Forced circulation equipment

Wilo circulation pumps will help ensure high-quality movement of hot water through pipes and radiators. They do their job well in large houses with complex heating systems. A review of Vilo models and instructions from the manufacturer will help you make the right choice of a modern and compact device that will show effective operation.

All German-made units are distinguished by their reliability, ease of installation and the ability to reduce the diameter of the pipes, which allows reducing the cost of heating installation.

For complete heating of private houses, two series of Wilo pumps were specially developed, which differ slightly in technical characteristics.

How to properly install a Wilo pump in a heating system

The installation of a Wilo brand circulation pump in a heating system is carried out in accordance with strict adherence to the operating instructions provided by the manufacturer. During installation work, the following rules should be followed:

- Only vertical installation is allowed. Horizontal installation of a Wilo pump in a system is prohibited. The only exceptions are models specifically designed for horizontal connection. The installation position of the pump can be found in the operating instructions.

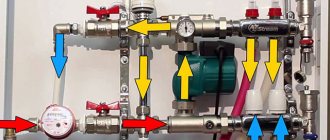

Connecting underfloor heating - the pump is installed in a special mixing unit. The correct location of the Vilo heating pump is indicated by arrows located on the housing and hydraulic wiring.

Connection to a radiator-type heating system - installed in the heating return, directly in front of the boiler. To prevent a complete stop of coolant circulation, install it in a bypass. The installation rules for Vilo pumps allow the use of equipment for heating systems with natural and forced circulation.

Installation and maintenance - the pump is installed in a vertical position, observing the direction of the coolant indicated by the arrows on the body and mixing unit. It is recommended that installation be carried out by qualified personnel. Pump installation methods depend on the selected model and are described in detail in the technical documentation. Provided the connection is correct, no special maintenance is required for the Wilo pump.

There are several recommendations to ensure long-term operation of the equipment:

- You can leave the pump constantly on. It is recommended to turn on the device for a few minutes after the end of the heating season.

A hum when the pump is running indicates several possible malfunctions. The air vent is clogged, resulting in air not being removed from the system. Another malfunction is the incorrectly selected operating mode. Reducing the operating speed usually leads to the cessation of the hum. If this does not happen, the pump will require servicing.

Which pump is better to choose - Wilo or DAB

Judging by reviews and statistical reports, individual heating systems with forced circulation of coolant, with Wilo and Grundfos pumps, are considered the most reliable. They are somewhat inferior to DAB products.

The Wilo pump can operate continuously for at least 7-9 years. The models offered by the manufacturer are designed for domestic and industrial heating systems. Models with two electric motors are optimal for simultaneous heating with underfloor heating and radiators.

The cost of products from the Danish concern DAB and the German concern Wilo is approximately the same, but in terms of technical parameters, Wilo modules are significantly ahead of their competitors.

source

Star-RS Series

This range of pumps has a low power and is suitable for use in houses whose area is in the range of 200 - 750 m².

Peculiarities

The main advantage of this series is the wet type rotor. It is continuously immersed in the pumped energy carrier, which prevents the graphite bearings from drying out. Another advantage of Star-RS is that a technical polymer is used to produce the rotor wheel.

This material is resistant to high temperatures typical of heating systems and is not afraid of sudden changes.

Housing and fasteners

The Vilo circulation pump is connected to the pipeline using a thread, the diameter of which may vary depending on the model. The unit has a cast iron body and a stainless steel shaft.

A comfortable working environment for such a device is water or a water-glycol composition. Star-RS pumps for forced heating systems are almost silent. They quickly pump coolant and consume little electricity.

Advantages

German equipment of this series has gained great popularity due to the following advantages:

- the body is coated with an anti-corrosion cataphoresis compound;

- speed is regulated using a three-stage mechanical switch;

- durable metal-graphite bearings do not wear out in aggressive temperatures;

- low cost.

Operating and installation conditions

Devices for heating systems of the Star-RS series can operate in a temperature range of +10 +110 °C at a pressure of up to 10 bar, and this makes it possible to use them in air conditioning.

When installing Vilo Star-RS, the manufacturer’s instructions must be strictly followed, which states that:

- insertion is possible after installation and cleaning of pipes from chips;

- the terminal box and motor must be reliably protected from moisture;

- The pump axis must be positioned strictly horizontally.

