Material selection

Work begins after installation and testing of the functionality of all engineering systems. Before covering it is necessary:

- Determine the type and volume of materials;

- Make a list of necessary tools;

- Perform heat and vapor barrier;

- Install the sheathing.

Previously, edged boards from various types of wood were used for interior cladding. The lack of necessary equipment and technology sharply reduced the range and quality of manufactured products. New production technologies have made it possible to increase the range and quality of modern lumber.

The main material for covering modern bathhouses is lining. The lining is a thin edged board with a special profile.

This is interesting. The name of the paneling comes from the thin wooden strips that were used to cover railroad cars.

The difference between lining and edged boards is the presence of recesses (grooves) and protrusions (tenks) along the long side. These elements ensure a tight connection of the panels during installation.

The widespread introduction of lining as a finishing material is facilitated by:

- Increased thermal insulation;

- Durability of the material;

- High installation speed;

- Ease of maintenance and repair;

- Beautiful exterior design.

Which lining to choose for a bathhouse

The selection criteria are determined by the characteristics and properties of the lumber:

Board type

When finishing a pair of wooden linings, it is better to give preference to Euro linings.

- Firstly, because it has a large tongue-and-groove system (the length of the tongue reaches 8 mm).

- Secondly, because it is guaranteed to have compensation slots on the back of the lamellas, which promotes ventilation of the coating and prevents possible cracking of the lamellas.

- Thirdly, because the eurolining is already pre-treated with wood preservatives that can be used in a sauna.

Eurolining for a bath

Type of lining

For a steam room, only the first or highest (elite) grade of wood is suitable, in which there are no knots, wormholes, etc. Please note that even living knots can gradually fall out under the influence of temperature changes.

Wood type

To understand which sauna lining is best, you need to know the characteristics of each breed. We will not review all the breeds available on the market, but will focus on those that are recommended by professionals.

The lining of the bathhouse can be made of deciduous and coniferous wood. The choice depends on the purpose of the bath room: steam room, dressing room, washing room, shower room, as well as on the properties of the wood itself.

The most popular material for a steam room in a bathhouse or sauna is hardwood lining. Their common advantage is that the wood does not heat up in the sauna and cannot cause burns when touched, and is also resistant to moisture.

Linden lining for a bath

The most popular for saunas and baths is linden lining. The advantages of this wood are its ability to create a special microclimate. From a utilitarian point of view, the undoubted argument in favor of linden lining will be the strength of the species, resistance to drying out, as well as the beautiful color and structure of the wood. Linden is considered an energy donor.

Aspen lining for a bath

The second most popular place for baths is occupied by aspen lining. Aspen wood is beautiful, soft, and easy to work with. The peculiarity of the breed is that over time, aspen lining only becomes stronger.

Aspen is also good because it provides easy care for the lining in the steam room. It is enough to lightly sand it when it begins to darken. And popular belief says that aspen draws negative energy from a person.

Alder paneling for a bathhouse

In third place was the alder paneling. From a medical point of view, alder is good because it contains tannins. The wood of this species is hygroscopic and has a low thermal conductivity coefficient. However, the high cost prevents its widespread adoption.

Note. Lining made from linden, aspen, and alder is usually sold in short pieces. Commercial length is up to 3 m. This should be taken into account when planning the finishing of the bathhouse and making material calculations.

Oak lining for a bath

The most expensive and difficult material to process is oak lining for baths. But it does not rot, does not lose its properties and can be installed in a sauna without the slightest additional processing. Unfortunately, all this is not available to everyone due to the high cost of oak lining.

The situation is similar with ash paneling - very expensive and rare lumber for lining a bathhouse.

A common disadvantage of hardwood lining is that it loses color over time and needs to be protected.

Coniferous species are rarely used in steam rooms. Because the resin emitted by softwood lining (pine, spruce) makes it practically unsuitable for use in a steam room. They are more suitable for washing and dressing rooms. This is facilitated by such indicators as moisture resistance and low price. In addition, coniferous lining is easier to process, has a beautiful structure and a rich palette of shades, allows you to veneer rounded shapes and does not require additional processing (except for de-resining). Often the pleasant pine aroma also becomes an argument in favor of pine lining.

Lining in the steam room: vertically or horizontally

There are two ways to solve the problem of how to line a bathhouse with clapboard quickly and efficiently:

- With horizontal planks;

- With vertical slats.

