Multilayer building blocks. Insulation and finishing

House made of multilayer building blocks

How have structures been insulated recently during the construction of houses and non-residential buildings? A layer of load-bearing wall, a layer of insulation and external finishing. But there are materials in which all these layers are present initially - relatively recently appeared multilayer blocks . Let's talk about different ways to build an insulated house.

Everyone understands: it is impossible to live in an uninsulated house - it is cold, damp, uncomfortable, and mold also develops. Even if the insulation is done, but the heat-insulating material is chosen incorrectly or the builders are careless in following the technology, heat loss can amount to up to 35-40%. But this is also your financial loss - for heating the house.

Features of construction from heat blocks

The technology of masonry from three-layer blocks has much in common with the process of constructing walls from gas silicate blocks. The fundamental difference, as we have already said, is the ban on cutting blocks to preserve their integrity and unity of textured pattern.

The masonry is carried out using construction adhesive, maintaining the thickness of the seams in the range from 2 to 4 mm. Dense laying reduces heat loss through mortar joints, improving the thermal insulation qualities of the wall. The glue is applied with a notched trowel to the inner and outer layers of the block. The solution is not spread on the foam. The construction of the walls is carried out with ligation of seams in ½ block.

Vertical seams when laying heat blocks are sealed in a special way. In the insulation zone they are sealed with construction foam. The outer and inner seams in the expanded clay area are sealed with mortar using a construction gun.

The seam in the insulation area is filled with polyurethane foam

An important nuance is the reinforcement of the masonry through 3-4 rows with steel mesh (mesh 5x2 cm, wire thickness 0.5 mm).

Manufacturers claim that a block with insulation and cladding does not require a reinforced belt (when building houses up to two floors high). However, practice has shown that it should always be done before installing floor slabs. To ensure that the reinforced concrete does not stand out on the facade, it is covered with thin belt blocks.

Installation of the armored belt frame. From the outside it is covered by a number of waist blocks

The support of the floor slabs on the wall made of thermoblocks must be at least 12 cm.

Multilayer building block - three in one

Manufacturers are offering new materials that simplify the process of building an insulated house. In recent years, to insulate structures in low-rise construction, facade multilayer blocks have gradually begun to be used, or, as they are also called, thermally efficient wall building blocks or polyblocks , which already contain insulation (for example, wall blocks from Khimki Concrete, “Teplosten” blocks from. Usually such the materials have a three-layer structure: the thickest load-bearing layer, an internal thermally efficient and protective decorative layer (at least 15-30 mm thick). The outer layers are responsible for the strength of the structure, and the internal insulation provides thermal protection. The total thickness of the multilayer block can be 30-350 mm.

Facade multilayer block

The outer layers of such a sandwich are one or another type of concrete. As a rule, the role of the load-bearing layer is played by porous expanded clay concrete, and dense concrete is used as the front layer, and you can choose colored or textured one that imitates natural material. Expanded polystyrene boards, mineral wool, polyurethane foam, and honeycomb are used as insulation in such blocks. Which material is suitable in each specific case is decided taking into account the customer’s requirements, the purpose of the object and the conditions in which the house will be used. The main thing is that it is moisture resistant and resistant to deformation. The layers are connected to each other by reinforcing bars.

Facade multilayer block

Multilayer structures produce warm walls with a thickness of 300-350 mm. If you use a homogeneous material, to achieve the same parameters for thermal and sound insulation you will need to create a wall with a thickness of at least 500 mm. Accordingly, structures made from single-layer materials weigh more, which means they require a solid foundation. Sandwich panels are durable, reliable, moisture-proof, resistant to fungi, mold and corrosion. In addition, the use of three-in-one materials significantly speeds up the installation process and reduces the cost of construction.

Multilayer materials are not only produced industrially; there are also panels that can be produced directly on the construction site in special forms. Installation of heat blocks does not require additional costs, a large amount of knowledge or high qualifications.

Laying a wall from multilayer building blocks

Composition and manufacturing technology of thermally efficient blocks

Wall blocks of a similar design are produced on semi-automatic lines using vibration casting followed by natural hardening. For their molding, one-piece metal molds are used, and the block is created sequentially, which is due to the complex multilayer structure of the material and the use of additional reinforcement.

- The geometric dimensions of the block are regulated by GOST 28984.

- Materials included in the block: Portland cement M400 according to GOST 10178, M500 - GOST 22266,

- quartz sand according to GOST 8736;

- chemical additives used in concrete mix according to GOST 24211;

- as insulation - polystyrene foam boards in accordance with GOST 15588.

Classification and subtypes of multilayer heat blocks blocks

Thermally efficient blocks are classified according to several parameters:

- according to the color and texture of the top decorative and protective coating. They can be anything depending on customer requirements

- according to the thickness of the thermal insulation layer. The thickness of the layer is selected depending on the expected climatic zone in which the specific material will be used, and on the heat loss characteristics of the building;

- according to the number of layers used to create a block - three- and four-layer. In a four-layer version of the block design, the heat-insulating layer is located inside a supporting structure made of lightweight concrete;

According to the size and shape of the blocks used for various types of construction work:

- regular block;

- block with a hole for ventilation;

- corner block;

- block with a quarter for organizing door and window openings;

- waist and additional blocks.

The maximum deviation from the specified dimensions of the heat-efficient block is 2 mm, which makes it possible, when constructing walls, to lay the material on a special glue and carry out interior finishing work without plastering the resulting surface.