Connection methods

Connection to the electrical network using a plug and socket . This method involves installing an electrical outlet in close proximity to the place where the circulation pump is mounted. Sometimes they can be supplied with a connected cable and plug included, as in the photo:

In this case, you can simply plug the device into the mains using an outlet located within reach of the cable. You just need to make sure there is a third, grounding contact in the outlet.

If there is no cord with a plug, they need to be purchased or removed from an unused electrical appliance. You should pay attention to the cross-section of the cord conductors. It should be in the range from 1.5 mm 2 to 2.5 mm 2. The wires must be stranded copper, ensuring resistance to repeated bending. The cord with a plug for connecting electrical appliances to the network is shown in the photo below:

Before connecting the circulation pump, you need to find out which of the three wires of the cord is connected to the ground pin of the plug. This can be done using an ohmmeter, while at the same time checking the integrity of the remaining wires.

Open the terminal box cover. Inside the box there are three terminals designed to connect the device to the network, marked as in the picture:

We unscrew the clamp of the cable coupling (in the first photo it is a plastic nut into which the cable is inserted), put it on our cord, and insert the cord into the coupling. If there is a cable tie inside the box, thread the cord through it. We connect the ends of the cord wires, previously stripped of insulation, to the terminals.

The wires connected to the plugs of the plug should be connected to the L and N terminals (don’t be afraid to mix them up, this is not critical), the wire of the grounding contact of the plug should be connected to the PE terminal (but you can’t make a mistake here). The instructions supplied with the product prohibit its operation without protective grounding. Next, tighten the clamp (if any), tighten the cable sleeve clamp tightly, and close the terminal box cover. The pump is ready to be plugged into the mains.

Fixed connection. The connection diagram for the circulation pump to the electrical network with grounding is provided below:

The requirements for the wire cross-section here are the same as in the previous version. The cable for this installation can be used either flexible or inflexible, copper, VVG brand, or aluminum, AVVG. If the cable is inflexible, the installation should ensure that it does not move. To do this, the cable along the entire route is secured with clamps.

In this option, a residual current device (differential circuit breaker) is used. Instead, you can use a regular single-pole circuit breaker, passing only the phase wire through it. If the machine is installed in a panel where there is a PE bus, then the cable from the pump to the machine must be three-core. If there is no such bus, the PE terminal should be connected to a grounding device. This connection can be made with a separate wire.

Separately, I would like to consider such an installation option as connecting the pump to the UPS. It is the most preferable and ensures the independence of the heating system from power outages. The connection diagram of the circulation pump to the uninterruptible power supply is provided below:

The power of the UPS should be selected based on the power of the pump motor. The capacity of the battery is determined by the estimated time of autonomous power supply of the circulation pump, that is, the time when the power supply is turned off. We talked about how to choose a UPS for a boiler in a separate article. Requirements for cable cross-section, as well as the presence of protective grounding, apply to all connection options.

Finally, we recommend watching video instructions for connecting various pump models to the electrical network:

So we looked at how to properly connect the circulation pump to the electrical network. The diagram and video examples helped to consolidate the material and clearly see the nuances of installation!

It will be useful to read:

TOP-S series

Models in this series are designed for use in buildings with an area of up to 1400 m². Such pumps with single or three-phase connections guarantee accelerated pumping of hot water through pipes and radiators.

They are made using materials similar to the previous line from the German company Wilo.

Operating and installation conditions

The equipment operates at a temperature of +20 + 130 °C, and for two hours the units can operate uninterruptedly at an increase in maximum temperature of 10 °C. The permissible pressure is 6, 10 or 16 bar (special version). As in the previous case, the speed is regulated by a three-stage switch.

The Vilo TOP-S series is available with increased engine protection and a thermal insulating casing. The versatility of Wilo equipment is due to the double-sided cable connection and the configuration with a 6/10 bar combined flange (for models with an internal diameter of 40 - 65 mm).

Product advantages

Circulation pumps from the German company Wilo successfully compete with similar devices due to the fact that they are made from anti-corrosion materials and can work with various coolants.

They are durable and easy to use, and also consume electricity economically. Another important factor that affects demand is the compact dimensions of the units with their multi-stage protection.

Installation rules

The design of a household circulation pump from any manufacturer provides for its fastening to pipelines or shut-off valves using union nuts (American). This allows it to be quickly dismantled if necessary, for example, for replacement or repair. When installing the pump unit, follow these recommendations:

- Place the device on any sections of pipelines - horizontal, vertical or inclined, but with one condition: the rotor axis must be in a horizontal position. That is, installation “head down” or up is unacceptable.

