Frame technology for the construction of residential buildings, commercial buildings, warehouses and outbuildings is becoming increasingly in demand.

A sauna made from SIP panels is a fairly practical and economical option for cold regions with minimal investment of time and money. And if all stages of construction are followed, such a bathhouse can be built in record time.

What are sandwich panels

The basis of the material most often includes chipboard sheets (if it is SIP) or steel sheets. The panel consists of several plates, between which insulation material is placed.

Sandwich panel composition

There can be several fillers for slabs:

- Styrofoam;

- mineral wool;

- polyurethane foam.

When building a bathhouse yourself, any of the proposed options can be used, however, based on such an indicator as environmental friendliness, mineral wool . Polystyrene foam and polyurethane foam are considered less environmentally friendly. However, such materials have excellent thermal insulation and sound insulation properties, and also have a very insignificant weight. However, when using these two materials, you should be prepared for the fact that the chimney will have to be completely insulated.

For the production of SIP panels, only high-tech equipment is used, which allows connecting individual elements to each other using an adhesive composition.

Manufacturing of sandwich panels

In this way, it is possible to achieve a high-quality, inexpensive and at the same time durable material that can withstand significant loads on a par with rounded logs. Based on its thermal insulation properties, the material can be compared to timber (kiln-drying) with dimensions of 20x20 cm or brickwork consisting of two bricks.

Comparison of material thicknesses to achieve the same thermal insulation value

Panels with a length of 7 m and a width of 2.4 m are considered standard. But the thickness can vary between 12-22 cm.

General information

Even a person ignorant of construction can voice the basic requirements for bathhouses of various designs:

- high thermal insulation;

- Fire safety;

- environmental cleanliness.

A sauna is not just a steam room. Traditional projects, depending on the type of bathhouse, may include a small dressing room, a separate room with a small pool, a room for gatherings at a table, etc. But it is the steam room that is the “heart” for which construction is started.

Pros and cons of sandwich panels

If you use high-quality thermal insulation material, then in terms of its characteristics, a bathhouse made from SIP panels will be in no way inferior to its wooden counterparts. And in some respects it will even surpass them. An example is the time allotted for warming up the entire bath, which will be needed several times less, largely due to the excellent thermal insulation properties.

It will take relatively little time to build a bathhouse from panels (about a week). The building can be made either free-standing or a continuation of an existing building (main house). SIP panels belong to the category of convenient, affordable and modern building materials that are used in construction. This type of technology is more accessible, and therefore has many fans around the world.

Construction of a bathhouse from sandwich panels (SIP)

The disadvantages include the need to independently produce a high-quality waterproofing and vapor barrier layer. The temperature in the bathhouse can reach 120°C, which is a detrimental indicator for a material such as polystyrene foam. But the combined material, presented in the form of SIP panels, can withstand temperatures of 200°C. However, over time, the material may begin to deform, which will lead to the loss of its basic properties and characteristics.

To avoid such deformations, strict adherence to the established technology for laying protective layers will be required:

- First of all, you should take care of waterproofing the walls, ceiling and floor.

- Using lathing (timber), insulation in the form of mineral wool is installed, as the most acceptable material in terms of properties.

- A foil-based layer is placed on top.

- This cake should be topped with a wooden clapboard.

Bath waterproofing

Surfaces near the stove need enhanced thermal insulation, which will serve more of a protective role. To do this, you will need several sheets based on gypsum fiber and soapstone. Sandwich pipes filled with mineral wool are used to furnish the space near the pipe outlet, as well as the roof and ceiling around it.

Disadvantages of SIP panels

Despite the obvious advantages, the material has some disadvantages:

- Short service life, which does not exceed 50 years.

- High cost of panels compared to other building materials.

- Susceptibility to combustion and deformation of the heat-insulating layer at a heating temperature of 125 degrees.

- Unattractive appearance of the material.

- The difficulty of building a bathhouse with your own hands. The technology requires compliance with all stages of construction and accurate calculations, on which the quality of the finished structure depends.

Preparatory work

If it has been decided to build a bathhouse using sandwich panels without outside help, then first you should select the most optimal project for the future construction.

Bathhouse project example

Once the project is ready, you should begin purchasing all the necessary materials. For a bathhouse, you should purchase panels with a thickness of partitions of 10 cm and external ones of 20 cm, which will be more than enough. Oriented strand boards will act as barriers. For their production, compressed sawdust is used, which are glued together with synthetic wax and resins.

Oriented Strand Boards

To increase the strength indicator, the outer panels are made longitudinal, while inside they will be placed transversely. Such materials have their own classification, which fully complies with all declared standards. The special additives contained in the material must be at a minimum level and be completely safe for human health. Otherwise, during the heating process, specific substances may be released that will negatively affect the general condition of visitors.