The classic way - single-layer materials

Multilayer materials have not yet been clearly accepted by consumers. Although, in fact, any building is erected using multilayer technology - no matter what material is chosen, the structure will still consist of a load-bearing layer, insulation and finishing. Buildings are insulated from the inside or outside, and the first method is chosen extremely rarely, when there is no other way to do it. When insulating internally, the surface is primed, and then sheets of heat-protective material (as a rule, these are extruded polystyrene foam boards) are secured with glue. The resulting base is primed and puttied, and then the finishing material is applied.

This option is cheap and simple, but you need to understand that the area of the room will be reduced due to the thickness of the insulation used. The wall will not retain heat. In addition, a room insulated in this way will always be too humid, as a result of which the formation of mold and fungi is possible. Therefore, proper insulation is external.

Types of external insulation

There are several types of external insulation. The most common of them is the creation of a plaster facade (the so-called wet type of insulation) . Due to wet processes, this method is only applicable in warm weather. With such insulation, a multilayer structure is created on the outside of the wall. Thermal insulation is attached to the load-bearing partition on top of the facade glue using dowels. Then reinforcement is made with fiberglass mesh, after which finishing material is applied in one or several layers. The role of finishing can be performed by plaster, primer or facade paint.

Plaster facade - wet type of insulation

This technique is inexpensive and reliable. Walls insulated in this way are protected from condensation and their sound insulation is improved. In addition, the absence of seams on the outer part of the wall guarantees the absence of cold bridges. And external insulation does not affect the area of the room. However, when applying this method, it must be taken into account that not any material is suitable for insulation: the insulation must have ideal geometry, be equally dense throughout its entire thickness and tear-resistant. Most often, slabs of high-density mineral wool or extruded polystyrene foam are used for plaster facades. The disadvantage of the wet insulation method is that the finishing material can be destroyed at sub-zero temperatures and during shrinkage of the structure. In addition, there may be high humidity in the house.

Plaster facade - wet type of insulation

Wall blocks with insulation and brick cladding

Wall blocks, like insulation for walls inside a house, are a building material that can not only facilitate the construction of a private house, in comparison with the construction of brick walls, but also reduce the time and financial resources required to implement the project.

Wall block with insulation and siding

This article will consider wall blocks with insulation and cladding. You will find out what these products are made of and what structure they have, what their advantages and disadvantages are, and what the estimated cost of facade blocks with insulation from different materials is.

1 Advantages and disadvantages of wall blocks

Walls are one of the main structural elements of any home. It is the walls that, for the most part, determine how strong and reliable the building will be, and what thermal insulation characteristics will be inherent in it.

Almost any house built from classic building materials - brick or concrete, including the recently popular materials of foamed concrete, must be insulated, since only high-quality thermal insulation can provide housing that is comfortable for year-round living.

Foam insulation for wall insulation is necessary due to the fact that common building materials have relatively high thermal conductivity - for brick it is 0.46 W/mk, for concrete - 0.7 W/mk.

This indicator determines whether the walls of the house will effectively retain internal heat in the cold season and coolness in the summer. The lower this indicator, the better.

The technology for building a truly comfortable home involves thermal insulation of housing even at the stage of its construction, which entails additional financial costs for the insulation itself, vapor barrier and waterproofing, and facing materials for the facade.

Wall blocks with insulation and cladding are a relatively new building material that allows you to take all of the above tasks off your shoulders.

Wall blocks with insulation from the inside of wooden walls are multilayer products, the structure of which consists of three layers connected by fiberglass reinforcement: a load-bearing part - a material that guarantees the strength and reliability of the wall of the house, insulation - responsible for the thermal insulation characteristics of the walls (foam plastic, or penoplex), and facing part - making the facade of the house visually attractive.

Structure of an insulated wall block

A comparison of insulated wall blocks with currently common building materials demonstrates that such structures have the following advantages:

- Cost - the financial costs of constructing walls from insulated blocks are significantly lower than building a house made of bricks, and subsequent thermal insulation;

- Dimensions – wall blocks are an order of magnitude larger than bricks, which significantly speeds up the pace of wall laying. For example, laying brick walls of a medium-sized house usually takes about two weeks; if wall blocks are used, the construction time for walls is reduced by at least 2 times;

- Thermal insulation for insulating the walls of an apartment from the inside - the presence of an internal layer of insulation - a material with a thermal conductivity ranging from 0.29 to 0.035 W / mk, ensures that the walls of the house will not freeze even in the coldest season, as a result of which an optimal microclimate will be maintained in the house ;

- Sound insulation – high-quality insulation materials used in the production of wall blocks, in addition to thermal insulation properties, have the ability to reduce noise, which guarantees the acoustic comfort of housing;

- Aesthetics - the cladding of wall blocks with insulation is made from a variety of materials - you can choose blocks with a facade made of brick, wood, marble, or any type that suits you.

2 Structure and characteristics of the wall block

As already mentioned, insulated wall blocks consist of three layers: the first is load-bearing material, the second is insulation (foam), and the third is facing panels.

The standard size of a wall block with insulation is, as a rule, 400 mm in length and 200 mm in height. The width of the block can vary from 250 to 400 millimeters, in most cases it is 350 mm. The width of the material depends on the thickness of the insulation layer.

