Types of blocks

Before you build walls with your own hands, you need to choose a material. It has already been determined that the house is being built from expanded clay concrete blocks, but this is not enough. There are quite a large number of their varieties, among which a person far from construction can easily get lost. The main classification is made by jointly assessing the two characteristics of density and thermal conductivity.

Diagram of the structure of expanded clay concrete block

Based on them, expanded clay concrete blocks for masonry walls can be divided into:

- structural;

- structural and thermal insulation;

- thermal insulation.

The former have a density of 1200 to 1800 kg per cubic meter. They are strong enough, so they can be used to build the walls of a multi-story building. The density of the material is close to brick (1800 kg/m3), so the scope of application is approximately the same. Thermal characteristics are also similar, so the wall thickness is also equal and for most regions of the country it is 510-770 mm.

Due to their strength and density, they can be used for laying load-bearing walls with their own hands without fear.

The second group is products with a density of 700-1200 kg/m3. They are the ideal option for building a private house with your own hands. If you build walls from such expanded clay concrete blocks, they will be strong enough for low-rise construction, but at the same time they will have lower thermal conductivity than ceramic bricks.

Types of expanded clay concrete blocks

The third category has a density of 500-700 kg/m3. Low density allows you to obtain fairly good thermal insulation performance. The disadvantage of such expanded clay concrete products is their low load-bearing capacity, since with a decrease in density, the strength also decreases. Such blocks are not used for laying load-bearing walls. They are suitable as external cladding of an external wall and will work as insulation.

It is better to use this type of product together in the second group. In this case, the inner layer of stronger expanded clay concrete blocks will take on the load from the floor, roof, useful and snow, and the outer layer of thermal insulation products will reduce the thickness of the wall and insulate the house.

In addition to density, expanded clay concrete products are distinguished depending on the number of voids in them:

- block with 30% voids;

- block with 40% voids;

- solid block.

Preparatory work

The construction of any house must begin with the design of the future building and a series of preparatory work on the land plot. Country houses made of expanded clay concrete blocks are no exception, and before you invite a construction team or decide to carry out construction work yourself, you need to have a ready-made design solution for building your own house.

Only after carefully studying the project and the explanatory note to it, you can begin preparatory work on the construction site.

Geological studies of soils at the site

Geological soil studies

Preparatory work for building a house includes the following stages:

- determination of the soil class (soil geology) and the depth of groundwater within the boundaries of the construction site for the construction of a building;

- preparation of the construction site for marking the foundation;

- linking the house project to the boundaries of the construction site (callout of the building axes).

Even at the design stage, it is recommended to carry out soil research in the area of the construction site. Because the type and depth of the future foundation depends on the results of geology.

You can obtain soil samples with your own hands, but without a professional approach to this process, the information may be unreliable. Therefore, it is better to contact a specialized organization that will provide you with a comprehensive report on the depth of groundwater and the condition of the soil in your area.

Recommended laying depth

Based on soil samples, the comprehensive report will also indicate:

- soil shear stability;

- probability of drawdown;

- swelling during freezing;

- calculated movement within the boundaries of the building (sliding).

The soil creep rate is especially important when building a house located on a slope or on a site with uneven terrain.9

Tips: it is better to conduct a soil analysis of a construction site before purchasing the selected site for construction in order to subsequently avoid additional costs for the construction of a complex and material-intensive foundation with additional costs.

Marking the building foundations

Next, we prepare the construction site for marking. First of all, it is necessary to cut down bushes and trees; uproot stumps and remove stones.

Then, remove the top soil layer in the building spot by 20–30 cm. Usually this is a layer of soil rich in humus, and subsequently it can be used on the territory of the personal plot. In addition, this layer is saturated with various organic residues (roots, grass, etc.). When rotting and decomposing, organic matter can cause the appearance of fungi, which will eventually attack the wood.

Site for building a house

When the site is ready, you can begin the next stage of construction preparation - marking trenches or a foundation pit for an expanded clay concrete house.

In civil engineering, measuring instruments are used for this: theodolite and level, which allow accurate measurements. But in real life, not every developer has such a tool, and they often lack the skills to use it.

Therefore, let’s consider the simplest marking method, which is most often used by ordinary developers.

Marking a site for building a house: diagram

Right angles can be defined in the following way:

- From the edged board we knock down a right triangle with sides of 3, 4 and 5 m. We select a point on the surface of the site, and place the vertex of the triangle at this point (we mark the vertex with a peg). Don’t forget that we mark the axes, which means that later we will need to plot the thickness of the walls to the left and right of the axis.

