Selection of material for insulation

After completing the glazing work, it is necessary to begin insulating the ceiling, walls and floor of the loggia.

Before this, you need to decide on the choice of materials. Today, the technology for laying various options is almost the same, since modern materials have similar shapes and structures. The most popular materials for insulating a loggia in a panel house are:

Most professional builders and craftsmen advise giving preference to penoplex, despite the fact that it is somewhat more expensive than the other two options. Its production is carried out using new technology, which makes the material the owner of:

- low level of thermal conductivity;

- long service life;

- ease of installation.

If your budget is limited, you can choose other materials, such as polystyrene foam. To insulate the ceiling, we choose penofol. The walls are insulated with foam plastic, the thickness of which does not exceed 7.5 centimeters.

What is it for?

The loggia can be turned into a warm office

At the beginning of the article it was already said that if you insulate a loggia in a panel house, this will serve as a barrier to the cold from the street. It should also be recalled that reinforced concrete has a high degree of thermal conductivity, and this negatively affects heat retention. Additionally, the small space can be used in many different ways. The first option is to connect the balcony with the adjacent room. The second is to use it for its intended purpose and design a separate room in its area.

A warm loggia will be an excellent option for a place of rest and relaxation after a working day, an ideal option for a schoolchild doing homework here, because the best lighting is natural, sunny. And if you install a computer and a desktop, the room can turn into an excellent office. In general, we can say that there are a lot of arrangement options. The only thing left to do is to insulate the balcony with your own hands.

Insulation of a glass balcony with cold glazing

Heat in the loggia in winter can be achieved in several ways

But before this, it is important to dismantle the cold glass. They need to be removed from the frame, and then all remnants of finishing components must be removed from the window openings

After this, new frames are installed to install double-glazed windows in them.

Specialists install inserts with H-shaped guides into the upper part of the double-glazed windows. The glass is attached to vertical bars. Fastenings are installed using profile sections. Their length is 20 centimeters. Next comes the laying of rubber seals.

Insulation of floors and walls

You can additionally retain heat inside the balcony by insulating surfaces

It is important to take into account the thickness of the insulating layer, which should be up to 63 millimeters, and this is equal to the height of the frame profile

Floor insulation with polystyrene foam and laminate covering

Surface insulation takes place:

With low thermal conductivity. Increased strength

It will no longer be possible to add another structure, so this will be the main covering. The ideal material is polystyrene foam 50 millimeters wide or a high-quality screed 1 centimeter wide. It is important to apply aluminum adhesive tape at the joints of thermal insulation boards. It is recommended to insulate the inside walls on the sides with high-density polyester foam. It is better to seal the external walls with a third polystyrene foam foil tape. Particular emphasis should be placed on sealing the gaps where the heat insulator is attached to the frame.

Coating walls with thermal insulation

Balcony heating

How to make a balcony warm? The first thing that comes to mind is installing a radiator with water coolant. But such a decision must be coordinated with the authorities, which often refuse this action (read more in the article “moving the battery to the loggia”). Then you can consider options with electric heating. This can be wall-mounted or floor-mounted equipment.

An original option is a fireplace on the balcony, such as a biofireplace. These are units with natural flames and fuel that is safe for health. But ventilation is necessary to renew the oxygen saturation of the air.

Possible options for insulating a loggia: choice of material

The most effective external insulation is an external multi-layer enclosing structure that protects the room from condensation, steam, mold and dampness, and the junction of the temperature difference occurs outside the room. This type of insulation requires certain skills, and in some cases, permission.

There are 5 more options for materials that can be used to insulate a balcony:

- Styrofoam. The most affordable and economical insulation of our time. Due to its lightness, the material is easy to install and cheaper than mineral wool.

- Mineral wool. Very effective material. Harmless and made from natural material of natural origin. The low cost of insulation with mineral wool allows you to inexpensively and independently use it to insulate walls, ceilings and floors.

- Expanded polystyrene (penoplex insulation). The material has more good properties than mineral wool or polystyrene foam. It is protected from moisture and can be laid without constructing a grate, as it is quite rigid. It has a smaller thickness, which has a beneficial effect when arranging a small area.

- Foiled polyethylene foam. A lightweight material with a cellular structure, internally formed on a layer of foil.

The latter option has a small thickness and cost, but is distinguished by the fact that it provides excellent thermal insulation and has high noise insulation, as well as being waterproof. Lining is also used, but only in a well-heated room. Otherwise, it is necessary to install basic insulation.

