Types of gas furnaces

Based on the nature of their internal structure, gas furnaces are divided into several types:

- by application - a conventional convection unit, which is the optimal solution for a sauna. The consumer receives dry steam at an air temperature exceeding ninety degrees. Such stoves are made of metal, the heater is closed. The peculiarity is that wet steam is supplied. Stones covered with a metal casing are able to retain heat longer, and the steam room does not immediately cool down after turning off the gas;

- According to the working principle, the steam room is heated using the convection method. Modern furnace designs are equipped with complex heat exchangers, and it is possible to connect a heating circuit. When such a stove operates, the steam room and adjacent rooms are simultaneously heated, while gas consumption does not increase significantly;

- for heating water - there are several models that heat water with different levels of efficiency:

- a stove with a remote water tank is a classic option. The storage tank is mounted on the chimney, the water is heated by accumulating heat from heated smoke, the temperature of which reaches one hundred degrees or more, which is quite enough;

- A heat exchanger is installed in the furnace body, maintaining a certain temperature regime for water. While the stove is heating, the water remains hot. The heating principle is flow-through;

- gas stoves with built-in water tanks are considered convenient for small steam rooms. For example, a tank with a capacity of forty to eighty liters will provide water for washing one to three people.

What does a gas sauna stove look like?

Operating principle and distinctive features

The oven consists of several elements:

- Kamenka . Part of the unit where heat from hot stones accumulates. Heated with wood, electricity or gas.

- Firebox . A container where heat is released from burning fuel. Equipped with a grill, the location of which depends on the type of fuel.

- Lattice . Most often it is made of cast iron, as this material is resistant to high temperatures and durable during frequent and long-term use.

- Ash pan . A container placed under the firebox. Designed to settle ash.

- Passage tunnel with door . It is installed in the dressing room so that you can heat the steam room in the adjacent room.

- Heat exchanger . An element designed to transfer heat to water from the firebox.

- Buck . A container of water mounted to the stove, located on top or on the side of the device. It differs in volume and type of material.

- Chimney . A pipe coming out of the firebox and directing smoke to the street.

Tank stoves operate on the following principle. Firewood is placed in the firebox to generate heat. The heated air rises through and heats the stones. They heat up and maintain the required temperature in the room. In addition, the tank heats up.

The speed of heating the water depends on the location of the tank . It may be located near the stove or in an adjacent room. To maintain the water temperature, you need to periodically add firewood.

There are stoves with long burning . They work without adding firewood for up to 20 hours, which eliminates constant monitoring during operation of the device. The combustion process in such cookies occurs in the opposite direction - from top to bottom.

Materials used to make a gas oven

There are quite a few options for arranging gas furnaces, and sometimes it is difficult to understand the complexities of installation work. To make the process easier, let’s look at what a gas stove can be made from.

Models made of brick or stone material are practically no different from conventional wood-burning stoves. In principle, these are the same devices, only converted to run on gas. With the help of such stoves, the classicism of the Russian bath is preserved, but at the same time there are significant differences - thermal energy is well retained, the steam room warms up evenly, gas today is a more affordable type of fuel. True, heating occurs slowly, so preference should be given to stone. It is not recommended to build stoves from such materials yourself - it is better to use the services of professional specialists.

Today the manufacturer offers a large number of metal furnaces that run on gas. They are much cheaper than their stone or brick counterparts, and installation work is easier to carry out. Metal stoves are compact, can be installed in small spaces, and quickly heat up a steam room. In addition, it is possible to select a model with the most suitable power, which will allow efficient use of fuel. Installing a metal gas stove in a bathhouse necessarily involves thermal insulation. It is made from the floor with brickwork and sheet steel, arranged along the walls and along the passage of the chimney duct through the ceiling and roof.

Foundation laying

Since the weight of a brick stove-heater exceeds half a ton, the foundation for it must be made accordingly.

The mass of one cube of brickwork is approximately 1300 kg. Use this information to calculate the weight of the stove.

We mark the future section of the concrete foundation on the ground (it should be half a brick larger than the size of the stove). The depth of its laying should be below the actual level of soil freezing.

The foundation for the “heater” should be located at least 10 cm from the foundation of the bathhouse building, and should not (even partially) be tied to it. We then fill the gap between them with dry sand and compact it well.

If the walls and partitions of the bathhouse are built from flammable material, the area must be secured. Sew up the opening for the firebox and part of the wall behind it with asbestos cardboard, and place a sheet of metal on top of it, at least 4 mm thick. The minimum distance to walls not protected by asbestos and iron sheets should be 350 mm, and protected ones, about 200 mm.

About foundation mortar

You can lay the foundation with lime, cement or a combination mortar.