With the horizontal method, the lining is installed parallel to the floor surface. In a vertical position - perpendicular to the floor.

The horizontal position more effectively protects the lining from water penetration. This ensures good ventilation of the space between the wall and the panels.

The choice of method affects the technology of work and the final cost of repairs. For lining the inside of a bathhouse, they prefer the horizontal method. In this case, the wooden panels are installed with the tenon facing up.

Choosing the method of installing the lining

The lining in the baths is fixed vertically and horizontally. But a more rational option for a bathhouse is horizontal.

Finishing the bathhouse with clapboard block house

Let's consider a number of advantages of this type of fastening:

- the lining is positioned with the tenon facing up, so condensation does not accumulate between the foil and wood, as well as in the grooves;

- the sheathing under the horizontal lining is located vertically, that is, the space between the wood and the vapor barrier film is well ventilated. In the case of vertical installation of the panels, the sheathing will have to be mounted horizontally, that is, it will become an obstacle to the air flow between the floor and the ceiling, and the walls are likely to become damp;

The arrow shows the ventilation gap between the sheathing and the foil

- Sometimes fresh log houses are sheathed with clapboards. Such baths “shrink” over several years, the height of the walls changes and the vertical lining can become deformed. With horizontal panels, it is not difficult to remove/replace/repair the top or bottom strip without damaging the entire wall.

When constructing and finishing turnkey baths, builders often install the lining vertically, choosing panels that are suitable in height and installing them without trimming. With vertical mounting it is easier to arrange the corners, the work takes a little less time. But saving time often backfires, because if a vertical board is damaged by an accidental impact, falling coal or high humidity, the entire wall will have to be dismantled.

Finishing with paired eurolining

Required tools and materials

To carry out the work, a significant amount of tools and materials will be required.

List of necessary tools and materials for sauna cladding

| Tool | Materials |

| Gasoline or electric saw | Bar 20x20 mm and 30x30 mm |

| Drill or hammer drill | Roll or piece insulation |

| Screwdriver | Kleimers |

| Axe | Nails and screws |

| Plane | Polyurethane foam |

| Hammer | Tape measure or laser level |

| Doboynik | Construction pencil |

| Clamps and Clamps | Ladder |

| Construction stapler | Workwear set |

Execution of work

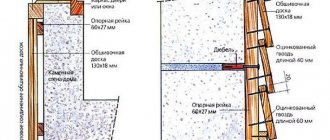

Sheathing device

A timber with a thickness slightly greater than that of the insulation used is used (mineral wool is usually used as a heat-insulating material). It is installed perpendicular to the selected direction of the lining in increments of approximately 45-55 cm. If the walls are uneven of significant size, it is necessary to use pads made of the same type of wood or some material of sufficient density. The sheathing is attached to the wall with screws and dowels made of plastic or self-tapping screws made of galvanized metal.

Laying insulation

In most cases, as mentioned above, mineral wool is used, which is available on the market in a wide variety of types and modifications. The main rule for laying insulation is that there are no gaps between the materials to avoid the formation of cold bridges.

Video instruction:

Sometimes mineral wool is not installed at all - if there is no need for additional insulation, and the lathing is done only to secure the lining.

Vapor barrier device

Glassine, roofing felt or simple plastic film can be used. The strips are fastened with a stapler for furniture work with an obligatory overlap of at least 5-7 cm. For greater reliability, the joints are additionally glued with adhesive tape or tape as wide as possible.

Ventilation device

A favorable microclimate in a bathhouse largely depends on proper ventilation. For its normal functioning, when installing insulation, it is necessary to provide ventilation holes.

Installation of lining on the walls of the steam room

Fastening must be done using a hidden method, using self-tapping screws, clamps or nails.

This is necessary in order to:

- avoid the possibility of contact with heated hardware;

- prevent it from coming into contact with steam or water, and as a result, prevent corrosion, which can ruin the surface of the lining

Coating bath walls from clapboard

Standard technology is used, during the production of which the following points must be taken into account.

- The lining is fastened with self-tapping screws made of galvanized steel into a tenon, and the holes must first be drilled to avoid chipping. It is allowed to use fastening with nails or clamps (special staples for wood).

- The coating device starts from the corner, access to which is most difficult. This is explained by the fact that the last board will need to be adjusted both in length and width, which is almost impossible to do if there is insufficient access to the place of its installation.

