In this article we bring to your attention a very successful project for a two-story bathhouse with a terrace; if desired, you can later install a heating boiler and use the building all year round. The dimensions of the bathhouse are 6x6 m, which makes it possible to have enough space for a comfortable stay. On the ground floor there is a steam room (3.4 m2), a sink (4.3 m2), and a relaxation room (16.7 m2). The second floor is allocated for two bedrooms, one of them is large and designed for two people. In the hall of the second floor you can place wardrobes for clothes.

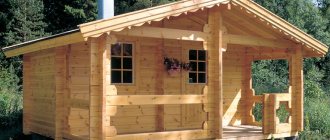

Two-story bathhouse made of 6 x 6 timber

General form

A rotary staircase leads from the first to the second floor.

Rotary staircase

Staircases on stringers

By the way, we have not yet considered in detail the construction of stairs; there was no such need for ordinary baths. In this article we will tell you in detail about the construction of a staircase and we assure you that making it if you have the desire and patience is not so difficult.

Floor plans

Choosing material for a two-story bath

Wood is considered a traditional material for building a bathhouse on your own site.

To build a wooden bath you will need the following material:

- Rounded logs or beams (from 6 thousand rubles per cubic meter);

- Boards for ceilings and floors (from 200 rubles per square meter);

- Material for insulation and waterproofing (from 1500 per cubic meter);

- Cement for the foundation (from 170 rubles per bag).

It is important that the wood is well dried and treated with all necessary pest control agents, and also impregnated with fire retardants.

If we talk about ease of construction, then, for example, two-story baths made of foam blocks are built faster and easier. The building material is much lighter, it is quicker to lay, and the foundation can be made simpler, because the structure as a whole is light. But a material such as foam block has one drawback - high heat transfer, which requires large financial expenditures on insulating material for a bathhouse.

When building a bathhouse from foam blocks, prepare:

- Foam block - density D700 (about 2400 rubles per cubic meter);

- Sand (about 250 rubles per ton), cement (from 170 rubles per bag);

- Construction adhesive (from 35 rubles per kilogram);

- Ruberoid for covering the foundation (from 230 rubles per roll);

- Materials for insulation and waterproofing (from 1500 per cubic meter).

Water disposal

Proper arrangement of drainage is one of the fundamental aspects of the construction of a two-story bathhouse. Close attention is paid to this issue, especially when placing a source for drinking water nearby. In the absence of high-quality technical structures, sewage can seep through the ground into a source of normal water, causing its pollution.

It is optimal when there is a collector near the two-story bathhouse into which you can install your own pipe. Otherwise, the sewerage system is diverted to a safe distance, and it is better to obtain permits for its installation.

Construction of a foundation for a two-story bathhouse

When building a two-story bathhouse from a log or timber, you must take care of a strong and powerful foundation, since compared to frame bathhouses or foam block buildings, a wooden bathhouse is very heavy, and the wood is subject to shrinkage.

Therefore, it is recommended to make a strip or column foundation. To build a strip foundation for a two-story bathhouse, follow these instructions:

- The first step is to dig a pit.

- Then, using sand and crushed stone, we build a cushion at the bottom of the pit.

- Next, we build the formwork, which we fill with concrete.

- When the concrete has dried, remove the formwork.

- After the formwork has been removed, a gap will appear between the foundation and the ground, which should be filled with fine crushed stone.

Use roofing felt or bitumen as a waterproofing material; these materials will protect the future structure well from moisture. Then the two-story wooden bathhouse will last for many years.

The procedure for building a columnar foundation for a bathhouse looks like this:

- We drive the support pillars (at the corners of the building and at the joints of the walls) into the ground approximately half a meter. If the ground is dense and it is not possible to drive a post, then first drill a hole and then place the post in it.

- Next, fill the entire structure with concrete.

- We carry out waterproofing using the same roofing material or bitumen.

If we talk about building a two-story bathhouse from a foam block, then the foundation layout will be slightly different. We dig a closed trench along the contour of the bathhouse. If, for example, a bathhouse of 3x6 m is planned, then the trench should be 50 cm deep and 40 cm wide. We drive wedges into each corner of the trench and stretch roofing felt around them. In addition, the bottom of the trench should also be covered with roofing felt. At the end, we fill the foundation and strengthen the structure with reinforcement. After 10 days (when the foundation has hardened), we divide the foundation into the rooms that are planned, lay the mesh and fill it with cement.

Availability of a swimming pool

The swimming pool in the bathhouse is built in a separate extension.

In large two-story bathhouses, a swimming pool is often built - the space allows this. Such a pool can be of any size and shape, but it is important to remember that moisture evaporates from plain water, and therefore waterproofing of the ceiling will be needed in this sector as well - so that the living quarters on the second floor do not end up damp.

If the two-story bathhouse is small in size, then you can choose a design for a bathhouse with a swimming pool in a special extension. For this purpose, a special room like a veranda is built next to the bathhouse, using one of its walls as a common one. The walls of this design can be completely glass - this is fashionable even today. But there is another option - a pool under the terrace. To do this, special, durable posts are placed in the ground, onto which the canopy is attached. And the pool is already installed under the canopy. Thus, you can enjoy cool water after a hot steam room in the fresh air, but not in the open air.

