What is a roofing pie

The term itself arose as a simplified name for the roof insulation and waterproofing system. The name “pie” very aptly describes the design. The roof consists of a load-bearing rafter frame and the roofing pie itself, consisting of several base layers:

- External roofing made of metal tiles;

- Waterproofing layer;

- Vapor barrier layer;

- Insulation.

According to building codes, the roofing package also includes elements of the wooden roof frame, such as sheathing, counter-lattice and even rafter elements. But in practice, master roofers are limited to laying vapor barrier, insulation and metal tiles. The assembly of the wooden base - rafters and counter battens is the responsibility of the carpenters who assemble the roof truss frame.

Advice! When planning an order for craftsmen to lay a roofing pie under metal tiles, it would be correct to clarify who will assemble the sheathing, since the durability of the roof covering and the insulation itself greatly depends on its quality.

It is clear that all of the listed materials do not have sufficient strength and rigidity to ensure the flat geometry of the pitched roof when laid on the load-bearing rafters of the slope.

An exception is a cake based on sandwich panels; this is an insulation package pressed into a thin sheet metal shell. In this case, the finished sections are laid directly on the load-bearing roof rafters, without any additional layers of insulation and waterproofing.

For private households, the sandwich is not used, since the roofing pie for metal tiles is more durable, warm and reliable, and most importantly, repairable. The only headache of using metal tiles is the high thermal conductivity of the metal and, as a result, the intense formation of water vapor condensate. If you don’t skimp on vapor barriers, the roof will remain on the roof for at least a couple of decades without any problems.

Pie of insulated metal roofing

For wooden low-rise buildings, two types of gable roofs under a metal roof are used:

- Insulation of the ceiling of the house box. Only vapor and waterproofing remains on the roof sheathing, and the roof pie under the metal tile turns into a thin, invisible layer of polymer film on wooden slats;

- With insulation along the surface of the sheathing, the so-called warm version of the attic or attic, the most widespread and convenient when using metal tiles as a roof covering.

In this case, the air temperature under the roof is only slightly lower than inside the house, so water vapor does not condense, but rises up to the rafters and insulation.

Important! Metal tiles greatly cool the roof, and since condensation occurs along the temperature difference line in the region of 6-7°C, if the thermal insulation is insufficiently thick, condensation can fall on the rafters.

As a result, the wood swells and deforms; any deformation of the rafter beam can lead to the tearing of the metal tile sheet from the sheathing slats, and a strong wind will only complete the destruction of the coating. But if the roofing pie under metal tiles with an insulated roof is laid according to all the rules, then the service life of wooden beams and slats of 20-25 years without repair is guaranteed.

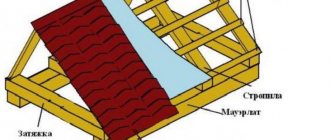

Rafter

In the roofing pie device, the rafter beam is immersed in the thickness of the insulation. The upper end rests on the ridge girder, the lower heel of the rafter rests on the mauerlat boards.

Thanks to this design of the roofing pie and the complete impermeability of the metal tile to water in any form, the rafter leg of the roof appears as if in an insulating shell, so the wood can be preserved and used for quite a long time.

Cornice strip

The element is a wooden strip, 25-30 mm thick and 10-15 cm wide, sewn to the ends of the overhangs or fillets. Since the lower part of the roof slope is suspended in the air without support, any, even slight, breeze creates a variable vibrating load. Metal tiles hold a static load well, but can tear off fasteners under alternating forces. Therefore, the eaves strip of the roofing pie is installed simultaneously with the sheathing.

After laying the vapor barrier, the canvas is placed over the eaves strip to the line where condensate drips into the gutters.

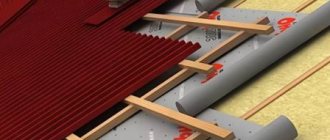

Why do you need a counter-lattice?

After completing the assembly of the rafters, the distance between the beams turns out to be too large for the relatively soft and pliable roofing pie to hold on to the pitched surface of the roof.

In addition, the external supporting surface of the rafter legs is far from ideal. Therefore, slats are sewn onto the rafters, which allows you to pre-level the laying plane and at the same time strengthen the base for laying metal tiles. If the roof is quite sloping, then the presence of a counter-lattice is mandatory; on high steep slopes, a simplified version of the cladding can be used under metal tiles.

Initial sheathing

In order to lay the coating efficiently, you need a flat and durable supporting surface, as close as possible to the normal plane. Lathing is the name given to horizontal slats sewn onto counter-lattice strips.

