One of the most heated debates surrounding the Russian bath is the choice of the best type of wood as the main building material. Most of these discussions, one way or another, are related to two species - linden and aspen. Although other materials can be used for construction - alder, cedar, larch, etc.

Moreover, this question arises twice: the first time - when determining the material for the log house, and the second time - when choosing the lining for finishing the heart of the bathhouse - the steam room. To answer the question: linden or aspen for a bath - which is better, it is necessary to consider the advantages and disadvantages of each type of wood.

Larch bathhouse

When choosing a material for a bathhouse, you need to take into account not only the heat capacity of wood, but also other characteristics. Unlike a residential building, the wood here is exposed to intense exposure to steam, water and temperature fluctuations, because the building is heated only during bathing. Not every material can withstand such a load.

An excellent option for a bathhouse is larch. The tree is a coniferous tree, meaning it contains a fairly large amount of resin. High resin content ensures amazing resistance of larch to rot, fungi, and water.

If the products are made of pine, it is necessary to varnish and protect them from moisture. Larch does not need this. On the contrary, over time it only becomes stronger than oak.

The advantages of wood are not limited to unique resistance to decay. Accordingly, a larch bathhouse will have the following features:

- strength - the density of larch is only slightly less than that of oak, a structure made from this tree will last a long time, as it is not subject to mechanical damage;

- resistance to rain, snow and heat ensures the longevity of the bath;

- larch lining includes a small number of knots, and this means not only aesthetics, but also greater strength of the boards and logs themselves;

- the wood has a beautiful texture and is very attractive;

- a log bathhouse made of larch does not require any protective measures; there is no need for periodic treatment with antiseptics, insect repellents, or stains;

- lining made from this material has the same advantages as logs.

There are also disadvantages to a bathhouse made of larch:

- it is at least 2 times more expensive than pine;

- wood is processed with some difficulty, so the bathhouse itself will also cost more.

Comment! Larch floors are still used in European castles. Its age reaches 300–400 years.

Varieties

Linden lining is presented on the world market in a wide range.

There are the following varieties of this material, each of which has individual properties:

- Extra class. It is considered an ideal option, as it has the most smooth and beautiful structure without knots, cracks or other defects. It is also characterized by impeccable shape and processing.

- Class A. It is of fairly high quality, as it has minor defects in the form of a small knot or small crack, which give the material a special charm. Products of this type belong to grade 1.

- Class B. It is characterized by an acceptable cost, and the board itself may have a small number of knots, and is also capable of changing color during long-term use.

- Class C. This wooden linden lining is considered the most budget option. There may be obvious knots on the front of the boards, although their presence does not at all distort the appearance of the products.

- Eurolining. It is produced exclusively according to European standards and is an example of impeccable quality. Its design difference is considered to be deep grooves, as well as the presence of additional channels for ventilation and drainage. Such heat-treated lining has a wide range of applications, despite its high cost.

Each of these types of linden lining has its own individual characteristics, which must be taken into account during the purchasing process. After all, one or another option is produced using a special technology intended exclusively for the manufacture of a specific type of finishing material.

Aspen bathhouse: pros and cons

If larch is used both as the main material and as a finishing material for the steam room, then with aspen the situation is different. This tree is very specific and not cheap. Moreover, the cost is determined not by high qualities, but by the features of the workpiece.

Aspen grows in wetlands, which causes the inside of the trunk to rot. You can only harvest aspen tops up to 4–5 m in length. The rest of the tree is unusable and is simply thrown away. In addition, aspen harvesting is only possible from March to May, while aspen is relatively easy to process. This “seasonality” makes the collection and supply of material a very expensive endeavor.

And yet, this is the material that people often prefer to linden and alder. In fact, the disadvantages of aspen turn into advantages when it comes to the steam room:

- aspen - hardwood, boards or lining from it do not emit resin, which is a valuable quality for a sauna;

- wood does not heat up as much as many other species, this eliminates the possibility of burns;

- out of 3 trunks, only one turns out to be suitable for construction, but it is extremely resistant to moisture and does not rot;

- wet aspen is easy to process; when dried, it shrinks greatly, but at the same time the tree acquires exceptional strength.