- Please note that the plastic box with electrical contacts is located on top of the case, otherwise it will be flooded with water in the event of an accident. Yes, and servicing the product will not be easy. This is easy to achieve: unscrew the screws securing the casing and turn it to the desired angle.

- Remember to follow the flow direction indicated by the arrow on the housing.

- So that the product can be removed without emptying the system, install shut-off valves before and after it, as shown in the diagrams in the previous section.

Electrical repair

The electrical part of the pump includes the following components:

- inductor;

- starting capacitor;

- connecting wires;

- control terminal.

If the stator winding breaks down, the pump becomes unrepairable; all other components can be repaired or replaced. To analyze the condition of electrical parts, you will need an ohmmeter.

Photo of the circulation pump Wilo MTSL 15/5 HE – 2.

Main symptoms of malfunction

If the boiler display shows an error code corresponding to a water circulation problem, and it is not reset, the problem may be hidden in the electronic part of the device.

Circulation pump with cover removed.

To identify the problem you must:

- Turn off the heating mode in the boiler, and after stopping all components, turn off the power (soft stop).

- Open the front panel of the case.

- If the pump is covered with a large layer of dust, clean its surface.

- Using the information in the diagram, remove the control terminals and remove the terminal with the capacitor.

- Visually examine the condition of the pump contacts and terminals; they should be free of oxides, burnouts and mechanical damage.

- Using a tester in diode testing mode, determine the integrity of the connecting wires that go from the control board to the pump.

- Use an ohmmeter to determine the resistance of the inductors. On a working device, the instrument readings on the contacts will correspond to the following values:

- No. 1, 4 – 150 – 160 Ohm;

- No. 1, 6 – 290 – 300 Ohm;

- No. 2, 3 - 0 (contacts connected together);

- No. 3, 5 – 220 -230 Ohm;

- No. 4, 6 – 150 – 160 Ohm.

- The device will be considered faulty if the ohmmeter reading on any of the above pair of marks is 1 (winding wire break) or 0 (short circuit, except for contacts 2,3).

- Check the condition of the starting capacitor. To do this, switch the tester regulator to the 20 microfarad capacity test mode. Connect the probes of the device to the terminals of the capacitor and determine its capacitance. It should match the nominal ± 10%. Loss of capacity leads to a decrease in pump performance; it will emit an uncharacteristic hum.

Common situations

During operation of the pumping station, various malfunctions may occur in its operation, the cause of the disturbances is incorrect switching on/off of the electric motor.

The need to replace the relay

Replacement is performed in the following order.

- Turn off the power and completely drain the water from the accumulator. Leave the taps in the open position.

After this, close all water taps or the main outlet valve, turn on the pump and fine-tune the water pressure according to the algorithm described above. Never rush. The work is simple, but the consequences of mistakes can be very sad.

The pump constantly turns on/off

This means that the water pressure rises sharply to maximum values, and the engine turns off. The pressure drops just as sharply to the minimum and the unit turns on again.

In this case, there is no need to touch the pressure switch, it is not to blame. The reason is in the hydraulic accumulator - the rubber membrane located inside the cylinder is torn or greatly stretched. It does not expand, does not accept water and does not compensate for increased pressure.

As you know from school physics lessons, water does not compress. When the pump is turned on, the pressure instantly rises, and when turned off it also immediately drops. You will have to disassemble the accumulator and change the membrane.

For normal operation of the pump, it is recommended to set the air pressure in the metal cylinder approximately 10% lower than the switching parameter of the electric motor. The pressure is checked only after the water has completely drained from the accumulator. If it is, then the values rise and distort the adjustment indicators.

The pump does not turn off for a long time

At first everything was fine, and then this problem appeared. The reason is the wear of the pump; it can no longer create the required pressure. The adjustment is simple - slightly reduce the maximum value until the pump turns off. To have a safety margin, it is recommended to further reduce the pressure by a few tenths of an atmosphere. If, as a result of adjustment, the indicators drop to critical levels, then the water pump will have to be replaced.

There is no water in the system and the pump does not turn on

There are three reasons: the wiring is faulty, the connection terminals have become acidic, or the electric motor has burned out. To check, you need to have a tester and ring the electrical equipment; work should be done strictly according to the rules of the Electrical Regulations.

