This type of foundation is considered easy to construct and quite reliable. On certain soil compositions, it has proven itself well for light structures, which include bathhouses built from any material except brick stone. The pile foundation for a bathhouse is popular; construction requires a minimum amount of materials, labor costs and time, which allows you to save money. This type of foundation can be erected independently, without special construction skills.

Advantages of a foundation on screw piles

Installing a floor in a bathhouse on screw piles is much easier to do than on a massive foundation. Advantages of this design:

- the foundation can be installed very quickly with your own hands;

- screw piles noticeably compact the soil, ensuring the stability of the entire structure;

- the foundation is convenient to repair if necessary;

- installation of screw piles is easy to do using modern devices and devices;

- the foundation can be installed in any weather;

- screw piles provide effective automatic ventilation of the underground space of the bathhouse;

- the service life and reliability of the pile foundation are quite long;

- a properly installed floor will protect the walls of the bathhouse on screw piles from the absorption of sediment and melt water from the soil;

- a screw foundation can be installed on unstable soil, which swells and swells during the season of heavy rainfall.

The foundation for a bathhouse on stilts can be installed even in winter

A screw pile foundation is installed very quickly.

The advantages of a pile foundation make its installation quick, and its operation reliable, simple and convenient. The main thing is to first study the properties of the soil in the area chosen for the bathhouse, carry out all the calculations correctly and carry out the necessary work in strict accordance with the instructions.

Screw piles must be selected depending on the type of soil

Scheme for installing a screw pile in the ground

Screw piles are installed for all load-bearing walls and elements

Types of supports

There are a total of 12 options for pile supports. 3 types of these products are suitable for the construction of baths

- bored;

- metal screws;

- reinforced concrete hammers.

The latter option is rarely used for baths, since their installation requires special equipment.

Bored piles are made directly on the site. Although the process is labor-intensive, it results in significant savings in materials.

Metal screw structures are convenient because they can be installed manually.

What is the floor in the bathhouse made of?

The floor in a bathhouse on screw piles can be made from different materials. Concrete screed and coniferous wood are mainly used. Installing a concrete floor will require significant material costs. However, such a floor is resistant to constant exposure to moisture. Therefore, the concrete floor in the bathhouse will last for decades. Wood is a lower cost material. However, when exposed to moisture, a wooden floor quickly deteriorates. Treatment with an antiseptic will significantly slow down this process. But after 7-10 years, the wooden floor will need to be replaced.

Scheme of fastening various floor materials to a pile

The concrete floor in the bathhouse is most resistant to moisture

The advantages of a wooden floor are not only the low cost of the material. If necessary, you can replace damaged elements without completely changing the coating. If you regularly re-treat wooden components with an antiseptic, you can almost double the service life of such a floor. The optimal option is when a concrete screed is made in rooms of high humidity - steam room and washing room. You can make a wooden floor in the locker room and rest room, because the humidity level here is much lower.

It is better to place a wooden subfloor in a bathhouse in the locker room area

Advantages and disadvantages

The construction of a bathhouse supported by piles is a popular construction option for a number of reasons:

- efficiency;

- installation speed;

- installation of supports is convenient on any site;

- no clearing of the area required;

- the supports have excellent load-bearing capacity;

- no shrinkage.

The technology has certain disadvantages:

- metal supports are susceptible to corrosion;

- in case of rocky soil, special equipment must be used to install piles;

- insulation causes additional material costs.

Preparatory work

So, the foundation is installed and the walls are erected. Now we are making the floor in the bathhouse on screw piles. You need to thoroughly prepare for this work, study the technology, purchase everything you need, and invite assistants.

For work you will need the following materials:

- tongue and groove board;

- beam;

- fastening material - nails, etc.;

- cement;

- coarse sand;

- expanded clay and/or other bulk materials;

- roll waterproofing;

- antiseptic composition;

- mineral wool or other insulation.

Tools and equipment for work will require:

- construction mixer;

- tank for mixing the solution;

- wood hacksaw;

- grinder saw;

- construction knife;

- hammer;

- mittens, work clothes, rags.