- Then, parallel to the legs of the triangle, using a cord, we plot the dimensions of the corresponding sides of the building (axes) in different directions and mark these points with pegs.

- We stretch a cord between these pegs, measure the distance and get the diagonal size.

- We shift the triangle to the next corner of our choice, and mark the last point.

- We check the correctness of the measurements with a cord stretched between the first and last measurement points. The length of the cord is equal to the length of the first diagonal.

Setting up axes and thickness of load-bearing walls of a building

After determining all four points indicating the corners of the house and the contours of the future trench, we proceed to detailed marking of the thickness of the walls and taking the dimensions of the building beyond the boundaries of the house spot. This process occurs with the help of special devices called castoffs (or callouts).

Axis leader

To equip one leader, two posts up to 1 m high are driven into the ground, and a bar is attached to them, into which three nails are driven. There should be two such callouts for each corner of the building and two for each load-bearing wall inside the building.

Leaders are installed once and serve to determine the basic dimensions of the house until the end of construction. Therefore, they are located at a considerable distance from the edge of the foundations.

Product sizes

Dimensions of expanded clay concrete blocks

Having determined which products should be used for reasons of strength, it is worth paying attention to the thermal protection of masonry walls with your own hands.

The required thickness determines the dimensions of expanded clay concrete products.

For laying expanded clay concrete walls for various purposes with your own hands, the following recommendations can be given:

- external – block thickness 400 mm;

- internal – 190 mm.

- partitions – 90-120 mm.

It is also worth paying attention to the density of the material; the lower it is, the thicker it is recommended to use blocks for laying walls.

Calculation of the required number of blocks

How to calculate the required number of blocks to build a house made of expanded clay concrete with your own hands?

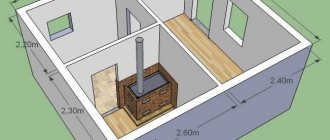

Very simple. The calculation is made without taking into account the thickness of the masonry joint. Initial data: width of the front wall - 6 m, length of the side wall - 9 m, height at the corner - 3 m, height at the ridge - 7 m, we lay the wall in half a block.

We calculate the total area of the walls: S(total) = 6×3×2 + 9×3×2 + 4×3×2 = 36 + 54 + 24 = 114 m².

We determine the area of window openings (taking into account that the width of one window is 1.4 m; height – 1.2 m; quantity – 4 pieces): S(windows) = 1.4 × 1.2 × 4 = 6.72 m².

We determine the area of the doorway (taking into account that the width of the doorway is 1.2 m and the height is 2.2 m): S(doorway) = 1.2 × 2.2 = 2.64 m².

Wall area (without window and door openings): S(walls) = S(total) - S(windows) - S(doorway) = 114 - 6.72 - 2.64 = 104.64 m².

Expanded clay block measuring 0.2 m × 0.2 m × 0.4 m has an area: S(block) = 0.2 × 0.4 = 0.08 m².

Number of blocks required for masonry: N = S(walls) : S(blocks) = 104.64 : 0.08 = 1308 pieces (this is the number of blocks needed for our construction).

The amount of material will decrease if the thickness of the masonry joint is taken into account in the calculation (about 15 mm), but it is better not to do this (let there be a small margin). Calculation of the number of products for internal partitions is done in a similar way.

Construction technology

Scheme for constructing a wall made of expanded clay blocks.

Building from blocks has several features. The following order of work can be given after completion of the foundation work:

- Laying waterproofing along the edge of the foundation. This is a mandatory event. As a material, you can use rolled lining materials with bitumen impregnation, for example roofing felt, linochrome or waterproofing. Waterproofing will ensure the safety of two types of materials, different in properties, but in contact with each other.

- Laying of the basement walls begins at the corners. The blocks are laid on masonry mortar. It is important to remember that cement-sand mortar has extremely high thermal conductivity and contributes to the appearance of cold bridges. To build a warm house, you should stock up on jute tape. The solution is placed only along the edges of the wall edge, and insulation is placed in the middle, which will prevent heat loss through weak points of the structure. Refusal of this solution in favor of less labor-intensive and costly simple cement joints 10-15 mm thick will lead to increased heating costs when operating the house. It is even possible that condensation may appear on the inner surface of wall structures at the locations of the seams.

- Masonry is no different from working with brick or foam concrete. The products are laid with dressing (there should be no extended vertical seams).