Wall blocks with insulation are significantly lighter than monolithic building materials, as a result of which their installation is much simpler.

Connection diagram of layers of insulated wall block

Installation of insulated wall blocks is similar to brickwork and insulation for protecting the walls of a house; it can be done either using cement mortar or using a special adhesive composition. The latter option is more preferable.

When laying blocks on cement mortar, in order to achieve the required strength characteristics of the wall, it is necessary to use at least a centimeter layer of mortar. When laying blocks with glue, similar structural strength is achieved with a 2-3 mm layer of glue.

A thick layer of mortar, firstly, is uneconomical, as the consumption of cement and sand increases greatly, and secondly, such a compound will significantly worsen the thermal insulation properties of the walls, since cement mortar has high thermal conductivity.

Cement joints will form cold bridges - elements in the wall structure that have greater thermal conductivity than the base material, through which the wall will freeze in the cold season.

This is not typical for adhesive mixtures used for laying wall blocks, since they contain special polymer impurities.

2.1 Load-bearing part of the wall block

There are a lot of materials used to make the load-bearing part of a wall block. It could be:

Expanded clay concrete blocks

All of the materials listed above are characterized by low weight and low thermal conductivity compared to conventional reinforced concrete. However, such diversity can only be found in foreign countries, where insulated wall blocks have been used for building houses for decades.

The main materials of the load-bearing part of the blocks presented on the domestic market, as a rule, are expanded clay concrete and clay brick. Expanded clay concrete is made from a mixture of cement, sand and expanded clay - thermally treated clay.

The advantages of expanded clay concrete include its low thermal conductivity, compared to ordinary concrete, which is 0.5 W/μ. And brick is also inferior in this regard.

The material is also characterized by high mechanical strength, which is an order of magnitude higher than the similar characteristics of gas silicate products - foam concrete and aerated concrete.

Compared to other porous concretes, expanded clay concrete has better noise-reducing properties, which, together with the soundproofing characteristics of the insulation layer, ensures almost complete insulation of housing from all external sounds.

The disadvantage of insulated expanded clay concrete blocks is the fear of serious point loads. Because of this, when building houses from this material, additional arrangement of a reinforcing belt under the roof rafter system is required. Sometimes Rockwool Cavity Butts are used.

2.2 Insulating layer

The middle layer of the block, located between the load-bearing material and the decorative cladding, is a layer of insulation.

As a rule, high-density foam is used as insulation. This material has good thermal insulation characteristics and a relatively low cost, resulting in a reduction in the final price of the wall block.

Foam insulated wall block

In blocks from foreign manufacturers, the insulation, in addition to polystyrene foam, can be represented by dense mineral wool or polyurethane foam. Polystyrene foam, used as a thermal insulation material, has a density ranging from 30 to 70 kg/m³.

The higher the density of polystyrene foam or sprayed polyurethane thermal insulation Polynor, the worse its thermal insulation properties and the better its strength, and vice versa, the less dense the foam is used, the worse its strength characteristics and the better its thermal insulation.

Layered (well) masonry

layered masonry is quite popular in low-rise construction . You may have heard other names for this technology: “well masonry”, “three-layer system”. The last name speaks for itself - the masonry really consists of three layers: load-bearing wall, thermal insulation and outer cladding. The thickness of the front layer is only one brick: this part does not bear a large load, it protects the insulation and performs mainly decorative functions. The insulation must be resistant to deformation and climatic influences (in particular, the influence of moisture). As a rule, extruded polystyrene foam or high-density mineral wool slabs act as such a layer.

Layered (well) masonry

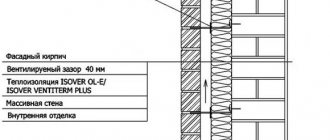

Ventilated facade

Another method of external insulation, although practically not used in cottages, is the installation of a system of ventilated curtain walls . This technology is called dry. It involves a ventilated air layer between the insulation and the cladding. Insulation (mineral wool slabs) is attached to load-bearing walls using dowels or anchors. A small gap is left between the insulation and the cladding due to the supporting profiles (15-60 mm) and a decorative layer of metal, plastic, or cement-sand coating is installed.

Construction of a system of ventilated curtain facades

Due to the air gap, moisture is removed and does not accumulate in the insulation. This eliminates the problem of cold bridges. Ventilated facades can be installed at any time of the year, since the technology does not involve wet processes.

Ventilated curtain facade system

The main thing is that the materials used for insulation are not only durable, but also resistant to wind loads, otherwise the insulation will change geometry and collapse. If you manage to choose the right insulation system for your home, in the future you will save on heating the premises, and also protect your home from dampness and drafts.

Why are foam blocks in great demand in the construction industry?

Foam concrete is successfully used in many areas of construction. It is used for the construction of not only cottage and country houses, but also garages, warehouse complexes, as well as various industrial and commercial structures (workshops, workshops, etc.). The popularity of this material is due to the fact that the façade cellular block has numerous advantages:

- Ease. Foam block weighs much less than brick, monolithic slabs, natural stone and other materials that are often used for the construction of low-rise residential buildings. Therefore, it is much easier to work with, easier to transport by truck and deliver directly to the construction site.

- Porous structure. Facade cellular foam block has a porous internal structure. Thanks to this, the walls of the building “breathe”, thereby ensuring comfortable indoor air humidity.