The list of necessary tools and materials can be specified after it has been determined from what material and in what way the floor in the bathhouse will be installed on screw piles.

Is it necessary to register the construction?

Although the law does not publish specific instructions regarding the registration of bathhouses in suburban areas, judging by real examples of its application, as well as judicial practice, some nuances should be remembered.

If the bathhouse has a buried foundation, the structure is provided with all communications, and has rest rooms, it is recognized by the competent authorities as an immovable object . After this, all consequences arising from such a determination come into force, including the need to register the facility under construction.

Floor insulation: general rules

Before installation and insulation of the floor, it is necessary to carry out an antiseptic treatment of all wooden components of the finished structure. A special composition for this can be purchased at a construction supply store. An antiseptic will protect the wood from the penetration of harmful microorganisms that can destroy it.

The depth of floor insulation depends on the premises of the bathhouse

If a bathhouse on screw piles will be used in winter, floor insulation begins with laying insulation between the supporting elements of the building. Most often, mineral wool (layer thickness 25 cm) or polystyrene foam (layer thickness 15 cm) is used for this.

Scheme of insulation of a concrete floor in a bathhouse

If the thickness of the beams is insufficient for laying insulation, additional bars are attached to them perpendicularly. Waterproofing is pre-installed. On top of it, between the beams, the bottom layer of insulation is laid out. The top layer is laid between additional bars. Next, another layer of waterproofing is laid, on top of which the finishing floor is mounted. An insulated layer in a bathhouse on screw piles will extend the service life of the structure and significantly increase the comfort in the bathhouse.

Scheme for insulating a wooden floor in a bathhouse

Cost of various options

The cost of installing a foundation on driven piles is not too high. But for the event it is necessary to use special equipment, which is why this procedure is quite complicated. The cost of reinforced concrete pillars is 1000 rubles per piece.

Screw piles are versatile, they are durable and guarantee long-term operation.

Such supports have many other advantages. A foundation built on screw products provides maximum cost savings. The cost of one pile varies between 1000–3500 rubles.

Bored piles are very popular because they are distinguished by their affordable price. At the same time, they guarantee excellent load-bearing capacity; such supports are universal in their application.

The budget for constructing a foundation on this type of pile depends entirely on the complexity of the work to be done, the required number of supports, and their technical parameters. Also, the final cost is affected by the need for additional work related to topographic soil survey and site preparation.

Base installation

Effective insulation of the floor in a bathhouse on screw piles is done using a base, which is mounted around a pile-screw foundation. The plinth reliably closes the free space under the bathhouse floor from the penetration of cold air and significantly improves the appearance of the finished building.

The empty space of the plinth is covered with some panels

The main materials for the base are thermal insulation boards and decorative panels. An additional layer of heat insulation is laid between them. Typically, penoplex, polystyrene foam and similar materials are used for this. Sealing the joints between the panels after assembling the base is done using polyurethane foam.

To reduce heat loss, insulate the basement under the bathhouse

You can insulate the base of a bathhouse using penoplex.

How to build a foundation with your own hands: step-by-step instructions

Installation of supports:

- Marking the territory . Determine the location of the supports, taking into account the standards SP 24.13330.2011. Where the racks are located, pegs are driven in.

- Installation of piles. A hand drill makes holes in the ground. Their depth is affected by the condition of the soil. The walls of the well are protected with roofing felt. The reinforcement is lowered into the hole. Concrete is poured, tamping it to obtain a monolithic structure. To raise the piles above the ground, formwork is made.

- connection . To connect the supports, a grillage is made. A timber or log is suitable for a bathhouse. The wood is placed on the heads, making cuts in it for them. Then the beams are fastened at the corners. The frame is secured to the ends with bolts. Next, walls are erected and covered with a roof.

Support for the stove

If there is a brick oven, additional supports are needed for it:

- They are digging a pit.

- Add sand.

- They lay broken bricks, then sand again, getting a dense cushion.

- They lay crushed stone. Formwork is installed on it to fit the dimensions of the furnace.

- A reinforcement cage is installed inside the formwork.