- Limestone (proportions): 1 part slaked lime/2 parts sifted sand;

- Cement (proportions): 1 part cement/2 parts sifted sand;

- Combined (lime-cement): 1 part cement/6 parts slaked lime/sifted sand, depending on the brand of cement and the fat content of the lime.

- Fill the bottom with clean (free from debris) sand to a depth of ≈ 15 cm. Lightly saturate it with water and compact it well;

- Pour ≈ 20 cm of crushed stone or broken brick on top and compact it tightly;

- Place the formwork along the walls of the dug pit so that it is approximately 5 cm above the ground level.

- Line the pit with roofing felt or waterproofing film so that it overlaps by 10-15 cm and extends beyond the edges of the formwork by 5-10 cm;

- Place a reinforced frame on the bottom. It must be metal (not polymer). Usually the rod is at least ø 12 mm, with a square cell of 10 cm;

- Fill with concrete mortar and pierce the screed several times with a metal rod (to prevent the formation of hidden air cavities), carefully level it using the rule and check the uniformity of the horizontal level. If necessary, “drive out” with the solution.

- Cover the concrete with any film and moisten it periodically to prevent cracking from drying out;

- After the concrete has set (≈3-5 days), dismantle the formwork and cover the edges of the screed well with bitumen mastic (tar). After it hardens, fill the gap between the foundation and the soil with clean sand and compact it;

- All that remains is to do the waterproofing. For this we use roofing material. It is spread in two layers, and the second layer must be laid with a perpendicular pattern of stripes in relation to the first. The pieces of roofing felt must overlap by at least 10 cm and extend beyond the boundaries of the foundation by 5 cm.

The consistency of the solution should be similar to medium fat sour cream. Fill in layers. They poured it - pierced it with a rod, slightly leveled it, and poured a new layer. And so on, to the desired level.

Foundation work indoors is always a messy process.

Therefore, cover the bath floor with polyethylene film. And better than reinforced. It is durable and will definitely last until the work is completed. Pay attention to the photo - this is an incorrect foundation.

I don’t know how it is arranged inside, but the fact that the stove foundation is tied to the main one is unacceptable. "General design" promises problems with strength and durability.

Advantages and disadvantages

The main advantages of gas-powered bath stoves include the following:

- high economic effect - each characteristic declared by the manufacturer will manifest itself during installation work and in the subsequent operational period. Equipment of this type is perfect for baths with an area of no more than fifteen square meters. In order for the stove to work efficiently, you will have to lay out at least two hundred kilograms of stones. As soon as the steam room warms up to the desired temperature, the gas can be turned off. The heat emanating from the heater will maintain a comfortable mode for four hours;

- good functionality - a gas stove can be used to heat water and a steam room. For this purpose, the equipment has a special container heated by fuel combustion products leaving through the chimney;

- high efficiency indicator - a common characteristic for furnaces of any power - efficient gas consumption. It is believed that for every 0.4 square of area, 250 kcal of thermal energy is needed. If the stove is completely heated, energy consumption is significantly reduced, because heated stones retain heat well for a long time;

- speed of warming up - gas stoves quickly increase the temperature in the steam room, the speed of warming up depends on weather conditions. In summer, it takes three to four hours to warm up; in winter, this time increases significantly.

A gas stove for a bath has a high economic effect.

The following can be noted as disadvantages:

- For the installation of a gas furnace, a prerequisite is the installation of a gas cylinder station or the installation of a centralized supply of gas fuel;

- installation of equipment is carried out in accordance with existing requirements;

- gas is a type of fuel that requires safe use.

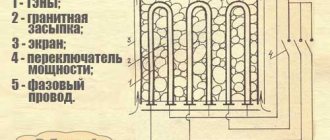

Electric heaters

In electric ovens, the heating element is the heating element. The advantage of this type is instant heating of the room and stable temperature of the steam room. For saunas, open types of heaters are used; for baths, a closed type is provided.

Advantages:

- quick, affordable installation without chimneys;

- lack of fire protection requirements;

- built-in steam generators;

- saving resources;

- safe operation;

- several operating modes.

Flaws:

- small niche volume for stones.

- the need for built-in steam generators to increase steam humidity.

PEKO EH-80

Heater stove with built-in control unit. The thermostat of the unit maintains the set temperature of the steam room and switches off if the temperature is exceeded in an emergency. The timer is set to a maximum duration of 6 hours of operation; after the period expires, it disconnects from the network.

| PEKO EH-80 | |

| Manufacturer | China |

| Volume for a steam room. m³ | from 7 to 12 |

| Steam room mode | Finnish sauna |

| Stones, mass, kg | 25 |

| Operating voltage, V | 380 |

PEKO EH-80

Advantages:

- wall installation;

- power 8 kW.