Availability

A frame sauna made of wave sandwich panels is available. Of course, if we are talking about a two-story bathhouse with a swimming pool and a relaxation room, you will have to fork out some money. But a small bathhouse for several people with a washing room, steam room and relaxation room is a rather small and quite budget-friendly building. It will not cost much more than a standard 4 by 6 meter garage. The area of the bathhouse should be approximately the same, not less. The main difference is the presence of several internal partitions and additional finishing.

Site preparation and foundation pouring

Before you begin building a frame-type bathhouse using SIP panels, you need to prepare a work site designated for construction. The area must be cleared of stones, construction debris, grass, trees, bushes and other vegetation.

If the site is inclined or there are significant unevenness, then the site is leveled using an auxiliary layer of soil, or the top layer is cut off until the optimal result is obtained.

Construction of a building on a slope

A cord and wooden pegs will be needed to apply the necessary markings for the future foundation for the bathhouse. Each angle must be carefully measured and be 90°.

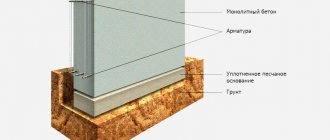

If the bathhouse is small, then installation is allowed without constructing a solid foundation. However, if the soil on the site is clayey, then it is still recommended to install a strip foundation. A small ditch, no more than half a meter deep, is dug under the foundation. But a width of 40 cm will be more than enough.

Strip foundation for a bathhouse

The formwork is being installed. The resulting molds are filled with cement-based mortar and pins are inserted into the still wet foundation, which will subsequently participate in fixing the strapping.

Pouring the foundation of the bathhouse

Immediately after the foundation has completely dried, you can begin laying a layer of waterproofing (2 layers of roofing material) and installing strapping type timber on it.

Installation of strapping beam

Before proceeding with the actual assembly of the structure, you should make sure that the cement is completely dry and mature. Drying should take about a week to be more convincing. Afterwards, the layer is opened and kept in the sun for several more days.

Safety

We try to build a warm garage from sandwich panels with polyurethane foam or polystyrene foam as insulation. But for the bath we use sandwich panels with mineral wool insulation. Such panels can withstand heating to high temperatures without any problems. But polystyrene foam, when heated strongly, begins to decompose, releasing harmful substances. Therefore, for the bathhouse - only sandwich panels with mineral wool.

Bathhouse project 6 by 4

And mineral wool is fireproof. This is relevant for a bathhouse, because you need to be careful with open fire.

Installation of the bath frame

It is the frame that will be assigned the load-bearing function of the future bathhouse, and the further operational life of the building and its level of safety will depend on its quality.

To make the frame, you will need a wooden beam, the surface of which is pre-treated with various antiseptic impregnations.

Bath frame

The required cross-section for the timber will depend on the load-bearing capacity of the insulation used. However, the thickness of the heat-insulating material used should not be greater than the timber itself. The material is placed between the posts.

To install the upper and lower trim and corner posts, you will need a beam with a slightly larger cross-section than the one that was used when installing the intermediate supports. The strapping is carried out starting from the corner part of the foundation, using timber with a section of 10x10 cm.

Installation and fastening of frame structure racks

When connecting in the corners of the strapping beam, it is necessary to use the paw method. And for greater reliability, it is also recommended to use nails. Previously placed pins will help avoid possible displacement of the beam in the future.

Connecting a beam into a paw

The concrete surface is completely cut off using roofing felt or any other similar material before laying the lining beam begins. Eight braces should be placed in the corners.

Bathroom flooring installation

In order for the structure to be durable and incredibly strong, all wooden elements should first be treated with special fireproof and antifungal impregnations several times with an interval of several days.

Sequence of upcoming installation work:

- A beam with a cross section of 10 cm is attached to the foundation pillars. Galvanized fasteners will help with fixation. However, first they need to be concreted into the thickness of the base.

- The bottom harness is done completely. Boards 5 cm thick are nailed around the inside perimeter.

- The logs are installed on the base of the floor, which are screwed using self-tapping screws. The step will be about half a meter.

- OSB on both sides is treated with a composition based on a bitumen primer, after which they are laid along the joists. Jumpers are installed between the lags, but only in those places where the individual sheets will be joined.

- After completing the installation work of the first layer of flooring, you should immediately begin the second. The order will be the same, but the material will spread across the joists.

Bathroom floor installation

Practicality

A bathhouse made of metal sandwich panels is an unusual construction. You may have doubts about the resistance of sandwich panels to high humidity. Metal doesn't like moisture.