- Every 3-4 rows of blocks it is necessary to place reinforcing bars in the seam. There are grooves in the stone for this purpose. For structural reinforcement, two rods with a diameter of 12-14 mm will be sufficient (selected depending on the number of storeys of the house and the design load). You need to buy class A 400 reinforcement. Due to the surface profile, it adheres well to the mortar and has good strength characteristics. You can also perform mesh reinforcement.

- Additional reinforcement must be provided in weakened and heavily loaded areas. These include: a row under a window opening, support areas for lintels, slabs and beams. Here, additional rods are mandatory. In places where beams and lintels support, concrete support pads can be provided for additional reinforcement. For small spans this activity is not carried out, but if it is necessary to block a large opening or lay a long-span beam, support pads are required.

- After the floor has been laid, you need to support the floors on it. Expanded clay concrete is stronger than foam concrete, but does not have sufficient strength to withstand an unevenly distributed load. The floor slabs are supported only along one edge, due to which eccentricity occurs (the load does not act centrally), which can lead to the destruction of the blocks. To avoid this, a monolithic reinforced concrete belt is poured in the places where the floors support. It evenly distributes the load and prevents damage to wall structures. In addition, it increases the rigidity of the building. After pouring the belt, it is necessary to allow time for it to reach 70% of its original strength. Under normal conditions (+20ᵒ C) this process takes 1-2 weeks. Next, lay the slabs and move on to laying the next floor.

- A monolithic belt is a serious bridge of cold, so the outside must be insulated. This is done with foam or extruded polystyrene foam inserts. It is better to opt for the second option.

- When the masonry is completed, the wall fences are insulated (if such an event is provided) and the façade finishing is installed, and interior finishing work is carried out.

Constructing a building from expanded clay concrete is not a complicated process. It is only important to choose the right products and provide all additional measures to increase strength and heat-protective functions.

Main types of expanded clay concrete blocks

Expanded clay concrete blocks (according to GOST, they are regulated like stones) are produced in different grades, indicating their compressive strength. Depending on the volume of expanded clay, the density of the blocks varies from 350 to 1800 kg/m³. The less expanded clay in a product, the denser, heavier it is and its thermal conductivity coefficient is higher, that is, the material is durable, but not very “warm”.

The high content of porous expanded clay significantly reduces the density of the material and its strength, but gives it good thermal insulation characteristics. Therefore, only after understanding the purpose of stones and their scope of application, you will be able to understand what products you will need to erect a building from expanded clay concrete blocks with your own hands. Based on density, all expanded clay concrete blocks are divided into the following types:

- Thermal insulation products with a density from 350 to 700 kg/m³: used for laying the thermal insulation layer.

Important! Thermal insulation blocks cannot be used for the construction of load-bearing walls.

- Mixed-purpose blocks with a density from 700 to 1400 kg/m³: used for the construction of wall panels and interior partitions that are not subject to heavy loads. Structural blocks made of expanded clay concrete, the density of which varies from 1400 to 1800 kg/m³ (they are quite heavy). Used for the construction of load-bearing structures.

Advice! A structure made from products of this type is durable, but “cold”, so plan how to insulate a house built from expanded clay concrete blocks.

Conclusion: a material with low density has a low thermal conductivity coefficient, but its strength leaves much to be desired; High-density material has good compressive strength, but when using it when building a house, it is necessary to provide insulation.

In the construction market, expanded clay concrete products are presented in two varieties: hollow and solid.

Solid ones are highly durable and are used for the construction of load-bearing walls and structures that can withstand heavy loads. Hollow blocks are not very strong, but have good heat-saving characteristics. They are used for the construction of internal partitions, and sometimes as an additional heat-insulating or sound-proofing layer.

To facilitate the construction of a building such as a house made of expanded clay concrete, reduce the amount of mortar and prevent the formation of cold bridges, products with a tongue-and-groove system are often used.

How to build a house from expanded clay concrete blocks with your own hands?

There is probably not a single family that does not dream of a cozy, warm home.

Often dreams are shattered by the realities of life related to the material side of the issue. In such cases, you should pay attention to a house made of expanded clay concrete blocks. In the construction market, products made from this lightweight concrete have not lost popularity for several decades due to the favorable price-quality ratio. Let's take a closer look at the characteristics of the building material and the technology of working with it.

Let's figure out how to build a house from expanded clay concrete blocks so that it warms not only us, but also our children, grandchildren and great-grandchildren.

House made of expanded clay concrete blocks

Expanded clay concrete - characteristics, advantages, disadvantages

Products made from lightweight concrete, the main filler of which is baked clay pellets, are in high demand in the construction of small private houses, as well as in the construction of country houses and auxiliary buildings. Expanded clay is a lightweight, environmentally friendly, porous and, at the same time, very durable material.

