Home / Articles / How to properly insulate interpanel seams in a panel house / Repair of interpanel seams and the technology for their insulation / How to determine the series of a house and calculate the volume / How to seal interpanel seams in an apartment / Sealing seams - determining the price / Who should repair interpanel seams in a house / How force the management company to seal the interpanel seams? / Reasons for the appearance of mold on the walls of an apartment / The walls in a panel house freeze, what should I do? / Typical mistakes in sealing joints between panels / How is the technical condition of interpanel joints, roofs and balconies inspected? / Frequently asked questions about sealing seams, what should I do if the seams are leaking? / How to get rid of fungus and mold on the walls of an apartment / Album of technical solutions: insulation and repair of open and closed joints / Technical instructions for sealing joints of prefabricated buildings with polymers

Primary sealing

It is carried out during the construction of a building and includes the following stages:

The seam between the panels is filled with foam; it provides not only insulation, but also additional waterproofing;

Vilatherm is placed in the seam. This is insulation with a high elasticity index, made from foamed polyethylene. The material may be cylindrical, sometimes with a hole inside. Thanks to its elasticity, the material can withstand repeated stretching and compression, which is important when a new house undergoes shrinkage. When laying the material, you need to ensure that it fits tightly to the concrete surface. If connections are made to vilates of different diameters, then the upper edge is trimmed with a wedge downwards, and the lower edge – upwards.

A sealant (mastic) is applied over the vilatherm; if all work is done correctly, the seam should be completely sealed.

Often, insulation and sealing of the seam is carried out without the use of foam; this is acceptable and does not greatly affect the final result.

Polymer waterproofing of seams

work on wall panel joints

must be carried out using

polymer sealing and sealing materials

. All materials used to insulate joints must meet the requirements of current regulatory documents (GOST, TU).

ATTENTION! It is PROHIBITED to use materials in conditions different from those recommended in GOST and TU, as well as new types of materials that have not been tested in construction without the permission of industry documents

.

A. Preparation of repaired joints for insulation.

When repairing, clear the outside of the cavity of the joint being repaired.

to a depth of up to

50 mm

.

ATTENTION! In this case, before carrying out work on insulating the joints being repaired,

the following work must be completed:

- repair of external and side surfaces of wall panels

; - drying wet joints, sections of walls or ceilings

(on the residential side); - the damaged sealant

was removed from the joint being repaired ; - damaged sealing gaskets

.

B. Installation of sealing gaskets.

ATTENTION! Sealing gaskets

, newly installed at joints must be

compressed by 20...25%

of the diameter (width) of their cross section.

To do this, the specified dimensions of the gaskets

should be selected

25% larger

(wider) than the size of the joint width.

Sealing gaskets are installed dry at the mouths of the joints, without coating with glue.

.

Insertion of gaskets is carried out using a rounded wooden spatula. The gaskets are connected along the length "on the mustache"

.

Mouth joints

in places where sealing mastics are applied (on top of sealing gaskets) must be dry and clean. The shapes and sizes of the mastic joint, depending on the type of mastic used, are shown in Fig. 5 and Fig. 6.

B. Sealing of narrow joints.

Non-hardening mastics

should be laid at the mouth of the joint without breaks or sagging using electric sealers such as “Bumblebee” and “Joint”.

Fast-hardening mastics

(with added hardener) should be applied at the mouth of the joint using pneumatic or manual syringes or spatulas.

After laying the sealant

The mastic layer should be leveled and its surface shaped using a wooden joint dipped in water or soap solution.

B. Sealing wide joints.

Sealing large width joints

must be done in two or three steps: first

along the edges of the panels being joined

, and then

in the middle

.

NOTE: If there is an intact cement-sand base, it is ALLOWED to apply hardening mastics

in the form

of a film base

on top of a pre-glued compensating

layer of polymer tape

with a width of

22...40 mm

.

NOTE: Thickness of the applied coating

should be

2...3 mm

and extend onto the surfaces

of adjacent panels

by at least

30 mm

.

The width of the film coating should be 110 mm

.

D. Performing sealing of joints.

ATTENTION! When sealing joints,

it is PROHIBITED:

- apply quick-hardening mastics

with a brush; - apply sealing mastics to dusty and damp surfaces;

- change the ratio of components specified in the material passport when mixing the components of two-component hardening mastics;

- add solvents to hardening mastics.

To protect sealing mastics

against atmospheric and climatic influences, it is RECOMMENDED to use the following coatings:

- polymer cement

mortars; - PVC mastics

; - styrene butadiene and coumaron rubber

paints.

NOTE:

Only

M-100 polymer-cement mortars

at the joints of panels

on the ground and first floors .

Apply protective coatings

follows:

- non-hardening mastics

can be applied directly after sealing the joints; - for hardening mastics

- after they harden, but not earlier than one day after sealing the joints.

NOTE: DO NOT use as a protective layer

cement-sand mortar, and also fill the mouth of the joint with polymer cement mortar.

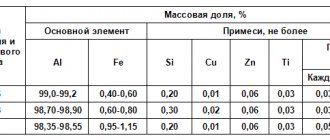

The consumption of materials

for insulation and sealing of seams in wall panels and

floor slabs is shown in Table 1.