Ventilation in the bath

I want to reassure you right away. Sandwich panels are produced with different coatings. For example, some models are designed for rooms not only with high humidity, but also with a chemically aggressive environment. This could be, for example, a chemical production facility, a pigsty or a cowshed. In such rooms, metal has a hard time.

Ventilation in the bathhouse - possible options

A very important nuance - the sandwich panel can be replaced. I love it. You will have to remove the shaped elements, loosen the fastening of the adjacent panels, but in principle - nothing complicated. Try replacing the log in the log house...

Construction of bath walls

In order to assemble a frame for a bathhouse, you will need a lot of free space. However, all work can be carried out directly on the site allocated for construction. The pitch will be calculated in advance and based on the material used for the sheathing. To avoid further adjustment of the sheets, so that the wall is formed tightly, the intermediate step between the racks will be about 60 cm. This distance is also optimal for the insulating material, because it has almost the same width.

The material should be placed spaced between the posts. In those places where, according to the project, there will be openings, the step should be increased by another 30-40 cm. In those places where the frame will be adjacent to the lintels, additional racks (made of timber) will need to be installed.

At the same time, you can start laying out floor joists from boards with a section of 5x15 cm. All elements will be carefully assembled into a single structure, which must then be leveled and connected. The resulting voids between the supports should be filled with heat-insulating material.

When carrying out work related to external cladding, carriage boards are most often used. It is also possible to use other building materials, such as:

- thermal panels;

- facing brick;

- block house;

- siding.

A building covered with clapboard will look natural and as good as possible. Its installation should be carried out in a horizontal orientation, having previously laid a layer based on waterproofing material.

Cladding on the outside

Foundation

After studying the designs of a bathhouse made from SIP panels and drawing up a plan for your own steam room, you need to bring a water supply to the site of future construction and take care of the sewerage drainage. To do this, you need to dig a hole no closer than a meter from the structure. Next, we clear the area for installation of the base. The best option for such a steam room is a columnar foundation.

A columnar foundation for a bathhouse is erected from SIP panels in this order:

- We remove the top fertile layer of soil.

- We mark the locations of the pillars at the corners of the future structure and the joints of the load-bearing walls. The distance between them should be less than 2 meters. Otherwise, it is necessary to mark the area in the middle for mounting the third support.

- In the marked places we dig holes with a depth below the freezing level of the soil. It is different for each soil type and must be known before starting work. The width of the recesses should be about 0.5 meters.

- We make formwork by twisting a sheet of roofing felt into a pipe with a diameter of 40 cm and fastening it with reinforced tape.

- We insert the finished structures into the recesses.

- We fill the sand cushion with a layer of about 15 cm and water it with water for high-quality compaction.

- We insert a reinforced frame with a diameter of 30-35 cm.

- We align all elements strictly in one plane. To check the evenness we use a hydraulic level.

- We pour the concrete solution on top, compacting it with a special vibrator or reinforcement.

- We fill the distance between the formwork and the ground.

It is advisable to insert special metal elements into the concrete pillars for the lower framing of the frame in the future. After this, you need to wait for the structure to dry completely. Moisten it with water in hot weather.

It is the light weight of buildings that makes it possible to equip them with lightweight foundations, for example, like the one in the photo - a pile-screw foundation.

The use of this type of foundation will significantly reduce the budget of the entire construction. Also, a bathhouse made from SIP panels can be erected very quickly and has a high level of seismic resistance.

Bath insulation

When assembling a bathhouse made from SIP panels, the main point is laying the heat-insulating material. Its choice should be approached as responsibly as possible. The usual mineral wool can be used as such a material. This material has a number of undeniable advantages:

- allows the structure to breathe;

- non-flammable material;

- excellent vapor permeability;

- acceptable cost.

Thus, you can achieve the same results as when building a bathhouse from timber. This material can be purchased in the form of rolls or slabs, which are equally convenient for subsequent installation. However, it is still more convenient to work with slabs.

Insulation in the form of plates is mounted between the racks. The sheets should be carefully straightened if they have become deformed in the corners or do not fit tightly together. With all wooden elements, the insulation should be butted and fit snugly to the base.

Insulation of a bathhouse from the inside

Many experts recommend laying two layers of insulation, each 5 cm thick. The first will consist of slabs, while the other will consist of rolls. In this way, the formation of connecting lines can be completely eliminated.

Waterproofing material is laid between the outer layer of cladding and the insulation boards. Tectotene film will be sufficient, but other materials can also be used. During subsequent operation, part of the insulation material will be blown through the ventilation gap, which will lead to a decrease in its thickness. This will lead to the loss of its original thermal insulation properties. A guarantee that this will not happen will be the creation of windproofing protection in the form of a vapor-permeable membrane.