Flaws:

- The only possible mode is dry steam.

POLYTECH KRISTINA SOFT STEAM

An electric oven with an evaporator, at a given temperature of 70°, provides the “Russian steam room” mode. When the temperature increases to 110°, steam from the evaporator is passed through heated stones, dried, and becomes finely dispersed, favorable for healing.

| POLYTECH KRISTINA SOFT STEAM | |

| Manufacturer | Russia |

| Volume for a steam room. m³ | from 6 to 8 |

| Steam room mode | Russian bath |

| Stones, mass, kg | 25 |

| Operating voltage, V | 220 |

POLYTECH KRISTINA SOFT STEAM

Advantages:

- the ability to add natural ingredients and flavoring to the filling tank to vary the shades of the steam room.

Flaws:

- low power 6 kW.

Criterias of choice

The main indicator by which a gas stove for a bath is selected is the power of the installation, to which special attention is paid. But there are other nuances that help you choose a suitable and reliable stove:

- Dimensions – due to its size, the oven should not take up much free space. It is recommended to choose models with extended remote fuel channels;

- fuel consumption - the data is indicated in the product passport, the operation of your stove will depend on them;

- acceptable type of fuel - there are stoves that run only on natural gas; some models provide for gearbox reconfiguration;

- versatility - there are stoves that run on two types of fuel - gas and wood. This option is convenient for cases where a bathhouse already exists. But the gas supply to it has not yet been completed;

- Having a storage tank in which the water will be heated frees you from additional problems.

Which sauna stove is better, steel or cast iron?

| Type of oven | Advantages | Flaws |

| Steel | + high reliability + long service life + when burning, the metal does not oxidize + warms up quickly | - not every stainless steel has high performance characteristics - price fluctuates greatly - cools down quickly |

| Cast iron | + keeps warm for a long time + withstands changes in temperature and humidity + reasonable price | - heavy weight - short service life - slow heating |

Brief overview of the best models

If you imagine the rating of gas stoves for a bath, then the following are considered the best models:

- gas stove for a bath “Thermofor” is a stove with a heater, the weight of which reaches forty-four kilograms. The installation is compact in size, operates on the convection principle, and is manufactured using high-strength steel material. The main disadvantage of such a stove is that it is capable of heating a room whose area does not exceed twelve square meters;

- gas stove for a bathhouse "Ermak" - the weight of such a stove is about sixty kilograms, it runs on two types of fuel (gas and wood). The equipment is made of structural stainless steel, the location of the chimney is central. It is allowed to install such a stove in the dressing room;

- stove “Taymyr” - the installation is reminiscent of “Terfomor” in its design. The main advantage is the presence of a double steam preparation system using an internal and external heater. There are no shortcomings noted by users;

- gas stove for saunas “Teplodar” is another universal device powered by gas and wood. The walls of the case are made of stainless metal, the weight of the product is 47 kg. The stove is capable of heating a room whose area varies between 12 - 20 meters;

- stove P-20GT is a universal device powered by gas and wood. Its power reaches 20 kW, weight – 85 kg. As an advantage, we can note the possibility of installing a storage tank for hot water; the disadvantage is that the model is considered the best option for a steam room, the volume of which is no more than 22 cubic meters;

- “Zhara-Malyutka” is an installation with a power of up to 16 kW and a weight of up to 54 kg. The main advantage of such a stove is its compact size, but it can heat an area from 4 to 12 cubic meters;

- “Geyser” stove – heat-resistant alloy metal is used to make such a stove. Steam generation is two-stage. The heavy steam created by the oven enters the second compartment and is dried, after which it exits into the steam room. The device can operate on two types of fuel. It has a heater with a capacity of up to seventy kilograms. The only drawback is the hum in the pipe that occurs during fuel combustion.

Gas stove for bathhouse "Termofor"

How to choose a stove for a bath and sauna

- Power

. One of the main criteria when choosing is the power of the furnace. It is selected taking into account the volume of the steam room, the presence of windows and doors. Making the calculation is not difficult using an online calculator. - Source of energy.

Solid fuel (wood), natural gas, and electricity can be used as an energy source. Most often, private baths and saunas use electricity and firewood. Some of them require a power network (380 V), while others need an efficient chimney. - Efficiency

. For rational consumption of firewood, you need to learn about the efficiency of the stove. If traditional models have an indicator of no more than 85%, then modern units reach a value of 91-95%. - Case material

. To make stoves for baths and saunas, manufacturers usually use cast iron or stainless steel. Each material has its pros and cons. - Type of heater

. By type, all heaters can be divided into open and closed. In the first option, the air in the steam room is heated by the heat of the stones. The room heats up quickly, but also cools down quickly. This type is suitable for individual use in the country. But closed stoves heat the steam room more evenly, the consumption of firewood will be more economical, but the bathhouse will have to be heated 3-4 hours before the start of water procedures. - Some wood stoves have a glass window in the door that allows you to admire the flames of burning wood. They successfully combine the best properties of a stove and fireplace.