- Concrete is poured at a level 10 cm below the floor. Wait until completely dry.

- The concrete is lubricated with tar, bricks are laid to zero level. A furnace is being built on them.

The photo shows an example of laying a foundation for a stove:

How to insulate?

To insulate the floor on a pile foundation, it is recommended to use penoplex . Before laying the insulator, craftsmen install a strip around the perimeter of the floor. It allows you to provide a drain slope so that water drains faster.

A detailed article about insulating a pile foundation is here.

Decoration

After completion of construction, it is necessary to improve the foundation. It is recommended to use various facing materials.

Suitable:

- stone;

- porcelain stoneware;

- facing brick;

- clinker.

To reduce the cost of the process, a false base is installed from various types of siding.

Installation of a pouring floor

The optimal solution is considered to be a poured floor in a bathhouse on screw piles. In the cold season, it is necessary to carry out mandatory insulation of the entire structure.

A large amount of water gets on the floor in the bathhouse, so it is necessary to increase its moisture resistance and trouble-free removal of used water. To do this, it is necessary to equip a special drain ladder. Through it, water will flow into the sewer pipeline or into the drainage system.

Diagram of a pouring floor in a bathhouse

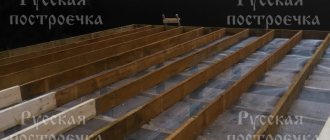

Installation of the pouring floor begins by laying logs on the grillage. They are placed strictly horizontally without tilting. Edged boards made of coniferous wood are fastened to the logs with nails. Gaps 7 mm wide or more are left between them. Even if the wood swells, the gaps between the individual elements will still remain. Used water will pass through them freely.

To protect the subfloor from the accumulation of water, you need to install a concrete screed in it in the shape of a cone with an inclination towards the sewer or drainage system.

Advice! To avoid the appearance of unpleasant odors and/or harmful microorganisms, the concrete structure must be regularly washed, cleaned and treated with special compounds.

To prevent anything from rotting and moisture from accumulating, it is necessary to install a concrete bowl with a drain in the bathhouse

Dry wooden floor in the bathhouse

The dry floor is laid from boards in 2 layers. First, the subfloor is installed. A waterproofing agent is placed on top of the boards. Then the insulation is laid. On top of it - 1 more layer of waterproofing. Finally, a finished floor covering is laid. For this, a tongue-and-groove board made of durable softwood is used. Individual floorboards must be laid close to each other without cracks or gaps. When laying the finished floor, a slope to one of the corners of the room is required. A hole is made here under which the siphon is attached. This will help you easily remove used water during use of the bath.

How to build a structure correctly?

The process consists of the following steps:

- After the foundation has been arranged, construction of the bathhouse begins:

- First, determine the height of the walls and the type of roof.

- At the corners, the supports are made of beams, fastening them with corners.

- Then edged boards are attached to the grillage. Struts are installed between them.

- The process is completed by connecting the parts with the top trim.

- Next, a reliable floor is built, immediately insulating it. To secure the floor covering, it is necessary to install the logs on the grillage, connecting them to the base using metal corners.

After completing the subfloor, the installation of walls begins. The technology here is somewhat different for timber and frame structures.

From timber

A month after the construction of the base, the crown of the trim begins to be attached . Strong bars are used for it. Roofing felt is laid between the grillage and the wood.

The bottom block is treated with an antiseptic. Nails are used to connect elements. When the beams are laid, they pause to allow the frame to shrink.

This process lasts about six months. Then the cracks are sealed using tow or sealant. First they caulk the lower crown, after which they gradually move upward.

Construction of a frame structure

The contour in the form of a frame is erected from timber treated with an antiseptic. Its cross-section is selected taking into account the insulation used and the load-bearing capacity of the material. For the strapping and corner posts you need a more massive beam.

Installation begins from the corner, connecting the timber with nails. Before laying, cover the grillage with roofing felt. Braces are attached in all corners. It is better to assemble the frame on the site. For its external cladding, it is recommended to use carriage boards, although other materials are also suitable. The lining is fixed horizontally, laying waterproofing underneath it.