Construction of walls of a two-story bathhouse

Undoubtedly, a bathhouse made of timber or rounded logs is not only practical, but also quite attractive and respectable. But, as the projects of two-story baths show, the technology for their construction is quite complex, and it is easier for professionals to work with them. For those who like to do construction themselves, there is a good option - a disassembled sauna. This option will not leave you without work - you will have to work hard with your own hands to assemble it.

The process of installing a two-story log bathhouse looks like this.

When the foundation is ready, the lower frame of the frame is made. We caulk the log house and cover it with antiseptic agents. Next, we install windows and doors, insulate and sand the walls. An important point: the stairs to the second floor must be built indoors. We recommend that it be shaped - this will significantly save space. After the walls are erected and the floor is made, you can begin installing door and window frames. To install them, small gaps are first made in the timber walls. After the frame has “settled”, openings are cut in the right places (according to the design) that correspond to the size of the windows and doors.

The technology for constructing bathhouse walls from foam blocks is not much different from a brick building:

- Determine the highest angle of the building using a level. The construction of walls will begin from this corner.

- We lay the first row and fasten the foam blocks with mortar.

- We level the first row using a rubber hammer and “plant” the blocks in place. This is a very important point, since the entire future construction depends on it.

- We lay subsequent rows using special glue. We apply it in a layer of about 5 mm on the foam blocks.

- Every three rows we lay a reinforcing mesh.

- Don't forget to leave free space for windows and doors.

Foam block baths are built in 2-3 weeks.

Installation of skylights in the roof of a bathhouse

Skylights look great, although installing them is a rather labor-intensive process, and this needs to be done at the stage of constructing the rafter system.

Proper ventilation and lighting in this room is ensured precisely thanks to the proper arrangement of windows. To make the most of window openings, we carry out the work in the following order:

- We install a large semi-oval panoramic window on the pediment. You can also choose any other shape except square and rectangular. Non-standard lines will visually expand the space.

- We install a wide wooden window sill near the window opening on the roof slope and insert a transforming window that opens in the vertical direction. It can easily transform into a small balcony. The upper doors will serve as a canopy, and the lower ones will be used as a fence.

- We install small vertical windows around the perimeter of the roof.

- We place blinds for inclined structures on the windows on the slopes. They are equipped with special supports and fasteners that make it easy to adjust the position.

- We install double curtain rods above small windows and attach roller blinds made of lightweight material in a soft pastel shade to them.

To ensure good ventilation, give preference to high-quality double-glazed windows. The best option would be “breathable” windows made of wood. The use of wooden structures is preferable, since PVC windows will not fit the overall style of a room decorated with wood.

Installation of a roof structure for a two-story bathhouse

At the final stage of construction of a two-story wooden bathhouse, shrinkage is carried out.

It usually lasts about 6 months. After this, you can begin installing the roof structure. Roofs on two-story bathhouses can be single-slope or gable. If the first type is cheaper and suitable for small buildings, then the second is more expensive. Gable roofs cover large buildings. This type of roof is perfect for a two-story bathhouse with an attic.

Let's look at the installation diagram for a gable roof:

- We lay a row of boards (beams) on the upper crowns.

- We mount the rafters on the boards. The step should be 1 m.

- We make a lath on top.

- We cover the ridge with galvanized iron.

- We sew up the roof gables. The material for the gables can be chosen at your discretion and budget.

Don't forget to insulate the roof. To do this, we install insulation between the rafters. Avoid gaps at joints.

Rules for dismantling an old bathhouse roof

Before starting work on the construction of a full-fledged attic floor, you should calculate the attic for the bathhouse and the rafter system.

If it does not correspond to your project, it will have to be dismantled along with the old roofing, only after which can you begin installing new rafters. Before dismantling the roof over the bathhouse, you should clear it of all communications - wires, antennas, drains. Stock up on the necessary tools and materials - a screwdriver, a nail puller, a rope, a saw, a crowbar. Be sure to take care of your own protection and insurance. It is also recommended to install a block system for lowering roofing materials to the ground.

We carry out the work in the following sequence:

- We begin disassembly by removing the roofing material around the pipes and walls.

- To remove metal tiles, we start with the ridge, wind and valley linings. We disassemble the sheets of material from top to bottom.

- To dismantle the layered rafters, we remove all metal parts. After this, we remove the loose elements. First, we tear off a couple of boards 1-1.5 meters from the ceiling. Through the resulting hole we remove the boards that lie below.

- We dismantle the rafters, formwork and sheathing using an electric or chainsaw or crowbar. If we are dealing with hanging rafters, then every 4-5 lathing should be left in order to avoid the collapse of the rafter system.

- We lower the rafter legs down one at a time.

If you are removing a soft roofing covering, then work on its dismantling should be done in cool or cloudy weather. Under the sun, soft roofing materials heat up and soften, making the removal process more difficult.

Interior decoration of a two-story bathhouse

If your bathhouse is built of foam blocks, then it is necessary to carry out internal wall cladding.