Video - Adjusting the pressure of the pumping station, pressure switch

After installing and connecting the pumping station, living in a private house becomes much more comfortable. But the quality of water in the area does not always meet accepted standards, which is why household appliances quickly fail. You can read about how to prepare water from wells and wells for household needs on our website.

source

| This spring sets the pump shutdown parameters. When it is compressed, the maximum pressure increases. Adjustable with a nut. When the nut is released, the pressure drops. The spring is mounted on a movable plate that has on/off terminals. The movable plate is connected by a metal pipe to the hydraulic accumulator. The water pressure lifts it, the contacts open. |

| With its help, water is supplied from the accumulator to the relay. At the same time fixes the device at the pumping station. |

| The phase and zero of the motor are connected to the lower ones, and the mains power is connected to the upper ones. It is not necessary to follow this order. |

| Connects the metal housing of the pumping station to the grounding of the house or apartment. Do not confuse the neutral wire and grounding, these are different concepts. |

Design features

Products from German manufacturers can work for a very long time without maintenance. And all because durable and reliable materials are used in its production. For example, the body of the product is made of durable gray cast iron. Inside it is a stainless steel shaft. It is secured using bearings made of graphite. The fluid supply speed has three-stage adjustment. In this case, the maximum possible coolant temperature parameters can reach +110 degrees Celsius. In industrial models, this ceiling may increase.

Note! The described pump is also designed for very high operating pressure. Standard products used in everyday life can withstand a pressure of 10 bar

Industrial designs in special designs can withstand pressures of 16 bar.

Operating principle of the Wilo MTSL 155 HE 2 circulation pump

The main part of the pump is an electric motor, consisting of a stator with several inductance coils to regulate the rotation speed, and a rotor, which is integrated on a shaft with bearings.

When power is applied to one of the stator windings, an electric field is created that drives the rotor with the turbine. The turbine blades capture fluid from the suction pipe and move it along the outlet pipe. In this way, the coolant circulates throughout the entire heating circuit.

Let's look at the main reasons leading to failure of the Wilo MTSL 15/5 HE - 2 pump.

Unstable voltage in the network

With reduced power, the pump motor slows down until it stops completely. With increased voltage, the inductor coils heat up, which can cause an interturn short circuit or burnout of the winding wire.

Contamination of pump mechanisms

When the liquid temperature is more than 60 ᵒC, scale may form on the turbine and shaft, which will slow down the rotation of the motor armature. Causes of pump jamming can also be increased oxidation of the driving mechanisms or the ingress of foreign objects.

Poor quality component material

If the pump uses parts made from low-quality materials, its service life is sharply reduced. For example, a shaft begins to jam due to the formation of a layer of rust on the surface of the bearings, because they are made of bronze, which contains iron. Such symptoms are typical for a non-original model.

Improper use of the device

Water through a working pump must constantly circulate at a certain speed. If the flow of the coolant is disrupted (the return or supply valve is closed, the system filter is clogged, etc.), the bearings and inductors in the device will overheat - this will lead to jamming of the rotor, breakage or short circuit of the stator winding.

The Wilo MTSL 15/5 HE - 2 circulation pump cannot be used when there is no water in the pipeline. But since Ariston double-circuit automatic units are equipped with liquid pressure sensors, the boiler will not turn on if there is no water in the system or its pressure is low.

Correct installation of the wilo pump

and PDF instructions (installation and operation)

Installation and operating instructions

To open the required pump instructions, click on the section you are interested in.

Pumps and installations for domestic water supply

Pumps and installations for water supply, pressure boosting and fire fighting

Water disposal - Pumping units

Water supply - Borehole pumps

Wastewater and polluted water/drainage

Installation and operating instructions can also be found in the free Wilo-Assistant smartphone app.

Wilo service contacts:

T M(029)144-74-41

If our specialist has not responded within 24 hours of your request, please contact the head of the Wilo customer service control service: M 8-029 612-27-52

source

How to properly install a circulation pump for heating in a private home

To make heated water flow more cheerfully through the pipes, a circulation pump is installed in the heating systems of private houses. This solution provides tangible benefits.

But the main question that concerns homeowners and is covered in this material is where it is better to install the pump and how to install it correctly. After all, the main part of the controversy and doubt is caused by the place where the unit is inserted.

And at the same time, we’ll figure out how to connect it to the house electrical network with our own hands.

What are the benefits of pump heating systems?