READ ALSO: The best slot machines at Vulcan casino

Table 1: Consumption of materials for sealing joints of external wall panels and jointing wall panels and floor panels.

| p/p | List of works | Materials | Unit change | Material consumption per 100 m of seam |

| 1 | 2 | 3 | 4 | 5 |

| 1 | Sealing horizontal and vertical joints of wall panels with adhesive gaskets in 1 row | Sealing gaskets thickness 40 mm | linear meters | 103,0 |

| 2 | Mastic glue N3 | kg | 12,3 | |

| 3 | Sealing horizontal and vertical joints of wall panels with mineral wool packages | Hard mineral wool bags with bitumen bond | m³ | 0,8 |

| 4 | The same, vertical joints | Hard mineral wool bags with bitumen bond | m³ | 1,13 |

| 5 | Bitumen for surface insulation | kg | 23,0 | |

| 6 | Sealing horizontal and vertical joints of wall panels with polystyrene foam | Expanded polystyrene boards | m³ | 0,53 |

| 7 | The same, non-hardening mastic | Non-hardening construction sealing mastic | kg | 71,0 |

| 8 | Installation of waterproof tape for vertical joints | Water barrier tape | m² | 9,3 |

| 9 | Installation of a waterproof apron for vertical joints | Waterproof apron | m² | 2,6 |

| 10 | Sun protection device using a polymer-cement composition | Polymer cement composition | m³ | 0,07 |

| 11 | The same, with PVC paints (styrene-butadiene or coumaron-rubber) | Perchlorovinyl paints | kg | 4,2 |

| 12 | Installation of embossing and jointing of seams of basement panels and external wall panels from the inside with mortar | Cement mortar | m³ | 0,21 |

| 13 | Coating and grouting the seams of floor panels with mortar | Cement mortar | m³ | 0,042 |

| 14 | The same, vertical joints | Expanded polystyrene boards | m³ | 1,03 |

| 15 | Sealing of horizontal and vertical joints of wall panels with vulcanizing thiokol mastic | Vulcanizing thiokol mastic | kg | 20,2 |

| 16 | The same, sealing non-hardening mastic | Non-hardening construction sealing mastic | kg | 75,0 |

| 17 | Sealing of window frames and balcony doors with vulcanizing thiokol mastic | Vulcanizing thiokol mastic | kg | 13,1 |

D. Sealing expansion joints

When repairing and insulating expansion joints

their sealing should be restored, similar to the repair of joints of wall panels

with the introduction of a porous rubber band and sealant into the joint

.

Before recovery

seal expansion joints, clear drainage holes and check the adhesion of drainage aprons.

NOTE: Drain holes

50...60 mm

wide should be placed in the area of intersection of vertical and horizontal joints.

To do this, appropriate gaps must be created

of the mouths of the joints .

The consumption of materials

for insulation and sealing of vertical expansion joints

in wall panels is shown in Table 2.

Now let's look at what mistakes are most often made when sealing interpanel joints?

For insulation, only polyurethane foam is used. Some companies consider this a simplified option, but our specialists do not use this technology, as it has disadvantages. Over time, the house will settle, causing the slabs to move. Polyurethane foam is not elastic, therefore, as a result of the movement of the slabs, the integrity of the foam will be compromised, which means water and cold will freely penetrate into the seams.

Use of low-quality Vilaterm. The use of high-quality insulating material is a very important fact, so we check the quality of vilatherm every time we purchase it. In our practice, there have been cases when, with vilatherms, such material does not provide a tight fit to the panels, that is, the material simply falls out of the seam.

Using vilatherm of the wrong diameter. When laying, it is important that it fits tightly to the walls of the seam and is in a compressed state.

Incorrect connection of insulation. One of the common mistakes that leads to the destruction of the sealing material and the opening of the seam.

Secondary sealing

Repeated work on sealing the joints between the slabs can be carried out using two technologies:

Without opening the seam. New sealant is applied to the old sealant (mastic joint repair) or over the concrete joint. In this case, it is very important that the seam is cleared of foreign debris and elements that are weak to adhere to. A carpet brush is used to clean the joint, after which the seam is treated with a solvent.

The second option involves opening the seam and completely cleaning it, removing the old sealing material. For cleaning, a hammer drill and a chisel and hammer are used to remove old material. After which the seam is degreased and goes through the stages of primary sealing.

Often, when carrying out this procedure, companies with unqualified employees make a mistake - poor-quality cleaning of the seam from old material.

Types of seams and their execution

Having mastered the theory, newly minted needlewomen usually pick up a needle, thread it and try to embroider the first rococo seam. You can do it step by step following a simple scheme:

- Thread the fabric from the inside out, not forgetting to secure the thread with a knot at the end.

- They step back from the place where the thread exits towards the future seam and pierce the fabric so that the tip of the needle comes out near the thread.

- Pull the needle out halfway and make the required number of turns around it.

- Pull the needle and thread through the turns, holding them with your free hand.

- Pass the needle through the wrong side and tighten the seam, straightening it from the front side.

Following these simple instructions, perform any stitches. They differ mainly in the number of turns and the density of the winding. There are four types of seams:

- Knot. The main difference from its counterparts is the small number of turns and the beginning of this seam coincides with its end.

- Spiral. A type of knot, only there are many more turns in such a seam (up to 15 times).

- Loop. The same knot, only the seam is made to the width of the turns. This type of seam has a step, unlike a knot.

- Stitch. A long loop is called a stitch. The difference from its brother or sister is the presence of a large number of turns and, accordingly, a longer pitch.