- The corners are finished using a wooden plinth, which is secured with stainless steel nails.

- We should not forget that all wooden structures must be treated with an antiseptic compound.

Installation of a ceiling covering for a steam room made of lining

The installation of a lining ceiling covering, as a rule, starts from the entrance. Only clamps or nails are used for fastening. This is due to a fairly serious load from the mass of the material. When installing the last boards, a hidden nail without a head is used, which is driven in using a hammer. To give a pleasant appearance, the place where this nail is driven is treated with sandpaper. It is necessary to take into account the need to leave a gap of 4-5 cm between the ends of the lining and the wall of the bathhouse for normal ventilation. In addition, it is necessary to provide the structure with the opportunity to “play”, since the temperature under the ceiling will be the highest.

Correct gap between boards

The coating looks most attractive when all joints are made of the same type.

This can be easily achieved by marking the boards when installing them, and also using a level to ensure that the boards are level or vertical. The wall covering must be closely adjacent to the ceiling covering.

Covering door and window slopes with clapboard

When finishing doors, you must first prepare boards of the required length. Doorways are trimmed with platbands.

To simplify the finishing of window slopes, it is recommended to use the initial strip to the plastic lining. A more complex option involves constructing a frame and then covering it with clapboard.

Preparatory work for wall cladding

Before quickly sheathing the inside of the bathhouse with aluminum foil and wooden clapboard, it is necessary to insulate the walls. Before laying the insulation, install the counter-lattice and sheathing. A layer of vapor barrier is laid on top of the insulation.

Thermal insulation device

The best material for insulating baths is basalt wool. This material has good thermal insulation and a high degree of fire resistance. Basalt wool does not rot. This type of insulation does not burn and does not emit harmful substances. Basalt can withstand temperatures up to 1500° C.

Experts recommend using Rockwool brand “Light Butts” mineral wool. The mineral wool of this company is of high quality, increased density and affordable price.

To cut basalt wool sheets, large, sharp knives with a high-quality blade are used. When cutting, the knife blade is held at an angle of 30-45° to the surface of the blade. When tilted, the blades dull much more slowly.

The width of the canvas is taken to be 2 cm greater than the distance between the vertical posts of the sheathing. The increased width helps to fix the blades in a constant position.

Thermal insulation sheets are laid in 3 layers with overlapping joints. The amount of overlap is equal to half the length of the canvas.

All layers are laid in height within one span of the sheathing. The laying direction is from floor to ceiling. They move to another span after laying all the layers of the previous span.

Attention! You should not choose insulation from artificial and synthetic materials. When exposed to high temperatures, they release substances harmful to health.

Laying the first layer begins from the floor. First, the whole canvas is laid. After laying all the canvases of the first layer, the second layer is laid.

Laying the second layer also begins from the bottom. For overlapping joints, the length of the first web of the second layer is taken equal to half the length of the standard web.

At intersections with obstacles, elements of the required shapes and sizes are cut out.

Before covering the bathhouse with clapboard, care should be taken to protect the walls from dampness and rotting. Therefore, after installing thermal insulation, they begin to install the vapor barrier material.

Vapor barrier device

The vapor barrier layer is designed to protect walls from condensation and increase the heat-reflecting properties of the insulation.

The work of laying vapor barriers is the most critical when constructing bathhouses. The efficiency of steam use depends on the quality of vapor barrier work.

Aluminum foil with a thickness of 50-80 microns is used as a vapor barrier. Attaching the foil begins from the corner of the room in the direction from bottom to top.

Advice. Finnish foil is in greatest demand. The products of this company have high quality, durability and increased heat-reflecting properties.

Vapor barrier sheets are sewn with metal nails or staples to the vertical posts of insulation cells. To attach the foil, use a pneumatic gun or a special construction stapler.

The foil is laid with an overlap of 2-3 cm of vertical seams. All seams are taped with aluminum adhesive tape.

Advice. To seal the seams of the foil, use Unibob adhesive tape, 50 microns thick. This tape adheres well, has high strength and durability.

In places of transition from the walls to the floor and ceiling, the foil is laid with an overlap of 5-10 cm in each direction. The free ends are sewn to the ceiling and floor with nails or tacks.

