About stoves

Such designs have their advantages:

- low heat capacity, but increased heating;

- increased heat transfer from one unit of active volume;

- the small weight makes it possible to install without first making a foundation (see article “Foundation for a stove - and not vice versa”);

- ease of manufacture and low cost: a qualified specialist can carry out installation in 4-5 hours ;

- It is possible to use any type of solid fuel.

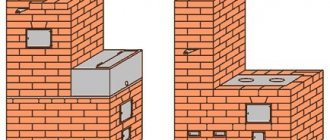

There are three types of such structures:

- frame thin-walled stove;

- frame thick-walled stove;

- small-sized frame oven.

Construction stages

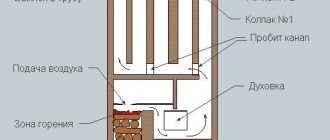

From the name of the fuel system you can understand that the main component will be the frame. You should retreat 15 cm from the masonry and install the frame near the chimney. Here you will need to make sure that all the holes for joining match.

We advise you to read more about the technology of laying a brick stove on our website.

Advice: If a metal pipe is used as an outlet, then at the first stage you should install an outlet from the pipe, and only then install the frame.

Before installing frame stoves for a cottage, garage or country house, you first need to familiarize yourself with the basic recommendations for installing the frame.

Installation of a frame stove

The very name of the stove indicates that the base for the stove is a frame. It should be installed near a stationary chimney, which must be mounted at a distance of 15 cm from the masonry. In this case, the vertical axis of the rear wall and the connection hole must coincide.

If you plan to use a metal pipe to remove exhaust gases, then you should first make a drain from this pipe, make fireproof cuts, and only after that install the frame in place.

General requirements for making a frame

The furnace frame is the foundation of the structure. It should be quite rigid and made of high-quality material.

- We lay the bottom on the horizontal corners of the bottom of the frame and install the lower sheets of the belt. To prevent the sheets from falling, they should be attached with temporary brackets, which can be made from wire with a diameter of up to 3 mm. And fasten them to the metal frame elements.

- We attach the fire door to the bottom façade sheet.

- On the very bottom of the frame we place a solution with a thickness of about 5 mm. Do not forget: the thickness of the seam directly affects the height of the masonry. The vertical seam can be increased to 15 mm.

- Before placing bricks on the mortar, the entire row must first be laid out dry. Only after this should it be laid out directly onto the solution.

- The seams should be carefully filled with mortar; air formations should not be allowed. Air should not be allowed to form in the seam between the facing material and the brick.

- Lay the material only in accordance with the order in which the location of each element is indicated. Follow the rules for installing stove appliances and follow all dimensions exactly.

- The fire door is usually located in the 4th and 5th rows of masonry, which are placed on the edge. The standard combustion door has a height of 206-210 mm. The connection is made to the bottom sheet, which is pre-cut. The masonry, made on an edge in two bricks, is 245 mm.

- The lower facade sheet is cut in such a way that the upper part of the brickwork in the fifth row coincides with the upper flange of the firebox door of the frame. A gap of 35-49 mm is formed between the brickwork in the third row and the bottom flange of the frame. This gap should be filled with broken bricks and mortar.

Please note that the doors of the structure must not be clamped with brickwork. If the brick fits very tightly in the 4th and 5th rows, trim the elements using a grinder and a concrete circle. It is better to fill vertical seams between the brickwork and the fire door with wet asbestos, but not with mortar. Install the cooking chamber.

- At the heating and cooking furnace, it is impossible to allow the sheet steel flooring to be clamped into the brickwork. In the eighth row you will need to make a selection in the material; this can be done with a hammer or grinder. Make the length of the groove along the entire length of the brick.

- With your own hands, you can easily make a connecting smoke pipe from sheet iron in the amount of two pieces and with a size of 270:390 mm. The sheets should simply be bent into a box with a right angle and one inserted into the other. One end of the pipe must be inserted into the connecting hole to a depth of about 70 mm. The second is inserted 60 mm into the exhaust gas outlet hole. After laying the furnace, the part of the pipe that is located outside should be wrapped in wet asbestos sheets. After this, twisting is carried out using steel wire and plastering with a clay-cement solution. When using steel wire, it must first be annealed so that it acquires the desired ductility.

- The chimney can be installed round with a diameter of about 120 mm or square with a cross-section of 130:130 mm. It is made from several sections, assembly is carried out on site.