An aspen bathhouse lasts for decades, and over time it only becomes stronger.

Important! Aspen wood is very wet and shrinks greatly when dried. However, once it dries, it becomes rock hard.

Manufacturing

The production of lining is divided into stages and begins with the production of edged boards.

Using a sawmill, the required workpieces are cut, corresponding to precisely specified parameters and dimensions, using the best purity material: between the bark and the core of the tree trunk. The next stage is drying - the correctness of the geometric dimensions of the material and their stability depend on it. During drying, all microorganisms located both inside and on the surface of the wood are destroyed, excess moisture is removed, which reduces the weight of the material and simplifies its further processing. The final stage is the final processing of the front side and chamfering, after which a perfectly smooth and even board is obtained. Some unscrupulous manufacturers often neglect this stage, not bothering with high-quality grinding and removing knots that may fall out. Also, dishonest manufacturers often do not completely dry the board, which causes the buyer to have huge problems: the lining begins to change geometry and bend, and therefore further use is impossible.

Linden or aspen for a bath: which is better?

It's really difficult to choose between these two materials. Linden is traditionally considered the best tree for a bathhouse and deservedly so. However, aspen, despite its external ugliness, poses serious competition to it.

Linden wood is soft, it is easy to process, and accordingly, the construction of a bathhouse requires less cost. If dried logs were used, the building does not shrink and can be used immediately after completion of construction.

Aspen, on the contrary, is processed with great difficulty. Since a bathhouse requires well-dried material, this makes construction an expensive and time-consuming task.

The softness of linden is also its disadvantage - the tree is short-lived, but dry aspen acquires the hardness of stone and lasts an exceptionally long time. Linden does not need to be processed for aesthetic purposes; even an unsanded log looks great, not like lining. To give aspen an aesthetic appearance, you should trim the bark from the log, sand it and plan it. In addition, repeated grinding will be required - the latter is performed 3 years from the date of laying. Otherwise, instead of a silver-white bath, you get a gray, unsightly one with dark spots.

Linden is not resistant to rotting and fungal attack. The bathhouse requires periodic treatment with special preparations. Aspen is not susceptible to rot or fungi. The only treatment that may be needed is for wasps. For some reason, the latter really love this tree.

The cost of linden is higher than that of aspen, so it is really difficult to choose.

Important! A log house for a bathhouse made of aspen and linden, as confirmed by reviews from builders, does not require additional finishing of the steam room. Both breeds are certainly suitable for sauna lining.

How to distinguish linden from aspen

Lining made from linden and aspen is very easy to confuse. It is not so easy to distinguish wood.

First of all, pay attention to the color. The wood of linden lining is very light, but still has a coffee tint. Against its background, the aspen is almost snowy white.

Linden boards have a characteristic sweet aroma. The smell of aspen is bitter, more reminiscent of birch sap. Aspen lining is rarely truly smooth, since this wood is difficult to process, but linden is smooth and silky;

Knots in aspen lining are more common. They are darker and clearly visible. In category B, even falling knots are possible here.

To distinguish linden boards from aspen boards, you need to not only inspect them, but also try them by touch.

What is better in a steam room: aspen or linden

The choice between linden and aspen lining is even more difficult. The materials have a number of common properties that are very useful for saunas and steam rooms:

- both linden and aspen do not heat up as much as other types of wood;

- shelves and walls finished with clapboard remain pleasant to the touch and do not burn;

- the wood of both species releases aromatic oils that are beneficial to health;

- the lining looks equally aesthetically pleasing;

- Both linden and aspen tolerate steam well.