After practicing the basic stitches, you usually begin to embroider simple patterns. Most often these are rococo roses. Embroidery of these flowers, beloved by many, is the most common decorative element.

A little about the technology of sealing interpanel joints

The simplest and cheapest sealing option is to coat the joints, but unfortunately, this method does not bring the expected results, moisture penetrates the seams and enters the home, drafts continue to flow along the walls and bring cold into the home.

The fact is that during rain, a large amount of water collects on the roof of the bay window and it flows along the seams, constantly leaking into the apartments, especially in areas where a vertical seam intersects with a horizontal one. The surface sealing method is often used by home management companies, where the main thing is to make the work look like it is done, and not to do the job properly.

Sealing the seam between the panels and filling it with foam is a good option, although not strong enough. This technology involves drilling the seam to create holes through which the void between the panels will be filled with polyurethane foam. This method is usually used when the distance between the slabs is minimal or the interpanel seams are firmly closed with cement-concrete mortar.

At the same time, there is emptiness in such seams and dampness and cold pass through them into the room. In addition, when a building settles, the slabs always shift and cavities form, which can expand over time, especially in the seams, since this is the weakest point.

It is impossible to lay vilatherm from the outside, so the voids are filled with foam, and the seam from the outside is covered with mastic. With a competent approach and compliance with all technologies, this is a fairly reliable method, especially if the foam is not affected by climatic influences.

Insulation of interpanel seams

- General provisions

This personal data processing policy has been drawn up in accordance with the requirements of the Federal Law of July 27, 2006.

No. 152-FZ “On Personal Data” and determines the procedure for processing personal data and measures to ensure the security of personal data taken by Termocomfort LLC (hereinafter referred to as the Operator). 1.1. The operator sets as its most important goal and condition for carrying out its activities the observance of the rights and freedoms of man and citizen when processing his personal data, including the protection of the rights to privacy, personal and family secrets.

1.2. This Operator’s policy regarding the processing of personal data (hereinafter referred to as the Policy) applies to all information that the Operator can receive about visitors to the website https://terkomfort.ru.

- Basic concepts used in the Policy

2.1. Automated processing of personal data – processing of personal data using computer technology;

2.2. Blocking of personal data – temporary cessation of processing of personal data (except for cases where processing is necessary to clarify personal data);

2.3. Website – a collection of graphic and information materials, as well as computer programs and databases that ensure their availability on the Internet at the network address https://terkomfort.ru;

2.4. Information system of personal data - a set of personal data contained in databases, and information technologies and technical means that ensure their processing;

2.5. Depersonalization of personal data - actions as a result of which it is impossible to determine without the use of additional information the ownership of personal data to a specific User or other subject of personal data;

2.6. Processing of personal data – any action (operation) or set of actions (operations) performed using automation tools or without the use of such means with personal data, including collection, recording, systematization, accumulation, storage, clarification (updating, changing), extraction, use, transfer (distribution, provision, access), depersonalization, blocking, deletion, destruction of personal data;

2.7. Operator - a state body, municipal body, legal or natural person, independently or jointly with other persons organizing and (or) carrying out the processing of personal data, as well as determining the purposes of processing personal data, the composition of personal data to be processed, actions (operations) performed with personal data;

2.8. Personal data – any information relating directly or indirectly to a specific or identified User of the website https://terkomfort.ru;

2.9. User – any visitor to the website https://terkomfort.ru;

2.10. Providing personal data – actions aimed at disclosing personal data to a certain person or a certain circle of persons;

2.11. Dissemination of personal data - any actions aimed at disclosing personal data to an indefinite number of persons (transfer of personal data) or familiarizing with personal data to an unlimited number of persons, including the publication of personal data in the media, posting in information and telecommunication networks or providing access to personal data in any other way;

2.12. Cross-border transfer of personal data – transfer of personal data to the territory of a foreign state to an authority of a foreign state, a foreign individual or a foreign legal entity;

2.13. Destruction of personal data – any actions as a result of which personal data are destroyed irrevocably with the impossibility of further restoration of the content of personal data in the personal data information system and (or) the material media of personal data are destroyed.

- The Operator may process the following personal data of the User

3.1. Full Name;

3.2. Email address;

3.3. Phone numbers;

3.4. The site also collects and processes anonymized data about visitors (including cookies) using Internet statistics services (Yandex Metrica and Google Analytics and others).

3.5. The above data below in the text of the Policy are united by the general concept of Personal Data.

- Purposes of processing personal data

4.1. The purpose of processing the User’s personal data is to inform the User by sending emails; providing the User with access to services, information and/or materials contained on the website.

4.2. The Operator also has the right to send notifications to the User about new products and services, special offers and various events. The User can always refuse to receive information messages by sending the Operator an email to the email address marked “Opt-out of notifications about new products and services and special offers.”

4.3. Anonymized data of Users, collected using Internet statistics services, serves to collect information about the actions of Users on the site, improve the quality of the site and its content.

- Legal grounds for processing personal data

5.1. The Operator processes the User’s personal data only if it is filled out and/or sent by the User independently through special forms located on the website https://terkomfort.ru. By filling out the appropriate forms and/or sending his personal data to the Operator, the User expresses his consent to this Policy.

5.2. The Operator processes anonymized data about the User if this is allowed in the User's browser settings (saving cookies and using JavaScript technology are enabled).

