Fused roofing "Technonikol" - characteristics of the material

The roof covering performs a protective function, preventing the building from precipitation and wind. Therefore, the main properties of the finishing coating should be tightness and durability.

These requirements are fully met by TechnoNIKOL weld-on roll materials, which are characterized by ease of installation and reliability during operation. Modern polymer-bitumen membranes are characterized by high tightness and can vary in technical characteristics and durability, and this must be taken into account during the selection process.

The founder for materials of this type is the well-known roofing felt. It is made using bitumen-impregnated cardboard. The material is not very durable, and its installation on the roof is fraught with considerable difficulties. Therefore, at present it is extremely rarely used for roofing work. The bitumen coating of the roofing material cracks, and the cardboard backing is prone to rotting. It is usually used for waterproofing.

Cardboard and bitumen provide reliable roof waterproofing

Currently used technologies for the production of roll waterproofing make it possible to use fiberglass and synthetic materials of increased strength as a base, and the addition of modifying components to bitumen gives it additional performance properties.

The welded material reliably protects the roofing pie

Photo gallery: soft roofing

Covering material stylized as tiles is suitable for arranging a pitched roof

The protective layer on a flat roof must be applied to a clean surface.

TechnoNIKOL films provide reliable roof covering

Soft roofing can last up to 35 years

Classification of TechnoNIKOL roll roofing

TechnoNIKOL soft roofing for Economy class roofs is designed for waterproofing a variety of construction buildings and utility rooms. Despite its low cost, such a roof provides excellent protection against temperature changes and lasts up to 20 years. Euroroofing felt and Bikrost are representatives of the economy class soft flow coating. These materials are characterized by ease of installation. Euroroofing felt is less carcinogenic and has low toxicity compared to regular roofing felt.

Bicroelast and Biopol belong to the Standard class. TechnoNIKOL coating of this class perfectly copes with the protective function, it is convenient to install, it has increased resistance to external factors and mechanical influence, and has a long service life. It is worth noting that this type of product has an acceptable price-quality ratio. Biopol is most often used for waterproofing foundations and additional carpet on roofs. Marking will help determine for which work a particular material should be used. Biopol P is used for the lower roofing carpet and protection of foundations from water. Biopol K – for the outer layer of the roof. Bicroelast has similar characteristics and markings.

Roof covering with soft roofing Bicroelast Source stroypay.ru

See also: Catalog of companies that specialize in roofing materials.

A representative of Business class roll soft roofing is Uniflex. It is widely used in construction in various climatic zones. Marking will help determine the type of topping and the area of application of this material. Uniflex K - used for the top layer of coating. It has a coarse grain coating. A Uniflex P - with fine powder is used for waterproofing structures. The basis for this coating is polyester, fiberglass or fiberglass.

Premium roll roofing has earned an excellent reputation in all countries. Technoelast is a representative of this class of coatings. Technoelast has increased waterproofing properties, the greatest strength and durability. It is used in different climatic zones for roofing buildings and for protecting structures and foundations in places with high groundwater pressure and high sub-zero temperatures.

Another representative of the Premium class is TechnoelastMost - a coating that is used for waterproofing bridge structures and floor slabs. The artificial rubber base will reliably perform its functions under conditions of increased loads.

When laying, the lower part of the roof warms up, which allows it to adhere to the surface Source hi.decorexpro.com

Technology for laying fused roofing "TechnoNIKOL"

Laying a soft roof from materials from this manufacturer can be done mechanically or by fusing onto a pre-prepared base.

The first of them is used to cover pitched roofs. The finishing layer is fixed with polymer-bitumen mastics and galvanized steel nails.

The fusing method is used when installing flat roofs and consists of melting the bitumen layer with a gas burner while simultaneously rolling it onto the surface to be covered with rollers. Laying is done from the lowest point of the roof. These are usually drainage areas.

The roll is rolled onto an insulated surface

Video: how to install a fused flat roof

https://youtube.com/watch?v=wofS8o7z9E4

Requirements for the surface under a fused roof

The base for installing such a finishing coating must meet certain requirements. Low-slope and flat roofs are most often built on a concrete base. The requirements for their surface are:

- Thermal joints must be installed between the roof slabs to compensate for thermal expansion when heated during operation. The gap size must be at least 5 mm; the gap must be filled with plastic waterproofing material.

- There should be no protrusions on the roof surface more than 5 mm high, but only smooth ones. All elevated surface elements must be cut down mechanically.