30 years ago, so-called steam heating was common in private homes, where the coolant circulated through pipes and radiators by gravity, and the heat source was a gas boiler or wood stove.

Pumps for pumping water were used in district heating networks.

When compact circulation pumps for heating appeared, they migrated to private housing construction, as they provided the following advantages:

- The speed of coolant movement has increased. The heat generated by the boiler has become faster delivered to the radiators and transferred to the premises.

- Accordingly, the process of heating the house has accelerated significantly.

- The higher the flow rate, the greater the throughput of the pipe. This means that the same amount of heat can be delivered to rooms through lines of smaller diameter. Simply put, the pipelines have become half the size thanks to the forced circulation of water from the pump, which is cheaper and more practical.

- Highways can now be laid with a minimum slope and water heating circuits can be made as complex and extensive as desired. The main thing is the correct selection of the pumping unit in terms of power and pressure created.

- The household circulation pump for heating has made it possible to organize underfloor heating and more efficient closed systems operating under pressure.

- It was possible to remove from view the ubiquitous pipes that run through the rooms and do not always harmonize with the interior. Increasingly, heating communications are laid in walls, under floor coverings and behind suspended (suspended) ceilings.

Note. A minimum slope of 2-3 mm per 1 m of pipeline is needed to empty the network in case of repair or maintenance. Previously, it was made at least 5 mm / 1 m.p.

Pumping systems also have disadvantages. This is a dependence on electricity and its consumption by the pumping unit during the heating season.

Therefore, if there are frequent power outages, the circulation pump must be installed together with an uninterruptible power supply unit or connected to an electric generator.

The second drawback is not critical; if you select the power of the device correctly, then the electricity consumption will be acceptable.

Leading manufacturers of heating equipment, such as Grundfos or Wilo, have developed new models of units that can save energy. For example, if you buy and install an Alpfa2 circulation pump from the Grundfos brand, it will automatically change its performance depending on the needs of the heating system. True, its price starts from 120 USD. e.

New generation circulation units from Grundfos – models Alpfa2 and Alpfa2L

Where to install the pump - supply or return

Despite the abundance of information on the Internet, it is quite difficult for the user to understand how to correctly install a heating pump in order to ensure forced circulation of water in the system of their own home.

The reason is the inconsistency of this information, which causes constant debate on thematic forums.

Most of the so-called specialists claim that the unit is installed only on the return pipeline, citing the following conclusions:

- the coolant temperature in the supply is much higher than in the return, so the pump will not last long;

- The density of hot water in the supply line is less, so it is more difficult to pump;

- The static pressure in the return line is higher, which makes the pump easier to operate.

Interesting fact. Sometimes a person accidentally ends up in a boiler room that provides central heating for apartments, and sees the units there embedded in the return line. After this, he considers this solution to be the only correct one, although he does not know that in other boiler houses centrifugal pumps can also be installed on the supply pipe.

We respond to the above statements point by point:

- Household circulation pumps are designed for a maximum coolant temperature of 110 °C. In a home heating network it rarely rises above 70 degrees, and the boiler will not heat the water more than 90 °C.

- The density of water at 50 degrees is 988 kg/m³, and at 70 °C – 977.8 kg/m³. For a unit that develops a pressure of 4-6 m of water column and is capable of pumping about a ton of coolant in 1 hour, the difference in the density of the transported medium is 10 kg/m³ (the volume of a ten-liter canister) is simply negligible.

- In practice, the difference in static pressure of the coolant in the supply and return lines is equally insignificant.

Source: https://carmen62.ru/pravilnaya-ustanovka-nasosa-wilo/

Positive and negative aspects of choice

Wet rotor circulation pump

Modern heating systems most often operate on the principle of natural circulation. But sometimes there is a need for forced circulation of the coolant. And then the question arises of choosing a suitable pump. The choice depends on many factors, the most important of which is the power of the device. It should be enough to generate the required feed intensity.

There are special mathematical formulas that allow you to make the necessary calculations. The finished tables are published on the Internet. They are also in the technical data sheet of the product. When choosing pump power, the area of the heated room and the speed that the circulation pumps are capable of generating are taken into account first of all.

By choosing Wilo products, everyone receives in return a whole package of operational benefits:

- German products eliminate the possibility of heat losses that often occur during evaporation.

- All its working mechanisms are made of corrosion-resistant materials.