When binding pellets with cement mortar, products are obtained that have many positive aspects:

- increased thermal conductivity. Thanks to the large number of air cavities inside the expanded clay, even a half-block house made of expanded clay concrete blocks perfectly retains heat in winter and coolness in summer;

- light weight. If you want to reduce the load on the foundation, expanded clay concrete blocks are used. Reviews from home owners confirm that reducing loads has a positive effect on the performance characteristics of the foundation;

- high strength characteristics. When you first get acquainted with the material, you may feel that building a house from expanded clay blocks is not justified due to its increased fragility. The material is indeed susceptible to impact loads. As for compressive forces, the composite is ahead of many building materials in this indicator;

- increased sound insulation properties. Thanks to the same voids inside the filler, wall materials based on expanded clay are characterized by increased sound insulation. With proper sound insulation of window and door openings, even in a busy city area, a comfortable noise level is always maintained inside such buildings; Expanded clay concrete block

- environmental friendliness. Since only components of natural origin are used in production, the environmental friendliness indicator is quite high;

- low shrinkage rates. This indicator can be appreciated during the operation of the building. Even after a long period, cracks do not appear on the walls, as often happens with aerated concrete products.

Advantages that do not affect the quality of work, but improve mood when purchasing materials and during construction activities include::

- low cost of production. The use of readily available components in manufacturing allows us to maintain a price range accessible to most developers;

- ease of masonry. Small dimensions and weight of individual elements allow installation at an accelerated pace;

- increased surface roughness, which improves adhesion to finishing compounds and facilitates cladding work.

Having studied the advantages, we can quickly conclude that a house made of expanded clay concrete blocks is ideal. Reviews from owners largely confirm this opinion.

But when choosing a building material, you should not turn a blind eye to the disadvantages, which include:

- increased porosity. The presence of a large number of air pores helps, on the one hand, to improve thermal conductivity and increase sound insulation properties, and, on the other hand, increases moisture absorption rates. Therefore, the construction of houses from expanded clay concrete blocks is associated with mandatory waterproofing of walls; Expanded clay concrete block in section

- reduced thermal conductivity compared to cellular concrete. In this regard, projects of houses made of expanded clay concrete blocks contain requirements for insulation of the box;

- appearance that needs additional finishing. Decorative panels, tiles, and siding can be used as cladding.

Studying the advantages and disadvantages will help you properly prepare for construction activities.

Calculator for expanded clay concrete blocks for home

One of the preparatory stages of construction is the design stage. After developing and agreeing on the project, it is necessary to calculate the need for materials. You can determine the required amount of building material yourself. Let’s take as an example a one-story house made of expanded clay concrete blocks with dimensions of 10x20 m and a ceiling height of 3 m.

Calculation can be done using two methods:

When calculating the required number of elements according to the first option, we proceed according to the following algorithm:

- Determine the total area of the walls. In our case – (10+10+20+20) x3=180 m².

- We calculate the number of units of production per 1 m². For an element with dimensions 400x200x200 mm this is 12.5 pieces (1/0.4x0.2=12.5).

- We multiply the total area of the walls and the quantity by 1 m² - we get the required number of units of production - 180x12.5 = 2250 pieces.

How many expanded clay blocks are needed to build a house?

The second calculation option is similar to the first, only when carrying out calculations they operate not with area indicators, but with the values of masonry volumes and one unit of production.

It is worth emphasizing that window and door openings are not taken into account in the calculation process. This was done deliberately to account for the loss of building materials during the work.

We build a house from expanded clay concrete blocks

Having understood the characteristics, advantages and disadvantages of products, studied methods for calculating the need for building materials and made their purchase, you can begin construction work. To build a strong and durable house from expanded clay concrete blocks with your own hands, adhere to proven technologies.

The general construction algorithm includes:

- foundation construction;

- walling;

- roof arrangement;

- waterproofing, insulation, cladding.

Let's take a closer look at each point.

Foundation for a house made of expanded clay concrete blocks

When choosing the type of foundation, you first need to focus on the structure and composition of the soil, as well as the groundwater level.

Foundation for a house made of expanded clay concrete blocks

Of the variety of foundations for structures made of lightweight concrete, only three types are suitable:

- tape;

- pile;

- slab.

By analyzing the soil at the construction site, you can determine which foundation will be preferable. A slab foundation is justified on unstable soils prone to movement.