In order for the metal roof tile to evenly apply pressure to the rafters along the entire roof plane, special rules for laying the sheathing are used:

- The first plank is laid on the lower edge of the rafter legs, hemmed with counter-lattice, strictly along the marking cord. It is important to align the slats strictly along the horizon line and the plane of the cornice;

- The first line is filled with timber 50x50 mm, all the rest are slightly thinner - 50x30 mm. This is done to provide ventilation, and at the same time to compensate for the deflection of the overhang under the weight of the metal tile cake;

- The pitch between the lathing slats is 25-28 cm, in the middle part of the slope you can fill it every 35 cm, in the upper half the pitch of the lathing under the metal tiles is increased to 40 cm. In the ridge area, two adjacent boards are nailed without a gap for installing metal tile vents and laying the ridge strip.

Important! The slats are nailed with a pair of nails using the carpenter's method, with an oblique slope to the surface.

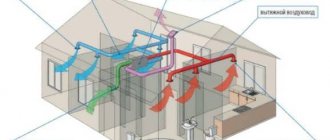

Since the metal tile will rest directly on the sheathing, additional conclusions need to be made for ventilation pipes and ducts.

Waterproofing

The next step is to install the vapor barrier. For conventional roofing coverings, a single-layer waterproofing is used, which prevents the flow of water and condensate into the thickness of the insulation. For a roofing pie based on metal tiles, a three-layer material with one-way conductivity of water vapor is used.

Some of the water vapor passes through an isospan-type sheet, comes into contact with the cold air under the metal tile and turns into condensation, and the moisture cannot return back into the thickness of the insulation.

Part of the condensate flows down the fiber sublayer of the sheet, but most of it is removed through the ventilation gap of the metal roofing pie.

Metal tiles

Most often, roofing material is laid in packs of four. First, the first two sheets of the bottom row are laid out on the sheathing, then a pair of metal tiles of the next top row are laid. The package is secured with self-tapping screws according to the diagram below.

To ensure the removal of condensation from the roofing pie, the waterproofing sheet is released from under the edge of the eaves under the nailed metal drip strip. The space under the overhang is covered with a grille, this will protect the ventilation ducts of the roofing pie.

A wind strip is placed on the sides of the gable overhangs of the roof, and silicone additional elements are placed under the ridge strip. This will protect the roof pie from water leakage and at the same time ensure the removal of water vapor.

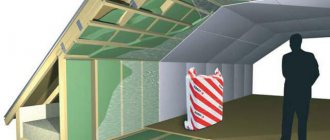

Insulation

Thermal insulation of the roofing pie is laid in the space between the rafter beams. Typically, the roof under metal tiles is insulated with mats made of pressed mineral fiber.

The roof can also be insulated with more convenient and safe polyurethane foam, but in this case, to form a warm layer of the cake, you will need to rent special equipment.

Roof vapor barrier

The last layer of the cake is a vapor barrier film. It allows hot and warm water vapor to pass through, which will definitely pass through the insulation without water condensation. Microdroplets from the already condensed steam remain indoors and are removed by attic ventilation.

Roofing pie under metal tiles with an insulated roof

The roofing pie fills the rafter frame. It is necessary to protect the house from rain, downpours, retain heat, and keep out noise. This is due to the fact that the roofing cake is multi-layered, it has forming elements, they need to be laid correctly and one by one, and at the same time follow the fastening technology, then the roof will be multifunctional.

Each layer of the roofing pie under metal tiles with an insulated roof is designed to perform some function; the pie should be installed in strict sequence.

In this case, the basic rule is that its mass should not be greater than the load-bearing capacity of the rafters.

Therefore, it is worth calculating all the loads on the building envelope, the required thickness of insulation and the strength of the rafters using our construction calculators.

Roofing pie for metal tiles. Scheme

Typically, a roofing pie includes: (from inside to outside):

- filing from the side of the under-roof room;

- vapor barrier, for example, polypropylene film;

- insulation, for example, mineral wool placed between the rafter system;

- waterproofing, for example, a membrane that is laid along the upper edge of the rafter joists;

- counter-lattice made of wooden slats;

- wood lathing;

- covering material, that is, metal tiles.

The roof can be insulated in different ways; it can be cold or insulated.

Roofing pie for metal tiles. Cold attic

That is, the roofing pie consists of certain layers, and each layer performs its own function:

1. The topmost layer of the pie is metal tiles. It provides protection from precipitation, temperature changes, and determines the appearance of the roof.