There are also differences between linden and aspen:

- the smell of linden wood is deservedly considered the most pleasant, while that of aspen is bitter and not everyone likes it;

- linden darkens over time, aspen practically does not change color;

- linden lining is susceptible to fungus, the finishing must be treated, but aspen does not have this drawback;

- linden costs almost 2 times more than aspen lining, but linden wood contains far fewer knots and stains and looks more beautiful.

For a steam room, linden or aspen linings are equally good. The choice determines the taste of the owner.

Dimensions

There are 2 standards regarding the size of linden lining:

- Standard. Its thickness is no more than 2.5 cm, its width is up to 15 cm, and its length can reach 6 m.

- Eurolining. Its thickness is 13, 16 or 19 mm, its width is available in sizes 80, 100, 110 or 120 mm, and its length starts from 50 cm and can reach 6 m.

It is worth remembering that for interior decoration, a lining with a thickness of 14 mm is sufficient, and for external use it is worth using options whose thickness is at least 25 mm. By adhering to this rule, you can easily create favorable conditions for staying in a particular room at any time of the year.

During the selection process, it is necessary to take into account the fact that the shorter the boards, the less their cost will be. You should definitely pay attention to the size table, as well as the individual parameters of a particular finishing material option. Each package must contain all the information regarding the lining located inside. The correctly chosen option and size of these products will make the room as comfortable and presentable as possible.

Cedar for a bath

Noble cedar wood belongs to the elite category. The material has exceptional qualities, not only functional, but also medicinal.

Cedar wood is impregnated with unusual resinous substances. They call it gum, emphasizing its special qualities. It has an antibacterial effect not only on the wood itself, but also on the environment. When heated, the substances begin to evaporate, disinfecting the room and relieving a person of a wide variety of diseases, so cedar is ideal for a steam room.

Important! In Siberia, a bathhouse decorated with cedar clapboard is recommended for those suffering from diseases of the respiratory system. The tree can even cure bronchial asthma.

Log bathhouse made of cedar

Cedar is the best option for a bath. The qualities of wood provide the log house with durability, beauty, and convenience:

- cedar has the lowest thermal conductivity compared to other conifers; a cedar bathhouse is warm even in the bitterest frosts;

- the wood is resinous, provides excellent antiseptic properties, therefore, it does not rot, is not susceptible to fungus, and even insects are not able to damage it;

- cedar resins are healing, cedar finishing provides an excellent antibacterial effect and natural air ionization;

- cedar is resistant to moisture and temperature changes. A cedar bathhouse is very durable and will last at least half a century;

- both the logs and the lining are very beautiful and do not need any processing: the natural color and texture are beyond praise.

There is only one drawback to cedar wood or lining - high cost.

Cedar lining for a bathhouse

Cedar lining for a bathhouse has all the advantages of a log. This material is ideal for a steam room, although it is not as effective as aspen:

- gum resin evaporates, but does not release when heated, so cedar lining does not burn and does not leave resinous stains;

- cedar lining guarantees an excellent healing effect;

- the specific fibrous structure of the wood ensures the absence of cracks and chips even at the ends;

- the lining is very beautiful: the colors are even, muted, the knots are small, the panels are smooth and delicate to the touch;

- the material is not afraid of moisture, steam, mold, or rotting, so it does not need any processing.

Important! Over time, cedar lining darkens, or rather, acquires a brownish tint.

Cedar bath: photo

Cedar is an excellent building material and allows you to implement any project - from a traditional Russian bathhouse to a complex hotel complex.

Finishing with paired cedar lining is no less impressive and beautiful and is suitable for any style.

Features of aspen lining

Aspen lining - almost without eyes or knots.

No resinous secretions, noble light smooth surface, high strength. All these properties make it possible to use lining not only for finishing walls and ceilings, but also for making furniture: benches, tables, cabinets.

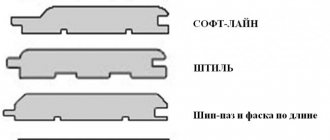

According to the structure of the outer edge, the lining (aspen) is:

- With a semicircular edge shape;

- Flat edge;

- Profile edge (wavy, tapered).