Due to its large area and increased strength, it is able to compensate for bending loads and prevent cracking of the material during soil shifts.

But there is a nuance that you need to be aware of - a slab base is labor-intensive to install.

A pile foundation has many advantages when erected on soils prone to frost heaving. It is also indispensable in cases where it is necessary to build a building on a site with a slope. But the pile foundation unevenly distributes the loads that occur during soil shifts. Therefore, when choosing a screw structure for a house made of lightweight concrete, carefully weigh the pros and cons.

Optimal for low groundwater levels is a strip foundation.

It has a number of advantages over other types of bases:

- distributes loads evenly, which prevents cracks;

- allows you to fill it yourself, since the work process does not require large-sized equipment;

- allows for the arrangement of a full basement.

How to pour a strip foundation

Carry out work on pouring the strip foundation according to the following algorithm:

- Plan the site surface. Uproot trees and bushes. Remove small vegetation by hand or using chemicals.

- Mark the base using pegs and rope.

- Dig a trench to a depth greater than the freezing level of the soil. Level the walls and bottom of the trench.

- Prepare and install the formwork. For formwork, you can use scrap boards or use plywood panels.

- Fill the trench with crushed stone and sand mixture. Perform tamping.

- Assemble the reinforcing frame. The connection of metal rods can be done using welding or binding wire.

- Prepare the concrete solution according to the recipe. Use a concrete solution of at least grade M400 for work.

- Pour the prepared composition into the trench. Tamp the solution thoroughly to remove any air bubbles.

- Level the surface. Cover with plastic to retain moisture.

- After completing the hardening process, remove the formwork.

- Waterproof the foundation.

After the base has gained strength, begin building the box.

Wall masonry

Professionals advise using adhesive compounds when laying expanded clay concrete blocks

Work on the construction of the walls of a two-story house from expanded clay concrete blocks, as well as a country house from expanded clay concrete blocks, is carried out according to the general algorithm:

- Place the first row. Start laying from the corner area.

- Check horizontality using a level.

- Lay the next row, shifting the elements relative to the lower level by a third or half of the thickness.

- Reinforce the masonry every 3-4 rows. Use metal rods or reinforcing mesh for this.

- Strengthen door and window openings.

- Concreting the reinforced belt at the upper level to install the roof structure.

Upon completion of work, proceed with the installation of the roof.

Roof arrangement

The roof, like the foundation, is the key to the durability of the building. Before you begin installing the roof, think over the design and select the appropriate floor material. There is no need to save when choosing roofing material.

It is important that he be:

- durable;

- durable;

- resistant to natural factors;

- environmentally friendly.

Arrangement of the roof of the house

To install the roof, prepare the following materials:

- wooden beam 150x150 mm for the Mauerlat;

- edged board for sheathing;

- roofing material;

- hardware for fastening structural elements.

Guided by the documentation, assemble the frame and secure the roofing material.

Insulation of a house made of expanded clay concrete blocks

Buildings made of expanded clay concrete need insulation. Developers often have a question about how to insulate a house made of expanded clay concrete blocks. To maintain a comfortable microclimate, it is advisable to install thermal insulation both inside and outside. Such an integrated approach to insulation will reduce the cost of maintaining a favorable temperature.

How to insulate a house made of expanded clay concrete blocks from the outside

For external insulation, it is important to choose the optimal heat insulator.

Insulation of walls made of expanded clay concrete blocks

The most common insulation materials include:

- Styrofoam. It is characterized by low price, ease of installation, ease of finishing. Disadvantages - flammability and damage by rodents;

- mineral wool. It has an affordable price and improved thermal insulation properties. When laying it outside the building, the use of waterproofing is a prerequisite;

- facing panels. They are characterized by a high price and increased installation costs. The installation technology ensures effective thermal insulation.

Any of the proposed options has the right to life. The choice depends on financial capabilities.

Estimated construction cost

The estimated cost of construction can be obtained by summing up the following cost items:

- development and approval of project documentation;

- purchase of materials for the construction of the foundation, walls, roof, finishing;

- transportation costs for delivery of building materials to the work site;

- expenses for the services of hired workers.

Using current prices, you can get an approximate cost and plan the amount of upcoming costs.

Source: https://pobetony.expert/stroitelstvo/dom-iz-keramzitobetonnyh-blokov

Roof construction

A high-quality roof truss system is the key to the durability of the entire structure. Pediments are most often made from the same blocks as the walls themselves. Do not forget that before installing the roofing material, it is necessary to carry out work on its hydro- and thermal insulation.