- The operation of the system is controlled automatically. There is a built-in thermostat, and all functions are displayed on the LCD display. However, there is a manual switching option that allows you to control the speed of the working shaft.

- Even the most powerful models operate completely silently. Almost all Vilo pumps are small in size, so their installation does not take up much space.

- Connection is quick and convenient thanks to the spring terminals.

- The rotor and motor have a multi-stage protection system, so the unit is not afraid of power surges.

There is only one drawback to such installations. Today, Wilo pumps can only be installed in areas where power supply problems are extremely rare. Without electricity, it is simply impossible to evaluate the advantages and quality of work of German equipment.

Wilo surface pump

Many years of experience allows the German company Wilo to produce high-quality pumping equipment that satisfies the widest consumer demand. Today it is used both in the household sector and in industrial production. High quality and ease of installation, ease of operation and the presence of a large number of technical advantages distinguish the products of the described concern among similar products. But this is not the most important thing.

German pumps can be connected not only to the heating system. They are widely used for air conditioning. The model range is represented by several dozen varieties. All devices are characterized by high performance, compact size, high power and low noise during operation.

Design and principle of operation of Wilo pumps

Vilo brand pumping equipment is manufactured at the German company’s own factories. The models traditionally use a wet rotor design. The impeller, as well as all moving elements, are completely immersed in the coolant.

The operating principle of the Wilo wet-type household heating pump is based on direct contact of the impeller with the liquid medium. This design has the following advantages:

- Noise characteristics – the operation of the module is absolutely silent, which allows installation directly in living quarters, in the kitchen and bathroom.

Air removal - a valve is installed in the design through which air is removed from the heating system.

Reduced energy consumption - all models consume a minimum amount of electricity. At the same time, high performance is maintained.

- Long service life. Wilo pumps for heating systems have a cast iron body. All important parts of the structure have anti-corrosion properties. All models undergo mandatory testing and certification.

Technical characteristics of Wilo heating circulation pumps are:

Convenient control - a mechanical or electronic switch is provided. The power and speed of the coolant are adjusted.

Models with electronic control are equipped with a built-in thermostat.

The electric motor and rotor are protected from voltage surges.

Mechanical repair

All other parts that are not listed in the section: “Electrical repair” refer to mechanical components. If vibration or noise occurs in a running pump, to determine the source of its occurrence it is necessary:

- Stop the boiler smoothly.

- Remove the front panel of the housing and lower the control unit.

- Close the cold water, supply and return taps.

- Drain water from the boiler system through the drain valve.

- Unscrew the pump air vent lock to completely drain the water from the system. After all the fluid has been drained, tighten the lock until it stops.

- Remove the terminal with the starting capacitor.

- Unscrew the fastening screws and remove the motor-turbine unit.

- Inspect the bearings, impeller, and pump cavity for oxidation, contamination, foreign objects, and damage. If there is wear on the bearings or the motor shaft rotates with force, then they need to be replaced with others, for example, fluoroplastic ones. All dirt from the turbine, internal compartments of the housing, and sealing rubber should be removed.

- Place the repaired mechanism in place and secure it.

- Insert the terminal with the capacitor.

- Open the return, supply and cold water taps.

- Using the make-up tap, check the pump for leaks; if it does not leak, then add coolant to the system up to 1.2 bar.

- Start the pump in circulation mode and check its condition.

- If the results are positive, set the heating circuit temperature control knob to the required position.

Maintenance

Page 26

- Image

- Text

Russian

20

WILO SE 01/2012

82 ˚C for ball bearings and 75 ˚C for plain bearings. If bearings overheat, the cause should be determined immediately.

• In case of successful verification on all points

Slowly open the valve in the discharge connection and run the pump to the nominal parameters indicated in the data sheet and on the pump nameplate, respecting the values measured with pressure gauges and amperemeter. Do not operate the pump with the pressure valve closed. It is necessary to ensure that the drive system is not overloaded when the valve is open. The cause of overload may be the operation of the pump in an empty system. If the pump unit does not reach the rated outlet pressure, it must be switched off immediately and the cause must be determined.

• Check the vibration load of the unit and

ensure that it meets the specified limits. Ensure that the noise level complies with the specified limit values.

• Allow the pumps to operate for 8 hours

trial operation and regularly record all parameters, including outlet pressure, current, bearing temperature, etc. The following checks should be carried out regularly. It is recommended to carry out these checks once per shift.

