It is believed that you can equip a steam room from anything; a vivid example of a folk principle is a change house - a bathhouse. Simple and at the same time easy to assemble steam and washing compartments are usually made from construction trailers and mobile temporary sheds. The comfort level is, of course, lower; the sauna car is the result of a remodel, not a purposeful design, but you can steam in it with no less pleasure.

What is the difference between a change house and a stationary bathhouse?

The idea of building a steam room based on a ready-made metal box has existed for quite some time. They are made from cabins, railway and sea containers, old car booths, and decommissioned refrigerator trailers. Making a bathhouse from a trailer with your own hands is no more difficult than from other types of mobile structures.

A change house or trailer, which is what anyone calls a small structure on a wheeled trailer or construction carriage, is an industrially manufactured room with the following characteristics:

- The cabin box is made on a metal frame made of aluminum or galvanized steel sheet;

- The walls of the trailer are a sandwich panel with insulation based on foam plastic or mineral wool. The floor of the cabin is reinforced with a steel profile, treated with mastic waterproofing and additionally insulated with a second layer of polystyrene foam;

- The dimensions of the future trailer bathhouse at the base of the structure are 2.3x6 m, 2.45x5.8 m, 2.8x6 m or 3x6 m. The ceiling height is 220 - 230 cm, depending on the thickness of the floor covering made of boards.

For your information!

The floor in the cabin, depending on the model of the trailer, can be made of pine timber; such structures are not placed on wheels, but are used for moving by trucks and cranes. Most often, trailer cabins have an entrance from the wide side of the box. The doors can be located in the center of the trailer, dividing it into two rooms. In the automotive version, the entrance is made with a folding ladder. This is the so-called sleeping trailer.

For insulated versions of cabins, the entrance doors can be shifted or installed at the end of the box.

A bathhouse made from a metal trailer turns out no worse than one built from foam concrete or timber, but the room itself, after installing additional insulation and lining the walls inside the cabin, turns out to be slightly cramped, especially in the steam room.

According to the owners, there is plenty of space for one or two people; a group of three people will have to take turns to take a steam bath. For a larger group, it is better to immediately build a bathhouse from two cabins. There is no particular difference, the basic circuit is the same as that of the single version. First, one of the side walls of each trailer is cut off, the two boxes are joined, after which the cladding of the outer walls is made from the timber of the entire bathhouse - the cabin.

Conclusion

A do-it-yourself bathhouse from a trailer is an interesting opportunity to use auxiliary structures. In the video presented in this article you will find additional information on this topic.

The question of how to make a bathhouse out of a change house is relevant among many compatriots. And this is not surprising, since cabins are relatively inexpensive and available to most people, especially if used buildings are purchased.

So, what is the technology for converting a cabin into a bathhouse?

Initially, it is necessary to insulate the roof, floor and walls in order to reduce their thermal conductivity to a minimum.

The interior space is lined with wooden clapboard. Next, the lining is treated with antiseptic agents in order to subsequently eliminate the possibility of mold formation and, as a consequence, destruction of the wood.

The total area of the room is divided into 3 equal parts: a steam room, a dressing room and a washing area.

After this, a sewer pipe is installed, which is diverted to a drainage pit or to a septic tank. Through this pipe, water will be discharged from the washing compartment to the outside.

The electrical wiring is well insulated to prevent the possibility of short circuits due to high humidity.

A wood-burning or electric stove-stove is installed.

Water and electricity are supplied.

It is important to take into account the small dimensions of the bathhouse based on the change house and therefore make the doorway of all doors as tight as possible in order to prevent the penetration of excess moisture from the washing compartment and steam room into the dressing room. In addition, the bathhouse is a potentially fire-hazardous structure, and therefore all doors must open towards the exit, that is, outward

What to pay attention to

At first glance, you can build a bathhouse from a construction trailer with your own hands in a couple of days. The rigid frame of the cabin does not require additional measures to strengthen the walls and floor. The trailer room is already insulated during the manufacture of the box.