- The procedure for collecting, storing, transferring and other types of processing of personal data

The security of personal data processed by the Operator is ensured by implementing legal, organizational and technical measures necessary to fully comply with the requirements of current legislation in the field of personal data protection.

6.1. The operator ensures the safety of personal data and takes all possible measures to prevent access to personal data by unauthorized persons.

6.2. The User's personal data will never, under any circumstances, be transferred to third parties, except in cases related to the implementation of current legislation.

6.3. If inaccuracies in personal data are identified, the User can update them independently by sending a notification to the Operator to the Operator’s email address marked “Updating personal data.”

6.4. The period for processing personal data is unlimited. The User may at any time withdraw his consent to the processing of personal data by sending a notification to the Operator via email to the Operator's email address marked “Withdrawal of consent to the processing of personal data.”

- Cross-border transfer of personal data

7.1. Before the start of cross-border transfer of personal data, the operator is obliged to ensure that the foreign state into whose territory it is intended to transfer personal data provides reliable protection of the rights of personal data subjects.

7.2. Cross-border transfer of personal data to the territory of foreign states that do not meet the above requirements can only be carried out if there is written consent of the subject of personal data to the cross-border transfer of his personal data and/or execution of an agreement to which the subject of personal data is a party.

- Final provisions

8.1. The User can receive any clarification on issues of interest regarding the processing of his personal data by contacting the Operator via email

8.2. This document will reflect any changes to the Operator’s personal data processing policy. The policy is valid indefinitely until it is replaced by a new version.

8.3. The current version of the Policy is freely available on the Internet at https://terkomfort.ru/privacy.

Warm seam

This is one of the most effective and common methods. To implement it, the joint cavity is foamed and vilaterm is placed in it, after which a layer of sealant is applied to the surface of the seam. At first glance, the “warm seam” technology is impeccable, but as practice shows, it also has disadvantages, or rather difficulties in operation. Panel slabs are produced with a thickness of 20 cm, while vilatherm is 3-4 cm, with another 16 cm remaining, but there are slabs with a greater thickness and this space will remain empty. The seam will be protected for several years, but then the vilatherm will turn into dust, begin to crumble, and the problem with the seams will again become acute for the owners. If the joint is heavily foamed, the foam will push both the vilatherm and the sealant out, which is, of course, unacceptable. Therefore, when using the “warm seam” technology, the joints must be foamed very carefully. It is described in more detail and in detail with examples on the page about sealing interpanel seams

Do-it-yourself methods for sealing interpanel seams inside an apartment

Over some time, residents of all panel houses begin to feel a draft in the room, even with the windows and doors closed. This means that the connections between the panels have become useless and no longer fulfill their purpose of retaining heat in the living space.

This problem is equally typical for both old houses and new buildings. It concerns the rest even more, since they still have to go through a settling process, due to which the connections between the slabs can crack and begin to crumble.

The problem can be solved by sealing the interpanel

seams, which can be done both inside and outside the wall. From the outside, sealing is, of course, more effective, but above the second floor it is done only by professional craftsmen who have special climbing equipment and the ability to work at heights. You can seal interpanel connections yourself only inside the apartment, if the non-compliance with their integrity is not very large.

The most popular materials for sealing seams are foam for installation work, artificial latex and sealant. They can be used as independent heat insulators or in a configuration with each other. To make a good selection of material, it is suggested that you familiarize yourself with the information below.

Sealing seams with foam for installation

Like different methods, this one has its own disadvantages and advantages. So, among the positive qualities it should be noted:

- Good filling of all empty spaces and cracks;

- Conditional simplicity of the process;

- Quick drying and hardening;

- Good thermal insulation properties.

There are only two drawbacks: the foam loses its properties when exposed to direct sunlight, its price is in the middle price segment.

Based on this, the material is perfect for sealing minor cracks and cracks. The main thing is to choose high-quality foam. With all this, it is necessary to provide for such properties as density, adhesion, expansion rate and shrinkage.

Sealing of interpanel seams begins with their preparation. They are cleaned of old sealant, its remains are removed from the cavities and the joints are wiped with a wet rag or brush. After completing the preparation work, you can apply foam. After making sure that it has hardened, you should cut off all protruding parts and putty the seam so that the foam does not collapse. It must be emphasized that if the gap is large, foam alone will not work and you will need to add additional heat insulation.

Sealing joints with artificial latex

This material is produced as a hollow or solid tube. For sealing seams, a hollow structure would be an excellent choice, as it is more versatile in terms of occupied volume. Among the positive qualities it should be noted:

- Inexpensive price;

- Ease of installation;

- Long service life;

- Resistance to rotting;

- Resistance to sun rays.

The disadvantage is considered to be hygroscopicity, which during winter can lead to freezing of moisture in the pores of the tube and its destruction. As with foam, you need to prepare the connections for work. When selecting a tube, it should be ensured that its diameter should be approximately 10-30% greater than the width of the slit. After the preparation work is completed, the tubes are placed into the joints, compacted with a specialized spatula. Finally, the seam is sealed using mastic.

Combined method

This method is also known as “warm seam” and is considered the best among all those mentioned. When performing work using this technology, you need to start by cleaning the seam. To do this, you need to remove all debris and clean the seam with an iron brush. Dust can be removed with a vacuum cleaner, and then wipe the seam with a wet rag.

