Taking into account the rising cost of energy resources, heating a living space requires large material costs. If we take into account an apartment with a small living space, then the cost of heating in the cold season is affordable. However, taking into account the heating system of a cottage or private house with a large area, the question arises of finding alternative heating sources. One such option is hydrogen heating. Scientists have proven that the heat capacity of hydrogen is several times higher than the heat capacity of natural gas, which allows for significant budget savings. What advantages does hydrogen heating have, its features and methods of self-made creation of this type of heating, we will analyze further.

What is hydrogen?

Hydrogen is a light gas that, when burned, produces heat several times greater than that of gas.

Its main advantage when used in a heating system is its relatively low combustion temperature (only 300°C). This allows the use of gas in a boiler made of traditional inexpensive types of metal.

The gas itself is colorless and odorless, and when combined with other chemical components, it does not form dangerous toxins harmful to human health. Therefore, its use in everyday life is extremely safe. The only danger is its increased level of explosiveness.

A story about heating a house with hydrogen

If gas is used incorrectly or comes into contact with an open source of fire,

an explosion may occur .

ICE on hydrogen fuel

For several decades, there has been a search for the possibility of adapting internal combustion engines for full or hybrid operation on hydrogen fuel. In Great Britain, back in 1841, an engine running on an air-hydrogen mixture was patented. At the beginning of the 20th century, the Zeppelin concern used internal combustion engines running on hydrogen as the propulsion system for its famous airships.

The development of hydrogen energy was also facilitated by the global energy crisis that erupted in the 70s of the last century. However, with its end, hydrogen generators were quickly forgotten. And this despite a lot of advantages compared to conventional fuel:

- ideal flammability of the fuel mixture based on air and hydrogen, which makes it possible to easily start the engine at any ambient temperature;

- large heat release during gas combustion;

- absolute environmental safety - exhaust gases turn into water;

- the combustion rate is 4 times higher compared to a gasoline mixture;

- the ability of the mixture to operate without detonation at a high compression ratio.

The main technical reason, which is an insurmountable obstacle to the use of hydrogen as a vehicle fuel, was the inability to fit a sufficient amount of gas on a vehicle. The size of the hydrogen fuel tank will be comparable to the parameters of the car itself. The high explosiveness of the gas should exclude the possibility of the slightest leak. In liquid form, a cryogenic installation is required. This method is also not very feasible in a car.

Universal diagram of a hydrogen generator

For those who do not have the ability to design, a hydrogen generator for a car can be purchased from folk craftsmen who put the assembly and installation of such systems on stream. Today there are many such offers. The cost of the unit and installation is about 40 thousand rubles.

We recommend: Choosing the best insulation for walls in a frame house

But you can assemble such a system yourself - there is nothing complicated about it. It consists of several simple elements combined into one whole:

- Installations for water electrolysis.

- Storage tank.

- Moisture trap from gas.

- Electronic control unit (current modulator).

Below is a diagram according to which you can easily assemble a hydrogen generator with your own hands. The drawings of the main installation producing Brown's gas are quite simple and understandable.

The circuit does not represent any engineering complexity; anyone who knows how to work with the tool can repeat it. For vehicles with a fuel injection system, it is also necessary to install a controller that regulates the level of gas supply to the fuel mixture and is connected to the vehicle’s on-board computer.

Reactor

The amount of Brown gas produced depends on the area of the electrodes and their material. If copper or iron plates are used as electrodes, the reactor will not be able to operate for a long time due to the rapid destruction of the plates.

The use of titanium sheets looks ideal. However, their use increases the cost of assembling the unit several times. It is considered optimal to use plates made of high-alloy stainless steel. This metal is available, it will not be difficult to purchase. You can also use a used washing machine tank. The only difficulty will be cutting out the plates of the required size.

Types of installations

Today, a hydrogen generator for a car can be equipped with three electrolyzers that differ in type, nature of operation and performance:

- Simple, cylindrical type. Produces 700 milliliters of gas per minute. This performance is sufficient for engines with a displacement of up to 1.4 liters.

- With cells of separate type. It is the most efficient in terms of design and performance. The gas output exceeds 2 liters per minute. This volume allows it to be used in freight transport.

