The simplest bathhouse in the form of a one-story building with a steam room, a dressing room and a tiny changing room will require an area of up to 25 m2 on its site. It doesn’t matter what the walls are made of or how to build the roof of the bathhouse, if you don’t want to deal with cracks in the walls of the steam room and patch the lining every year, be sure to make a foundation. Laying a strip mini-foundation for a bathhouse requires a lot of time, effort and money. It’s better to make a strip foundation for a bathhouse right away with your own hands, this guarantees quality. All the same, it will be cheaper than remodeling a finished bathhouse, or dismantling an almost built but cracked bathhouse body and starting a small construction project with the problem of how to pour a strip foundation for a bathhouse.

DIY sauna foundation tape

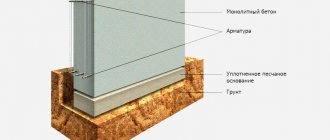

A strip foundation for a bathhouse is used quite often in construction and is a continuous strip of concrete mortar, blocks of different configurations or red brick, which is laid in the ground below the groundwater (but above the freezing level) and rises at least 20 centimeters above the surface.

When is a strip foundation for a bathhouse optimal:

- If you plan to use the basement floor for different purposes (as a utility room, tool storage area, pump, etc.)

- If the building is planned to be large with considerable weight (assembled from rounded logs, bricks)

- When there is a high groundwater level

A strip foundation for a bathhouse is capable of taking on loads from the entire structure and transferring them to the soil. The base protects the base from cold, wind, moisture; its walls can simultaneously serve as a basement or ground floor. The cost of the foundation is in the average range - higher than columnar, but lower than monolithic. Ideal price-quality ratio, especially if you build a strip foundation for a bathhouse with your own hands.

Building size

A strip foundation is a support structure closed around the perimeter under a building. When planning the construction of a bathhouse on a personal plot, the dimensions of the bathhouse in plan and the type of foundation are initially determined.

A facility for hygienic water procedures should have an optimal set of premises - these are:

- steam room,

- shower room,

- toilet,

- vestibule,

- restroom,

- small terrace.

All this can be placed on a bathhouse plan measuring 6 x 6 m. The bottom picture shows the location of the rooms:

The configuration of the support belt of a closed perimeter depends on the size of the structure . The common dimensions of the building are a bathhouse with a plan of 6 x 6 m with axes of 5.4 x 5.4 m running in the middle of the width of the foundation.

The dimensions of the foundation are a fundamental factor influencing the total estimated cost of building a bathhouse. This determines the consumption of materials and the volume of overhead construction work.

Calculation of the foundation for a bathhouse

When pouring a strip foundation for a bathhouse with your own hands, step-by-step instructions will definitely not be superfluous.

You cannot perform the foundation “by eye” (like any construction work). It is necessary to calculate everything in advance, draw a diagram, draw up a work plan, a project, and then strictly follow the standards, maintaining all values and parameters, without skimping on materials.

To correctly calculate the foundation, you need to know the weight of the future bathhouse (with all the floors, interior fittings, roofing) and the level of freezing of the soil layer and the flow of groundwater in the prepared area. By examining the soil, the depth, width and height of the strip foundation for the bathhouse can be correctly determined. Research can be entrusted to specialists or performed independently.

To implement the first stage of calculations (to study the groundwater levels and the soil freezing limit), it is necessary to drill wells at the construction site in several places until water appears. For clayey and dense soils, with low groundwater levels, a shallow strip foundation 40-60 centimeters high will be sufficient. For middle strips, choose a strip base buried 1.6-1.8 meters (below the soil freezing line).

The loads on the strip foundation, which are placed on the structure, are calculated using special tables that contain approximate weight indicators for all elements of the bathhouse.

Much depends on the materials used and design features. The weight of all bathhouse equipment and people (in the amount that can be in the building at the same time) are added to the indicators. The tables also determine soil resistance.

The dimensions of the strip foundation are determined by the total load from above, which is divided by the soil resistance.

How to correctly calculate the depth and width

A complete foundation calculation is a complex engineering task, accessible only to a trained specialist.

It is required to perform a comprehensive study of the soil, calculate the weight of the bathhouse without and with a foundation, and take into account a large number of special quantities, coefficients and indicators.

For outsiders who do not have the appropriate education and experience, such a calculation will not be possible.

The solution to the problem will be to contact specialists who professionally deal with such calculations. This option is optimal, but will require certain financial investments.

Another possible way is to use online calculators, of which there are many on the Internet . The results obtained using this method must be duplicated on other resources in order to be able to check the data obtained and select the most reliable values.

Foundation installation methods

Before making a strip foundation for a bathhouse with your own hands, it is important to decide on the materials and geometry of the structure, the method of installing the structure, and other important points that influence the choice of foundation parameters.

Brick strip base

A bathhouse can be built exclusively from red brick, since white silicate brick is resistant to moisture and deteriorates quite quickly. When choosing a brick base, be sure to pay attention to the seams - they must be well waterproofed, since the concrete solution allows water to pass through.