Afterwards it is necessary to fill in foam for installation work. It is necessary to fill the seam only 30% so that the foam has room to expand. Without waiting for it to harden, you need to lay the polyurethane foam tube, tamping it down with a wooden spatula. Then the seam is covered with mastic or cement plaster.

Depending on the specific situation, any of these methods can effectively protect your living space from the cold. With all this, they are quite doable without the involvement of professionals. But if you have neither the time nor the desire, you can contact a construction and repair company and hire professionals to carry out insulation work on the seams. The price of the service does not go beyond reasonable limits, and the user will be able to evaluate the advantages of professional seam sealing using his own example.

masterdom35.ru

Sealing seams in panel houses

In this case, it is assumed that the joint between the panels is completely filled, where the final stage is the application of a sealing layer of mastic. When the material is completely foamed, it comes out, so it doesn’t make any sense to lay Vilatherm and mastic right away. You need to wait a few hours, or better yet a day, until the foam gets stronger, then you need to remove its excess, lay the vilatherm and apply mastic. If the joints are filled through holes that are pre-drilled, then the technology is the same. Foam is injected into the holes, which are then tightly closed. The foam, not finding a way out, is forced to fill all the voids inside.

Is it necessary to open the seam?

There are a number of factors under which the seam must be opened, namely:

- The material from the seam disintegrates when struck with the sharp edge of a climbing hammer;

- The seam is surface plastered and a light layer of sealant is applied to it;

- The wall is very old and the material falls off even with a light touch.

Such seams must be opened, filled and sealed. If the seam is securely concreted or the slabs fit tightly enough to one another, then tearing down the walls is not recommended. It is more advisable to drill neat holes and foam the voids. Some people believe that in order to ensure thermal insulation of the seam, it is necessary to lay vilatherm. This is not so, the fact is that vilatherm itself does not provide heat, it only protects the seam from the penetration of cold by “sealing” the joint. If the seam is foamed correctly and reliably, then heat leakage will not occur.

Features of sealing interpanel seams

Today, before starting renovations on apartments in a new building, owners have to wait several years for the house to settle. As a result of settlement of the house, voids and cracks form between the slabs, which must be repaired. Houses that were built during the cold period have a number of disadvantages. The panels often did not always have time to dry thoroughly and reached their condition already during the construction process. As a result, due to temperature changes and high humidity inside the slab, its integrity was compromised, since in cold weather the water inside the concrete froze and destroyed the slab.

Sealing of joints between panels should be carried out during the construction stage. The work should be carried out from an elastic material that has good resistance to the negative influences of the environment, because practice has already proven that the structure of solid materials is quickly destroyed due to the constant (even microscopic) movement of panel slabs.

Seam sealing at a professional level

To ensure thermal and waterproofing, it is necessary that all joints and cavities between the slabs be filled and sealed. Only properly sealed seams provide comfortable and healthy living conditions. As practice has shown, the most effective method of insulation today is the “warm seam”.

In the past century, the seam was filled with tow and rubber; recently, new materials and techniques have appeared on the market, which have made it possible to significantly improve the technology of sealing seams and guarantee high results. For this purpose use:

- Swellable cords made on the basis of hydrophilic rubber;

- Cement mortar is common;

- Dowels and specialized profiles.

But such sealing methods cannot give a good result due to:

- Different thicknesses of gaps between plates;

- Chips and microcracks of slabs;

- A defect that could occur as a result of non-compliance with construction technology.

Houses made of sandwich panels once received an unfortunate practice. The first buildings built using the new method had to be strong and warm, since the structure was made of two strong slabs. But over time, it turned out that there was an empty space between the panels, although in theory it should have been filled with insulation, in practice it was not there, as a result, air accumulated in the empty space, which created drafts. Due to the large number of empty cavities, such houses did not warm up well and cooled down quickly. Condensation led to the formation and active reproduction of mold and mildew, which became faithful neighbors.

Step-by-step sealing of interpanel seams

Sealing seams in buildings of this type is a very painstaking and time-consuming job that requires experience and specific knowledge. Our company’s employees, thanks to many years of experience, have been able to master the technology of closing seams for such houses.

To reliably fill the seams, our employees use special foam, which, when expanded, penetrates even small cracks and reliably fills all voids. Vilater blocks the foam from escaping to the outside, as a result, the entire flow goes inside, and the sealant reliably protects the seams from moisture penetration.

Protection of the upper floors should begin with sealing the seams

The reputation of panel houses suffers greatly due to poor waterproofing, especially on the top floors. In most cases, the space between the slabs in such buildings is not filled with anything, and this is a fact proven by practice and experience. In addition, the roofing material of balconies and loggias does not meet the waterproofing requirements.

The technical floor becomes a place where rainwater steadily accumulates after every rain, which penetrates into the apartments through drainage channels and empty seams, and the upper floors are the first to suffer.

To free your apartment from the constant penetration of dampness, drafts and cold from the roof, it is enough to properly insulate the joints and repair the roof on the loggia. To do this, craftsmen remove the old material and lay in a new one that has good strength and elasticity. Additionally, the work uses a burner and special modern waterproofing materials. Next, waterproofing of vertical joints in the area of the customer’s apartment is carried out on all floors. Afterwards, the joints between the panels are cleaned, where vilatherm and polyurethane foam are laid. Afterwards, the seam must be thoroughly coated with waterproofing material – mastic. Only compliance with this technology can guarantee a high result of waterproofing work and provide dry and warm walls in the premises.