- Effective thermal insulation. In terms of thermal insulation properties, the façade foam block is noticeably superior to brick, stone and other building materials. Buildings built from such material maintain a warm and cozy environment in winter. Owners do not have to install powerful heating systems and spend a lot of money on heating the premises. In summer, the foam block creates a cool microclimate in the house, which, in turn, eliminates the need to install expensive air conditioners.

- Durability. Since foam concrete is not subject to rotting and does not deteriorate due to changes in humidity or temperature, buildings made from such material remain in perfect condition for many decades. During its entire service life, the building will not require major repairs. It is enough only from time to time (as necessary) to carry out minor cosmetic repairs if any defects arise on the facade.

The exterior decoration of a house made of foam blocks performs not only a decorative function. Its important tasks include:

Heat block - characteristics, features, scope of application

The thermally efficient block, abbreviated heatblock, consists of three layers:

- Structural (load-bearing) - porous block of expanded clay concrete, density 1300-1500 kg/mᶟ.

- Thermal insulation - expanded polystyrene (EPS) or extruded polystyrene foam (EPS), 150-200 mm thick.

- Facing (decorative) - a thin block of expanded clay concrete or concrete (on average 50 mm), characterized by increased density, strength and frost resistance; the surface imitates figured or smooth brick, natural stone.

Heat blocks are produced using two methods – vibrocasting or vibrocompression:

- Vibration casting - an insulation insert is installed in the matrix, the liquid solution is poured into the mold and processed on a vibrating table until the block is completely compacted.

- Vibrocompression - the solution is poured semi-dry into the form of a vibropress with an installed liner, the block is simultaneously exposed to vibration and pressure.

After molding, blocks produced by vibrocompression are placed in a heat chamber for finishing, and the vibrocasts dry naturally.

The layers are connected to each other not only due to adhesion - manufacturers use special bonds, this can be metal-plastic, fiberglass or basalt rods. Heat blocks are also produced with additional voids in the structural layer; during the laying process, reinforcement is installed in them and mortar is poured.

The facing layer can be either the original gray color or multi-colored; almost any shade can be ordered at the factory.

The main advantages of the blocks include minimal thermal conductivity, due to which a wall 30-40 cm thick does not need additional insulation, and the presence of a finishing layer. The facade is immediately decorative and does not require cladding, plaster or various hanging screens. In addition, the load-bearing part of the block made of lightweight concrete significantly reduces the weight of the structure, making it possible to get by with a strip foundation. As for the speed of construction, which is also an advantage of the material, it is also inherent in other block categories and largely depends on the skill of the performers. The same can be said about the minimum consumption of the solution - a thin seam is typical for wood concrete, gas silicate or warm ceramics, but whether it can be done this way depends on the craftsman and the geometry of the blocks.

There are also some shortcomings, the main one of which is the harmfulness of polystyrene foam, the battles on the topic of which do not subside. Perhaps PPS is not the most environmentally friendly of insulation, but still it is covered with a load-bearing layer and interior decoration, and the thermos effect inherent in such houses is neutralized by a good ventilation system. Users have much more complaints about unscrupulous manufacturers, whose products boast “walking” geometry, reduced strength and other “amenities” associated with violation of technology.

The main area of application for heat blocks is low-rise private construction, which includes not only houses, but also various outbuildings. Blocks intended for additional reinforcement can be used for laying higher buildings, but, of course, we are not talking about “candles”.

Durability, operation

The frost resistance of the textured layer exceeds F150. The face has low water and moisture absorption, which reliably protects the walls of the building from the influence of the external environment. A reliable and strong connection between the front and load-bearing parts of the block and the high quality of the front surface guarantee a long service life of the building walls without cosmetic or major repairs. The walls of the house do not fade or fade thanks to the use of high-quality iron oxide pigments and complete painting of the front layer.

How I built a house from thermal blocks

One of the craftsmen of our portal with the nickname Skazochnik14 posted a detailed description of the construction of a house from a heating block and his feelings from its operation in the topic of the same name.

At first I didn’t know what to build a house from, but by chance I saw a house made of thermal blocks and I liked the material. I went to that construction site, asked around, and decided to build a house from a heating block. Firstly, the house should turn out to be very warm, secondly, there should be savings on finishing work on the outside, the heating block is already lined beautifully, and thirdly, there should be savings on the work of insulating the facade and painting.

At the production site, calculations were made based on the project, the craftsman ordered wall, corner blocks and quarters, chose colors, and for the base - concrete tiles with a texture like the blocks, fastened with dowels. The promised deadline was a month, but in reality they didn’t even meet it in two; instead of October, the blocks were ready only in May. On the plus side - no problems with storage, one hundred thousand penalties and free delivery. The downside is that different batches differed in the shade of the cladding, the gamma is the same, but the saturation is different, we had to solve this problem during the laying process. To save additional money, we purchased all the lumber (150×150 boards and inch boards) in winter.

The foundation is an insulated tape 1 meter deep with compacted sand bedding and crushed stone cushion, insulation with PSB slabs. In the outgoing construction season, the base was laid out from expanded clay concrete and left to winter.

The box -walls began to be erected in May, since the foundation was not initially tied to the wall material; the thickness of the seam on different walls ranged from 5 to 10 mm. This led to difficulties with the masonry mixture - the purchased adhesive for foam concrete was not designed for such fluctuations, so they began to mix it with cement, and the seams were also foamed with polyurethane foam. The addition of cement showed itself as efflorescence on the masonry.