Stages of work

First of all, you need to measure the room to know how much materials will be needed. After purchasing the latter, you can begin preparatory work. There should be no foreign objects on the balcony or loggia, the space should be free so that nothing interferes. Before insulating the balcony from the inside with your own hands, if you chose mineral wool, you will need to create a lathing. Wood blocks 4 cm thick are suitable for this. The frame must be created along the entire perimeter of the room, starting from the walls and ending with the ceiling and floor. The bars are secured with dowels. The distance of each block should be 40-50 cm from the next, in the end you will get large squares of 40 by 40 cm.

Making lathing for a balcony

It is necessary to pay attention to the corners of the structure. If, for example, the sheathing runs under a window, it is worth installing several bars in the vertical direction, since in this place the structure will experience additional loads. Methods for insulating a balcony from the inside are usually the same, regardless of what material is chosen

First, you will need to seal all the cracks in the concrete base: if they are large, they are filled with cement mortar, if not, you can use polyurethane foam. It penetrates deep into the gap, effectively filling it and preventing cold air from entering the house. After this, you can begin to install the insulation. It is convenient to secure it using special glue. When thinking about how to properly insulate a balcony from the inside, do not forget that you first need to insulate the walls, then the ceiling and floor. It’s better not to break the sequence

Methods for insulating a balcony from the inside are usually the same, regardless of what material is chosen. First, you will need to seal all the cracks in the concrete base: if they are large, they are filled with cement mortar, if not, you can use polyurethane foam. It penetrates deep into the gap, effectively filling it and preventing cold air from entering the house. After this, you can begin to install the insulation. It is convenient to secure it using special glue. When thinking about how to properly insulate a balcony from the inside, do not forget that you first need to insulate the walls, then the ceiling and floor. It is better not to break the sequence.

To insulate the floor, lathing is required.

Once you have secured the insulation, you can move on to the exterior finishing. To do this, you can use any hard materials, for example, drywall, plywood, or less often plaster.

Repairing a balcony in a panel house with your own hands is not too troublesome or expensive. It is enough to devote one weekend to this, and you will receive a warm structure that will make your home more comfortable.

Materials used for insulating floors on balconies and loggias

Before starting work on insulating the floor on the balcony, you need to select the type of material for thermal insulation. The technological process and the choice of additional tools and parts directly depend on this.

Floor insulation with penofol

The following types of materials are used:

- Penofol is a roll insulation consisting of layers of foamed polyethylene and reflective foil. It is quite thin, used mainly as an additional element in combination with other insulating materials;

- Polystyrene foam is a well-known building material, rigid, and retains heat well. It comes in different densities and thicknesses, which allows you to use it economically, and the installation technology is quite affordable;

- Expanded polystyrene is foamed plastic, the second name is penoplex. Compared to conventional foam, it has an increased density, smaller pores, and a ridge profile, which eliminates the occurrence of cold bridges. This is the most expensive insulation compared to others;

- Mineral wool is a soft insulation that cannot hold its shape. When using mineral wool, it is necessary to make lathing with logs. A significant advantage is that small gaps can be filled with such insulation. Available in roll packs or in the form of mats. Before working with mineral wool, it is necessary to glaze the balcony, since it is a hygroscopic material.

- Expanded clay is a bulk heat insulator. It has obvious advantages - environmental friendliness, non-flammability. Produced in granules of various sizes, it is used as filling the space between joists, for mixing mortar for ceramic concrete screed.

Floor insulation with mineral wool

Choice of insulation

Before choosing insulation, you should first decide how the loggia will be insulated. This is due to the fact that some types of work require the use of a certain category of insulation. Therefore, below are the most alternative types of thermal insulators offered on the modern construction market:

- Mineral wool.

- Expanded polystyrene.

- Extruded polystyrene foam.

- PVC foam.

- Polyurethane foam.

- Polyurethane mastic.

- Bulk expanded clay

- Polyuria (polyurea).

Related article: Do-it-yourself processing of antique wood products

The main coefficients regulating the composition of thermal insulators are considered to be 3 characteristics:

- Density.

- Thermal conductivity.

- Vapor permeability.