The edge of a concrete wall with joints is often jagged and uneven, so if the joints are not sealed carefully, they begin to leak. The problem is that the seams on the inside of the slab are inaccessible for work, so the only solution is to carefully waterproof the joints on the outside.

Errors when performing joint repairs

If the work is performed unsatisfactorily and the quality of the materials used is poor, the facades of buildings will require repair within a few years. Facades with seams carelessly coated with black sealant look bad. Stripes of various widths (up to 20 cm

) go beyond the dimensions of the seams and cover the front part of the wall structure.

Coating the seams of wall panel joints

It is applied even in places where possible water penetration is expected - as a result, mottled, roughly applied black stripes appear on the facade. When aging, the sealant comes off the seams, exposing the tarred tow used to caulk the seams, which in turn causes local darkening of the surface and leakage of the joint.

NOTE: Surface sealing of joints

wall panels, made

without proper cleaning of the seams

and

deep compaction of the mortar

, does not give the desired results and requires rework again and again.

Construction organizations and housing and communal services offices quite often resort to re-caulking seams and sealing with mortar. Such work is usually carried out in autumn or winter (when leaks intensify), and the quality of such work is very low.

ATTENTION! Repair work and insulation of joints

should be performed in the warm season in dry weather.

The insulation diagram of vertical and horizontal conventional open joints

of reinforced concrete wall panels

is shown in Fig. 5.

Joints (seams) between wall panels

should be no wider than

30...35 mm

(Fig. 5 pos. "b") and somewhat

recessed

(due to the chamfering).

NOTE: Depending on the joint width

it is filled with sealant to such a depth that after laying the filler (Fig. 5, item 3), there remains sufficient area for adhesion between

the sealing gasket of the filler and the sealant

(Fig. 5, item 4).

The thickness of the elastic band of sealant

take the smallest width in the middle of the seam (Fig. 5 pos. "a").

Typically, the thickness of the sealant bundle should be at least 10 mm

.

And for wide joints

of more than

20 mm

- about half the width (with size “2a”) of the joint.

READ ALSO: Decorative plaster: application and varieties

ATTENTION! If it is impossible to ensure clamping of the adhesive bitumen waterproofing

Its use is NOT RECOMMENDED.

Therefore, glued bitumen waterproofing

in the seams of wall panels

is used in places where this is allowed - in wall panels with wide seams (for example, in the seams

between the ceramic cladding

of external wall panels).

The insulation diagram of vertical and horizontal wide open joints

of reinforced concrete wall panels

is shown in Fig. 6.

Repair of joints

can be carried out with or without preliminary clearing, depending on their condition. Insulating compounds and materials must be applied in continuous and uniform layers or in one layer without gaps or sagging.

ATTENTION! Each layer must be arranged on the hardened surface of the previous one.

with leveling of applied compounds,

with the exception of painting ones

.

Sealing seams in different types of houses

Sealing technology is selected for each home and case individually, since there are many factors that must first be calculated and taken into account. At the same time, craftsmen also consider the economic feasibility of using one or another sealing method.

Our company uses the “warm seam” technology for its work; today this is perhaps the only reliable, proven method that gives high results. The secret of our company is that we use our own, improved and time-tested technology for waterproofing seams. We use Vilaterm as a sealant, a material characterized by high wear resistance, Macroflex sealant and Oxyplast mastic.

Previously, houses of the KOPE type were built from sandwich panels that were empty inside. The tightness of the adhesion of such panels was simply terrible; as a result, the houses were not distinguished by good thermal insulation and airtightness.

Let us say right away that sealing seams using foam does not bring the desired result due to the specifics of the material; the foam did not linger in the seams after filling, but spread throughout the interpanel space. To achieve good tightness, a vilatherm seal is used. This material has already proven its effectiveness in ensuring tight sealing of seams and sealing.

In houses of the p.44 and p.44t series, problems periodically arise associated with chips on the slabs or with the formation of large seams between the panels, through which heat leaves the house, a draft penetrates from the street and condensation forms. In winter, such walls are not protected from the cold, as a result, fungus and mold become permanent residents in such apartments, and drafts also add to the dampness.

In such cases, interpanel joints are sealed using the “warm seam” technology. If the width of the joint does not allow the use of Vilaterm insulation, the seam is reliably foamed and covered with sealant on top. Construction foam has good resistance to environmental influences and can perform its functions for a long time.

To be fair, it should be noted that blown seams are not only a drawback of panel houses. Monolithic brick buildings also face this problem; poor sealing is especially often observed at the junction between the brickwork and the concrete monolithic floor. Similar problems also often arise at the junction of brickwork and windows. From personal experience, we can say that such seams must be sealed very carefully, using not only foam, but also sealed plaster.

Sealing of seams using the “Tight seam” technology. Sealing of seams.

The most advanced method of insulating and sealing seams is “Tight seam” . Unlike other technologies, the “Tight Seam” technology does not combine the use of Vilatherm or foam, but uses both Vilatherm and polyurethane foam in a comprehensive and systematic manner.