• Pressure gauges on the suction and discharge side -

Please check for normal operating pressure. If there are significant deviations from previously recorded values, the pump may be running dry. In this case, it is necessary to turn off the pump and determine the cause of the loss of fluid.

• Check the sliding end for overheating

seal and, if necessary, seat of the stuffing box.

8.3.4 Sealing system

Gland seal ATTENTION! Possible damage to the pump! If the seal pressure cap is tightened too tightly, the seal will be damaged immediately.

During the first hours of operation, a large leakage of the stuffing box is required, which must be reduced after several hours of operation by uniformly tightening the pressure seal cover. The stuffing box seal must not heat up during operation. A properly adjusted packing should leak slightly at all times (1 to 2 drops per second during operation). If this leak is too large and it cannot be adjusted by tightening the oil seal pressure cap, then the oil seal rings are worn out and must be replaced.

Mechanical seal ATTENTION!

Possible damage to the pump!

Mechanical seals must not operate without the pumped medium and lubricant, even for a short time. Ensure that the system is completely filled before starting the pump. During break-in, small leaks may occur, which should stop after a few hours of operation. If the leaks continue, turn off the pump, remove the mechanical seal and check its condition.

8.3.5 Decommissioning

CAREFULLY! Risk of burns! If the temperature of the pumped medium and the pressure in the system are too high, it is necessary to close the valves installed below and above the pump. First you need to cool the pump.

• Close the valve on the pressure side to

reduce the motor load.

• Turn off the pump motor. • When the pump stops, close the valve to

suction side.

• Turn off measuring instruments, alarms

tion and protective systems.

8.3.6 Emergency shutdown

In the event of operational malfunctions, immediately switch off the pump. After turning off the pump, it is necessary to close the shut-off valves, disconnect the motor and eliminate the malfunction.

9 Maintenance

Any repair work may only be carried out by qualified personnel. CAREFULLY! Danger of electric shock! Avoid the risk of electric shock.

• Before carrying out work on electrical equipment,

During this process, the pump must be de-energized and protected against being switched on incorrectly.

• Damage to the connecting cable

should only be repaired by qualified electricians. CAREFULLY! Risk of burns due to liquid or steam! If the temperature of the pumped medium and the pressure in the system are high, it is necessary to first cool the pump and then reduce the pressure in the system.

Latest Arrivals

E.syboxmini – the world's most compact electronic pressure booster system! Happy Independence Day Ukraine! EVOTRON circulation pumps with a “wet” rotor and frequency regulation The Vulver company at the Aqua-Therm Kiev 2015 exhibition GENIX - a new pressure station for collecting and automatically pumping fecal wastewater Submersible 4″ electric motor DAB Centrifugal pump DAB K-HA Greetings from Novy Rok! Help the guys who are defending our Motherland! Hydraulic accumulators GWS ATTENTION, FAKE! The season is in full swing! Autumn offer New series of DAB filters for forward filtration Vertical centrifugal pumps of the NKV 32, NKV 45 series Representatives of the Wulver company visited the 18th international exhibition on water treatment, water purification, recycling and waste disposal, IFAT 2014. Horizontal frequency-controlled pump KDNE MCE/P Horizon nal frequency-controlled pump KDNE MSE/S Cavitation is a risk factor Horizontal frequency-regulated pump KE Dab monoblock frequency-controlled pumps NKM-GE/NKP-GE MSE/S Centrifugal pumps with built-in pre-filter - EUROPRO EVOPLUS SAN - glandless circulation pump and electronic control for the hot water system ERHARD ROCO Premium - innovative butterfly valve EVOPLUS D - double glandless circulation pump with electronic control

DABDAB sewer pumpsAqua-Therm KievDomestic pumping stationsValve valves with a rubber wedgeSewer pumpsPumping stationCirculation pumps DABdomestic pumping stationwater supplychoice of a pumping stationchoice of a well pumpwhere to buy a water pumpdeep pumps for wellswhy do you need a check valvehow to choose a circulation pumpbuy a pump for a wellbuy dab pumpsbuy a check valvebuy a circus lation pumpDab pumppump for seweragepump for well buypumping station Dabpumping equipment DABpumping stations DABpumping stations for increasing pressuredab pumps Ukrainepumps for heating systemswaste water treatmentsubmersible pumps dabsubmersible pumps for wellssubmersible well pumpsselection of a pumping stationsale of pumping equipmentsale of pumping equipment dabsale of pumping equipment Ukraineself-priming pumps dabwell pumps dabpressure increasing stationspressure increasing installation for the homesewage pumpcentrifugal pumps DABcentrifugal pumps for wells

Basic problems and methods for resolving them

In cases where vibration appears during operation of the device, extraneous noise occurs, or the pressure in the system changes, you should determine the cause and, if possible, troubleshoot the problem yourself.