At the junctions of walls and ceilings, gaps often appear in the foil. To eliminate these gaps, use foil corners. To make such a corner, a piece of foil is placed on the corner of a table or chair. The resulting shape is carefully beaten with a light object to soften the foil. The broken corners are glued with aluminum adhesive tape. The manufactured corner is inserted into the corner and carefully taped.

Advice. To prevent damage to the foil, it is necessary to cut the edges of the bars at 45 degrees using a plane.

After completing the work, check the quality of the vapor barrier installation. Any damage found is covered with adhesive tape.

After installing the vapor barrier, the installation of the counter-lattice begins.

Counter-lattice device

The counter-lattice serves as the basis for the main sheathing. Designed to ensure air exchange in the space between the foil layer and the lining.

To construct the counter-lattice, wooden blocks with a cross-section of 20x20 mm are used. The bars are nailed to the vertical posts of the insulation cells. The distance between the slats is taken to be 400-500 mm. Installation of counter-lattice slats is carried out according to level and plumb.

Advice. Do not use cheap knives with low quality blades to cut basalt wool. Such knives cannot withstand high mechanical loads, quickly become dull and fail.

When installing a counter-lattice, a hole with a diameter of 80-100 mm is drilled in the ceiling for the exhaust duct pipe. A sealing cap (valve) is inserted into the hole. During bath procedures, the hole is closed. To ventilate the bath after washing procedures, the hole is opened.

Periodic ventilation prevents the appearance of dampness and rotting of the lining. To ensure air exchange, a gap of at least 2 cm is provided between the lower end of the lining and the floor.

Choosing lining for cladding

Lining

Wood paneling can be regular or euro. The first has roughness and lint on its surface, the second is perfectly smooth. On the back side of the eurolining there are ventilation channels that prevent the accumulation of moisture (condensation) and relieve stress in the material. According to GOST 8242-88, the moisture content of wooden products is allowed within 12±3%, however, ordinary lining can be made from wood with a moisture content of up to 25%, which can lead to deformation during the operation of the bathhouse. Based on this, we will choose a suitable wooden eurolining for lining the bathhouse.

Prices for wooden lining

wooden lining

Marking and technical requirements

The lining is made from coniferous and deciduous wood. The best options for a steam room are aspen, linden, cedar, spruce, alder, oak, and pine.

| Wood | Color | Properties | Photo |

| Aspen | White, acquires a silvery tint. The yellow growth rings are barely visible. | Lightweight, withstands high humidity and temperature well. Over time, it hardens so much that it is difficult to even hammer a nail into an aspen panel. Does not emit resin, does not heat up. | Aspen lining, Extra |

| Linden | Light, brown, less often reddish shades. There is a matte shine. | The fibers are homogeneous, the surface heats up little, and in the steam room it releases aromatic components that are beneficial to health. When in contact with linden wood in a humid environment, the iron oxidizes and rusts, and streaks appear. | Linden eurolining |

| Linden Cedar Canadian or Siberian | Brown with a pink tint. | One of the most expensive and healthy wood species. Does not rot, withstands mechanical loads well, does not crack. | Canadian red cedar paneling |

| Pine | Beige, brown with red shades. It gets darker with time. Pronounced pattern of growth rings and resin canals. | Good mechanical properties, toughness, moderate warpage. Does not cause difficulties during processing. It releases resin when heated, so it is not used for covering those surfaces in the steam room with which tactile contact is possible. It is not suitable for covering the ceiling of a steam room or it requires repeated heating of the steam room followed by removal of the resin that has emerged (repeat the procedure until all the resin comes out of the lining). For a bathhouse, it is better to choose Extra-class pine lining. | Pine |

The following table shows the classes and their descriptions. It is worth knowing that wood with a large number of knots heats up faster and can burn. The markings are the same for all types of wooden lining.

| Class or variety | Description |

| Extra | Free from cracks, knots and other defects. The surface is perfectly smooth and even. |

| A or 1 | The surface is smooth or slightly rough. There is 1 healthy knot per 1 linear meter (knot diameter no more than 1.5 cm). There may be cracks: hairline cracks - no more than ½ panel long, non-through cracks - less than 9.5 cm long (the crack exit is directed towards the end of the panel) that appear when drying - no more than the width of the panel. There may be tars and resin pockets of 2 pcs. by 1 m.p. |

| B or 2 | There are many knots, of which no more than 2 can fall out. by 1 m.p. There may be through cracks up to 1 mm wide and up to 15-30 cm long; hairline cracks are allowed along the entire length of the board. The presence of wormholes (3 pieces per 1 m.p.) and rot (no more than 1/10 of the panel) is allowed. Grade B lining is suitable for painting. |

| C or 3 | The quality is low. Many different defects. This lining is suitable for upholstery of technical rooms or rough work. |

Marking

Lining marking

The standards for defects according to GOST are shown in the table below.