To build a roof in a house from expanded clay concrete blocks, powerful wooden beams (mauerlat) are used, which are fixed on top of the load-bearing walls parallel to the ridge. Next, the rafters are installed, the roof is waterproofed and the sheathing is installed on which the roofing material is laid.

Remember that a house made of expanded clay concrete blocks, competently and efficiently built with your own hands, will last for quite a long time - from 50 to 100 years. As you can see, there is nothing complicated here, and anyone can get acquainted with the features and build the house of their dreams! We wish you success!

Estimated construction cost

The estimated cost of construction can be obtained by summing up the following cost items:

- development and approval of project documentation;

- purchase of materials for the construction of the foundation, walls, roof, finishing;

- transportation costs for delivery of building materials to the work site;

- expenses for the services of hired workers.

Using current prices, you can get an approximate cost and plan the amount of upcoming costs.

House made of expanded clay concrete: Reviews from owners

Initially, expanded clay concrete blocks were produced as a kind of insulation for a brick wall.

The masonry of blocks was organized on the outside of the structure and its purpose was to retain thermal radiation inside the structure.

Due to its strength characteristics, expanded clay concrete is not suitable for the organization of enclosing and load-bearing structures. However, with the development of science, the production of this type of building material has also improved.

Characteristics of expanded clay concrete structure

Today, expanded clay concrete with a relatively low specific gravity (it all depends on the degree of porosity of the material and the quality of the binding solution) is up to 1.5 times less than that of brickwork, and has a compressive strength of 5-25 kg/cm2. This allows it to be used for the construction of ordinary low-rise houses. The advantage remains its low thermal conductivity and high noise insulating properties.

What is a house made of expanded clay concrete like in practice?

Reviews from owners of residential buildings are only positive.

- First of all, there is a myth that expanded clay concrete blocks emit harmful gases and radon into the indoor atmosphere in the first years of their operation. Particularly inquisitive developers have conducted some experiments and refute this fact. Houses made of expanded clay concrete blocks are environmentally friendly. And their background radiation is several times lower compared to crushed stone and brick.

- Secondly, reviews from owners of houses made of expanded clay concrete confirm information from the manufacturers of this material about its low thermal conductivity. In such a design it is cool in summer and not cold in winter. However, the statement that heating costs are reduced by 3-4 times is incorrect. Yes, there are savings if you carry out proper insulation.

People complain about the presence of condensation on the walls and, as a result, the development of fungi and mold. This is not a consequence of wet expanded clay concrete blocks. This material is hygroscopic. The solution to the problem is to insulate the building from blocks. This measure protects the room from heat loss, and the construction material of the house from moisture.

Expanded clay concrete – vapor permeable

This has been proven in practice. The atmosphere in a house made of this material is no worse than in wooden houses. There is no excess moisture. However, improper interior decoration can upset this balance. The owners insist on vapor-permeable plasters and decorative materials.

However, during construction there are many nuances, neglecting which can lead to a disastrous final result.

Material selection

What is better to choose for low-rise construction? It is recommended to use the following grades of materials:

1). M25, M35, M50, M75, M100. M50 - for outbuildings, but it is also suitable for load-bearing walls up to 400 mm thick (see Dimensions of expanded clay concrete blocks).

2). M75 - a load-bearing wall with a thickness of 200 mm is being erected.

3). Hollow blocks are an ideal solution for building a country house. This is a lightweight version of the material. It has an uneven surface, which will affect the cost of further processing.

4). You can use a solid block, but it weighs a lot (more than 1000 kg/cubic meter) and requires a strong foundation.

Subtleties of the construction process

Regarding the foundation, the opinions of most owners favor a monolithic structure with a reinforcing frame.

If the soil is not stable and geodetic studies confirm the proximity of groundwater, then it is better to use a pile option for the foundation of the house. Of course, the price of construction in this case will increase significantly (due to the complexity of the design and the use of special equipment), but the result will be a durable house.

The basement floor is erected if the ground difference is large, and its artificial leveling has not been carried out. For this, a special base brick is used, plus a reinforcing mesh in several rows. The result is in the figure.

The ceiling of the first floor is installed after the base has gained strength. To do this, concrete slabs with reinforcement inside are taken.

Direct laying of blocks:

For load-bearing and enclosing structures, a block of the M50 brand is used. For partitions in the house - partition material. The blocks are placed on cement mortar. According to the recommendations of house owners, every fifth row of masonry is reinforced. Work begins with forcing out the corners, then moves along the wall.