All these types can be used either individually or in combination of different types, for example, in the manufacture of furniture or arranging a bathhouse.

The standard for board sizes differs in that during the cutting and drying of wood there is a lot of waste, so boards longer than 4 m are extremely rare.

Standards:

- thickness – 12-15 mm;

- width – 87-88 mm;

- width with spike – 95-96 mm;

- length - from 1.0 to 3.0 meters (rarely 4 m).

Separately, it is necessary to say about aspen lining of the “Euro” type. Firstly, its cost is quite high. It is distinguished by high-quality surface treatment and a special type of connecting lock.

Standardization of manufacturing quality in Russia is regulated by GOST 8242-88, and if the country of manufacture is a European state, then there must be compliance with DIN 68126. Based on humidity and the quality of planed surfaces, the lining is divided into grades:

- “Extra” is the highest grade. There are no defects or knots. Smooth white and flat surface;

- “A” - there are deviations, a small number of knots, uneven color;

- “B” - knots, the color is not even, there may be defects: scratches, etc.;

- “C” – low quality board, a lot of dry knots, cracks and chips, rotten parts at the end. Used for rough work or finishing of utility rooms.

Eurolining belongs to the “extra” class.

The deeper the lock on the lamellas, the stronger the connection. The lock groove should not be less than 8 mm.

If you use lining (aspen) with some minor defects, then using dark varnishes you can hide the defects, and even small cracks can be hidden with putty.

Varnishes are divided according to the substance that makes up the base:

- Acrylic;

- Polyurethane;

- Acrylic-polyurethane;

- Alkyd;

- Water-based.

Acrylic varnishes are universal. Will not allow dirt to concentrate on the surface. Dries quickly. Negative property - they begin to emit a specific odor when heated.

Varnishes containing polyurethane are suitable for treating indoor and outdoor surfaces. There are translucent compositions and darker ones - tinting. Lacquered panels will not turn yellow.

A combination varnish containing both acrylic and polyurethane gives some shine to the coated products. Protects against fungal colonies and mold.

Alkyd compounds will protect the wood from moisture. The negative property is the long drying time and unpleasant odor, so the room will have to be ventilated for several hours. Complete drying is guaranteed after two days.

Water-based varnishes are almost completely odorless, dry very quickly, and most importantly, there is no harm to health. In addition, water-based varnishes do not support combustion and do not emit harmful substances when heated.

When purchasing any varnishes and paints for residential premises, you should carefully read the instructions on the can. There must be a note stating that the composition is allowed to be used inside houses and apartments. If necessary, it is better to consult the seller.

In most cases, the surfaces will have to be primed before varnishing.

A number of craftsmen prefer to use factory-made varnishes and impregnations based on oil and wax. They penetrate deep into the pores of the wood, flow into all microcracks, and provide protection from moisture and mechanical stress.

For example, alkyd-oil solutions have a beneficial effect on the properties of aspen lining, protecting it from cracks and deformation. It is believed that treating wood with impregnations and varnishes can extend the life of products by 3-4 times.

Varnishes are applied in accordance with the rules:

- On dry and clean surfaces;

- After applying the primer;

- The ends are painted first;

- Temperature not lower than 5 degrees;

- Humidity not less than 70%.

An antiseptic is applied before varnishes. In addition to a brush and roller, you can use a spray bottle; with good skill, you will get the most even surface without defects.

For the dressing room or kitchen, water-based or wax varnishes are suitable.

In some cases, aspen lining is coated with special fire retardant compounds. There are combined mixtures: fire protection and antiseptic.

When finishing wood products, common mistakes occur. Firstly, the use of cheap products from the Chinese chemical industry, which can cause harm. It is not recommended to purchase varnishes, paints, impregnations and primers in markets without the appropriate certificates.

Secondly, the type of impregnation/primer does not match the finishing varnish or type of paint. Otherwise, high-quality coverage will not be achieved.