Foam concrete will not last long if moisture protection is not provided. High-quality moisture protection is especially important on the ground floor, where the steam room is located. The interior decoration of a bathhouse made of foam blocks comes down to the following:

- We impregnate the foam blocks with a water-repellent solution.

- We lay insulating film.

- We carry out vapor barrier using vapor-tight membranes. We fix them between the wall and the facing material.

- We provide decorative wall cladding. Wooden lining is ideal for this.

- You can plaster the walls and cover them with polymer paint or cover them with tiles.

If your bathhouse is made of logs, then it also needs interior decoration. This will help reduce heat consumption, and, accordingly, heating time.

Features of the interior decoration of a log bath:

- We lay foil on top of the walls.

- Cover the top with a layer of insulation.

- The facing layer, as in the previous version, is recommended to be made using lining. However, waterproof materials such as gypsum fiber, drywall, PVC, and tiles are also suitable for decorative finishing.

Concrete, wood or ceramic tiles are used to finish the floor in the bathhouse.

The ceiling can be covered with wood or covered with PVC panels or plasterboard. The main condition is that all materials must have increased resistance to moisture. For wood that is suitable for cladding walls in a bathhouse, we choose maple, pine, ash, birch, hornbeam, and oak. Coniferous species are not suitable for finishing walls in a steam room. But they are perfect for the dressing room, washing room and second floor.

Two-tier stove for main and additional heating of the house

The presence of a two-tier heating structure provides your cottage with the highest level of autonomy. Such a stove for two rooms, located one above the other, can create comfortable conditions throughout the entire country house. Its rear walls are also well heated, which helps maintain the necessary microclimate in two or even four adjacent rooms.

Depending on the layout of the house, a two-story heating furnace can be used as the main system. However, recently, due to the widespread laying of gas mains and the allocation of sufficient electrical power, this structure is increasingly becoming an additional facility.

A brick two-tier stove, decorated with tiles or special ceramic tiles, becomes the central decorative element of many designer interiors.

Tips for heating a two-story bathhouse

To fully heat the first floor of a bathhouse, it is enough to make a brick stove.

Warming up may take some time, but it is economical and the heat will be distributed evenly. You can warm up the second floor in autumn and spring using a chimney duct. At the same time, do not forget about insulating the walls. But if you plan to use the second floor of the bathhouse during the winter months, then the stove will not be enough. Therefore, it is recommended to arrange full gas heating.

Staircase in a two-story steam room

This is one of the integral elements of a 2-story house. It must be not only reliable, but also practical. If the relaxation room in the bathhouse is not too large, then it is better to use screw structures. Although they are not very comfortable, they take up little space. But standard stairs are too bulky, but they are comfortable and safer. There are also projects with a ladder on the street. This is not so convenient, but nevertheless saves space in the bathhouse.

An important role in the construction of stairs is played by its safety. It is necessary to take into account the fact that there is high humidity in the bath, which causes slipping. Therefore, materials for the construction are needed not only of good quality, they must fully meet all the requirements for operating the steam room.

Features of the construction of a two-story bathhouse with an attic

The most attractive aspect of a two-story bathhouse is the attic.

Some connoisseurs sometimes build a two-story bathhouse just because of it. Many builders and architects consider the attic the optimal solution as a replacement for the second floor for a bathhouse. It does not load the foundation like a full second floor. The attic frame is made of horizontal rafters and vertical posts. They are the basis of the future ceiling and walls. The angle of inclination of the rafters should be within 30-60 degrees. This will provide more usable attic space.

An attic in a bathhouse can be built in different ways:

- On the finished bathhouse, we complete the walls upward.

- We will convert the attic space of the bathhouse into residential space.

The easiest way to complete the attic is on a bathhouse made of timber.

The attic can be made of a wooden structure that will weigh a little. It is not recommended to construct an attic made of foam blocks separately. It is worth considering the project from the beginning to calculate the load on the foundation. Watch the video below about building a two-story bathhouse with your own hands:

The two-story bathhouse with your own hands is ready! While a frame bath can be used immediately, this will not work with a wooden one. You need to wait about 6 months for the structure to settle down. Then you can safely begin the internal improvement of your bathhouse.

Construction of a two-story oven with a hob

A modern two-story stove with one firebox, in addition to the main heating function, provides the ability to prepare simple dishes, heat food and heat water for household needs. For these purposes, it is equipped with a hob with a massive cast-iron plate - monolithic or with two round holes. The latter are equipped with a composite lid in the form of a set of overlapping rings of decreasing diameter.

When developing a design for a stove intended for heating a two-story house, the following are taken into account:

- Tying the heating system to the internal main walls allows not only to reduce the load on the structure of the house, but also to balance the operation of the stove.

- Furnaces weighing up to 700 kg do not require a complex foundation.

- The stove, which is designed as the main source of heat in a two-story house, is a single system that runs through the entire building and is linked to the load-bearing elements.

When laying a stove, both one- and two-tier, a refractory clay mortar should be used. This will significantly increase the degree of resistance of the furnace design to high temperatures. Brickwork with the formation of vaults ensures high reliability and durability.