Blocks with cladding and insulation as the best materials for thermal insulation of your home

Whatever type of thermal insulation you choose, the insulation process will invariably include such elements as a directly mounted wall, a layer of insulation and external finishing.

However, not so long ago there was a small revolution in the building materials market: special blocks with built-in insulation and cladding appeared. Thus, it is now possible to work not with several layers, but with only one, which greatly simplifies the process and reduces time costs.

What are thermal insulation blocks?

Innovative blocks with cladding and insulation as a base include a dense layer of expanded clay concrete. The insulation in them is, as a rule, polystyrene foam, although different manufacturers may vary this composition. For example, polyurethane foam, mineral wool and honeycomb are suitable.

Specific preferences depend on the wishes of the customer and the type of residential property. The elements of the insulation structure are tied together with fiberglass or metal.

The outer decorative layer is textured concrete that prevents negative environmental influences. It is thinner than the main layer - only 1.5 - 3 centimeters.

Multilayer blocks have a wide palette of shades, so you can choose them to suit every taste. The front surface can be represented by natural stone, sandstone or wood - almost unlimited scope for stylish design.

Thermal block: foam block with a finished facade (with insulation)

If you already have foam concrete blocks consisting of a load-bearing and façade part, it would be logical to add a thermal insulation layer. The output is a heat block. And in our example, where the load-bearing part is made of foam concrete, a foam block with cladding and insulation. As a rule, it looks like this:

- front, facade part;

- insulation in the middle;

- internal load-bearing part.

But there can be more layers. For example, plus a hollow layer, where the air provides additional thermal insulation. All layers are fastened with fiberglass reinforcement or other variations of plastic. Metal is excluded so that “cold bridges” are not created. The resulting foam concrete block is a powerful competitor to any building material. Ready-made façade, reliable protection from the cold. However, there is one “but”. It is not enough just to produce high-quality foam blocks in compliance with the technology. Absolute adherence to masonry technology is mandatory! The slightest inaccuracy can lead to through gaps in the house! In fact, the wall is one row of building blocks. This nuance can offset all savings on separate insulation and exterior finishing, since skilled, expensive workers are needed. If you plan to do the laying yourself, do it carefully and carefully.

All materials provide reliable protection for foam block walls, and their appearance is varied. In the external design they use both colored tiles and imitating ceramic bricks or natural stone. Despite the aesthetics and cheapness, tiles should be used with caution (for partial cladding) - foam concrete removes moisture to the outside; this destroys the mixture that holds the cladding together.

Properties of blocks with cladding and insulation

Materials for thermal insulation of your home, such as multi-layer blocks, have important advantages over other materials. So, if you decided to use a more conventional version of external insulation, then for an excellent effect you would definitely have to make a wall at least 50 centimeters thick. Agree, this does not inspire optimism.

What other advantages are noted?

- Layered blocks have a huge margin of safety. They are very reliable because the layers in them are in close contact through reinforcing bars. Overall, the final design is guaranteed to be complete.

- Eco-friendliness is a nice addition to your home. Unlike separately located thermal insulators, in this case there is no tendency for moisture to enter, that is, treatment with waterproofing insulators is not necessary. Accordingly, the walls of the house are not at risk of biocontamination by mold and mildew. In addition, corrosion is also not a problem.

- Multilayer blocks combine the features of both stone and wood - they “breathe”, regulating the humidity in the building itself.

- In addition to other advantages, the very quality of thermal insulation, achieved by means such as blocks with cladding and insulation, is at its best. They are very resistant to temperature changes and frost-resistant. And at the same time, the walls, as you remember, will have a small density - only 30-35 centimeters, so you won’t have to sacrifice useful space.

- High fire resistance is an important component of the thermal insulation of a house. In the case of expanded clay concrete blocks, a potential fire will not only not destroy them, but on the contrary, will make them stronger.

- They are installed quickly and without problems, even at the construction stage. And it is not at all necessary for a mason to be highly qualified.

- Expanded clay concrete blocks are cheaper than many thermal insulation analogues.

Strengths and weaknesses of heat blocks

One of the main advantages of using heat blocks is its low cost compared to similar building materials. The use of thermally efficient blocks in the construction of a house or building will bring you significant economic benefits. If you evaluate this building material using a five-point system, it will be a solid 5.

Thermal block (as a building material) has the following strengths:

- The light weight of the materials will make it possible to transport without much difficulty, and also not to use lifting mechanisms in construction;

- The fact that the blocks are attached using glue will save on the purchase of sand and cement;

- The speed of laying will also increase due to the range of geometric shapes and sizes of blocks;

- No need for insulation and cladding of the building;

There are also some disadvantages that are inherent in heat blocks, namely:

- a wall made of a heat-efficient block is not intended for facing with brick and some other building materials;

- an incorrectly selected width of the internal insulation may be insufficient for certain geographical areas.

Block dimensions

Multilayer block materials for thermal insulation of your home have the following dimensions as standard:

- height - 20 centimeters;

- width - from 25 to 40 centimeters. 30-35 centimeters are more common;

- length - 40 centimeters.

As you can easily imagine, blocks with cladding and insulation are not large in size, which means they are convenient to work with. Such material does not carry a large load on the foundation of the house. The blocks are laid using a method similar to bricks.