The table below shows the average coefficients of these insulation categories.

| Insulation category | Density coefficient, kg/m3 | Thermal conductivity coefficient, W/(m*C) | Vapor permeability coefficient, mg/(m*h*Pa) |

| Mineral wool | 50 — 200 | 0,048 – 0,070 | 0,49 – 060 |

| Expanded polystyrene | 33 — 150 | 0,031 – 0,05 | 0,13 – 0,05 |

| Extruded polystyrene foam | 45 | 0,036 | 0,013 |

| PVC foam | 125 | 0,052 | 0,23 |

| Polyurethane foam | 30 — 80 | 0,020 – 0,041 | 0,0 – 0,05 |

| Polyurethane foam mastic | 1400 | 0,25 | 0,00023 |

| Expanded clay (bulk) | 250 — 800 | 0,10 – 0,18 | 0,50 – 0,70 |

| Polyuria (urea) | 1100 | 0,21 | 0,00023 |

How to insulate the floor on the balcony

Waterproofing

The first step is to waterproof the floor using penofol or polyethylene. Penofol must be laid out so that the reflective side faces up. Then the walls are waterproofed with the same material. The joints between the insulator plates are sealed with foil tape. Bitumen mastic is also used for waterproofing. However, it needs to be allowed to dry before carrying out work.

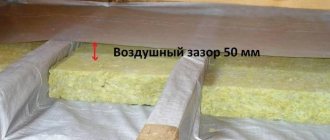

Metal beams or wooden blocks 10-15 cm high are used as lags - the basis of the floor covering. The beams are pre-treated with a primer or antiseptic to prevent rotting or fungal infection. The logs are mounted in such a way that insulation lies between them. Using polyurethane foam, the spaces between the joist and the wall are eliminated, and excess foam is cut off.

Thermal insulation

Then thermal insulation materials are laid. Do not allow gaps between the joists and the insulator. When laying thermal insulation materials in two or more layers, it is necessary to lay the subsequent layer offset - the joints of the material should not be concentrated in one place. Everything is covered with a vapor barrier film that prevents the formation of condensation.

Flooring

Boards, plywood and other materials (chipboard, fiberboard) are attached to the joists with self-tapping screws. Finishing materials (carpet, laminate or linoleum) are laid on top.

Insulation of walls and floors of a loggia in a panel house

Rice. 11. Insulation of walls using polystyrene foam

Insulation of loggia walls begins with the installation of a supporting frame. Next, the insulation boards are installed. Most often, polystyrene foam or mineral wool is used for insulation.

Floor insulation always begins with the installation of waterproofing. For this purpose, polyethylene film is used, which reliably protects the floor surface from leaks. Logs made of wooden beams are installed on top of the film. They must be aligned horizontally. It is between the joists that the insulation is tightly placed. Density is necessary to ensure that cracks do not form in the structure. It is customary to use mineral wool as insulation, on top of which a vapor barrier film and a subfloor in the form of plywood or OSB board are laid. Self-tapping screws are used to secure the subfloor.

Which thermal insulator is best to use?

Types of insulation

To decorate the balcony, you can use both roll and tile materials that provide reliable thermal insulation:

- polystyrene foam: an inexpensive tile material that has fairly high thermal insulation properties, but has two significant drawbacks; the first is the large thickness of the sheets; when using it, the already small area of the balcony will be significantly reduced; the second disadvantage is the high fire hazard; to ignite it, a lighted cigarette accidentally thrown from the top floor is enough; therefore, for balcony cladding, purchase G2 class material that does not support self-combustion

- penoplex (extruded polystyrene foam): the composition of this material is similar to polystyrene foam, but due to a special production method with equal thermal insulation properties, it has a smaller thickness and greater mechanical strength; however, the cost of penoplex is higher; since the material has a low water absorption coefficient, the balcony will need to be regularly ventilated to avoid condensation; We’ll tell you below how to insulate a balcony with penoplex from the inside.

- “Penofol”: foamed polyethylene, protected on both sides with aluminum foil, which simultaneously serves as wind and moisture protection; a significant plus is the minimum thickness; for insulation, it is enough to use a material a few millimeters thick; “Izolon”, “Penolon”, “Teplofol”, “Energofol” have similar composition and properties; disadvantage - high price

- mineral wool (glass wool, slag wool or basalt wool): the undoubted advantage of all these materials is their high heat-insulating properties; some experts believe that the increased moisture permeability of the material in the case of insulating a balcony is only a plus - by absorbing excess moisture well, the material will protect the room from the accumulation of condensation on windows and walls; however, over time, mold can form in mineral wool, so it must be reliably protected from moisture penetration on both sides using hydro- and vapor barrier

It is undesirable to use thermal insulation materials that have a significant mass (for example, brick) for insulating balconies. After all, the load-bearing capacity of a balcony slab is limited. If there is excessive load, such a structure simply may not withstand the additional weight.