- Electrolyzer with open plates. This design provides additional cooling to the system, as a result of which it can be used during long-term operation of the unit. The gas output is controlled by the number of reactor plates.

The first type of design is quite sufficient for many carburetor engines. There is no need to install a complex electronic circuit for a gas performance regulator, and the assembly of such an electrolyzer itself is not difficult.

For more powerful cars, it is preferable to assemble the second type of reactor. And for engines running on diesel fuel and heavy-duty vehicles, a third type of reactor is used.

Required performance

In order to truly save fuel, a hydrogen generator for a car must produce gas every minute at the rate of 1 liter per 1000 engine displacement. Based on these requirements, the number of plates for the reactor is selected.

To increase the surface of the electrodes, it is necessary to treat the surface with sandpaper in a perpendicular direction. This treatment is extremely important - it will increase the working area and avoid “sticking” of gas bubbles to the surface.

The latter leads to isolation of the electrode from the liquid and prevents normal electrolysis. Do not also forget that for normal operation of the electrolyzer, the water must be alkaline. Regular soda can serve as a catalyst.

Current regulator

A hydrogen generator on a car increases its productivity during operation. This is due to the release of heat during the electrolysis reaction. The working fluid of the reactor experiences heating, and the process proceeds much more intensely. To control the progress of the reaction, a current regulator is used.

If you do not lower it, the water may simply boil and the reactor will stop producing Brown gas. A special controller that regulates the operation of the reactor allows you to change productivity with increasing speed.

Carburetor models are equipped with a controller with a conventional switch for two operating modes: “Highway” and “City”.

Hydrogen in the heating system

Despite the presence of such favorable qualities as environmental friendliness and a high level of heat capacity, hydrogen does not occur in nature in free form . It is synthesized by a specially assembled boiler, in which, using electrolysis, ordinary water breaks down into hydrogen and oxygen. Accordingly, the heating system must include two irreplaceable components: water and electricity. The gas mixture obtained as a result of electrolysis is called an “explosive mixture.” This name is fully justified, because with a small spark the gas can provoke an explosion.

Let's take a closer look at how to convert hydrogen into an energy resource .

As mentioned above, this gas is obtained by electrolysis of water, so its synthesis will require special equipment, which is a container in which metal plates with water are immersed. A current of a certain frequency is supplied through the plates, after exposure to which hydrogen and oxygen are released, but not in pure form, but mixed with water vapor (it is formed as a by-product of electrolysis). To separate the steam and isolate the hydrogen, the gas mixture is passed through a chemical separator that can separate the hydrogen from other impurities.

Negative aspects of hydrogen heating of buildings

In discussions on the feasibility of using hydrogen fuel for heating systems, skeptics provide compelling arguments:

- High cost: even in the most efficient electrolysis plants created today, to produce hydrogen it is necessary to spend 2 times more energy than its subsequent combustion.

- Explosiveness: people became convinced of the ability of hydrogen to easily explode during the crash of the Hindenburg airship, the cylinder of which was filled with this particular gas.

- The complexity of the preparatory process: getting hydrogen from water is half the battle. To be used effectively in heat generators, it must be supplied at a stable pressure, which requires a compressor and an additional tank with a reducer. In addition, you will need to get rid of water vapor, which will require the use of a dehumidifier.

We recommend: Pandora's Box - Engine on water or What is Brown's gas?

Thus, the installation for producing hydrogen turns into a whole plant, which not every homeowner will be able to purchase and host.

Technical components of a heating system

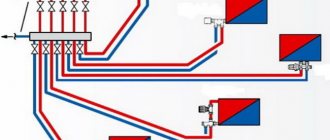

The design of a hydrogen heating system is extremely simple and consists of two structural elements:

The boiler is the most important element in which the process of hydrogen production occurs. The boiler includes such structural units as:

- An electrolyzer is a device where the electrolysis reaction actually occurs, as a result of which water breaks down into oxygen and hydrogen. Its cavity is filled with water, in which metal plates with the highest current conductivity are placed. Special wiring is connected to them, through which current is supplied.

- Burner valve - located at the top of the device to make it easier for the resulting gas to overcome the barrier and flow directly into the burner.

- A burner is an element into which a spark is supplied and the resulting gas begins to burn, releasing heat.