After organizing the window openings and the first floor for laying the floor for the next floor, an armored belt with removable formwork is organized.

After the cement stone of the arma belt has matured, the floor slabs are laid. Regarding the insulation of the walls of the house and the basement, most owners are inclined towards foam plastic with glue, a ventilated gap and facing the house with decorative bricks.

Advantages and disadvantages

Like any structure, a house made of expanded clay concrete blocks has its advantages and disadvantages.

Positive aspects of the design

Positive characteristics include low thermal conductivity, large volume with low specific gravity. This allows you to save some money on the purchase of material. Knowing the mass of one structural element, it is easy to calculate its strength and thermal conductivity. In accordance with the data obtained, the optimal thickness and height of the foundation can be determined.

Negative points

When purchasing products, it is recommended to weigh several blocks from the purchase lot. In practice, there are cases where the parameters and weight of the material do not comply with the standards of the declared batch.

To organize normal temperature conditions in a house made of expanded clay concrete blocks, a wall thickness of up to 1.2 m is required. Of course, no one will build such a thing. Therefore, all developers insist on additional insulation of the building.

Polystyrene foam is not suitable in this case, since it is flammable, and under an additional facing layer on top of the insulation, it will be difficult to extinguish it in the event of a fire. However, this is a theory. Many people still resort to using this particular insulation and are satisfied.

According to building codes, to insulate the walls of a building made of expanded clay concrete blocks, it is better to use mineral or basalt wool in slabs. Additional waterproofing is also necessary, since expanded clay concrete is a porous structure.

Duration of operation

There are also no complaints from owners of expanded clay concrete houses regarding the strength of the blocks. All the nails on the dowels hold well. The main thing is to choose the right dowel. For furniture I'll use 10 mm. For heavy structures, you need to use self-tapping screws. Expanded clay concrete does not crack when the temperature changes.

Build a house from expanded clay concrete blocks yourself

Expanded clay concrete blocks are the optimal material for building your own home. They have low thermal conductivity, low cost, lightness and strength. With certain skills, you can build a private home from them with your own hands.

Pros and cons of the material

The main filler of the blocks is expanded clay. It is porous, durable and lightweight. Granules of the material are made from baked clay. Thanks to it, expanded clay concrete has a low specific gravity and low thermal conductivity.

The blocks are produced simply. First of all, concrete is mixed, consisting of Portland cement, quartz sand, expanded clay granules and water. Next, the material is placed in molds and dried.

Advantages of expanded clay concrete houses

Walls made of expanded clay blocks have many advantages:

- Low thermal conductivity. The source of this parameter is the porosity of the filler. Thanks to it, the building retains heat well.

- Low weight. This parameter becomes possible due to the lightness of expanded clay. In addition, in addition to solid analogues, manufacturers also produce hollow blocks. This further reduces the weight of the material. Thanks to this, the walls made of it do not put much pressure on the foundation.

- Expanded clay concrete is durable and strong. Walls made from it can easily withstand loads from lintels, purlins and floor slabs.

- The cost of the material is low. This makes it possible to carry out low-budget construction.

- Expanded clay concrete walls shrink little. Thanks to this, cracking does not occur on them.

- The material is environmentally friendly. Therefore, it does not emit any harmful substances.

- Porous concrete has excellent sound insulation properties. As a result, the house will be well protected from external sounds.

- Plastering walls made of expanded clay concrete blocks is very convenient. The cement-sand mortar adheres well to them. Thanks to this, finishing work can be carried out at lower costs.

How to finish the foundation with panels yourself, read in this article.

Due to their not very large dimensions and lightness, expanded clay concrete blocks are relatively easy to lay. Therefore, you can build a house from them on your own.

Disadvantages of the material

Expanded clay concrete also has disadvantages:

- The porous structure of the material is not only its advantage, but also its disadvantage. As a result, the blocks actively absorb moisture. At subzero temperatures it turns into ice, which begins to destroy walls. Because of this, expanded clay concrete must be protected with cladding - plaster, decorative brick, etc.

- Due to the small dimensions of the blocks, their masonry has a large number of seams. They are cold bridges, because... they actively let him inside the house. Because of this, the building must be additionally insulated.

- Expanded clay concrete has a higher thermal conductivity than, for example, gas silicate or aerated concrete analogues.

- Manufacturers produce only two sizes of blocks: ordinary 39×19×18.8 cm and half-blocks; their thickness differs only - 9 or 12 cm. Therefore, near the walls it can only be 39 or 19 cm.