The use of expanded clay for floor screed is also not recommended. Its significant disadvantage is its ability to absorb moisture. As a result, its mass increases significantly.

Perennial flowers (TOP 50 species): garden catalog for the garden with photos and names | Video + Reviews

Installation of loggia windows

The selection of balcony glazing should be approached with all responsibility, because the degree of thermal insulation of your loggia will depend on the selected windows. Currently, the most optimal, attractive and economical glazing option is windows with two-chamber glazing, made of metal-plastic and having a five-six-chamber profile.

The second glazing option is to install aluminum windows. The main feature is the presence of a thermal break, which allows you to retain and retain heat in the loggia during the cold season.

The third most environmentally friendly, but also the most expensive option is to install wooden window frames.

Their main feature is that this type of window perfectly combines the characteristics of the two types listed above.

How to choose the right material for insulation?

The next, and also one of the most important stages, is the selection of material suitable for insulating the loggia with your own hands. It should be said right away that on the modern market there is simply a colossal variety of materials intended for insulation. The laying technology of each variety is similar due to the similarity of the structure of the material and its shape.

On the modern market, the most common materials for insulation are:

When choosing, you should pay attention to such characteristics as thermal conductivity, ease of installation and installation, cost, and long service life.

Of the three materials listed above, the leader in most characteristics is penoplex. Its only drawback is its increased cost.

If your financial situation is too limited, then you can easily choose another material, for example, polystyrene foam.

Materials for insulating balconies

After glazing a balcony or loggia in a panel house, insulation materials are selected. During the selection process, the installation method and operational characteristics are taken into account.

Most often, mineral wool, penoplex, polystyrene foam and penofol are used to insulate balconies. Materials differ in their density and methods of fastening.

Mineral wool is used only if there is sheathing. Polystyrene foam and polystyrene foam can be installed using the frame method or attached directly to the surface.

It influences the choice of heat-insulating material and the nature of subsequent finishing. If cladding with sheet materials is used, then it is necessary to install a frame. You can perform plastering work on glued polystyrene foam and penoplex.

How to insulate a balcony in a panel house?

Residents of panel houses may face the problem of cold in their apartments in the winter. Despite the hot radiators, the room is not warm and comfortable enough. This is especially true for rooms with loggias. This is due to the fact that a fairly large amount of heat can escape through the loggia.

Thermal insulation of a ventilated room will help solve the problem. Insulating a loggia in a panel house is not difficult if you have minimal construction skills.

What can be done?

There are several ways to eliminate heat loss through a loggia. First of all, it is necessary to make glazing. After this, experts recommend performing thermal insulation, because the reinforced concrete slabs from which panel buildings are built have high thermal conductivity, which leads to inevitable heat loss.

To give the loggia an aesthetic appearance after insulation, interior finishing will be required. In principle, these steps will be enough to achieve the goal, but some owners additionally spend on the loggia and heating.

Glazing

Currently, three types of window designs are most common:

- metal-plastic;

- wooden;

- aluminum.

Modern wooden frames can be made in any variety and successfully protect against external factors, incl. and from the cold. However, high-quality products have a fairly high price.

Aluminum profiles are not recommended for use in residential premises due to their low thermal insulation qualities.

Thermal insulation

The most important stage of insulating a loggia is the installation of heat-insulating material. The process itself is divided into several stages. But before you start work, you need to select the insulation itself.

Selection of thermal insulation material

The building materials market today provides a huge selection of insulation materials, in particular:

- penofol;

- polyurethane foam;

- Styrofoam;

- penoplex;

- extruded polystyrene foam.

When choosing insulation, you should take into account several features of the loggia. Firstly, there is no need to resist moisture, because... The loggia is a fairly dry room. Secondly, the work will be carried out from the inside, therefore the thickness of the material should not be very large, so as not to take away precious centimeters of internal space.

In this regard, thermal insulation is most often performed using foam plastic or penoplex.

Lathing

To create the frame, well-dried wooden blocks 40 cm thick (50 cm in cold regions) are used. The frame elements are fixed to the ceiling, walls, under the window at intervals of 50 cm. The bars are secured with ordinary screws and plastic dowels.

A block adjusted to size is applied to the installation site, after which holes for screws are made in it every 40 cm. Next, dowels are inserted into the holes, after which the block is secured with screws.