An important stage of construction is thermal insulation of the structure . Mineral wool is often used as insulation. It has a good vapor permeability, the material does not burn, and allows the walls to “breathe.” You can also lay mineral fiber rolls. The slabs are mounted between the racks.

It is recommended to insulate the bathhouse by laying two five-centimeter thick layers: the first from slabs, and for the second, take rolled material.

Waterproofing in the form of a film is attached between the insulation and the outer skin. The inside is lined with aluminum foil with a polyethylene layer. The joints are taped, then the interior finishing is done.

When equipping floors, take into account the purpose of the room. Where there is a lot of water, a torrential foundation is installed . It consists of a boardwalk with gaps allowing drainage to pass down. Such floors do not provide insulation.

To make the floor dry faster, you should not attach floorboards to the joists.

Small gaps are made between the boards, leaving gaps around the perimeter as well. If there is sandy soil under the bathhouse, crushed stone is poured on top of it, leaving a gap of 10 cm to the floor. If the soil is clayey, a tray is built that directs water to the drain tank.

Recreational areas require a floor that does not leak . First, make a rough flooring using a couple of layers of boards. A continuous pine covering is installed on them, with insulation placed underneath.

Concrete floor in the bathhouse

Before pouring a concrete floor, it is necessary to carry out preliminary work in a bathhouse on a screw foundation:

- laying water supply and sewerage pipes;

- installation of a ladder on which the finishing floor will be laid;

- forming a cushion of bulk material under the base of the bathhouse building;

- laying roll waterproofing on foundation sections;

- laying insulation.

Scheme for preparing concrete mixture

Nuance! It is better to fill the pillow for forming a floor cake from bulk material of different fractions, which must first be completely dried.

Insulation of concrete floor

The concrete floor in a steam bath on screw piles begins to be insulated when the screed sets and hardens. The following is usually used as insulation:

- extruded polystyrene foam;

- expanded clay;

- perlite;

- mineral wool.

Insulation materials for bathhouse floors: perlite, expanded clay, expanded polystyrene, mineral wool

Before laying the insulating layer, it is necessary to completely clean the surface of the concrete floor from foreign objects, dust, debris, etc. then lay a roll of waterproofing material. Fractional insulation is applied as part of a special mixture. After it dries, a cement screed is poured on top.

Tile insulation requires sealing the joints between panels after installation. This is usually done using polyurethane foam. After it dries, a 2nd layer of roll waterproofing agent is applied. To evenly distribute the load on the floor in a washing bath on screw piles, in a steam room or in another room, a reinforcing mesh is laid.

You can insulate a pouring floor in a bathhouse using expanded clay; it must be laid before the concrete screed

Floor tiling

Ceramic tiles can be laid on top of the wooden floor in the bathhouse. In this case, instead of boards, fibreboard, fiberboard or plywood are used for the rough coating.

In the washing compartment you can lay tiles on the floor in the bathhouse

Ceramic tiles are laid on top of the laid sheet covering. This is done in the usual way. Under the tiles, you can lay a system heated floor in a bathhouse on screw piles. You can use a hydraulic or electric infrared option.

In the locker room you can install a heated floor in the bathhouse

Electric heated floor installation

Water heated floor diagram

Preventive measures

A bathhouse on screw piles has a high level of moisture; special preventive measures will help make the floor inaccessible to fungus and mold, which inevitably appear in a humid environment. During the construction process, all structural elements used must be coated in several layers with a special antiseptic composition.

To prevent the floor from rotting longer, it is necessary to cover it with an antiseptic against fungus.

It is imperative to use high-quality waterproofing materials. This can be roofing felt or plastic film. These measures will help increase the service life of the structure and protect it from rotting and premature destruction.

Scheme of waterproofing the floor in the bathhouse

If pockets of rotting of the wooden material are noticed, the entire structure must be dismantled. Damaged elements need to be replaced.

Nuance! After thorough drying, treat all components with an antiseptic and dry again. Before assembly, you need to coat the wooden elements with wax or water-repellent varnish.