When turned on, the pump hums, but the shaft does not rotate:

- The shaft jammed due to prolonged downtime. Remove the protective cap on the motor housing and rotate the shaft using a flat-head screwdriver;

- if foreign objects get in, disassemble the pump and clean the impeller, after which replacing the cleaning filter, which is installed in front of the device;

- problems with power supply (insufficient voltage in the network).

When turned on, the device does not work:

- there is no voltage in the network. Electrical wiring and protective automation are checked;

- The fuse has blown. Replaced with a new one.

Automatic shutdown of the device after a short period of operation:

accumulation of limescale in the stator cup. The glass and rotor of the electric motor are cleaned.

The pump makes a lot of noise when running:

- dry operation with air in the system. Release the air and make sure the pump shell is filled with liquid;

- cavitation. The pressure in the fluid supply line must be increased.

Excessive pump vibration:

critical condition of support bearings due to severe wear. The bearings should be replaced.

Reduced head and flow compared to manufacturer's specifications:

- power supply failure or phase change, which leads to a drop in power or reverse rotation of the impeller. Checking the phases (three-phase motors) and replacing the capacitor (for single-phase power supply);

- the pipeline has great resistance to fluid movement (hydraulic resistance). Clean (replace) the filters, check the shut-off valves, and increase the diameter of the pipes if necessary.

Automatic pump shutdown by external protection system:

malfunction of the electrical components of the device. Check connection terminals (oxidation, short circuit), capacitor (replacement), control unit.

Read more about modern circulation pumps

One of the main requirements for a modern heating system can be considered flexibility - that is, the ability to adjust its power over a wide range. Circulation pumps for heating systems from Wilo are ideal for this purpose.

In the distant past, circulation pumps were unregulated, that is, they were not able to reduce the rotor speed. This resulted in the heating system operating at approximately the same power at all times, even when there was no particular need for it.

Performance characteristic of non-adjustable model

Features of adjustable pumps

Nowadays, special attention is paid to energy saving issues, so unregulated devices are practically not installed in new heating systems.

The use of adjustable devices allows you to:

- change the rotor speed at any time, for example, to save energy at night the device automatically resets the speed;

- set any operating mode manually, this is useful if the owner plans to leave home for a couple of days. In this case, heating can be left at a minimum level.

Basic adjustment information is displayed on the screen

Note! The German manufacturer Wilo produces models for working in very harsh conditions. If the lime content in the water is high, then you should pay attention to the Wilo Star models.

This is what the performance curve looks like for a variable pump

As a rule, a Wilo heating circulation pump can operate in several modes:

- PP1 and PP2 - in this case, the pressure in the system will change, and the designations correspond to the operating characteristic with maximum pressure (PP1) and minimum pressure (PP2);

- CP1 and CP2 - in this case, the pressure remains unchanged, and the pump adapts to the coolant flow, changing the rotor speed;

- operating modes numbered I, II and III . One corresponds to the rotational speed at the minimum operating characteristic, II and III – rotational speed at the average and maximum rotational speed;

- It is possible to switch day/night modes.

Performance characteristics of the same model

Placement and installation rules

If it is not possible to invite specialists, you can do the installation yourself.

You just need to remember a few simple installation rules:

- It is forbidden to place the pump at the outlet of the boiler - hot coolant will reduce the service life of the device several times. It is considered optimal to place it on the pipe section in front of the entrance to the boiler;

- the arrow on the body shows the direction of movement of the coolant, it should be directed towards the boiler;

The photo shows an arrow showing the direction of rotation of the rotor

- when the pump is already installed and filled with water, air is removed from it;

- the pump is installed so that, if necessary, it can be quickly isolated from the flow of water. For this purpose, a bypass is arranged and shut-off valves are installed.

The bypass will allow you to quickly cut off the pump from the coolant

The instructions for installing the pump are not particularly complicated; threaded connections are used, so if necessary, it can be quickly removed for repair or replaced. Before installation, the boiler must be shut off using shut-off valves. Also during installation, a check valve (except for open systems) and a filter are installed.