Strictly speaking, the “Canvas seam” technology is the same as the “warm seam” plus extensive foaming of the seam cavities to seal the entire interpanel space of the seam. With the “Warm seam”, in the best case, the cavity inside the vilatherm foams and the foam, expanding the vilatherm with a “bloated sausage”, seals the interpanel space well, but this works with a perfectly even joint of the plates. In practice, reinforced concrete slabs are chipped inside and the interpanel space is of irregular geometric shape with openings of unpredictable size. When building a house, builders try to install the slabs with the chips facing inward so that the house makes a good impression. And also, when the building settles, the crosshairs of the vertical and horizontal seams shift, forming an irregularly shaped interpanel space, so Vilaterm does not insulate the seam tightly enough with the “Warm seam”. For high-quality insulation of the interpanel seam, it is necessary to foam not only the cavity inside the vilatherm, but also the space behind the vilatherm, not sparing the mounting foam. Then the joint of the panels must be properly sealed with good mastic.

Even following simple everyday logic, compare the thickness of the slab and the diameter of the insulation. The thickness of the panel slab is from 30cm to 70cm, depending on the series of houses, and the Velatherm insulation has a diameter of up to 70mm; usually when insulating interpanel seams, 30mm or 40mm is used. Thus, with a “warm seam” only the outer part of the slab is insulated. If your neighbors did not insulate and seal the seams, then cold air will penetrate to you through the “neighbor’s seams”. There is only one way out - to insulate with Velatherm - on the outside of the seam, and with polyurethane foam - in the depths, between the panels. It is necessary to foam ALL the empty space between the slabs using the “Tight seam” technology. The use of polyurethane foam “costs a pretty penny”, so management companies, at best, use the “warm seam +” technology, i.e. the crosspieces foam, and then “a little bit.” Real insulation involves completely filling the seam with polyurethane foam. Polyurethane foam allows you to achieve proper sealing of the seam

. Polyurethane is widely used as insulation in construction, for example, in clinker panels, sandwich panels, and the application of foam insulation for roofs and walls.

If the seams of the panel joints were not sealed or were not done well, water can seep into the apartment, flowing down the vertical seams and spreading along the horizontal ones. Or form as condensation on a cold wall. Cold air penetrates through the seam cavities and blows heat out of the apartment. Fungus and mold form on the walls in apartments, wallpaper peels off and plaster falls off. In winter, in such apartments you can easily get the flu.

Every resident of a modern panel house sooner or later comes to the conclusion about the need for high-quality sealing of interpanel seams.

Sealing materials must be elastic. Since the seams in a panel house concentrate the entire load. When a house settles, rigid, inelastic seams inevitably crack. For example, the cement mortar used by builders cracks, and various profiles and cords made of hydrophilic rubber are deformed unevenly. The most correct way is to insulate and seal the seams with dense filling of the voids between the seams with elastic materials using the “Tight Seam” technology.

Sealing interpanel seams is the sealing of the joint between wall slabs of a panel building. Seam insulation

This is achieved by filling the space between the panels with foam and vilatherm. First, vilatherm is laid between the panels. After this, the entire intrasuture space is filled with foam into the hole made in the vilatherm. Vilatherm prevents the foam from coming out. The foam fills all the voids inside the seam, forming a blind plug. Then the joint between the panels is coated with sealing mastic. Sometimes the joint between the panels is very small, i.e. the panels are pressed tightly on the outside, but inside there is still a cavity, an expansion joint. In this case, the vilatherm is not laid. The seam is filled with foam through drilled holes, and the joint is sealed with mastic. The foam in this case is completely covered by the panels and lasts a very long time, and the sealant prevents moisture from penetrating into the seam.

High-quality sealing of interpanel seams and insulation of the interpanel cavity can only be carried out using the necessary technologies and the necessary materials. Any deviation from technology or in the choice of materials when sealing seams leads to disastrous results.

High-quality repairs, insulation and sealing of seams imply work using the “Tight seam” technology

followed by waterproofing the joint between the panels with sealing mastic.

Sealing and insulating seams using the “Tight seam” technology will completely insulate and seal the seams. Many companies only partially solve the problems of insulation and tightness of interpanel seams, as they violate the technological order of work. Either they simply foam the cavity of the vilatherm, or lay an empty vilatherm, but do not foam the cavities between the panels. Or they don’t pull out the old, rotten seal. We guarantee high-quality - tight insulation of seams, ensuring complete sealing of the inter-panel space and waterproofing of the joint of external wall panels.

If the seams are being sealed for the first time, it is necessary to dismantle the cement putty (plaster) made by the builders, then remove the tow or rubber (boards, rags) with which the builders filled the space between the panels. And then it is necessary to carry out high-quality sealing of the seam (waterproofing of the joint). If the seams have already been sealed, but the required result has not been achieved, it means that the technology was violated or low-quality materials were used. In this case, it is necessary to repair the interpanel seams. It is necessary to inspect on site what repairs to the seams should be made. If vilatherm has already been laid in the seam, it is necessary to foam the seam and seal the joint. If the seam is completely insulated, the sealant has simply cracked over time, then it is enough to coat the joints between the panels with sealant.

TOP

See also: Insulation of panel facades “Warm facade”. Insulating the walls of panel houses is the best solution for any panel building. If the walls of a panel building are thin or defective and do not retain heat, a layer of insulation will not only retain heat and make the room much warmer, but will also protect the facade from destruction as a result of climatic influences. Our experts believe that all buildings must be insulated from the outside, and not only for insulation, but also in order to transfer the dew point from the load-bearing wall to the insulation.