Polyethylene foil on an aluminum base is placed on the inside. The resulting joints are glued using masking tape or regular tape. And only after this can you begin subsequent finishing work. Over time, mineral wool can shrink significantly if the above technology is violated.

Pleasure

Sandwich panels have a very low heat capacity and very good thermal insulation properties. This means that the sauna will warm up very quickly, which saves time and energy.

If you still think that there should only be wood in the bathhouse, cover the steam room with boards.

A bathhouse made from a sandwich panel is a small building, but the development of the project must be carried out very carefully. There are many nuances. You need to move the hottest objects away from the walls. The sandwich panels are connected almost hermetically, so ventilation should work well. It is better to use the same pipe from the oven not an ordinary pipe, but a sandwich pipe.

Pipe sandwich - design

The entrance to the bathhouse must be made with a vestibule, otherwise every opening of the front door will be accompanied by a cold draft. The penetration of cold air into the bathhouse in winter is especially unpleasant. In general, it is better to make a vestibule right away than to build on it later.

The bathhouse not only needs to be built correctly, even the stones need to be laid in a special way

A bathhouse is usually built on a hill or a slight slope. This is necessary to avoid dirt. An ideal addition to the bathhouse would be a swimming pool. And it is not at all necessary to make the pool stationary. You can buy an inflatable one, or better yet, a frame one. But you should think in advance about a flat, sand-filled area of at least 2 by 3 meters. Well, in winter, when you close the pool, after a bathhouse on the same site you can fall face down in the snow.

The floor in the bathhouse is another part of the structure that requires a special approach

Late autumn, winter and early spring are the best times to build a bathhouse. Materials are becoming cheaper, and if you build from sandwich panels, then low temperatures will not affect the quality of construction. The main thing is not to put off building a bathhouse until later, otherwise you will never build it. The bathhouse is an excellent means of treating and preventing winter colds!

Bathhouse roof installation

First you need to install the rafters. All necessary manipulations are performed on the ground, after which the finished frame will be raised for construction. Before working with wood, all surfaces must be treated with one of the many antiseptic compounds.

Then you should follow the following sequence of actions:

- Beams (mauerlat) are fastened along the perimeter of the building and their subsequent fixation.

- The ridge board is fastened in the central part.

- The outer rafters are installed, and then the inner rafters. The step will be about half a meter (no more!).

- A persistent corner is installed on the rafters.

- Jumpers are installed between the rafters, the main (end) part is installed, and overhangs are installed.

- The vapor barrier material (membrane) is laid overlapping.

- The sheathing is installed, into the holes of which the insulation is placed.

- Waterproofing material is laid (the overlap will be 10-15 cm).

- A counter-lattice is formed, the thin strips of which are nailed on top.

- The roofing material is being fixed. In this case, it is necessary to leave a small space for waterproofing, which will be 1.5-3 cm.

Bath roof layers

If the structure must be lightweight, then the floor material should be selected based on this parameter. Ondulin will fit perfectly.

Interior and exterior works

Everyone will have their own preferences regarding the interior decoration of a bathhouse made from SIP panels. From the influence of external factors, such as weather conditions, additional protection should be provided for the panels themselves. Only in this way can its service life be significantly increased. The waterproofing layer must be covered with more plastic materials. Afterwards, you should arrange the sheathing, to the surface of which the selected type of sheathing will be nailed. It can be siding. However, lining made of natural wood is still preferable.

It will also need to be protected from moisture using one of the many impregnations. Internal surfaces can be covered with waterproofing mastic, securing aluminum foil to it. Afterwards you will need to nail another sheathing on which the lining will be located. A ventilation gap is required. The interior decoration will depend on the personal preferences of the owner and his budget. In the steam room itself, the walls can be additionally lined with brick, while natural wood of inexpensive species can be used to cover the surfaces in other rooms.

Negative reviews

It is difficult to believe in the impeccability of the material described, so we tried to find on the forums those consumers who are dissatisfied with the result.

The issue of money is very sensitive for everyone, but maybe another home owner will make more specific claims about such a house?

“To seal the joints of the panels, polyurethane foam is used, which came to the building materials market relatively recently. Manufacturers claim a guaranteed service life of up to 20 years. And what will happen next? Not yet known".

Sometimes it happens

Typically, the construction of a country house lasts from 2 seasons. A house of 150 m² from SIP can be assembled in two weeks. Close attention to the construction process certainly won’t hurt.

So, the result is, of course, very subjective, but we identified the following disadvantages:

- the use of resins in the material that can cause health problems;

- low noise insulation against impact sounds (for a private single-family home this is not critical);

- the house is a “thermos” and requires additional ventilation, which implies rather complex solutions.

Nevertheless, the positive aspects of SIP houses are much stronger and more convincing than the negative aspects inherent in any building material.