For installation you will need reinforcement (it should be laid in three rows), a level and a wooden hammer. Cement-sand mortar is prepared in a ratio of 3:1. Upon completion of the installation, a reinforced concrete structure is fixed along the height of the working wall - a support for the rafters.

The amount of required material is calculated as follows: the total length of the wall, taking into account the partitions, is multiplied by the height of the prospective ceiling. Then this figure must be divided by the height and length of the multilayer block, if the technology for building walls includes masonry 2 blocks thick - the resulting number must be multiplied by 2.

To summarize, it is worth noting that such multilayer blocks can turn the process of thermal insulation of a house into a simple event that does not require back-breaking work from you.

Blocks with cladding

The essence of this material is that it combines almost all the components of the walls of a stone house necessary for complete, comfortable living. The use of expanded clay block (our block uses encapsulated expanded clay of fractions 10, 20) DSK "Innoblock" relieves builders from such labor-intensive and expensive operations as wall insulation and finishing!

Expanded clay wall blocks are a modern, environmentally friendly building material, which is characterized by high thermal efficiency, strength and resistance to sudden temperature changes. You can get acquainted with a wide range of products, as well as buy wall blocks through the services of our company, whose specialists are ready to provide support in the choice and organize timely delivery.

Payment by cash and bank transfer

, being a leading Russian manufacturer of facing tiles and decorative stone, cooperates with both private clients and large companies. At the same time, we strive to make cooperation with us as comfortable as possible for everyone, so you can pay for products purchased from us in any way convenient for you - we accept both cash and non-cash payments. You can receive detailed payment instructions from the manager when placing your order.

The use of blocks with insulation and cladding for the arrangement of facades

Most owners of private houses have learned from their own experience that an uninsulated house is a source of constant cold, dampness and mold. Therefore, the issue of wall insulation should be considered at the stage of designing your own home.

Already existing buildings are insulated with various types of insulators. When constructing new buildings, it is worth considering the capabilities of modern building materials, for example, ready-made building blocks that already have a layer of insulation and suitable cladding.

However, the modern market has provided buyers with a unique building material, the block of which contains all three necessary layers - frame, insulation, siding. They are called “three-in-one”, heat block or multiblock. The structure of this material is worth a closer look.

The basis

The thickest part of the heat block is the load-bearing part. It is usually based on expanded clay concrete, polystyrene concrete and other types of lightweight concrete.

The main filler in lightweight concrete is porous materials with small cells and voids. This feature of the filler allows the production of a load-bearing part with different density and volumetric mass options.

This is an advantageous building material with reduced material consumption and significantly reduces the cost of the finished block.

In addition, the low density ensures low weight of the finished blocks. These factors greatly facilitate the process of transportation, laying walls and increase the speed of construction of the finished building.

Walls built from such lightweight blocks are comfortable, safe from an environmental point of view and provide a high level of sound insulation.

Thermal insulation

The second layer on the block is responsible for thermal insulation. Expanded polystyrene is used as the main material, but not all manufacturers use this design. There are known heat blocks insulated with polyurethane foam, mineral wool, honeycomb and other modern materials. Depending on the source material, the second layer of the block can have a thickness from several millimeters to several centimeters.

Various materials have characteristics that are suitable for use on some objects, and not acceptable for the construction of others. Therefore, responsibility for the choice of source material lies with the owner of the building or the designer.

Decorative layer

The final outer layer on the front surface is decorative. The variety of design options for the outside of a multilayer block allows you to decorate walls in various styles, creating your own unique compositions that are in harmony with the overall architectural design. The thickness of this layer usually does not exceed 3 cm.

In addition to a purely aesthetic function, external finishing allows you to protect the inner layer from mechanical damage, thereby significantly increasing the service life of the entire building. The front side can be multi-colored or textured, and also imitate noble natural materials - such as granite, marble and others.

Fastening

All three layers are fastened together with polymer rods. The tip of such a rod is directed into the facing layer, the opposite end has a hook and is attached to the base layer. The rods contain disc or cross-shaped protrusions that allow you to securely fasten all layers of the block and avoid the formation of shifts and gaps during operation.

Advantages

Thanks to its “multi-layering”, any multiblock has a number of advantages over any traditional building materials. Firstly, strength. All layers of the multiblock are bonded together not only with binding solutions, but also with strong reinforcing bars. This ensures high strength and durability of the multilayer structure.

Secondly, ease. It was already noted above that due to the special composition of the load-bearing part, the multilayer block has much less weight compared to traditional materials. Accordingly, their dimensions will be small. A modern building, built from multilayer blocks, has a thickness of external walls of about 3-3.5 cm. Therefore, there is no need to dig a deep and reinforced foundation for such a structure.

Thirdly, thermal insulation. Modern heat-retaining materials allow the structure to have high insulation characteristics. For comparison, the thickness of conventional insulation laid on the finished walls of a house will be at least 2-4 cm. The thickness of the entire wall, made of multilayer building blocks, will be only about 3.5 cm. And in such a room it will be as warm and comfortable as and in standard insulated buildings.

Moisture insulation and resistance

Modern thermal insulation materials are sensitive to the ingress of steam and moisture. Constant contact with a damp environment gradually destroys the insulating layer and reduces its characteristics. In multiblocks, the layer is reliably protected by cladding. The outer layer is designed in such a way that the thermal insulation retains its properties for many years.

They are also characterized by resistance to corrosion, fungi and mold. The “three in one” design consists of chemically inert substances that weakly interact with the aggressive environment.