In theory, you will need to make only small additional equipment for a bathhouse with your own hands:

- Lay electrical wiring to connect lighting and ventilation systems, heating, if an electric heater will be used in the steam room of the bathhouse instead of a wood-burning stove;

- Supply water, make a drain for the shower and steam room, connect communications to the septic tank or sewer;

- Finish and install the stove.

Important! In practice, everything turns out to be more complicated. Before making a bathhouse from an iron trailer, you will need to solve the problem of arranging steam and thermal insulation.

The problem is that the steel or aluminum walls of the trailer, as well as modern sandwich panels based on bakelite plywood, do not allow water vapor to pass through at all. The task is not even how to make a bathhouse from a change house; it is important to ensure maximum comfort and durability of the building.

In such a situation, you have to choose - either build a bathhouse from a construction trailer with metal walls, durable and reliable, capable of standing for 20 years in the middle of a swamp, but at the same time rack your brains and look for the best insulation option. Or look for a ready-made change house assembled from timber. In this case, the construction and insulation of the bathhouse is no different from the arrangement of a conventional frame steam room.

Furnace structure

An electric heater or a metal wood-burning stove must be installed in the steam room (it requires a separate base). To accumulate heat and create steam, it must be equipped with a compartment for stones, which must be checked before using in the sauna. To do this, light the stove and heat the stones. After 500-600 degrees, soot begins to burn out of them.

Pour hot water onto the stones: 70 degrees (never cold - the stone will crack), steam will begin to release. The main thing here is to determine whether the steam is pure or with an admixture. To do this, you can hang a white sheet in front of the stones and, after the steam has dissipated, see whether it is clean or not. If dirt or soot is found on the sheet, it is better to remove such a stone, it contains many volatile fractions that are harmful to the body. Select broken and crumbling stones and leave the strongest ones.

Make an opening on the ceiling for the chimney. Protect the places where it passes from fire. It must be taken into account that there must be at least 38 centimeters from the chimney to the wooden parts.

The length of the stove chimney is of no small importance. Too short will overheat and will not provide the required traction.

Double-circuit chimneys of the “sandwich” type have proven themselves very well: they are more fireproof and condensate harmful to the stove evaporates faster. Be sure to install a water tank on the chimney pipe - this is the fastest and most economical way to heat water. You can also use an electric broiler. Do not forget about protective metal sheets where the stove is installed (on the floor, adjacent walls and ceiling).

For the steam room, you cannot use materials such as linoleum or wooden slabs, since when the air is heated, they release substances that are bad for human health. The same applies to plastic. Tile finishing is also not recommended, as it can crack at high temperatures, and touching it can cause severe burns. It is better to cover the outside of the change house with a more airtight (windproof) sheathing, for which use an OSB board, and only then perform decorative finishing with clapboard or siding.

External thermal insulation must be done in the following sequence (from outside to inside):

- exterior decoration;

- waterproofing;

- insulation;

- polymer hydrobarrier placed on the cabin.

To use the sauna safely, you should take care of a high-quality ventilation system. In this case, it is necessary to adhere to the rule: the influx of fresh air should always be located below the outflow of used air. If the ventilation in the cabin is not organized correctly, then in the steam room you begin to inhale what comes out of you and, as a result, feel discomfort.

How to convert a change house into a bathhouse

First of all, a few words about the price. Good-quality wooden cabins, which currently flood the construction equipment market, cost about $1,100-1,200, without foundation and delivery. The best option for building a wooden bathhouse from a cabin with your own hands, photo, will be difficult to find.

The design of the trailer, the presence of a durable frame made of 150 mm timber, allows you to transport a two-ton “blank” for a bathhouse to any place accessible to a truck without any problems.

Planning Guidelines

The change house is a secondary utility room, but you should not take the process of its construction and arrangement too lightly.

First, prepare a drawing. You can make it yourself or find a ready-made version in available sources. The drawing will allow you to imagine how the finished building will fit into the surrounding landscape, as well as calculate the required amount of building materials.

Select the dimensions of the structure and its layout at your discretion. As a rule, industrial structures intended for living are about 5-6 m long, about 2.5 m high and similar in width. Otherwise, regarding the dimensions of the house and its layout, be guided by your needs and preferences.

