Arrangement of floors in a frame house on stilts is one of the most important stages of this construction technology. If the so-called “pie” of the floor is done incorrectly, then the rooms will be damp, uncomfortable, and cold. Not only residents, but also building materials - wood and insulation - can suffer. We offer you a brief excursion on the topic of proper arrangement of floors in a frame house on stilts, taking into account the features of this type of foundation.

Floor materials

When constructing a floor in a house on screw piles, it is equally important to use well-dried wood. If you are going to make the floor with your own hands, you first need to choose the right building materials.

When choosing the type of wood from which the main load-bearing parts of the structural floor pie will be made, you should take into account the climatic conditions of the construction region, the intensity of the loads on this structural part of the house, your financial capabilities, as well as the characteristics of each room, for example, in the bathroom you will need good waterproofing of the floor. When building a house on screw piles, the frame of the first floor can be made using the following types of wood:

- Needles. This type of wood is relatively inexpensive, durable and strong. It is suitable for construction in small spaces, for example, in a bathroom or hallway.

- Aspen and oak are more expensive types of wood. Their performance indicators of strength, reliability and durability are significantly higher than those of other breeds. Using elements from these types of wood, you can make frame structures in a children's room and bedroom.

When constructing a floor in a house on screw piles, it is equally important to use well-dried wood. If you build a floor from wet material, then as it dries, cracks will form in the structure. The external condition of wooden elements for building a house is no less important. They should be free of stains, cracks and other defects.

Advice: to install a floor in a house on stilts, it is better to buy 1st grade wood with a moisture content not exceeding 20%.

To correctly calculate the required volume of material, it is necessary to add 10% to the area of the room. The flooring of a house on screw piles is best made from two-meter boards. To avoid discrepancies in color and texture, you should purchase products from the same batch. The best flooring for any floor of a frame house will be a tongue-and-groove edged board. It does not require finishing grinding, which will reduce work time and reduce labor costs.

Features of a screw pile foundation

Most often in our country, frame houses are placed on a pile foundation. This is due to the fact that, at a fairly low cost, it is suitable for most types of soil. It can also be furnished with the owner’s own hands.

The main principle of such a foundation is that along the line of the future partitions of the structure, piles of a length that correspond to the type of soil on the site are placed. The main principle for selecting the length of the pile is that it should go half a meter deeper than the horizon with stable soils.

The optimal distance between piles is two meters. This is quite enough for a two-story house of average size to stand normally. In some cases, the distance is reduced. It should not exceed a maximum of three meters.

Piles are made of stainless steel. Their diameter must be at least 108 mm - in this case they can withstand a load of up to 9 tons. There are also thicker piles, but they are usually used for stone, monolithic structures.

Before you start driving piles, you need to thoroughly prepare the area for work. To do this, it must be cleared of plants and debris. If there is curvature, straighten it.

Also, you need to apply markings that correspond to the layout of the future home.

Screwing piles into the ground often does not require the use of special equipment, since there is a special thread at their end. To install them, it is enough to use the mechanical force of two people, one of whom must hold the pile in a vertical position.

Flooring materials

An example of tongue-and-groove solid wood boards for flooring When making a floor in a frame wooden house, most often the following is used as a floor covering:

- glued parquet boards (inexpensive material with low performance characteristics);

- parquet (a more expensive and durable product);

- solid parquet board (durable coating);

- solid wood board (material with high wear resistance).

Naturally, all of them are not suitable for the floor in the bathroom, kitchen and toilet. For bathrooms and toilets, it is better to use ceramic tiles. The main thing in the design of the second floor floor is to provide good waterproofing in places with high humidity.

Construction and installation of a floor in a bathhouse on screw piles

Why is insulation necessary?

The need for thermal insulation material is not always clear to a person far from construction. From the point of view of the future owner of the house, it is much easier to start from the load-bearing capacity of the structure.

Neglect of thermal insulation standards can lead to the following problems during the operation of the building:

- condensation on the surface of the floor in the technical underground;

- decreased building energy efficiency and increased heating costs;

- High humidity leads to wood rotting, mold and mildew, as a result of which wooden structures quickly fail and require expensive repairs.

Insulating the floor in a frame house allows you to avoid these troubles and ensure a long service life of the building and all its individual structures.

Load-bearing structures of the floor of a frame house on stilts

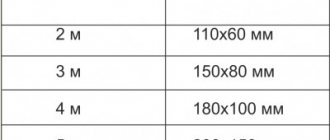

The installation of a floor in a frame house can begin after the construction of a pile foundation and completion of the strapping. It is better to make it from timber, I-beam or channel. We will use wooden beams for strapping, to which we will attach logs. The span length of the framing beams should be no more than 3 m. If the span is greater than this value, then it is necessary to use additional supports from piles. For beams, you can take a beam with a cross section of 100X100 mm made of softwood.