In addition, the special properties of the starting materials that make up the building block make the environment inside it unsuitable for the proliferation of microorganisms.

Climate and convenience

Buildings constructed using multilayer blocks will last for many years even in the most difficult climatic conditions. Concrete blocks retain their performance characteristics over a wide temperature range, and special technologies for creating the facing layer make it resistant to various mechanical damage.

Using three-layer building blocks, you can significantly speed up the process of building your own home, thereby saving time and money. In addition, a building built from multiblocks will ultimately cost much less than the same structure built from classical building materials with subsequent insulation.

Dimensions

Insulated building blocks are available in standard sizes: 40 cm length; 20 cm - height. Depending on the insulation used, its thickness varies. For calculations, you can take the average thickness value - 30-35 cm.

Such dimensions and low weight make the blocks very convenient for building walls. This building material is laid in exactly the same way as standard brickwork.

Therefore, even builders with little experience can do an excellent job of erecting walls without any special instructions.

After the walls of the building are erected, no additional insulation or waterproofing work is required. The load-bearing wall inside the room is finished with plasterboard panels or covered with a layer of plaster. Blocks based on lightweight concrete allow the construction of buildings up to three floors high without the use of a frame.

Thanks to the precise geometry of this building material, walls built from it will have strict proportions. Since the seams between the blocks will be about 5 mm, and there will be no cold bridges in the walls. Insulated heat blocks can be drilled and sawed, but such a multi-block will be too tough for rodents.

Reinforcement

Reinforcement of blocks can be done using reinforcing mesh, filling it with masonry glue. Every third or fourth row of masonry can be reinforced.

Internal partitions are connected to load-bearing walls using grooves, which can be made with a chisel, wall cutter or hammer drill. Sometimes fiberglass or steel embedded elements are used.

Collections

- BS VRF1221 wall block Forte up to RUB 395.30 1 piece Buy

- BS VRF1201 wall block Forte up to RUB 395.30 1 piece Buy

- BS VRT1221 Travertin wall block up to 400.61 rub. 1 piece Buy

- BS VRF961 wall block Forte up to RUB 395.30 1 piece Buy

- BS VRT1201 Travertin wall block up to 400.61 rub. 1 piece Buy

- BS VRT961 Travertin wall block up to 400.61 rub. 1 piece Buy

- BS VRF801 wall block Forte up to RUB 395.30 1 piece Buy

- BS VRT801 Travertin wall block up to RUB 400.61 1 piece Buy

- BS VRF191 wall block Forte up to RUB 395.30 1 piece Buy

- BS VRF181 wall block Forte up to RUB 395.30 1 piece Buy

- BS VRT191 Travertin wall block up to 400.61 rub. 1 piece Buy

- BS VRT181 Travertin wall block up to 400.61 rub. 1 piece Buy

- PG 00 tongue and groove without facing up to RUB 199.56 1 piece Buy

- BS VRF122 wall block Forte up to RUB 262.77 1 piece Buy

- BS VRT122 Travertin wall block up to 286.74 rub. 1 piece Buy

- PG VRT122 tongue and groove Travertin up to RUB 286.74 1 piece Buy

- BS VRF120 wall block Forte up to RUB 262.77 1 piece Buy

- PG VRT120 tongue-and-groove Travertin up to RUB 286.74 1 piece Buy

- BS VRT120 Travertin wall block up to 286.74 rub. 1 piece Buy

- BS VRF96 wall block Forte up to RUB 262.77 1 piece Buy

- BS VRF80 wall block Forte up to 262.77 rub. 1 piece Buy

- PG VRT96 tongue-and-groove Travertin up to 286.74 rub. 1 piece Buy

- BS VRT96 Travertin wall block up to RUB 286.74 1 piece Buy

- BS VRT80 Travertin wall block up to 286.74 rub. 1 piece Buy

- PG VRT80 tongue-and-groove Travertin up to RUB 286.74 1 piece Buy

- BS VRT19 Travertin wall block up to RUB 286.74 1 piece Buy

- PG VRT18 tongue-and-groove Travertin up to RUB 286.74 1 piece Buy

- PG VRT19 tongue-and-groove Travertin up to RUB 286.74 1 piece Buy

- BS VRT18 Travertin wall block up to RUB 286.74 1 piece Buy

- BS VRF19 wall block Forte up to 262.77 rub. 1 piece Buy

- BS VRF18 wall block Forte up to RUB 262.77 1 piece Buy

- BS VRB181 Brega wall block up to RUB 395.30 1 piece Buy

- PG VRB96 tongue-and-groove Brega up to 262.77 rub. 1 piece Buy

- PG VRB18 tongue and groove Brega up to RUB 262.77 1 piece Buy

- PG VRB19 tongue and groove Brega up to RUB 262.77 1 piece Buy

- PG VRB122 tongue-and-groove Brega up to 267.77 rub. 1 piece Buy

- PG VRB80 tongue-and-groove Brega up to 262.77 rub. 1 piece Buy

- BS VRB1221 Brega wall block up to 395.30 rub. 1 piece Buy

- BS VRB801 Brega wall block up to 395.30 rub. 1 piece Buy

- BS 00 without cladding up to 199.56 rubles. 1 piece Buy

- BS VRB961 Brega wall block up to 395.30 rub. 1 piece Buy

- BS VRB1201 Brega wall block up to 395.30 rub. 1 piece Buy

- BS VRB191 Brega wall block up to RUB 395.30 1 piece Buy

- BS VRB80 Brega wall block up to 262.77 rub. 1 piece Buy

- BS VRB122 Brega wall block up to 262.77 rub. 1 piece Buy

- BS VRB96 Brega wall block up to 262.77 rub. 1 piece Buy

- BS VRB19 Brega wall block up to 262.77 rub. 1 piece Buy

- BS VRB18 Brega wall block up to 262.77 rub. 1 piece Buy

- Reinforced lintel block up to RUB 3,800. 1 piece Buy

- BS VRB120 Brega wall block up to 262.77 rub. 1 piece Buy

Several types of blocks are used for the construction of buildings.