2. Vibration-isolating elements. They stop vibration, and with them you can’t hear the noise of rain pounding on a metal roof.

3. The frame of the lathing is made of wood. It is required to attach the outer covering - metal tiles - and to create a gap under the roof so that there is ventilation between the materials.

4. Counter-lattice, consisting of wooden slats. Provides the necessary air circulation between metal tiles, sheathing and insulating materials.

5. Waterproofing. It prevents moisture from penetrating the frame of the rafter system and the insulation.

6. Thermal insulation material. Performs the function of insulation from noise and does not allow heat to escape from the room.

7. Roof rafters. The roofing pie and insulation are attached to them. With the help of a rafter system, free space is obtained in the attic.

8. Vapor barrier. It takes the vapors that form inside the house outside.

9. Layer of internal roof cladding. Designed for fastening finishing materials.

Rafters

The rafters under a metal roof are identical to other rafters on which sheet or heavy coverings are attached. But these rafters are different in that the metal tiles do not load them very much, so to build the rafters you do not need to take a large cross-section of timber.

The distance between the rafter legs is usually 600-900 mm. When selecting the pitch of the rafter bars, it is worth taking into account the width and thickness of the material used for insulation. It must be placed tightly between the frame so that there are no gaps.

The rafter system is made from bars with a section of 50x150 mm. If the boards have this width, then you can choose insulation with a thickness of 150 mm. If you need to build a roof in cold regions of the country, then you should select bars with a width of about 200 mm. Then you can choose insulation with a thickness of also 200 mm.

Vapor barrier

Vapor barrier is required to protect the insulation from moisture, as well as to maintain a certain microclimate in the rooms. Usually the steam generated in the room rises. If the installed roof does not have a vapor barrier layer, then the steam will be absorbed into the insulation.

During frosts, steam will begin to stop on the outside of the insulation. There it will first become frost, and then a crust of ice on the material. And in the spring, when it gets warm, the insulation covered with a crust of ice will become unusable. The ice will melt and water will flow onto the insulation. Previously, glassine was used as a vapor barrier. Now they install films made of polyethylene or polypropylene:

1. Polyethylene film is not very strong, which is why it is reinforced with mesh.

2. And polypropylene film is a woven fabric, it is laminated on both sides with a thin layer of the same material. One of the sides is rough.

Thermal insulation

The most widely used insulation materials are mineral wool or polystyrene foam. They're pretty inexpensive. Mineral wool and foam blocks are placed between the rafter beams. They are mounted end-to-end. If this creates cracks and gaps, fill them with polyurethane foam.

If you do not have time to install insulation, then you can insulate the roof with polyurethane foam.

Waterproofing

Previously, glassine or roofing material was used as waterproofing. Now, to make the roof last a long time, special membranes are used. Although this material is not cheap, it is reliable and durable. The membrane material consists of 2 layers: the first is reinforcing, the second is moisture-repellent.

Counter grille and ventilation gap

The counter-lattice is created from wooden slats. They are attached to a layer of waterproofing, which is placed on top of the rafter joists. Then the mounted counter-lattice bars provide a gap between the waterproofing layer and the roof covering.

Lathing

The sheathing is the basis for attaching metal tiles. It is made from wooden blocks, they are mounted perpendicular to the legs of the rafters. Slats, boards or sheathing bars are attached end-to-end or through a small gap equal to the pitch of the metal tile wave. A wooden sheathing is created by attaching it with nails, screws, and staples.

But in this case, do not forget that the entire tree should be treated with antifungal compounds, otherwise it will rot.

Vibration isolation

You should definitely do vibration insulation if you plan to cover the roof with metal tiles, since when it rains or downpours, quite a lot of noise appears.

To protect a metal roof from noise, sound-absorbing materials are used.

To reduce noise and vibration you can:

1. Tightly attach all layers of the roofing cake, thereby increasing its rigidity. This is easy to do if, when attaching, you screw in many screws per 1 m.

2. Calculate the distance required for the installation of bars and slats relative to the length of the roof.

3. Make the sheathing and counter-lattice in the same plane. Because if the slats are attached unevenly, then after installing the metal tiles, the final coating will be deformed, and this may cause noise.

4. You can also reduce noise if you place a seal between the counter-lattice and the rafters that insulates sounds.

Metal tiles

To make metal tiles, thin sheets of aluminum, steel, and copper are taken. If you are planning to buy metal tiles in Kyiv, we recommend that you follow the link citybud.in.ua/krovlya/metalocherepica/, where you will find your option for purchasing roofing at an excellent price.

Such material can serve as a roof for several decades; it is reliable and durable. True, such properties depend on the density of laying the metal tiles when creating the roof. To lay the material tightly, sealing elements are used.

metal tile installation lesson

Source: https://o-remonte.com/krovelnyy-pirog-pod-metallocherepic/

Cold roof pie made of metal tiles

The cold design of the coating is characterized by the absence of a heat-insulating layer in the under-roof space. A roofing pie for metal tiles with a cold attic is twice as light and three times cheaper than in the case of a “warm” scheme.

Rafter

When using an uninsulated roof, the wooden structures of the frame and pie do not have warm, dry protection, as in the previous version. Therefore, rafter beams must be impregnated with protective compounds that prevent moisture from penetrating into the thickness of the wood.

A small amount of condensation on the rafters and sheathing does not pose a particular threat to the metal tile pie with normally functioning ventilation.

For your information! Ventilation of the attic occurs cyclically as the wind direction and air temperature change.

In summer and winter, there are no problems with ventilation of the pie under the metal tiles, but in the transitional spring and autumn months it is important to protect the wooden frame not only with the help of attic ventilation and the use of air supply compounds.

Counter-lattice or initial lathing

The technology for installing load-bearing counter-lattice slats is no different from the method used in the warm version of the pie. The surface of the rafters is trimmed and leveled with a hand plane, after which the counter-lattice support slats are glued and nailed onto the rafter beams.

Vapor barrier and waterproofing

The next step is to stretch a vapor barrier sheet over the manufactured roof counter-lattice made of metal tiles. The fabric is stretched in the direction with overlapping edges. Usually, the places where the film is attached to the frame are taped with construction tape. After the insulating sheet has been evenly stretched and leveled, it is fixed to the rafters with another layer of counter battens.

This cold roofing design is designed for the complete absence of water vapor under a metal tile roof. If the owners neglected to waterproof the ceiling, or the attic ventilation system does not work effectively enough, there is a need for additional protection of the waterproofing film from water vapor accumulating in the attic space. In this case, an additional sheet of vapor barrier film is placed under the waterproofing layer.

Lathing

The last stage of arranging the roofing pie is the laying of horizontal crossbars, onto which the sheets of metal tiles will be directly attached. The planks are nailed so that the caps are completely recessed into the wood, or they are sewn on with a construction stapler.

Often, the previously tensioned sheet slightly sags in a bubble; this is not a defect in the roofing pie; according to experts, such a deflection even contributes to more efficient removal of condensate from under the metal tiles.

Metal tiles and eaves strip

Due to the installation of additional counter-lattice slats that secure the roofing waterproofing of the pie, additional space is obtained between the metal tile covering and the film. This does not affect the fastening strength and stability of the roof. The increased clearance provides two additional benefits:

- The air gap acts as an improvised layer of insulation in which condensation does not accumulate and freeze;

- Due to the lateral flow of flows through the sheathing, moisture is removed more evenly, without the formation of stagnant zones under the metal tiles.

Correct fastening of additional elements also contributes to effective removal of condensate. The eaves strip not only covers the edge of the metal tile from the wind, it also promotes air flow inside the roofing pie.

Installation of a roofing pie under metal tiles and what are the risks of violating the installation technology?

Metal tiles are roofing materials made from sheets of steel, copper or other metal.

The material has a wave-like structure of various configurations.

This material is coated with a protective coating.

In order to cover the roof with metal tiles, it is necessary to ensure the correct under-roof space .

When arranging a roof, an important indicator of its functional purpose is the roofing cake.

What is a roofing pie for metal tiles and what does it consist of?

A roofing pie is a set of layers from which the roof is laid. Depending on the purpose of the room (warehouse, industrial, residential), the number of layers and the method of laying them may vary .

How are metal tiles constructed? The roof pie under the metal tiles is laid in the following order:

- rafter system ( roof frame , made, as a rule, of wooden beams, serves as the basis for applying layers of roofing pie);

- vapor barrier ( prevents moisture from entering the roofing pie);

- thermal insulation (ensures heat retention in the room);

- waterproofing (serves to ensure dryness of the room, prevents moisture from entering the room (waterproofing films, membranes));

- counter-lattice;

- sheathing ( a wooden frame that is applied and transfers the roofing load to the rafters. The sheathing has a pitch smaller than that of the rafters, and the beams are laid perpendicular to the rafter boards);

- roofing material ( external roof covering that protects the roof from atmospheric influences, wind, dust, moisture entering the room: metal tiles, ondulin, corrugated sheets).

In addition, ventilation gaps are installed between the layers of the roofing cake.

Each layer separately has its own laying characteristics.

Sheathing pitch for metal tiles and counter-lattice

Sheathing is a continuous or lattice roof deck that provides a base for laying roof layers .

How to calculate the step?

To calculate the amount of material consumed per sheathing, you need to know the pitch of the sheathing and the size of the tile material. The step size is affected by the wavelength of the coating. The sheathing pitch is the distance between the boards of the structure.

When laying with gratings, determine the pitch based on the dimensions of the roofing covering.

It should be borne in mind that the distance from the edge of the roof (first board) to the second board should be less than the pitch along the entire perimeter of the roof. Sometimes two boards are fastened in a row from below with a pitch of 1-2 cm , and then the boards are laid out with the pitch calculated for a given type of tile.

Here you can calculate the pitch of the rafters using an online calculator.

Manufacturers of quality materials often indicate the recommended step size on the packaging of the coating material.

So, for tiles with different transverse wavelengths, the sheathing should be laid:

- with a wavelength of 300 mm - the lathing pitch of the first two boards is 230 mm, then - 300 mm;

- at a wavelength of 350 mm - 280 mm and 350 mm, respectively;

- at a wavelength of 400 mm - 330 mm and 400 mm.

If there are no step width indicators, the step is measured as follows: a level is placed on the rafters and the distance from the top slope of the first wave of tiles to the end of the sheet is measured.

The thickness of the board under the sheathing should be 30 mm. For the first board, the recommended width is 50 mm.

The removal of the tile covering for shelter from rain directly depends on the angle of the roof: the greater the slope, the longer the removal of the material beyond the sheathing line. The overhang of the metal tile must reach the drain, so it is necessary to calculate the first step taking into account the protrusion of the metal tile over the edge of the roof (30-50 mm).

Continuous sheathing requires greater consumption of materials, simpler installation, and provides a higher level of load-bearing capacity of the roof. Continuous sheathing is installed on roofs that have a small degree of slope and is laid from edged boards or beams (section 50x50 mmmm) in increments of one centimeter.

How to protect the roof from moisture?

Important elements of the roofing pie are waterproofing and vapor barrier of the roof.

The difference between these two layers is that the waterproofing layer protects the thermal insulation layer from moisture , releasing it to the outside, and the vapor barrier prevents the penetration of moisture vapor from the room into the insulation, thereby preventing the thermal insulation from getting wet.

Let's look at what types of waterproofing exist.

Insulation of metal tiles - choice of material

Insulation has important properties of the roofing pie. This layer provides:

- maintaining heat in the room, preventing it from escaping outside;

- sound insulation (especially with metal roofing);

- durability of the roof.

When choosing a material for insulating a metal roof, you should take into account its features :

- life time;

- weight;

- frost resistance;

- vapor tightness;

- dimensional stability;

- environmental friendliness;

- water absorption;

- soundproofing;

- thermal conductivity;

- safety.

The most common materials for insulating metal roofing are:

- expanded polystyrene (features: good soundproofing, thermal insulation properties, however: fragile during installation);

- mineral wool (features: does not burn, does not absorb moisture, safe);

- polyurethane foam (non-flammable, good heat insulator, applied by spraying);

- cellulose insulation or ecowool (features: environmentally friendly, lightweight, cheap, however, susceptible to the influence of microorganisms, used exclusively for dry rooms);

- foam glass (features: dense material, good insulation, durable, but installation is ensured with glue).

The material for roofing should be selected based on its quality indicators, the complexity of the roof structure, and the price indicator.

Roofing cake for a cold roof

The difference between a roofing pie for a cold roof lies in the arrangement of its layers. It is important to provide clearance for the movement of air masses under the roofing and to apply the layers correctly.

Layers of roofing pie for cold roofing:

- rafter system;

- waterproofing layer;

- counter-lattice;

- sheathing;

- metal tiles.

In this case, the possibility of ice formation , condensation in the roof, and precipitation entering the room will be excluded.

Tips and tricks

In general, a cake with metal tiles as a covering resists moisture and accumulating condensation much better. But under one condition - the geometry and quality of laying the material must be ideal.

If, when installing corrugated sheeting, it is enough to ensure the required overlap, then for metal tiles the sheets of the pie must be adjusted as accurately as possible, otherwise leaks and non-fitting will have to be sealed with a sealant, and the procedure must be carried out at least once every two years.