We suggest you familiarize yourself with How to choose the size of a clamp for lining

Alder for a bath

Another traditional material is gray and black alder for the bathhouse. The wood of these species has a very unusual porous structure. This feature makes alder lining a suitable option for a bathhouse:

- gray and black alder practically does not shrink. Due to its high porosity, moisture evaporates very quickly, this quality makes the lining an extremely suitable solution for a steam room;

- the wood is soft, easy to process at any stage, so the construction of an alder bathhouse will not require large expenses;

- sauna lining made of alder does not warp or deform even after several decades;

- wonderfully beautiful shades - from fiery to brick, give the building real beauty;

- In the dressing room, it is recommended to open the lining with wax to emphasize the color and texture.

However, judging by the reviews, alder for baths also has serious disadvantages.

- Wood is not very resistant to water. On the one hand, in the steam room moisture evaporates from the pores, and this is a plus. However, at low temperatures it stagnates in the pores and causes rotting. The external side of the log house requires periodic processing.

- Over time, the alder darkens almost to black.

- The cost of the lining is quite significant. The fact is that alder wood includes many knots. To get rid of them, a very thick layer of wood is cut from the trunk. In this case, the whips are short, and the material is expensive.

- The alder bathhouse needs insulation: there are too many joints.

Alder baths are built in mid-latitudes, where there is no need to insulate it.

Colors

The coloring of eurolining is no less important than its size or other aspects. Most manufacturers color this material in one way or another. In many cases, a universal solution is a white or beige tone. If you want to decorate the interior, you can radically use any bright paint. This is exactly what they use: even an initially inconspicuous surface can be transformed with your own hands.

Slightly indifferent warm shades are an excellent choice in bedrooms and kitchens. But a study or corridor, which is purely utilitarian in nature, is painted mainly in cold colors. Returning to white paint, it is worth saying that it should only be used where there is the least risk of clogging. You should also be more careful with pearlescent shades. Despite their external effect, they get dirty extremely quickly, and this only gets worse in bright rooms.

Despite the comparative simplicity of painting yourself, industrial coating is still preferable. It is obviously smooth and clear. The quality of the paint is strictly controlled at the factory; they even test it randomly in laboratories, which is impossible in everyday life. There is no need to talk about less time and effort, and the elimination of errors. Moreover, the product arrives already dried and completely suitable for installation.

Reviews

Boris Nevelov, 42 years old, Novosibirsk

I hesitated for a long time between linden and aspen, but in the end I made the traditional choice: linden. It costs more, but for a steam room, I think, you won’t find a better one. The wood is warm, silky, and does not heat up. And the smell in the steam room will make you pumped.

Nikolay Morozov, 35 years old, Omsk

There used to be a bathhouse on the site - made of pine. The inside of the steam room was lined with linden. But something went wrong: it began to rot. And in the bathhouse there was always mold or something else. They dismantled and built a new one - from aspen. It has been standing for more than 6 years, nothing rots, there is no trace of fungus. But, of course, it took me a long time to choose a tree. I went to the base three times to take away the barrels.

Alexander Fedorov, 52 years old, Ufa

A bathhouse was started on the site as soon as the house began to be built. I chose aspen: the price is lower than cedar, and it is not afraid of water, if it is good. Banya is already 15 years old. The color, of course, is not the same, it has become gray, but the tree is like stone. During all this time there was never mold in either the steam room or the dressing room.

Recommended Posts

Bathhouse made from a sea container

Bathhouse made from sleepers

Sauna tent

Do-it-yourself bathhouse repair

Russian wood-fired sauna

Why is there no draft in the sauna stove?

Surface finishing

Varnishing will help extend the life of wooden surfaces and change their appearance at the discretion of the owner. It is not recommended to use ordinary paints; they will obscure the texture of the wood. Before varnishing, you need to treat the surfaces with fine sandpaper and then remove dust.