Standards of defects according to GOST

Lining defects

All that remains is to choose the profile of the lining, because... each has its own installation nuances.

| Profile | Description | Scheme |

| Standard | Similar to the classic quarter-plank lining. It has a tongue-and-groove connection, with the tongue being shorter than the groove to prevent deformation. | Lining Standard |

| Calm or Kolkhoz Woman | It differs from the previous one in its rounded edges and the presence of channels on the reverse side to prevent the accumulation of condensation. | Calm |

| Euro | Manufactured according to DIN 68126 standard. Has an extended tenon. After installing the lining, the wall surface is ribbed. | Euro |

| Soft-line | Soft-line or soft line is a symbiosis of Euro and Shtil lining. Soft rounded corners, elongated tenon, relief texture of the wall after assembling the panels. | Soft-line |

| Block house | Used for finishing external walls and rooms. Stylized as a rounded log. There is a tongue-and-groove connection, the front side is usually rounded, and the back side is flat or with channels for ventilation. | Block house |

Lining profiles

Video - How to choose lining

Features of finishing a brick bath

A brick bathhouse in terms of the features of wall cladding with clapboard is no different from if the external walls were built from any other material. It is necessary to begin work, moving from the corner farthest from the entrance. In the dampest room, it is better to avoid using nails, as they are prone to corrosion when exposed to vapors.

A brick bathhouse is usually lined from the inside with clamps, which are good because they do not damage the lining. If you have not yet started construction, then it is best to make a dressing room no larger than 150 x 250 cm. This way you will not only eliminate drafts and the creation of a cold space, but also save on lining, which will be used for finishing brick walls.

The premises should be insulated; mineral wool or polystyrene foam are excellent for this. The first is fixed using wooden slats, but for foam plastic special fastenings must be provided. Brick walls should be finished from bottom to top. This also applies to work on the floor, walls, and ceiling. Experts recommend abandoning products in “quarter” and “rabbet”. The most recommended lamellas are those with tongue-and-groove profiles. Such finishing on brick walls will not move over time, and the density of the joints will not be disrupted, which is especially important for a material that transmits heat so easily.

Subtleties when working with lining, extending the life of the finish

The question of how to properly line a bathhouse with clapboard has been studied, along with videos, photo instructions and details of each stage. Compliance with certain features will help make the finish durable and protect the lining from rotting, blackening and bending:

- Before sheathing begins, all wooden parts are kept in the room where they are planned to be installed. The packaging is removed from the lamellas; it is desirable that there is an air gap between them, which can be ensured with the help of small bars or slats.

- When the steam room is fully finished with wood, work begins with the ceiling, then the walls follow, then the ceiling.

- Pre-treatment of sheathing boards and linings with antiseptic solutions prevents rotting and extends the life of the wood.

Vote post

Possible errors and solutions

Quite often, errors occur during the installation of lining. It is better to try to eliminate them during installation, otherwise it may be necessary to dismantle the coating. So, the lamella is cut to length before attaching it to the wall. You should not cut the material so that it is installed end-to-end, because the slats will expand and contract under the influence of moisture and temperature changes. In order to prevent the wall from going in waves, you need to leave a gap between the finish and the floor, as well as the ceiling, all of which is then covered with baseboards.

It is also important to install the fasteners correctly. This requirement is due to the fact that the material dries out and becomes saturated with moisture during operation. Because of this, the fasteners sometimes pop out. To prevent this from happening, you need to install it without additional effort.

Beginners quite often encounter this problem when the first lamella is installed incorrectly. It should be leveled, and for diagonal installation, the angle of inclination should be determined. If this is not done in time, individual products will be tilted to one side, falling out of the general plan. This problem can be solved, again, at the installation stage by marking. According to it, the position of the panel is set, and then it is secured with nails. You need to start installing fasteners from the edge closest to the corner, and also from the floor, moving higher.