Brick is an ideal choice for those who build a bathhouse with their own hands on sandy, dry soil. If the groundwater level is high enough, it is better to make a foundation of concrete mortar with mandatory reinforcement with steel rods and screed. A reliable brick foundation is installed on a sand-crushed stone bed, well compacted. You can do everything yourself, since the brick is light in weight and is relatively simple and quick to lay.

From blocks

When designing a strip foundation for a bathhouse with your own hands, you can choose reinforced concrete blocks, but the work will require special equipment, since the blocks can weigh a lot and you won’t be able to lift them yourself. For a small structure, you can make a block base from blocks measuring 20x20x40 centimeters, which are laid preferably in a checkerboard pattern and require a cement connection. The blocks are laid clearly according to the markings on a sand bed, installation takes a maximum of 1-2 days.

From stone

A high-quality rubble concrete base can also be made with your own hands; it consists of cement and most often river stone, preferably flat in shape (preferably the same size). The stone is carefully laid out in the formwork in layers, poured with a concrete mixture - this way a strong, beautiful base is created, which will be relatively inexpensive, provided that the stone is not delivered from afar.

With permanent formwork

Installation of a strip foundation for a bathhouse with permanent formwork is a new technology that involves the use of two expanded polystyrene slabs. They are connected with metal pins, the inside is tied with reinforced steel wire, and everything is filled with concrete on top. The strength of the base can be compared with any other installation method; it does not require additional waterproofing or insulation.

Made from concrete

A concrete base is the simplest and most affordable option for making a monolithic foundation. To create it, formwork is installed, steel reinforcement is placed in it (tied and correctly installed on clamps), and filled with durable concrete. Pouring is carried out at a time, so the work will have to involve several more people to supply the solution or use a concrete mixer to supply the solution to the site.

The concrete hardens for 28 days; after the initial setting, the formwork is dismantled, and the base is ready for further construction work.

Materials for preparing concrete

- Cement . The main grades of cement are: Portland cement M200, M300, M400 and M500. For example, in the name of Portland cement, the number “300” means compressive strength in kg/cm². This is a gray-green dry mixture of fine-grained consistency based on calcium silicate, which has astringent properties. The prepared solution begins to set after 45 minutes and ends after 24 hours. The full hardening cycle is no earlier than after 28-30 days.

- Sand grain size from 0.15 mm to 5 mm.

- Gravel . Loose sedimentary rock ranging in size from 1.00 to 10 mm. It is divided into the following types: river, lake, sea and mountain. Mountain gravel is considered the best because of its rough surface, which allows for the best adhesion to cement.

- Crushed stone. Coarse-grained bulk material measuring over 5 mm to 70 mm, obtained by crushing hard rocks. “ flakiness” (flatness) and is divided into groups from I to V. Crushed stone of group I is considered the best, since it has a shape that is closest to cuboid. The use of crushed stone of this group is advisable from both an economic and technological point of view - significant savings in cement and increased strength of the foundation are achieved. It is recommended to use crushed granite rocks of the popular M1200 brand.

- Water. Only clean water from a tap or well is used. The use of contaminated water is not permitted.

Marking

Before you properly pour a strip foundation for a bathhouse, you need to know how to mark the territory. The marking corresponds to the project and involves marking all internal and external boundaries of future walls.

To perform external markings you will need: a cord, a square, a plumb line, regular pegs, and a large tape measure.

The starting stake is driven into the point where it is planned to locate any of the corners of the building (with mandatory control of the vertical level). The remaining stakes for the corners are also driven into the ground, and the diagonals of the perimeter of the structure are checked. Then a cord is pulled between the stakes, the horizontal level of which corresponds to the height of the foundation. Check the evenness of the cord with a level.

Next, mark the internal walls around the perimeter, noting the locations of the partitions. Then they retreat from the outer perimeter to a width equal to the strip base, drive in stakes, pull the cord, and mark the location of the partitions. Here, too, everything must be level, so you can’t do without a tape measure, a plumb line, or a construction square.

Excavation

The depth of the foundation directly depends on the type of soil on which it is built. A trench is dug along the marked elements, the bottom of the ditch is compacted manually or with a vibrating plate, making sure the base is even. Then they are covered with sand 7-40 centimeters thick, which is directly dependent on the type of base.

Thickness of the sand layer depending on the type of foundation:

- 7 centimeters – shallow foundation

- 7-15 centimeters – deep foundation

- 15-40 centimeters - if a floating base is laid

A layer of sand is poured horizontally, watered, and compacted. If you need to lay a lot of sand or add a layer of crushed stone, the work is carried out in stages, in layers of 5-7 centimeters. Further work is allowed after 2-3 days, after the pillow has completely dried.

Formwork for concrete screed

The formwork of a strip foundation for a bathhouse is constructed from pieces of slate, fiberboard, any boards, plywood panels and any other materials. Collapsible structures made of metal or plastic can even be rented. The material is wrapped in polyethylene, mounted inside the trenches, the outer sides are immovably supported with stakes and lumber.