Varnishes are applied to the surface with a roller or soft brush in several layers. The coating should be renewed every few years; this will extend the life of aspen lining panels. There is no need to apply synthetic varnish in the steam room; when heated and temperature changes, it will most likely fall off; in addition, the fresh smell of wood is very pleasant in the bathhouse.

One of the ancient ways to protect walls in a bathhouse is impregnation with vegetable oil in two layers. Now there are special impregnations from European and Russian companies. You need to focus on the purpose of the composition: for baths or saunas.

Adviсe

Before choosing a product, first of all, you should decide on the material of the lining. Wooden lining has long established itself on the market as an affordable and reliable material for finishing premises. Among the positive qualities of wood, good sound and heat insulation, as well as ease of working with the product itself, should be noted. Wooden lining has a wide range of applications: it is used to cover both bathhouses and living rooms, both inside and outside.

Wood lining can be made from different types of wood, respectively, they are all divided according to their properties. When choosing wooden lining, you need to pay attention only to Euro lining. The main difference is quality. A thicker lock, high requirements for wood and its moisture content, as well as surface treatment make eurolining incomparable in quality to the conventional version. However, if you need to save money, then classic lining is also a good option. But you should closely monitor the quality when choosing a material, and also be prepared for difficulties in the form of a poorly connecting lock, a rough surface, falling knots and possible cracks if the installation is carried out in a damp room.

The wooden paneling should be secured using clamps. A clamp is a bracket that is attached to the sheathing using nails or self-tapping screws and presses the lining lock to the base, but is not itself rigidly fixed to the board. This allows the lining to easily change its dimensions due to thermal expansion and humidity and move vertically, which guarantees reliable fastening and the absence of cracks or extraneous sounds in the future.

Separately, it is worth noting such areas of application of lining as finishing baths and saunas. Softwood lining is rarely used in bathhouses because it can release resins, but this helps it resist aggressive conditions such as changes in temperature and humidity, as well as fungus and microorganisms. In saunas and baths, alder or linden lining is most often used - such wood does not emit any resins after processing.

Plastic panels appeared on the market not so long ago, but have gained a good reputation. They are not suitable for exterior decoration, but are great for cladding loggias and bathrooms or showers. Since plastic is impervious to water, the panels can withstand any humidity and are also insensitive to sunlight.

MDF lining can be laminated, veneered and painted. Laminated options are covered with PVC film, have a lower price and are more wear-resistant than veneered ones, which are covered with premium wood veneers. Painted panels, as the name implies, have a uniform color. Overall, this is a good alternative to the previous options. MDF lining has all the advantages of the wooden version and is produced in a wide range of colors. This alternative is suitable for the entire apartment - it can be used both in the kitchen and in the hallway, using it as wall or ceiling cladding.

You should definitely monitor the quality of the material when choosing it: the surface of the product should be even and smooth, uniform in color, without darkening or cracks. You should not trust exhibition samples, since the sample may be from a different batch, or the lining may have been stored in unheated and damp areas. Unfortunately, it is impossible to know exactly the storage quality of the material, so, as an option, you can buy one or two packages of the material and see what happens to it at the installation site.

Installation can occur in various ways. After impregnation, wooden slats dry for 48-72 hours, at the same time the wood adapts to the microclimate of the premises. Then they form a sheathing for the slats, attaching 1-inch pieces of wood at a distance of 500-600 mm from each other. When cladding external surfaces, it is better to lay insulation in the gap from the surface to the sheathing. The choice is made individually.

Having completed the preparation, install the coating itself in a vertical or horizontal direction. The second option is chosen mainly by those who intend to expand the perceived space. It is advisable to orient the rack grooves down to prevent the accumulation of dust and dirt. Quality control is carried out every 7-10 slats. It will be more difficult to fit the last board, and a lot of time will be spent.