The range of which includes the following blocks: – ordinary (size 390*190*400 and 1185*390*400) – corner (size 590*190*400 and 1185*390*400) – reinforced lintel block (size 2400*390 *400 and 2800*390*400)

In the future, we will create new types of blocks: – belt – additional – bay windows (internal, external)

Buy wall blocks for finishing houses

The speed of building houses from expanded clay block DSK Innoblock is several times higher than the speed of building houses from any materials. Construction teams have the opportunity, at lower costs, to build several times more modern houses in the same time, the demand for which is growing more and more every year.

The construction of houses of any number of floors must be profitable and of high quality. It is important to use good wall units because the cladding or insulation can be replaced and the walls will remain forever. These are the products that are produced under the DSK Innoblock brand. Wall blocks with decorative finishing, which are sold at the most affordable prices, allow you to save on a number of parameters:

- insulation design - the blocks have high heat-saving characteristics, so there is no need to use additional heat-insulating materials,

- finishing works - DSK Innoblock blocks are ready-made fragments, so the walls look attractive and do not need cladding,

- labor costs - wall blocks, the price of which pays off even at the construction stage, significantly speed up the process of constructing a building.

Houses built from DSK Innoblock blocks are economical not only at the construction stage, but also during maintenance. You can buy wall blocks with a decorative facade “Innoblock” from 247.80 rubles per piece. Affordable prices allow us to build truly high-quality buildings at minimal cost.

High-speed housing construction technology

- construction is carried out by specialized teams of highly qualified workers of 3-5 people;

- the continuous construction method is used using network diagrams;

- preliminary training of workers in technologies and methods of construction work is carried out;

- Effective building structures, materials, power tools, fixtures and engineering equipment must be used;

- To speed up construction time and conduct it with consistently high quality, the principle of material interest of workers and engineering staff is applied.

As a result, it became possible to build quickly and inexpensively, which is so necessary for our country at the present time.

The practice of erecting walls using high-speed housing construction technology from multilayer heat-efficient blocks has shown the following advantages of construction compared to traditional ones:

- High thermal characteristics of walls When operating houses built from these blocks, heating costs are 3-3.5 times less than in brick houses. Walls made of these blocks create the so-called “thermos” effect, i.e. they do not allow either cold or heat to pass through. Therefore, such a house is warm in winter and cool in summer.

- Reduced construction time Walls made from multilayer heat-efficient blocks with a decorative outer layer are laid in one row (chain system) by analogy with children's building blocks and using adhesive compositions (tile adhesive for exterior work). Therefore, the work does not require high qualifications. Put the block down and the wall is ready. The outside of the wall block has a decorative finish, and the inside of the wall is finished with plasterboard sheets or plastered. This type of masonry allows for faster construction of walls.

- Saving material costs

- Savings when constructing foundations Walls made from multilayer Plitstrom blocks are 2-3 times lighter than brick ones. Therefore, they create a significantly smaller load on the foundations, which leads to a reduction in the cost and labor intensity of this work. The savings are approximately 15-20%.

- Reduced transportation costs Transportation costs depend on the volume and weight of wall and ceiling structures. The thickness of walls made of thermally efficient blocks is almost 2 times less than that of brick, and the weight is three times. Thus, the volume of transportation, and, consequently, transportation costs are several times lower.

- Savings in the construction of 1 m2 of interfloor slabs The cost of 1 m2 of prefabricated monolithic slabs is 60% lower than that of hollow slabs, and the weight is halved.

- Getting additional usable space The usable space in your home increases without any additional costs. The technology used makes it possible to reduce the thickness of the wall compared to a brick one, while maintaining all the thermally efficient properties of the house itself.

The technology of high-speed housing construction, using the capabilities of KSD - a high-speed housing construction plant, allows you to quickly build houses at a low cost, which opens up real opportunities for the use of mortgage lending, attracting funds from extra-budgetary and pension funds, as well as savings of citizens and vouchers for military personnel discharged into the reserve.

Product certificates

Advantages of expanded clay concrete wall blocks

- Light weight - the walls do not heavily load the foundation, allowing you to choose more economical foundations.

- Ability to withstand any temperature changes.

- Acceleration of the construction process (DSK Innoblock blocks allow you to build a two-story house of 120 sq.m. in just a month).

- Resistance to the development of putrefactive processes, mechanical destruction and combustion.

- Affordable cost - the process of producing blocks is quite simple, so the material, despite having so many positive qualities, remains affordable.

Our specialists will help you buy wall blocks in the required quantity. You can submit an application for calculation directly on the website.

More than 20 years on the market

Number of projects implemented using our blocks