Please note that the frame elements are installed not only in planes, but also in all corners in which any load is subsequently expected. For example, under the window it is necessary not only to install bars vertically, but also one horizontally

Installation of insulation

Since the distance between the sheathing bars is 50 cm, a sheet of foam plastic measuring 50x100 cm is laid without adjustment.

If the slab measures 100x100 cm, use a sharp knife to cut it in half.

The material is fixed using assembly adhesive, which can be conveniently applied with a special notched trowel.

Small cracks are sealed using polyurethane foam, the excess of which is removed after hardening. Large grooves are filled with foam scraps.

Interior decoration

To cover the inside of the loggia, you can use MDF wall panels. The products are attached to a previously made crate. Foam plastic provides stability and rigidity to the structure, preventing damage to the panels. The panels are secured with self-tapping screws.

For the ceiling, it is better to use lightweight polyvinyl chloride panels, which can also be secured with self-tapping screws or a construction stapler. A starting profile or ceiling foam plinth is installed in the corners.

Plywood sheets are laid on the floor and secured with self-tapping screws. It is better to treat the plywood coating with drying oil twice. You can also lay linoleum or laminate. Lastly, fix the baseboard.

Do-it-yourself insulation of a balcony with mineral wool

Insulation with mineral wool is especially popular. The work can be done in-house.

This is done in the following sequence:

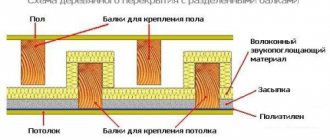

1. The frame is mounted. A beam measuring 50 by 50 cm is attached to the insulated surface. The distance between the elements is consistent with the size of the slabs being laid. It should be 10 - 20 mm less than the corresponding geometric parameter. The frame can be vertical or horizontal. The optimal location of the sheathing is selected taking into account the subsequent finishing. The position of each element is controlled using a level.

2. Mineral wool slabs are laid between the frame posts without additional fastening. If necessary, the insulation is cut to size using a construction knife.

3. A beam is attached to the frame posts on top, which is placed perpendicular to the previously fixed elements. It is attached with a similar step. Mineral wool slabs are laid perpendicular to those laid earlier.

4. A vapor barrier is attached to the top of the frame using a construction stapler. All joints of the vapor barrier material are taped using double-sided tape. The individual elements are connected with an overlap of at least 100 mm. In places adjacent to the window, walls and ceiling, vapor barrier is used using a special sealing tape.

5. The counter-lattice is installed. The pitch and spatial position are selected taking into account the subsequent finishing. The facing material is attached to the counter-lattice.

Source https://www.youtube.com/watch?v=G7rZmJG-L38

Thermal conductivity of walls - approximate calculation

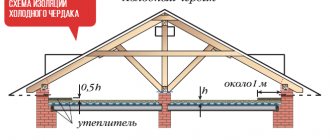

In the case when it is necessary to maintain a certain temperature regime, when insulating a loggia in a panel house, one should be guided by the standards of SNIP 2-3-79 “Construction Heat Engineering”.

In fact, it will be necessary to change the standard indicator of heat transfer resistance adopted for loggias (it is equal to 0, since in our country the building is rented with this structural part not glazed), to the one that applies to walls (in this case it is in the range from 2.1 to 5.6).

All this data is summarized in the following table:

Density kg/m3

Thermal conductivity (W/m 0 C)

The large area of light-penetrating space also presents a certain difficulty . Because of it, significant heat loss occurs in the room during cold weather. An option to solve the problem is to reduce the glazed area by sealing the side parts with brickwork, followed by insulation with mineral wool slabs.

The heat transfer resistance indicator for glazed openings on loggias in panel houses is assumed to be the same as for window openings in living rooms. Depending on the temperature zone of residence, it varies from 0.3 to 0.55.

Where to begin? Inspection and repair of balcony slabs

Balcony slab requires restoration

The condition of balcony slabs is not always satisfactory - over time they may partially collapse. Therefore, before you start insulating the balcony, you should check how strong and reliable its base is.

Minor and medium repairs can be carried out independently. If significant cracks appear, or even more so, exposed reinforcement, the collapse of fragments of the slab, or its separation from the wall, you should call specialists.

Remember that major or emergency repairs should only be carried out by qualified installers from the management company. If the reinforcement is severely corroded, it may be necessary to reinforce it with steel beams. In case of severe damage, the balcony slab can be completely cut off.