Pipes - provide heat through water heating, which allows you to heat the entire house.

Pros and cons of heating

Among the advantages that allow you to use this type of heating in everyday life are the following indicators:

- Absolutely environmentally friendly - water breakdown products (hydrogen, oxygen and steam) do not affect health even during combustion.

- The maximum efficiency level, reaching 96%, is much higher than the same coal, diesel or natural gas.

- The use of hydrogen as an alternative source of energy resources can significantly save reserves of exhaustible natural resources, reducing their production several times.

- Low cost - for heating residential buildings, the cost of the system is insignificant, and the simplicity of operation, based on the primitive chemical reaction of electrolysis, allows you to assemble the system yourself.

Hydrogen heating: myth or reality?

A generator for welding is currently the only practical application of electrolytic water splitting. It is not advisable to use it for heating a house and here's why. Energy costs during gas-flame work are not so important; the main thing is that the welder does not need to carry heavy cylinders and fiddle with hoses. Another thing is home heating, where every penny counts. And here hydrogen loses to all currently existing types of fuel.

Important. The energy costs for separating fuel from water by electrolysis will be much higher than explosive gas can be released during combustion.

Serial welding generators cost a lot of money because they use catalysts for the electrolysis process, which include platinum. You can make a hydrogen generator with your own hands, but its efficiency will be even lower than that of a factory one. You will definitely be able to get flammable gas, but it is unlikely to be enough to heat at least one large room, let alone an entire house. And if there is enough, you will have to pay exorbitant electricity bills.

Rather than wasting time and effort on obtaining free fuel, which does not exist a priori, it is easier to make a simple electrode boiler with your own hands. You can be sure that this way you will spend much less energy with greater benefit. However, DIY enthusiasts can always try their hand at assembling an electrolyzer at home in order to conduct experiments and see for themselves. One such experiment is shown in the video:

Factory and homemade installations

In terms of meaning, do-it-yourself hydrogen heating generators are not much different from analogues that were produced at the factory. Their operating principle is identical, the only difference is the selection of material, as well as other components. Many users and supporters of hydrogen heating agree that creating a system with your own hands is:

- profitable - the selection of materials is made at your own discretion;

- convenient - you can save on minor elements;

- simple - no need to resort to the help of specialists;

- reliable - you yourself are responsible for the quality, which gives you the right to choose materials that would satisfy all your needs.

Some users complain that Chinese units, which are more affordable, break down after the heating season. Moreover, their repair in most cases requires large investments. While a homemade installation guarantees that its productivity will be at the highest level, and any breakdowns will be eliminated as easily and quickly as the system itself was assembled.

Manufacturers of factory hydrogen heating systems

Among the most popular models of factory-installed hydrogen generators are the following:

- MegaTank100 is an electric hydrogen generator powered by the network. It has several levels of protection systems against short circuits and overheating, which makes its operation more productive and less dangerous. Its cost is 55,000 rubles, depending on the configuration.

- STAR-2000 - is capable of heating an area of about 250-300 square meters, has economical energy consumption, but has a high price - 230,000 rubles.

- Kingkar - has high performance, works on the network, but its cost exceeds 100,000 rubles.

- H2-2 is an Italian manufacturer that provides a good hydrogen generator capable of heating from 300 square meters of area while minimizing energy consumption. Its price is about 250,000 rubles.

- Free Energy - has a multi-level pressure and voltage regulation sensor, but most processes are fully automated. Costs from 15,000 rubles to 35,000, depending on the expected heated area and power.

Hydrogen boilers have one distinctive feature - the type of power supply. Among the most popular electric ones, there are also gas ones. The design of the boiler itself, as well as its cost, varies depending on the type of power supply. Boilers adapted for the electrolysis process using electricity are the most economical, but have an increased level of danger.

Making a simple hydrogen generator with your own hands step by step

We'll tell you how you can make a homemade generator to produce a mixture of hydrogen and oxygen (HNO). Its power is not enough to heat a house, but for a gas burner for cutting metal, the amount of gas produced will be sufficient.

Rice. 8. Gas burner diagram

Designations:

- a – burner nozzle;

- b – tubes;

- c – water seals;

- d – water;

- e – electrodes;

- f – sealed housing.