Characteristics of a cabin for arranging a bathhouse

Structurally, the trailer differs little from a frame-type bathhouse; the building has everything necessary for organizing the washing process:

- A room for a steam room and a dressing room, the total area of the steam room and washing room is at least 12 m2;

- A shower with an electric boiler was built in, a dirty water collection system was built, and a 120 liter boiler was installed;

- The body of the future bathhouse is insulated with mineral fiber panels, and a double-sided vapor barrier is installed. The walls of the change house are lined with 12 mm thick aspen lining.

The dimensions of the box are 2.3 x 5.8 m. Construction of a small bathhouse from timber of the same size and device, “from scratch”, with your own hands, will cost about 2.5 times more than refurbishment from a ready-made box.

From two trailers it is already possible to build a real bathhouse complex, while part of the premises can be allocated for a full-fledged rest room, and the second toilet can be converted for storing firewood.

Functionality

Bake

The main part of any bathhouse, since without it it is impossible to create a real steam room. Most often, heater stoves are used, when stones are placed on the top of the stove to accumulate heat.

The most practical location of the stove is the firebox outside the steam room. In this case, there are all conditions for creating a safe zone around it using a metal sheet. The heater should be installed on a brick base, and the roof must be insulated with asbestos and other non-combustible materials to avoid fire.

Configuration

The rooms in the bathhouse trailer are located one after another.

- An entrance that must have two doors and a vestibule between them.

- The locker room is usually not heated, but electric heating can be installed.

- A rest room or dressing room with or without a shower.

- Steam room.

Sewage and water

Hot water in the shower can come from an electric boiler, or a heating radiator can be diverted from the stove. In the first case, the shower can be used without lighting the bath. Water is discharged either into a separate pit on the site or into the central sewer system. Cold water should be supplied to a separate storage tank located inside the trailer.

Foundation for installing a domestic bathhouse

Particular attention must be paid to the arrangement of the foundation system for the installation of a wooden cabin. The frame's own structural strength is enough to lift the box with a crane and transport the building without any additional reinforcement struts. Therefore, the bathhouse can be placed on almost any ground. First, a 50 mm sewer pipe is buried in the ground. The entrance to the pipe is left above the surface; after connecting the drain corrugation from the bathhouse, the unit will need to be closed and insulated with polystyrene foam.

The best option is installation on a concrete slab or columnar foundation. All you need to do is make a storm drain, level and compact the soil within the dimensions of the future bathhouse.

For a columnar foundation, you may need to backfill the site with a mixture of sand and fine gravel.

What needs to be converted in a change house

The only drawback of this design is the inconvenient location of the toilet. For an ordinary room, the division into residential and sanitary zones is welcome. In the case of a bathhouse, it is recommended to cover the open mini-terrace at the entrance to the room with clapboard and install double-glazed entrance doors.

In addition, you will need to additionally install a partition separating the steam room from the common room of the change house. For the internal walls of a bathhouse, they usually use “Thermoplate” with a thickness of 100 mm; rolls of 50 mm thick are additionally laid on the ceiling and floor under the vapor barrier.

The stove in the cabin is installed according to the general rules adopted for wooden steam rooms. The chimney pipe is led out through the side wall at a height of at least two meters from the floor and 35 cm from the roof overhang.

About choosing a place

- First, decide on the most suitable place for building a bathhouse. If the site is located near a lake or other body of water, then you need to place the bathhouse at least fifteen meters from the water - this simple move will protect the building from possible flooding.

- If there is a road on one side of your yard, choose a place on the other side, as far away from the road as possible.

- If the site can hardly be considered spacious, then combine the bathhouse with another building - a summer kitchen, for example, or a garage. At the same time, you should not worry about third-party odors - properly organized ventilation combined with good insulation can protect you from this.

How to make a sauna from a trailer

Usually, the idea of a bathhouse from a work shift comes to the owners after completion of construction work on a suburban area. A decommissioned metal box with insulated walls is very cheap, and it makes a very decent bathhouse.