The vertical layout implies the ability to visually raise the ceiling. In addition, it differs in that it allows you to install lining of various sizes. Action is required from the corner; the boards are fastened into the grooves of the previous slats. The first board is attached to nails, the heads of which are covered with decorative caps. The clamps are attached to the rear wall. The builders themselves decide whether to cover the caps driven inside the finishing board.

In addition to dividing the eurolining into grades and its fastening, you need to pay attention to painting. Situations are different; in some cases, the color that initially seemed nice did not work in reality. Or design priorities have changed. Or a new renovation is being done, after which the old coloring becomes unacceptable. It is important to distinguish between compositions for internal and external work and never confuse them in principle.

Before painting, use protective mixtures and tinting stains. Also, instead of paints, varnishes and oils are widely used to coat wood. Which of these options to choose largely depends on personal preference. We must not forget that the color on the monitor screen or in a printed catalog, and even when opening the can, will not be the same as at the end. Sometimes you have to paint an inconspicuous area for the sake of testing.

Snow-white textiles, if diluted with lining and timber, will be perceived even fresher. Bright, rich walls are ideal as a backdrop for light furniture. But painting the entire lining in a perfectly white color scheme is unreasonable and uncomfortable. It is much more correct to make a slight deviation from it, add a slightly different color, even if it is only a low tide. To reduce paint consumption, wood is primed with antiseptic additives.

Complex tones with a feeling of the presence of a layer of dust help to create a feeling of thoughtfulness and demonstrate a deep design. A great move is to pair colorful walls with white floors or a darker ceiling. But you shouldn’t combine all three elements at the same time; only trained designers can make an educated decision about whether this is justified. Before installation, all foreign matter and dirt should be removed from the surface to be finished. The sheathing is placed at right angles to the future course of the lining.

It is advisable to work from an angle. Driving a nail or tightening a bolt into the first board can make the job easier. But the perception will be spoiled, and if necessary, it will not be possible to dismantle the lining unless the integrity is violated. It is much better to use clamps, and they are also more reliable. And if anything happens, you can remove the fasteners without damaging the cladding.

It is advisable to support the eurolining, which is to be mounted vertically at a certain distance from the floor, with a “pallet”. This is the name given to a strip with a convex contour, held on the sheathing.

It is necessary to dismantle the lining not only if you no longer like it. Gradually, the wood will lose its varnished coating. Its color will also deteriorate. Reconstruction of these characteristics is best achieved after the blocks have been removed. All work should be performed at normal room temperature. The ideal humidity for installation and reconstruction is from 50 to 70%.

Restoring the appearance begins with removing the trim and refinishing. Then the material is painted twice (it must dry). Then the varnish is applied and dried under normal conditions for two days. Then they install the lining on the sheathing. Waiting time should not be wasted; the sheathing should also be examined and repaired.

The original step is to apply eurolining to the walls, which differs in tone. Various rooms located nearby are decorated with contrasting colors. An exception is made for very dark colors, which will only create a depressing impression. Another way to show your extraordinary approach is to choose an atypical ornament. So, along the perimeter of the board you can place it in the form of a square, the inside of which is trimmed diagonally.

This practice is applicable both in isolation from color refinements and in close connection with them. Not only the colors play a big role, but also the overall stylistic concept. For example, in a country setting, the most preferred color is white and its various shades. It will be no less good in a Scandinavian interior. Then the appropriate color is selected for both walls and ceilings.

Eurolining allows you to create an attractive soft interior in an environmentally friendly manner. Kitchens are usually either sheathed completely, or only dining areas are separated with this material. An interesting and not yet hackneyed move is to fill the panels exclusively in the lower part of the wall. To separate dissimilar fragments, the use of moldings gives good results. If you don’t understand in which room the lining is most appropriate, you need to focus on the bedroom.

The varnish that will be applied to the material should not be intended for baths. It is much better to use special compounds for external or internal work, depending on what exactly is planned. Installation of eurolining on brick and reinforced concrete walls without lathing is not allowed. It can be launched immediately onto a wooden surface. But only if the surface is extremely flat.