Between the walls of the formwork you need to insert transverse struts and attach metal pins every 50 centimeters. This will eliminate the possibility of a mass of mortar escaping from ruptured seams. The shields are fastened to the ground with 20-centimeter nails and secured to each other with a stapler or self-tapping screws.

Special holes for communication pipes are made in advance in the panels, so that later you do not have to drill into the concrete and make it less durable. Using film or glassine to protect the formwork will not only preserve the panels, but also reduce the absorption of moisture into the wood (because of this, concrete often becomes covered with cracks).

Reinforcement

Making a foundation for a bathhouse is impossible without reinforcement. For strengthening, choose reinforcement with a cross-section of 12 millimeters (for laying longitudinally) and 6-8 millimeters (for laying vertically and perpendicularly). To perform reinforcement, you need to prepare: wire, steel rods, an angle grinder, a tape measure, a welding machine (if you plan to weld the frame rather than knit it).

The structure is made up of 4 or more rods lying in three planes (longitudinal, perpendicular, vertical). The finished frame rises above the ground by at least 5 centimeters, the corners are further reinforced. The work is completed correctly if the cut of the armored belt turns out to be either a square or a rectangle.

Stages of creating a reinforcement frame for a bath:

- Measuring the perimeter, cutting the reinforcement to the required length.

- Laying out the reinforcement on the ground, tying it with wire - the longitudinal rods are laid with an overlap of 30 centimeters and tied together. Between vertical and perpendicular rods there should be a step of a maximum of 50 centimeters. To lay a foundation wider than 120 centimeters, a frame is made from a larger number of rods.

- Strengthening the foundation in the upper part with special clamps in the shape of the letter P.

- Complementing the frame with steel rods, which are placed at an angle of 45 degrees with respect to the horizontal rods.

Selecting reinforcement and its diameter

Selecting fittings is a procedure that in any case will have to be done independently. If concrete or other material can be purchased ready-made, the frame of the tape is made on site, so you need to choose the best option.

There are two types of reinforcing bar:

- Traditional metal rod with fins.

- Composite reinforcement made of fiberglass or other similar material.

Composite reinforcement is 9 times lighter than metal. In addition, it is approximately 20% cheaper, which gives it a significant advantage. But metal rods are capable of bending, which fiberglass does not allow.

In addition, the coefficient of adhesion of fiberglass to concrete is lower than that of metal. If you plan to assemble the frame using a welded method, it is possible to use only the metal type.

The consumption of reinforcing bars for foundations is high, so the opportunity to save is seen as a big advantage. If you plan to assemble the frame using the knitting method, and there is no need to bend the rods, the best option would be to use a fiberglass rod.

For a bathhouse, the recommended diameter is 10 mm, if the structure is large - 12 mm.

Filling the tape

It is best to pour the foundation for a bathhouse in one day (preferably in one go), which will ensure the strength and reliability of the structure. You can’t do this without a concrete mixer, but if you don’t have one, you can order the required volume of cement mortar.

DIY recipe for mixing concrete mortar:

- Clean sand – 2.5-3 parts

- Cement grade M400 at least – part

- Clean crushed stone - 4-5 parts

- Water - in sufficient quantity to obtain a mixture of medium consistency

The solution is poured into layers of 20 centimeters, leveling each with a tool (trowels or shovels). Then they are compacted by piercing or a vibrating drill, tapping the walls of the formwork. If the work is completed in the evening, it is better to cover the foundation with a polyethylene film at night. During the day you need to spray water on the surface for the first 10-12 days. Then the formwork is dismantled, they wait until it reaches full strength (28 days), lay a layer of insulation and continue work.

Features of the construction of the furnace base

The furnace foundation is the area that is most susceptible to temperature changes due to heating and cooling of the furnace.

To prevent temperature fluctuations from spreading over the entire tape array, the base for heating equipment is localized from the tape array .

The foundation for the furnace is separated with sand backfill 500 mm thick or asbestos sheets. To prepare concrete mortar, cement M 500, crushed gravel and sand are used in the ratio: 1: 4: 2.5.

Pouring a warm strip base under the bath

A relatively new technology that allows insulation of castings in the soil based on porous polystyrene boards. To create the formwork, in this case, take plastic plates of a permanent type, install them in a trench, connect them end-to-end, and fix them with steel spacers. After pouring, the concrete mixture fixes the thermal insulation, creating complete insulation of the structure.

Creating a strip foundation for a bathhouse is a task that can be done with your own hands. Provided that preliminary calculations are carried out correctly, quality materials are purchased and technology is followed, it will be possible to obtain a high-quality, strong and reliable, durable base for a bathhouse.

Waterproofing

There are many ways to waterproof a strip foundation. The most popular and simplest option is to apply hot bitumen or ready-made bitumen mastic, which does not require preheating.

The material is applied in at least two layers. Additional waterproofing is often used using roofing felt, densely distributed along the internal walls of the formwork before pouring . The main task is to ensure complete tightness of the waterproofing layer, continuity and uniformity of application of the material to the surface of the foundation.