- Cracks or potholes must be carefully repaired with cement-sand mortar after preliminary cutting and cleaning of the damage.

- Oil stains are not allowed. If any are found, they must be removed with a solvent.

Sheets of moisture-resistant plywood, OSB boards and other similar materials are often used as a base for the finishing coating. Laying a fused roof over such substrates is dangerous due to the high risk of fire. Therefore, before starting work, careful surface treatment with fire retardant compounds is necessary. Before installation, it is recommended to ensure that you have a fire extinguisher.

Find out more about the design, installation technology and operation of the Technikol soft roof from our article - The Path to Perfection: DIY Technikol soft roof.

Before fusing the roofing material, the roof surface must be thoroughly cleaned of dust and debris using an industrial vacuum cleaner.

Work can be carried out in dry, windless weather at temperatures from -5 to +25 degrees. The roof surface must be clean. The ideal air temperature is 6 degrees with a humidity of about 80%. If this rule is not observed during work, it is permissible to use a hair dryer to additionally heat the surface of the slabs.

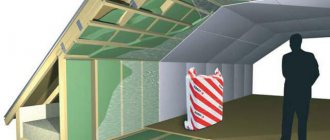

The roofing pie includes insulation, vapor and waterproof films

Forming a roofing pie with TechnoNIKOL film

The roofing pie is a multi-layer structure designed to reliably protect the interior of the house from precipitation and wind. It is formed depending on the characteristics of the base. For a wooden roof, the pie may consist of the following elements (from top to bottom):

- Soft roofing material "TechnoNIKOL".

- Lining made of chipboard, plywood or OSB.

- Lathing, the design of which depends on the type of the previous layer.

- Waterproofing made of membrane or polyethylene film.

- A layer of insulating material with a thickness that depends on the climatic conditions of the construction region.

- Internal lathing for thermal insulation.

- Vapor barrier material.

When installing a roof over a concrete slab, the roofing pie is formed differently:

- Finish coating from TechnoNIKOL.

- Slope (creation of guaranteed slopes in the required directions) using expanded clay concrete or cement-sand screed.

- Thermal insulation.

- Vapor barrier membrane.

Fused roofing is effective only if there is a roofing pie

Video: installation of a roofing pie under a fused roof

Laying technology step by step

In order for the roof to last as long as possible, it is recommended to buy TechnoNIKOL fused roofs made from polymers and fiberglass fabric. Products coated with large and small grains are used as a finishing layer.

You can install euroroofing felt on the following types:

- reinforced concrete slabs (without screed);

- lightweight concrete;

- mineral wool (without screed);

- cement-bonded particle boards, asbestos-cement sheets with a thickness of 8 mm or more and other building materials laid in 2 layers;

- monolithic screed.

The technology requires careful preparation of the roof and all the parts on it - ventilation pipes, parapets, and so on. If there are elements built from brick or other block materials, then they should be plastered with a cement-sand mixture of grade M150 at a distance of 25 cm from the base.

Before laying TechnoNIKOL, the roof is cleaned of debris, dirt, old coatings and oil stains. Protruding parts, reinforcing bars and others are removed as they can damage the waterproofing. Deep potholes and cracks are sealed with cement-sand mortar grade M150, small ones are covered with bitumen mastic.

Work begins only after the base has become completely dry. You can check the humidity level with special equipment, for example, a moisture meter, or put plastic film on it for 12 hours or 24 hours. If there are no drops of water on it, then the roof is ready for treatment.

Installation should only be carried out on a completely flat plane so that the material adheres tightly to the entire surface. In areas where vertical structures are adjacent, it is necessary to install fillets with an inclination angle of 45°. They can be made from mineral wool or cement-sand mortar.

Technology:

- The cleaned surface should be treated with a primer. It will increase the degree of adhesion to euroroofing felt. To do this, you can buy a ready-made bitumen primer and apply it with a roller or brush. Installation begins only after the base has completely dried.

- Laying the first roll of TechnoNIKOL overlay coating begins from the bottom of the roof. First, it is rolled out and the position is adjusted. After this, one edge is heated with a burner so that it sticks tightly and rolled back.

- While heating the insulation and roofing, slowly roll out the roll, moving forward, and press it down with a soft roller. The edges need to be heated especially well. The burner is held at such an angle that it simultaneously heats the euroroofing material and the roof.

- After placing the first sheet, check the quality of adhesion. If there are peelings, they are lifted with a spatula, heated again and pressed down. It is not recommended to walk on newly laid material, as this will leave dents on it.