Before laying the strapping, it is necessary to waterproof the base using penofol, roofing felt or plastic film.

Before laying the strapping, it is necessary to waterproof the base using penofol or roofing felt.

After installing the beams, you can proceed to laying the logs. The pitch of these elements is 500 mm. The construction of the floor in a house on stilts is carried out using beams (joists) with a section of 100x250 mm for the first floor and 70x200 mm for the second floor. If the spans to be overlapped are small, for example in a bathroom, then the cross-section of the beams can be reduced to 50x150 mm. In some cases, a lag pitch of 40 cm is used to increase the strength of the structure. For more information on how to install a floor frame, see the video at the end of the article.

Before laying the logs on the harness, you need to make markings equal to their pitch. Next, recesses along the width of the lags are sawed into the strapping beam. After laying in the grooves of the strapping, the logs are fixed with dowels, screws, nails or self-tapping screws.

Important: all wooden load-bearing floor structures must be treated with antiseptics and fire retardants to protect them from rotting and burning.

You need to attach 30x30 mm boards to the joists from below. To increase the strength of the floor structure, sometimes during construction the logs are connected to each other by transverse jumpers with a pitch of 150 cm. But this is not necessary. This kind of structural reinforcement is recommended if a heated concrete floor is to be installed.

As for the second floor floor frame, floor beams will be used here, not joists. We take their pitch to be 500 mm. The flooring will be laid directly over the beams.

Thermal insulation of the first floor floor

If you decide to build a house on screw piles with your own hands, then special attention should be paid to insulating the floor of the first floor. The structural design of a wooden floor on the second floor does not require such careful thermal insulation.

As a rule, the construction of houses on stilts is carried out using beams. To do this, we lay OSB boards or plywood along the slats attached to the bottom of the joists. The design in cross section will resemble the letter W.

Installation of floors in a private house on the first and second floors

Layout of a wooden floor on joists with insulation

Now you can begin installing hydro- and vapor barriers. To do this we do the following:

- We spread the waterproofing film over the joists so that it sag into the gaps between the joists. You can use membrane waterproofing or regular film.

- We place thermal insulation material in the spaces between the joists (on top of the film). Mineral wool is suitable for these purposes. If you want to properly insulate your house on stilts, then it is better to use basalt wool.

- The waterproofing film on the joists must be secured with a stapler.

- The structural design of the first floor floor in a house on stilts must include a vapor barrier. If you are building with your own hands, then do not forget that the vapor barrier material is laid with an overlap of 150 mm. The joints must be taped.

Using the method described above, the construction of the ground floor floor is carried out in any room, be it a bathroom, kitchen or living room. As for the structural pie of the second floor floor, it can be done without heat and waterproofing material. But in the bathroom and other places with wet processes, it is worth laying a waterproofing layer into the floor structure. In the video below you can learn in more detail about the construction of the floor of a house on stilts with your own hands.

Flooring installation

An example of laying tongue-and-groove boards of the finishing coating.

The next layer of the structural cake is made with a board 3 cm thick. When laying the boards with your own hands, keep a step of 40-50 cm. This sheathing along the joists will allow you to get a ventilation gap. You can attach the boards to the joists with self-tapping screws.

We then proceed with the construction of the floor in the house in this order:

- We lay the subfloor on the sheathing of boards. It can be a tongue-and-groove board or a regular board. We fasten it to the sheathing with self-tapping screws.

- You can lay purchased flooring on the boards with your own hands.

Since the front layer of the floor in the bathroom and toilet will be tiles, it is better to lay plywood or OSB on the rough boards to level the surface. At the same time, the structural pie in such rooms must include additional waterproofing, which is laid over plywood.

Warm floor of a frame house

You can make a warm floor in a house on stilts with your own hands. This is not shown in the video below, but the process is simple and takes place in the following sequence:

- A structural heated floor pie includes the same load-bearing wooden frame as for a non-heated floor, with the only difference being that the plywood sheets are not laid on backing boards, but on cranial blocks attached to the joists with self-tapping screws on the sides. You can use a cranial block with a cross-section of 30x30 mm and fasten it in increments of 15-20 cm.

- After laying the plywood on the beams and performing waterproofing, we lay expanded polystyrene in the gap between the joists. The top surface of the polystyrene foam boards should be flush with the top of the joists.

- Next, you need to lay a layer of vapor barrier film, placing it on the walls above the expected level of the finished floor.

- We lay a reinforcing mesh over the film and fill it with a thin layer of cement mortar.

- Then we lay the heating mats of the underfloor heating system on the reflective layer of foil insulation. We perform concrete screed.

- We install flooring. If the floor is in the bathroom or kitchen, then you can use tiles.

For more information on how to make a floor in a frame house, watch the video below: