Rules for installing a stove on a wooden floor

If the stove is installed on a floor made of flammable materials, you will need to install a layer of thermal insulation and lay a protective board on the floor.

Metal furnace

If you plan to install a large cast-iron stove, then the foundation, which must be equipped for a heavy structure, will serve as protection against deformation and fires.

You can not install a foundation under a steel stove or make it out of 2-3 rows of bricks:

- The wooden floor is disassembled taking into account the protrusions beyond the dimensions of the stove. This must be done carefully so as not to damage the entire floor structure.

- The first row of bricks is laid out on edge. In our work we use cement mortar with the addition of clay.

- The second row is laid out with the recesses downwards and a cavity can be left in the middle to separate the collection of ash and additional ventilation when igniting the stove.

If you need to build a foundation for a cast iron stove on finished floors, in this case it is better to use a base design with 4 pipes and a concrete slab:

- The floor is disassembled similarly along the contour of the slab.

- In the corners, 4 holes are drilled or drilled according to the diameter of the support pipes.

- The supports are lowered into the holes and cemented.

- Along the top, we fasten the individual pipes with an angle into a single structure and weld steel rods along the diagonals to reinforce the slab.

- We install the formwork and pour the foundation slab under a heavy cast iron or steel stove.

Important! The foundation for iron stoves on wooden floors should be 400-500 mm larger than the dimensions of the heating device on each side.

You can make protection from 3 layers. To do this, a CSP board (cement-bonded particleboard) is fixed to wooden floors with self-tapping screws. A layer of brick is laid on it. It will serve as a heat accumulator and a stainless steel or galvanized sheet with a glossy surface is placed on top. This layer will reflect thermal energy and the heat will quickly spread throughout the room.

Brick kiln

For a brick kiln, no additional protective measures are required. It is laid out on a prepared foundation, which is initially made taking into account fire safety requirements and SNiP standards. Laying an additional layer of thermal insulation is not required; the brick itself will cope with this work.

Installation procedure

Of course, the simplest solution is to order a stove for your dacha with installation. However, installation often costs more than the product itself, and pride can suffer: is an adult really not able to do such a simple job on his own? Let's get acquainted with other people's experience - study the report on the installation of a buleryan stove by one of the regulars of the dacha forum.

A 100-kilogram buleryan was brought into the house.

The first stage is to perform a fireproof cut for the chimney. The wall of the frame house between the posts is carefully drilled out and sheathed with galvanized sheets with an asbestos sheet lining.

Like that.

Next, a support bracket for the chimney was made. Since welding was not available, it was bolted together; The only tools needed were a drill and a grinder. The wall frame had to be strengthened for the bracket; a tee with a container for collecting condensate was immediately installed on it.

Bracket with tee.

By the way: if your site is not electrified, and you don’t want to work with hand tools, renting a diesel generator for your dacha may be a solution. With a power of 2-4 kW, it costs 800-1200 rubles per day.

The inner surface of the wall around the cutting area is prepared for the proximity of a hot stove: it is lined with asbestos sheets and sheathed with galvanization.

Protective screen on the wall surface.

The owner of the stove approached the installation of the base with all seriousness.

- The first layer was thick porcelain stoneware, laid out on a wooden floor and secured with ordinary screws along the edges.

- Asbestos and a thin layer of basalt wool were laid on top.

- The cake was covered with a galvanized sheet, secured around the perimeter with galvanized screws. A low side was made along its perimeter, which will prevent drafts from carrying wood chips and spilled ash throughout the house.

Base assembly.

The oven is connected to the tee through an adapter mounted on heat-resistant silicone sealant.

After installing the adapter.

The last stage is assembling the chimney and fixing it to the wall with clamps. In our case, a sandwich pipe was used; five meter pipes provided the required height, taking into account the distance from the ridge.

Assembled chimney.

Steel and cast iron fireboxes

Steel and cast iron fireplace inserts with glass doors are a combination of fireplace and stove. The configuration of the firebox in this case is very similar to the classic options, due to which the maximum amount of thermal energy enters the home. The damper and transparent door provide not only visual observation of the burning flame, but also a adjusted dosage of air necessary for combustion.

Developed fins are used on the metal body, which, together with the large area, leads to a noticeable increase in the convective heat supply to the room, compared with a brick fireplace. Such design solutions make it possible to increase the efficiency level of modern fireboxes to almost 80%. These effective, inexpensive, compact and visually attractive products are lightweight.

The presence of these undeniable positive qualities explains the high popularity of steel fireplaces. Their only noticeable drawback is the rapid cooling of the heated surface. On the other hand, cold rooms are heated at a high speed, and one stack of firewood lasts for a long time.

The degree of heating of a metal combustion surface is an order of magnitude greater than that of a thick-walled brick structure. Because of this, you need to carefully plan where to place the stove in a wooden house: placing it close to the walls is strictly prohibited. The minimum possible distances to combustible wooden structures are indicated in the accompanying documentation for the operation of the firebox. In their absence, the guideline is the building codes on how to properly install a stove, which contain corresponding regulations for fireplaces.

It is prohibited to install an unlined iron stove closer than one meter from an unprotected wooden wall. Closer placement is permitted only if there are fire-resistant heat-insulating screens on the walls. This kind of protection is available for sale in many variants of substrates for stoves in a wooden house. The simplest and most inexpensive of them is 50 mm thick stone wool, gypsum fiber boards and a 20 mm air layer. As a result, the total distance between the rear and side walls of the metal firebox and the wooden surface will reach 100 mm.

Pouring a monolithic foundation

It is carried out according to the rules for installing a stove in a bathhouse, exactly according to the diagram it is necessary:

- To carry out the main excavation work - carefully dig a small vertical pit 1.5 m deep so that on all sides of the perimeter it is 10 centimeters wider than the future foundation. To speed up the process, it is possible and even recommended to use special equipment.

- Set up a sand-crushed stone cushion - fill the bottom with river sand, compact it, watering it with water. At the same time, mix the fine-grained material in a ratio of 1 to 1, then lay it in an even layer of 15-20 cm.

- Mix the “milk”, that is, not a thick cement mortar, then gradually pour it into the pit. Allow time to harden so that the crushed stone and gravel adhere firmly.

- Waterproof the initial layers of the base using roofing felt or liquid bitumen.

- Assemble the formwork - make panels from plywood (or boards, as an option), nailing them together or fastening them with screws, and then placing them in the pit. Align vertically (the height of the structures here should rise right up to the finished floor), check the diagonals, making sure that the finished sole will be in the shape of a rectangle (square).

- Reinforce - tie the frame (10 cm less than the perimeter and height of the formwork) with wire and place it inside.

- Pour - prepare a solution (in a ratio of 1 to 2.5 to 4 from sand, cement and crushed stone, respectively), mixing thoroughly, and tie it in layers with everything that was placed in the foundation pit earlier. Don’t forget to compact it with an in-depth vibrating device or a regular rod. Allow to dry for 3 weeks, then remove the formwork and fill the resulting voids with a mixture of sand and soil.

- Waterproof the finished concrete slab, first leveling it with grout (if necessary). To do this, lay the roofing material in two layers, fastening each with liquid bitumen mastic.

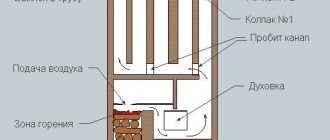

General description of the device

The number of different fireplace models is extremely large. The complexity of installation will depend on the type of fuel, the structural features of the house and the firebox material. According to the type of body, the hearths can be straight or angular; the first type is also divided into built-in and wall-mounted structures.

Depending on their location, fireplaces are classified into:

- an autonomous structure that is installed in the center of the room, regardless of the presence of nearby walls;

- frontal devices that are built near the walls;

- corner fireplaces, which are installed in the corner of the room.

In this video we will look at installing a fireplace:

Types of fireboxes

The heating device market offers a large number of different types of furnaces for heating devices that run on alternative fuels and can be installed without a chimney pipe in premises of any purpose. Depending on the type of fuel used, a fireplace in a log house can be:

- Classic (solid fuel). You can put coal or firewood into the firebox of these devices. They are equipped with standard chimney structures. In this case, installing a fireplace in a wooden house with your own hands requires pouring a foundation independent of the base of the building, as well as thermal insulation of floors and surfaces that come into contact with the fireplace.

- Gas. In this device, there is a burner inside the chamber. Liquefied or natural gas can be used as fuel. Installing a fireplace in a wooden house will require the same measures as with traditional types of equipment, including a chimney.

A fireplace is not only a decorative element but also a means of heating in your home.

- Biofireplace for the home. This device is considered a new type. Ethanol is used as fuel for such a fireplace. Inside the combustion chamber there is a burner and a container intended for refueling. The main advantage of this device is the absence of ash, soot and other harmful combustion products for the human body. To completely heat a room, this device is not enough, since its main purpose is decorative. Biofireplaces can be floor-mounted, wall-mounted, table-top or hanging. The peculiarity of the devices is the release of steam during combustion, which humidifies the air in the room. There is no need to build a chimney.

- Electric fireplace. This equipment is considered the most reliable in terms of fire safety. These devices do not have an open flame, and the air is heated by a hot electric coil. An imitation of a real hearth is created using lighting - a decoration that is located inside the device. Electrical equipment is easy to install, since it does not require pouring a foundation or installing a chimney. This device will be an ideal solution for installation in attics and on the upper floors of the house. The main thing that is needed is proper electrical wiring and reliable insulation that can withstand high loads.

Selecting a location

Before installing a fireplace in a wooden house, you need to choose the right location. Do not allow hot surfaces to come close to wooden elements

Please pay attention to the following important requirements:

- The installation of a fireplace cannot be done in small spaces, since combustion requires a sufficient amount of oxygen. To heat large areas, you need to use air ducts.

- It is not recommended to install the fireplace opposite window and door openings, since drafts can cause smoke in the room.

- The proposed installation of a fireplace is foreseen at the design stage of the house.

- The ideal solution for the location of the fireplace in the house is to install it in the center of the room, without reference to the surface of the walls.

Find the best fireplace location in your home

Chimney installation

First of all, a chimney should be installed to the selected location of the fireplace. The chimney is one of the most important elements of the heating system, as it is responsible for the timely, safe and correct removal of combustion products from the firebox.

Installation of a smoke exhaust route can be divided into the following stages:

- chimney foundation installation

- collection of modular chimney elements

- wall mount

- passage of floor slabs to the next floors

- passage of roof slabs to lead the pipe to the roof

- assembly of the following sections of modular chimney elements

- carrying out sections of the chimney through the ceilings and roof

- attaching the chimney to walls or supporting structures

- installation of components - umbrellas and brackets on the roof, valves and revisions in selected places of the smoke route

- insulation of the chimney in areas adjacent to the walls, in places of passage through floors, walls, ceilings, ceilings and roofs

- connecting the chimney to the heating device

How to install

The installation location is selected in advance, long before the installation process. When building a cottage or house made of wood, the foundation is laid so that in a certain place a monolithic concrete slab can withstand a load of up to 300 kg. They are also thinking about ways to heat the second floor in a two-level building. For this purpose, a small stove-stove is provided or steam heating is carried out. This will cost you a lot, so you should worry in advance about installing a steam boiler and filling it with water in a timely manner. If you want to use the stove for cooking, an outside wall is the best option. First of all, you need to be careful when connecting to the stove if they are combined for cooking.

Stoves located in the center of a wooden house perfectly warm the entire room. According to the standards, a metal sheet is laid out in front of the fireplace, which is not capable of burning even with prolonged exposure to fire. The distance from the stove doors to each of the walls and ceiling should exceed 125-130 cm, and the side walls of the fireplace should be at least 50 cm away from the wall.

Stages of installing a fireplace stove:

- Preparing the floor. It is necessary to lay the base out of brick. It is mounted smoothly using plasterboard, plywood or glass magnesite, cut with self-tapping screws. If the slabs gradually merge into the floor surface or a ceramic podium is built, the structure looks especially beautiful.

- Installation of walls made of fireproof material followed by cladding.

- Finishing the base with tiles. The walls are primed twice and covered with ceramic tiles fixed with heat-resistant glue.

- Equipping the stove with a chimney or flue.

It is important to beautifully decorate all parts of the fireplace so that they look organic in the interior of a wooden house and are in harmony with each other. For example, decorate the ladle and add decorative elements so that it does not look out of place next to the stove.

As for chimneys, modern types are assembled from ready-made elements using the “sandwich” principle. For comparison, we can cite asbestos or brick chimneys. The last one will last longer than the others. The easiest way is to vent the chimney not through the ceiling, but through the wall.

The main material used to lay the fireplace is solid ceramic brick. Brick grade – up to 250 kg/cm2. Bricks of the same size and washed in clean water are connected to each other using a refractory mortar. Stove fittings made of cast iron include:

- blower, combustion and cleaning doors;

- grate;

- valves and dampers;

- stoves and oven.

The layout of the stove must not be disturbed, and the first row must be done especially carefully. After laying the second and third rows, guides are erected in the corners. These are driven nails or wedges and slats secured from the ceiling. The seams are grouted with a fire-resistant grout. Then they begin to install the metal parts - grilles and doors, drilling holes if necessary. Since the thermal coefficients of metal and brick are different, when installing cast iron parts, gaps are left. The grate is mounted with a bevel so that the coals roll towards it.

A properly installed fireplace stove will become a decoration in your home. The installation price does not exceed two and a half to three thousand rubles.

How to choose a stove for your home

When choosing a heating stove for a frame-type house, consider not only the cost and appearance, but also the technical characteristics of the equipment.

The main purpose

First of all, you should consider the mode of stay in the house. That is, if you plan to use the building for permanent residence, then it is rational to install a stove with high thermal inertia, since the heat will last a long time and you will be able to heat it less often. If the house is used as a summer cottage in the summer season, and only sometimes in winter, then it is more rational to install a fireplace. A compromise option in this case would be a fireplace stove.

In addition, you need to ask yourself the question: will the stove be used only as a heating device or for constant cooking?

Choice of power and location

The required power is determined at the rate of 1 kW per 10 sq. m of room area with an average ceiling height of 2.5 m.

The power of a factory-made furnace can be easily found in the technical data sheet

Determining the power of self-built stoves is not an easy task, when solving it it is necessary to take into account the influence of many parameters: surface area, firebox volume, type of fuel used and others. The average value can be obtained by multiplying 400 kcal/h by its free surface area.

As for the location, do not forget that fireplace stoves can heat the air in no more than three adjacent rooms. The ideal place to install a fireplace stove in a frame house is the living room, where time is most often spent.

A good solution for placing the stove is in the wall. Thus, adjacent rooms will be heated from it. In the end, the best option is a stove with a heat exchanger or a water boiler. In this case, the location no longer matters much.

Material

When building a brick oven in a house, you can be sure that all the individual wishes of its owners will be taken into account. But this will require a certain time investment in finding a good craftsman, and the construction process itself can drag on for a long time. That is why factory-made heating stoves have become most popular.

To heat the air in the room faster, the best option is a stove-fireplace made of sheet steel. It heats up instantly, but cools down faster than cast iron.

The main stages of installing a fireplace or stove

Installing a fireplace in a house is carried out step by step in the following steps:

- choosing a location for installing a stove or fireplace

- identifying the technical feasibility of installing a fireplace in a chosen location and running a chimney to it

- calculation of technical parameters and requirements

- preparation of a design plan for the installation of a chimney and heating device

- choice of firebox, lining or finished stove

- selection of chimney and components

- construction of a smoke exhaust route

- installation of the hearth, assembly of all structural elements

- connecting the chimney to the stove or fireplace

- installation of fire walls, bases, foundations, protective insulating materials in areas adjacent to the heater and chimney

- commissioning, testing of equipment and correct operation of all systems

Selection and types of devices

A fireplace cannot replace a stove, as it ventilates rather than heats the room. But a clear advantage is the ability to observe long-term combustion and the type of flame. A difficult decision in choosing the type of heating is the combination of a fireplace and stove. True, it will be more difficult to make such a system correctly with your own hands. Installing stove appliances will require care and precision, especially at the junctions of the stove and oven. You can also use the services of a stove maker at your dacha if you discuss the details with him in advance so that you don’t have to wait a long time.

The stove in a wooden house can be either a purchased metal potbelly stove or a brick one. When choosing among them, consider the disadvantages and advantages of each type.

A metal stove has the following advantages:

- long service life;

- quickly heats the room;

- unit of reliable design;

- any fuel is suitable for heating a potbelly stove;

- the temperature can be controlled by installing oven devices;

- reasonable price for potbelly stoves.

The fact is that rapid cooling is directly proportional to heating, and this is one of the disadvantages of metal structures. They need to be looked after. For a large room this type of heating is not economical. It will be more difficult to use it for cooking purposes if there is no stove.

It is more appropriate to install a brick oven at the dacha because of its undeniable advantages:

Turnkey installation of stoves and fireplaces in Moscow and the region

If you require competent, correct and professional installation of a fireplace in your home, the price for the services of installation specialists from our organization will pleasantly please you. Depending on your budget and wishes, our managers will draw up an individual commercial offer for you and an adequate price list, which may include both individual services and turnkey installation. The cost of our services is at a level favorable to clients, and the purchase of a stove or fireplace, chimney, components and insulating materials for your convenience can be carried out in one place with reliable guarantees provided - both for the equipment itself and for related services. Our engineers and designers will also prepare a full technical calculation for you, identify the possibility of installing a fireplace and chimney duct, and if this is not possible, offer alternative solutions - for example, an electric fireplace, a boiler and other options.

In our company you can buy a fireplace with installation by competent certified specialists with a full package of guarantees for the work performed. Long experience in the Russian heating market, a staff of professionals in their field, thorough knowledge of fire safety rules, instructions and guidelines, standards and norms in force in Russia and Europe, allow us to provide services of the highest quality.

Firing the furnace before installation

It is carried out outdoors, as increased formation of caustic gas is possible. First you need to treat the heating unit with an anti-corrosion agent, and at the same time carefully inspect for cracks, chips and other defects on the grill, door, heat exchanger, and also make sure that there are no cracks or gaps. Then:

- Place the equipment on a flat and heat-resistant base, connect a temporary chimney (longer than 200 cm).

- Load firewood up to half the volume of the firebox and set it on fire (with the door loosely closed), maintaining the flame for an hour.

- Wait until the fire goes out (do not extinguish it).

Thanks to this, the internal coating of the heat generator will finally harden, and it will be possible to proceed to permanent operation.