- The next sheet is mounted on top of the previous one with an overlap of 8 cm at the edges and 15 cm at the end. The joining is carried out so that water does not stagnate or flow in the places of overlap.

If the roof has already been covered with euroroofing felt and it remains in good condition, then it is enough to put 1 new layer on top. 2-3 layers are fused onto foundations without waterproofing. When laying in several layers, it is necessary to ensure that the joints do not coincide.

You can make a primer for processing yourself. To do this, mix bitumen with a solvent (gasoline) in proportions 1:3 or 1:4.

If a bubble has formed on the surface of TechnoNIKOL, it is carefully pierced and air is released, after which it is heated and pressed firmly. On old coatings, blisters are removed by making a cross-shaped cut. The hole is cleaned and left to dry, after which the cut site is covered with bitumen mastic and sealed back.

Cost of work and materials

The price of a built-up roll roof depends on its brand and characteristics. The cost is greatly influenced by the type of base. Polyester is more expensive than fiberglass fabric products. The lower the prices, the shorter the service life.

| View | Price per m2, rubles | |

| Technoelast | TCH | 160 |

| EPP | 170 | |

| HPP | 115 | |

| Uniflex | HKP | 110 |

| ECP | 140 | |

| EPP | 130 | |

| HPP | 100 | |

| Bikrost HPP | 60 | |

| Linokrom HPP | 65 | |

| Cost of work per m2 | ||

| Installation in 1 layer | From 110 | |

| In 2 layers | From 220 | |

| In 3 layers | From 330 | |

| Flooring for parapets and walls, height up to 50 cm | From 120 per 1 linear meter | |

You can install a fused roof from TechnoNIKOL yourself, the main thing is to strictly follow the instructions from the manufacturer. The quality of the final result largely depends on preparation. If the base is thoroughly cleaned and properly primed, the waterproofing will be installed as tightly as possible.

Safety rules must be followed. The operator should wear gloves, goggles and clothing not made of synthetic fabrics so that if hot bitumen or fire accidentally gets in contact with it, a fire does not occur, this will help avoid burns. Work is carried out in dry weather. Euroroofing material should be stored only in a vertical position and at a remote distance from heaters; it should not be exposed to water or sunlight.

Fused roofing installation technology

Installation of a roll finish coating is carried out by melting the lower polymer-bitumen layer and rolling it to the surface. For this, special gas burners are used. As the bitumen layer softens, the roll is rolled onto the surface with an overlap of 50 mm. To control the degree of softening, a geometric pattern is applied to the bottom protective layer of polymer film. When its outlines begin to distort, the bitumen of the lower layer is softened enough for fastening. The work is carried out in the following order:

- To accurately position the next sheet at the installation site, the roll must first be rolled out. After this, the material is laid on the roof area intended for it. During installation, it is necessary to ensure overlap on vertical surfaces - parapet walls, at the junction of the roof with ventilation pipes, chimneys and other elements of intra-house systems.

- Roll up the roll and start fusing. The process consists of rolling the canvas towards itself - this way it is easier to control the degree of heating of the surface.

It is convenient to fuse the fabric when moving “towards you”

- The movement of the gas burner should be uniform and smooth; special attention should be paid to those places where there is overlap.

- The direction of the flame jet should ensure heating of both the canvas and the surface of the base.

- If there is a need to glue a sheet onto the topping, treating only the lower bitumen layer is not enough. You must first warm up the surface, then roll it with a roller until it is completely immersed in bitumen. After this, you can continue laying as usual.

- Before fusing the roof, the surface of the concrete slabs must be primed. You can purchase a standard mixture at a hardware store or prepare it yourself by mixing bitumen mastic with gasoline in a 1:3 ratio. The treated surface exhibits much stronger adhesion to the deposited material.

Primer treatment enhances adhesion when fusing the film

Such coatings can be used both for traditional roofs and for existing ones. Depending on the materials used, the life cycle of the surface ranges from 10 to 35 years.

How to choose the right roofing material

The quality of the roof depends on the choice of material for the roof. All Technonikol products are certified according to ISO 9001. This indicates the high, stable quality of this material, which meets European standards.

When purchasing material, you should pay attention to its labeling, which will help you select the film in accordance with the purpose of the roof. The letters mean the following:

- “K” - material with coarse-grained topping;

- “M” - products with fine powder;

- “P” - indicates the presence of a protective film;

- “B” - for products with ventilation ducts;

- “C” is a self-adhesive film.