To restore damaged areas of concrete:

- Everything unnecessary is removed from the balcony, and all debris, as well as the remains of loose concrete, are completely removed

- If the reinforcement is exposed, it is cleaned of rust. Reinforcing mesh is laid on top. To prevent it from rusting over time, it must be completely buried in concrete. To do this, you need to leave a gap between it and the plate.

- Formwork is placed around the perimeter of the balcony slab

- After pouring the concrete mortar, the screed is ironed - sprinkled with dry cement, then rubbed into the undried mortar

- To protect against moisture from below, the balcony slab is primed and then plastered. Galvanized steel ebb is mounted on the sides

Pouring floor screed on the balcony

After reconstruction of the slab, it is advisable to waterproof it. For these purposes, roll materials or bitumen are used. Modern waterproofing materials include penetrating impregnation of the “Penotron” type. It is better to apply it in 2 layers.

The balcony railing may also require repairs. New structural elements in the form of profile pipes are attached to anchors or by welding.

Veranda attached to the house - expanding the living space: projects, tips on how to create it yourself (200 original photo ideas)

Preparation for thermal insulation

Do-it-yourself insulation of the floor on the balcony begins with preparing the surface. It is necessary to inspect the balcony slab and assess its condition. It may require some minor repairs. But first it is necessary to strengthen the outer wall and install aluminum or plastic double-glazed windows.

If the balcony fencing is a lattice covered with lightweight fencing material, then it is recommended to line the outer wall with foam concrete blocks. When cantilevering the slab, it is necessary to coordinate these actions with the architecture department, since it may be necessary to strengthen the load-bearing capacity of the balcony. If you need to insulate the floor on the loggia, approval is not required.

Slab reinforcement, glazing, external cladding

Strengthening the balcony slab

The preparatory stage looks like this:

- Remove from the balcony all “extra” objects that will interfere with the work.

- Remove the railings from the fence and remove the trim. Assess the condition of the metal and the strength of its attachment to the facade. If the rust damage is insignificant and the fastening points are not loose, then the grille is left as a load-bearing subsystem. In this case, the old paint and rust are removed from the fence down to the metal, degreased, a primer is applied, and painted in two layers.

- Mount the frame for the sheathing, tying it to the fence grid. It can be made of wooden beams or a combination - a profile on the outside, timber on the inside. The timber must be treated with an antiseptic. A profile is attached to the top of the fence. Its width should be such that the window block and ebb will fit. The distance between the sheathing posts is chosen to be 600 mm (according to the size of the EPS sheet). The total width of the profile (wall height) or beam must correspond to the thickness of the insulation. And when reflective thermal insulation is additionally used, another 20 mm is added. Or a counter-lattice is also attached to the racks, which will create the necessary gap between the foil surface of the insulation and the inner lining.

- If the grille is heavily rusted or the strength of its attachment to the facade is in doubt, then it is dismantled. Instead, a supporting structure made of galvanized square pipe is installed. The frame is fixed to adjacent surfaces

- For apartments on the top floor, along with the frame, a truss made of pipes and a corner for a canopy (canopy) is installed above the balcony.

- Strengthen the slab. If a balcony with an extension is being installed, then the reinforcement and frame profiles are combined in one structure.

- If necessary, repair the stove. Clean the crumbling areas from all sides (preferably from below). They find cracks. Small (thread-like) cracks are covered with a repair compound. If there are large cracks, they are widened. If there are areas with exposed reinforcement, then treat the metal with an anti-corrosion primer and then cover it with a non-shrink repair compound. When the area of concrete destruction occupies more than 40% of the surface, it is completely repaired - a new reinforcing frame is laid with fastening to the facade, a screed is poured, the integrity of the ends is restored, and cracks from below are covered up.

- They carry out a rough “cosmetic” repair of the facade inside the perimeter of the balcony - they clean off dirt and old paint. Treat with a primer and antiseptic, seal cracks and chips. The surface of the upper balcony slab is repaired in the same way.

- Install window frames. Fastening to the facade and from above (to the slab) is carried out through expanders. The cross-sectional size of the upper profile of the expander must be greater than the thickness of the insulation plus the ceiling sheathing. The height of the profiles of the façade extensions should protrude beyond the finishing of the façade inside the balcony (a layer of decorative plaster or wall panels together with the sheathing).

- Install a canopy or canopy. The fencing sheathing is attached to the outside. Blow out the cracks with foam. External and internal decorative corners are attached to the fencing sheathing.

- The junction of the side expansion profiles of the window frames to the facade is covered with external strips. Install ebb tides. Double-glazed windows are installed.