention to some issues:

- It is necessary to comply with the wire cross-section in accordance with the manufacturer's requirements.

- The boiler switch must be located in the same room as the boiler.

- The connecting dimensions to the boiler should not be narrowed.

- It is necessary to lay the wiring for the connected sensors in advance.

- When designing a scheme for the simultaneous operation of a boiler and a hot water supply boiler, it is necessary to provide for the height of the suspension in such a way that it is possible to install the boiler.

And, of course, when installing and operating an electric boiler, it is necessary to follow safety rules to avoid electric shock.

It is imperative to ensure that there are no leaks or leaks in the connecting and shut-off valves, and to prevent physical contact of live parts and elements with moisture.

Solar collector installation

The solar collector used in the scheme described in this article can be manufactured independently or purchased assembled through a retail chain.

The first option is less expensive and more interesting, since it involves not only installation, but also making it yourself.

The simplest diagram of a solar collector device looks like this:

- A solar panel consisting of a PVC pipe installed on a section of roof painted black.

- Insulated container located in the attic.

- Circulation pump.

- Automatic protection and regulation system.

The efficiency of this system is inferior to factory analogues, but is a completely acceptable option for equipping a country house or a large bathhouse.

Choice of coolant and other nuances

Heating, arranged not only according to the scheme described in the article, in a frame house can be effectively operated with various coolants.

When choosing a coolant, it is important to seek help from a professional. Click to enlarge.

Currently, along with the water familiar to most people, various non-freezing liquids are actively used, reducing the risk of freezing of the heating system when forced to stop in winter.

When switching to non-freezing liquids, you should pay attention to the boiler parameters and the manufacturer’s recommendations. Some manufacturers of boiler equipment provide a guarantee only when water is used.

A good alternative to using non-freezing liquids instead of water would be to solve the issue of equipping circulation pumps with an additional source of energy.

Connection of underfloor heating collectors or radiator lines to the boiler is carried out according to standard piping diagrams for boiler equipment.

There are no nuances regarding use in frame housing construction conditions here. In the case of using an electric boiler described in the article, copper and soft solder were used for connection.

Mandatory elements used when piping a standard closed-type heating system (without the use of coolant for hot water supply needs) include a circulation pump, safety group equipment (instrumentation and automation devices, safety valves, check valves, etc.), shut-off, control and drainage fittings, automatic air vents.