- The appearance of

the stove often becomes a stumbling block when choosing a model. Some manufacturers use artistic design, thanks to which the device can fit into any interior.

Our review includes the 12 best stoves for baths and saunas. The rating included only those models that were approved by experts and received good reviews from domestic users.

General installation rules and safety standards

Installing a gas stove for a bath with your own hands is a responsible task, and it is better to entrust it to experienced professionals, because there are certain requirements for installation:

- the distance between the stove and the wall should vary between five and fifteen centimeters;

- a prerequisite for a room in which a gas stove is installed is the presence of one or more windows, a reliable ventilation system;

- the surface of the wall located behind the furnace equipment is additionally covered with fireproof material;

- the chimney is made of stainless material.

If all of the above requirements are met, it is allowed to install a gas-powered stove. Any deviation will be considered a violation, for which serious penalties are provided.

Rating of the best stoves for baths and saunas

| Nomination | place | Name of product | price |

| The best sauna stoves | 1 | Harvia Forte AF9 | 152 900 ₽ |

| 2 | Harvia Club Combi K15GS | 94 500 ₽ | |

| 3 | Sawo TOWER TH6-120Ni-WL | 46 125 ₽ | |

| 4 | Thermophore of Vitruvius | 20 900 ₽ | |

| 5 | NARVI Oy NC 16 | 26 300 ₽ | |

| The best stainless steel stoves for a Russian bath | 1 | Harvia 20 Duo | 37 000 ₽ |

| 2 | Feringer MAXI | 64 000 ₽ | |

| 3 | Termofor Tunguska | 19 300 ₽ | |

| 4 | Termofor Geyser 2014 | 13 500 ₽ | |

| 5 | Teplodar Sahara 24 LK/LKU | 17 800 ₽ | |

| The best cast iron stoves for a Russian bath | 1 | Hephaestus PB-04 M | 33 000 ₽ |

| 2 | Vesuvius LEGEND FORGING 28 Fireplace (205) | 44 470 ₽ |

Tips for use

Even the best sauna stove in a Russian bathhouse requires constant maintenance. Here are some simple tips:

- Combustion products must be removed after each use.

- The chimney should be cleaned at least twice a year.

- It is important to carefully insulate all structures to avoid heat loss.

- Only pour warm water onto the stones. A fairly sharp temperature change will reduce the service life of the stove, especially cast iron.

- It is better not to open the steam room again. Hot air flows should not mix with cold air - this disrupts the uniformity of heating.

The best cast iron stoves for a Russian bath

Cast iron stoves still have many adherents. Although they take longer to heat up, they retain heat better. Here are the best representatives of this category.

Hephaestus PB-04 M

Rating: 4.8

True connoisseurs of Russian baths prefer cast iron stoves. The Hephaestus PB-04 M model is made from a special type of cast iron containing chromium. Thanks to the remote portal, the firebox can be located in one room, and the heat-resistant door in another. Since the stove is delivered disassembled, there will be no problems with transportation and unloading. Experts pay attention to the innovative design of the firebox. It has a gas afterburning system, a flame arrester and turbulent fins. As a result, even when the combustion chamber is heated to 750°C, the exhaust gases enter the chimney after being cooled to 300°C. The efficiency of the furnace reaches 87%.

The model wins our rating for its record wall thickness (6 cm), so heat is retained in the oven for a long time. The picture is complemented by an artistic frame around the door.

Advantages

- long service life;

- high efficiency;

- unique firebox design;

- artistic door frame.

Flaws

- not detected.

Vesuvius LEGEND FORGING 28 Fireplace (205)

Rating: 4.7

The cast iron stove Vesuvius LEGEND FORGING 28 Fireplace (205) creates worthy competition for the leader of the rating. It can work in a steam bath with a volume of up to 30 cubic meters. m. Externally, the model looks elegant; there are no problems with transportation and installation. The cast iron firebox is divided into 3 parts; the manufacturer used a ceramic cord for sealing. The safety and reliability of the design is ensured by bolted connections of units and parts. A special type of cast iron can withstand strong temperature changes; it does not burst when exposed to a large volume of water.

The stove takes second place in the ranking due to its higher price and smaller firebox wall thickness (1.2 cm). In addition, the design has greater weight (178 kg) and dimensions.

Advantages

- high power;

- safety and reliability;

- resistance to changes in temperature and humidity.