- Expanded clay concrete is fragile. Blocks made from it break when dropped or hit.

Foundation for a house

The construction of a house begins with the construction of its foundation - the foundation. For expanded clay concrete buildings, the strip type is most often chosen. Such a foundation is easy to build, inexpensive and has sufficient strength.

First you need to select a place on the site to build a home. Then prepare the site for its construction: clear it of debris, level the surface.

Foundation construction algorithm:

- First, you will need to mark the location for the future trench using construction cord and pegs.

- After this, the ditch itself is dug out. Its depth should be about 40-50 cm.

- Then you need to fill it with a cushion consisting of 10 cm of sand and 10 cm of crushed stone. These layers are well compacted.

- After this, a reinforced frame of steel rods is welded in the trench.

- Then wooden formwork panels are installed on both sides of the trench.

- Then a solution consisting of 1 part of Portland cement, 2 parts of sand, 1 part of crushed stone and a sufficient amount of water is mixed in a concrete mixer.

- Then the mixture is placed in the formwork.

- Simultaneously with pouring concrete, it is necessary to lay all necessary communications in the foundation, for example, sewer pipes. In addition, ventilation ducts should be left in the base.

After pouring it, the foundation must dry completely and gain strength. This will take 28 days. After this, it is highly advisable to wait another six months for the base to shrink.

After the specified period, the foundation must be insulated and waterproofed. After this, you can begin building the walls of the house.

Calculation of expanded clay concrete blocks for a house. Calculation example

Before purchasing blocks, you will need to calculate the required number. As an example, let's calculate the required material for a building measuring 10x10 m. Let it be a two-story building with a ceiling height of 3 m and a total area of 200 m².

First, the length of the external perimeter walls is calculated: 10+10+10+10=40 m.

Then it is necessary to determine their area; for this purpose, the perimeter of the house is multiplied by the total height of the two-story house: 40∙(3+3)=240 m².

After this, you need to determine the required number of blocks. To do this, you need to multiply the area of the walls by the number of blocks per 1 m². If this is an ordinary material, the dimensions of which, taking into account the seams, are 40 × 20 × 20 cm, then there are 12.5 pieces of it in one square meter. This means that the walls of the building need: 240×12.5=3000 blocks.

In the example given, door and window openings were not taken into account. When making calculations, subtract their dimensions from the area of the walls to obtain the exact amount of material required.

How to place blocks correctly: step-by-step instructions

Recommendations for building walls:

- Wall laying must begin from one of the corners. Lay several rows there in the shape of a pyramid. Check the correctness of the masonry with a level and plumb line.

- The size of interblock seams should be at least 1 cm.

- The blocks must be laid offset so that the seams of adjacent rows do not coincide.

- Having laid out all the corner pyramids, stretch the construction cord between them. It will show the exact level of subsequent masonry. Next, start building walls along the cord.

- Reinforce the masonry with rods every 3-4 levels. They should be folded at the corners.

- For reinforcement, you can also use steel mesh. If the house will be faced with decorative brick, then it must be extended beyond the plane of the external walls. This is necessary for binding the finishing and expanded clay concrete blocks.

- Load-bearing walls and partitions are best constructed at the same time. When this is not possible, reinforcement should be left in the structure adjacent to the future pier, which will then connect them.

- A reinforced concrete reinforcing belt should be poured along the perimeter of the first floor. It is necessary to redistribute the load from the floor slabs.

Tap or move the material only with a rubber mallet. Expanded clay concrete is fragile and can burst from hard impacts.

How to insulate a house

Expanded clay concrete loses some of its thermal insulation properties during its operation. Based on this, the house needs to be insulated.

Read how to insulate a house with polystyrene foam here.

Mineral wool is best suited for this. It is laid in a pre-assembled frame in two layers. The insulation must be protected on the outside with waterproofing, and on the inside with a vapor barrier film. Thermal insulation is installed on pre-prepared walls. They need to be plastered, dried and cleaned of dirt.

Read here how to properly insulate walls with mineral wool.

Expanded polystyrene boards can also play the role of thermal insulation. This material, unlike mineral wool, is vapor-proof. Therefore, it does not need to be protected from condensation. The disadvantage of polystyrene foam is that rodents love it. To prevent them from getting to the insulation, it must be walled up under the plaster.

Thermal insulation of expanded clay concrete walls is best done from their outside. This way, less condensation will form, which will have a destructive effect on the house.

Source: https://stroyobzor.info/materialy/nulevoj-cikl/kamen/dom-iz-keramzitobetonnyx-blokov.html