You can make a bathhouse from a trailer with your own hands in two versions. In the first case, the metal box remains unchanged, it is only insulated and equipped with a shower cabin and a heater stove.

In the second case, all the side walls of the metal trailer are cut out, and the surface is covered with siding or block house. Thus, the bathhouse solves the problem of combating water vapor and condensation falling on the steel walls of the room.

Materials for finishing work

The next step in equipping the department is the purchase of building materials for finishing work, where an important point is the purchase of a sufficient amount of waterproofing products to insulate the walls of the foundation of the steam room. Typically, for these cases, an insulating layer is used, which is capable of qualitatively protecting the car interior both from the outside and inside the container from heat loss and moisture gain.

After completing the finishing of the premises, it is necessary to install hydro- and thermal insulation material on the external and internal walls of the car. It is not recommended to leave dirt and debris indoors because it has a destructive effect on the protective material. The construction of the steam room should be carried out in accordance with the rules, then the bath will last for many decades.

Foundation for a trailer

Unlike a wooden cabin, bathhouses from a trailer can be built directly on the ground. Of course, in practice such options are not used due to excessive hypothermia of the floor. It is considered optimal to install a bathhouse on a strip shallow foundation. For loamy soils, the steel box is often placed on columnar supports.

The design of the trailer is designed in such a way that the main load falls on two beams laid in the base of the floor along the entire length of the body. Therefore, for reliable fixation, it will be enough to install the body on two rows of concrete blocks.

This solution will allow you to insulate the space under the trailer by backfilling or sealing the base with red brick. At the same time, the appearance of the bathhouse improves and the risk of metal corrosion is reduced.

Car interior inside

Typically, the bath compartment of a carriage contains four compartments:

- The vestibule corridor occupies the space up to the door of another room.

- Steam room.

- Shower in the dressing room.

- The section where they undress.

The place for clothes is never heated in order to save money. In order for the water to heat up, you need to place a barrel in the carriage to store water, which is heated from the stove, or connect an electric boiler. The arrangement of the bathhouse depends on the preferences of the owner and his financial wallet.

Laying insulation in a metal box of a trailer

The insulation scheme is selected based on the design of the side walls. If the box is made of profiled sheets, then to lay the insulation it will be enough to open the inner lining and lay an additional layer of “Teploizol” on top of the mineral fiber slabs. After which the surface of the slabs is covered with glassine and lined with clapboard along the sheathing. Alder or linden are used for interior decoration of trailer baths.

On the walls of the trailer within the location of the steam room, additional slats are placed on the existing sheathing using mineral insulation, foil polyethylene foam is laid, and only then the finishing is applied.

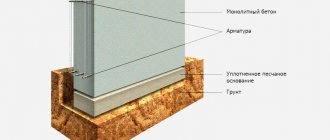

Sheets of expanded polystyrene, penoplex or polystyrene are usually laid on the floor, the insulation is filled with mastic waterproofing, a reinforcing mesh is laid and a cement screed is applied. Ordinary ceramic tiles are laid on top, which turn out to be much more practical in a bathhouse than wood.

The second option for insulating the trailer

For the manufacture of old-style metal boxes, non-profiled, smooth sheets of aluminum, galvanized or plastic were usually used. In this case, the insulation of the bathhouse must be done with a ventilation gap. A galvanized profile is sewn onto the walls inside the bathhouse.

Next, a grid of wooden planks, larch or aspen is filled, thus creating an air gap through which water vapor will be removed from the steam room and bathhouse. The rest of the insulation is installed similarly to the previous option. It is necessary to bring the ventilation duct to the roof from the gap between the walls.

We carry out external cladding

We cover the frame with film

. The cabin trailer can be left without cladding, but a structure made of wood or metal will require mandatory external finishing. We won’t just leave the “bare” frame, will we?

We cover the frame with waterproofing film. Carefully seal the joints of the waterproofing strips with tape. Many different materials are suitable for external wall cladding:

- wooden boards;

- composite panels;

- siding, etc.

Choose at your own discretion. The cabins covered with a block house also look very nice.

External cladding of the cabin with siding