Sealing joints that were previously plastered

Often, instead of sealing, utility workers simply plaster the walls and seams, but these actions do not solve the problem, the void between the seams remains, water and cold air constantly penetrate into apartments, as a result, the home is cold and uncomfortable, fungus and mold develop, which not only allows you to create comfortable living conditions, but also negatively affects the health of residents. Over time, dampness destroys the plaster layer and cracks open.

Of course, it is not always necessary to open the seam completely. Such measures are taken if the joint between the panels is narrow or the plaster is held tightly, then construction foam is used. Holes are made in the plastered seam, every 20-30 cm, foam is released through them, which penetrates into all the cracks and fills the entire space. Afterwards, a layer of sealant – mastic – is applied to the plaster; this coating will provide additional protection against moisture penetration.

Partial seam opening

If part of the coating is damaged or there is no seal behind the cement mortar, it is necessary to partially open the joint between the panels. This method is more reliable than cosmetic repairs. The work is performed in the following order:

- First, the destroyed cement composition is removed. When opening only a certain part of the seam, you need to drill holes in it every 25 cm. In this case, you must use a 10 mm drill.

- Then the empty areas behind the plaster should be filled with foam. To do this, use a construction gun, which conveniently dispenses foam.

- After the foam has hardened, its protruding part must be cut off. The entire seam should be treated with a primer. All areas that have been exposed must be plastered.

At the final stage of work, the joints are treated with bitumen mastic.

Sealing seams at the joints of loggias and windows

The design of loggias and balconies implies the presence of joints between the slabs and walls, through which water can penetrate during rain. Constant dampness negatively affects materials, destroys them, develops fungus in them, and mold appears on the walls and ceiling. If the loggia is also blown out, then the furniture and materials on them begin to deteriorate, and there is nothing to say about comfort.

To eliminate drafts and moisture penetration inside, you need to provide sealing. Before starting work, the loggia must be carefully examined by employees of the sealing company, which will allow you to first draw up a competent work plan and select the necessary materials.

What advantage does sealant have over other building materials?

According to its technical characteristics, the sealant has good elasticity, which allows the material to adapt to external changes, slab shifts and other deformations that may occur as a result of the operation of the building. A high-quality sealant withstands exposure to sunlight well and is a reliable protection for foam, which can collapse under the influence of UV rays. At the same time, the sealant protects the foam not only from sunlight, but also from moisture, and prevents the formation of flax, mold, and fungus inside the seam.

Our specialists use only materials proven by experience and time, which provide long-term safety for the seam and the apartment (house) from moisture.

A question or request for work using the warm seam technology method for a panel building can be submitted to the contact phone +7 (495) 585-79-00 or sent right now: Order

Frequently asked questions about sealing seams: / How to properly seal internal seams between slabs / Who should I repair the interpanel seams in my house? / Sample application to the Management Company for the repair of interpanel seams / Secrets of correctly writing an application for interpanel seams in the management company / Reasons for the appearance of mold on the walls of an apartment / Walls freeze in a panel house, what should I do? / Typical mistakes in sealing seams between panels

Thermal insulation of closed and open joints in wall panels

A. In closed panel joints.

In closed joints, to ensure air and moisture protection properties, one common channel area of the joint itself is provided. When constructing a “closed” joint at the mouth of the joints

along their entire length,

elastic pads made of porous rubber

, over which

sealing mastic

.

Film-hardening materials are used as sealants.

(thiokol, silicone) or

bulk non-hardening

(polyisobutylene, etc.)

mastics

that retain their properties at temperatures down to

-40°C

.

The durability of sealing materials does not exceed 20...30 years

, i.e. significantly lower than the durability of building structures.

The insulation of closed vertical joints

in external wall panels

is shown in Fig. 2.

The closed joint of the panels being connected

can be repaired if it fails.

One of the main reasons for the aging of polymers in joints

is exposure to sunlight.

To do this, the sealant

(Fig. 2, item 7) is placed deep in the seam and coated with

polymer compounds

or

reflective painting

(Fig. 2, item 9).

READ ALSO: Official website mirror of the bookmaker PinUp Bet

To reduce the air permeability of vertical panel joints

they are insulated from the inside of the panels

with air-protective tape

(Fig. 2, item 5).

However, the low durability of sealing materials characterizes the low reliability of closed joints

.

B. In open joints of panels.

In open joints, two design schemes are provided, one of which is designed to provide air-protective

, friend -

waterproof properties

.

In open joints

in front of

the main air insulation zone

there is a free part that communicates with the outside air (Fig. 3).

Insulation of open vertical joints

in external wall panels

is shown in Fig. 3

Open joints can be drained or undrained

.

A drained joint

is

an open joint

in which the design of the main or reserve waterproofing zone is made in such a way that it is possible for moisture to enter these zones and ensure its removal to the outside using drainage channels.

In open undrained joints

, rainwater that gets inside them evaporates.

In open joints,

sealants are protected

from atmospheric influences. Water barrier tape prevents water from penetrating. Corrugated joint surfaces allow water to be drained to the outlet tray. The inclined grooves on the side edges of the wall panel ensure that moisture, when penetrating the first waterproof layer (waterproofing tape), flows down along them to a horizontal joint into a drainage tray made of galvanized sheet.