First of all, we make an electrolyzer; for this we need a sealed container and electrodes. As the latter, we use steel plates (their size is chosen arbitrarily, depending on the desired performance), attached to a dielectric base. We connect all the plates of each electrode to each other.

When the electrodes are ready, they must be secured in the container so that the connection points for the power wires are above the expected water level. The wires from the electrodes go to a 12-volt power supply or car battery.

We make a hole in the lid of the container for the gas outlet tube. Ordinary 1-liter glass jars can be used as water seals. We fill them 2/3 with water and connect them to the electrolyzer and burner, as shown in Figure 8.

We recommend: Hydrogen heating boilers: why you should not choose a hydrogen fuel boiler for heating a private home, review and comparison of efficiency and cost-effectiveness, the best models and their prices

It is better to take a ready-made burner, since not every material can withstand the combustion temperature of Brown gas. We connect it to the output of the last water valve.

We fill the electrolyzer with water to which ordinary kitchen salt has been added.

Apply voltage to the electrodes and check the operation of the device.

Project (drawing)

To make the generator, you will need a hermetically sealed container, which will be filled with water before starting hydrogen production.

The electrodes located inside will look like a set of plates (16 pieces will be needed), installed with a gap of 1 mm.

To ensure this, nylon spacers must be placed between the plates (any other dielectric is allowed).

A distance of 1 mm is optimal: if you increase it, you will have to increase the current strength; When the gap is reduced, the escape of gas bubbles will be difficult. The plates will be alternately connected to the anode and cathode of a 12-volt power supply. In this case, they must be put on an axis, also made of dielectric material.

Once the electrodes are attached to the holder, it will need to be attached to the housing cover from below.

To select the gas mixture, a tube from a conventional dropper is cut into the housing cover. In addition, it is necessary to drill two more holes through which the wires will be passed. After assembling the installation, all holes in the cover will need to be sealed using silicone sealant or glue.

An important component of the generator is the water seal. To make it, you will need a small container (a regular bottle will do) into which you will need to pour water before using the device. In the hermetically sealed lid, you need to drill two holes: into one we pass the tube from the generator (it must be lowered to the very bottom), and into the second - another tube through which the gas mixture will flow to the burner. The holes in the water seal cover must also be sealed. Water should be poured into the bottle to ¾ of its volume.

In order for the water poured into the generator housing to have better conductivity, you need to add a couple of tablespoons of table salt or caustic soda (sodium hydroxide) to it.

Selection of electrodes

The material from which the electrodes will be made must have low electrical resistance and be chemically inert with respect to oxygen and substances present in the solution.

If the second requirement is not met, a chemical reaction will take place with the participation of the electrodes connected to the cathode pole, as a result of which the solution will become saturated with foreign substances.

This is why copper, one of the best conductors, cannot be used in an aqueous solution. It is recommended to use stainless steel instead. The optimal thickness for electrode plates made of this material is 2 mm.

Container

Taking into account the risk of explosion, the generator housing should be made of durable and plastic material that is resistant to high temperatures. Steel best meets these requirements. It is only necessary to completely exclude contact of wires or electrodes with the housing, which will result in a short circuit.

In residential and commercial buildings, polyvinyl chloride pipes are widely used to organize water supply. Using PVC pipes for water supply: advantages, disadvantages, installation features and technical characteristics.

Connecting to a power source

Connect the terminals of the container screws to the positive and negative terminals of the DC power supply using clamps. If the wires don't make a convincing connection, use wing nuts instead.

You can connect it directly to the battery, the negative contact is connected to the same terminal of the battery, and the positive contact is connected to the ignition relay of the fuse box. This is necessary so that the generator turns on only when the car is also turned on.

It will not be possible to make a full-fledged hydrogen engine for a car with your own hands, since the technology is quite complex.

Fasteners

The fasteners must also be made of stainless steel so that the materials match each other. It is important to ensure a tight fit of all elements, which will prevent sparking. Remember that you are dealing with flammable gas.

In our particular case, we assemble a system of 16 plates with a distance between them of about 1 mm. The larger surface area, plate thickness, and bolts allow higher currents to pass through the system without resistively heating the metal. The total capacitance of the electrodes is -1nF when measured in air. This set of electrodes can be used in simple tap water up to 25A.