- A frame oven will look like a complete structure if you cover it on top using a lid or sheet steel.

- The grate can be made as follows. You should find 7 metal rods with a diameter of about 12 mm, take a couple of pieces of wire rod with a diameter of 6 mm and a length of about 130 mm and 12 washers with a thickness of more than 6 mm, in which the hole should also be 6 mm.

- For a small frame stove, 7 steel rods for the grate are cut, about 140 mm long. After this, you should drill holes with a diameter of 6 mm at each end of the rod. One of the ends is riveted and washers are put on the rod, after which the other end is also riveted.

- For heating-cooking and frame-heating stoves, 7 rods with a length of 190 mm are made. Holes are drilled along the edges at a distance of 170 mm from each other with a diameter of 6 mm. The rest of the details remain the same.

Flaws

Frame stoves are characterized by uneven heat transfer. Therefore, the air temperature in the room will constantly fluctuate. If such a structure is installed against a wooden wall, then fire safety rules must be strictly adhered to. To ensure that the draft does not decrease, condensation does not fall out, or the flue gases do not become noticeably supercooled, it is necessary to insulate the chimney with slag wool, asbestos, or plaster it, having previously wrapped the pipe with a metal mesh.

Let's summarize

Having weighed all the pros and cons, it can be noted that frame stoves have high heat transfer, but they transfer heat unevenly, as a result of which temperature fluctuations may be observed. Such a structure can be built in any room and given a beautiful appearance using modern facing materials. In addition, to heat such a stove you can use any type of fuel, from wood to coal.

- Cast iron fireplace inserts: model options and installation

- How to make small stoves for a summer residence

- How to make a chimney out of brick

- How to choose and what kinds of wood-burning stoves there are

Manufacturing of thin-walled frame furnace

The thin-walled frame oven weighs about 300 kg. A foundation is required for its installation. The bathhouse design provides for an attached pipe, which must be connected to the wall chimney (see article “Calculation of a chimney - possibilities and reality”). Its heat output is 1.2 kW, which the furnace produces when running two fireboxes throughout the day.

Accessories

To carry out the work we will need:

- ordinary solid brick – 64 pcs.;

- refractory brick – 16 pcs.;

- ordinary clay – 40 kg;

- river sand – 90 kg;

- metal corner 2.5/2.5/0.3 cm – 10 kg;

- steel strips 3/0.4 cm - 2 kg;

- asbestos-cement sheet 5 mm thick – 2 m²;

- grate 13/13 cm – 1 pc.;

- combustion door – 25/20.5 cm – 1 pc.;

- sheet steel with a thickness of 1 mm – 12 pcs.;

- roofing steel – 7 kg;

- valve with pipe.

Making a frame

When lining the furnace with a small-sized sheet of metal or asbestos cement, in addition to the corner that forms the lower and upper chords of the frame, strip steel is also used, which should be installed at the joint points of the facing material. For quick installation, it is allowed to use bolted connections in the structure.

- The oven frame is made from a 25/25/3 mm corner, which includes vertical posts.

- In the lower belt, front corners and gussets are attached by welding.

- In the upper belt, the linings and front corners are fastened. The linings use 40/3 mm strip steel.

This installation allows you to form the rear and front pivot frames. They are equipped with stripes and side corners.

- The overlays must be located inside the frame joints. Asbestos-cement sheets should be cut in accordance with the overlays.

- For technological execution of bolted connections, holes should be made in the plates and welding should be done flush with the inner plane of the nut.

- The furnace fittings and cleaning doors should be attached to the front frame of the frame.

- When preparing the frame, the facing material should be cut at the same time. You can paint it to match the color of the room.

How to choose a stove for your home

When choosing a heating stove for a frame-type house, consider not only the cost and appearance, but also the technical characteristics of the equipment.

The main purpose

First of all, you should consider the mode of stay in the house. That is, if you plan to use the building for permanent residence, then it is rational to install a stove with high thermal inertia, since the heat will last a long time and you will be able to heat it less often. If the house is used as a summer cottage in the summer season, and only sometimes in winter, then it is more rational to install a fireplace. A compromise option in this case would be a fireplace stove .

In addition, you need to ask yourself the question: will the stove be used only as a heating device or for constant cooking?

Choice of power and location

The required power is determined at the rate of 1 kW per 10 sq. m of room area with an average ceiling height of 2.5 m.

The power of a factory-made furnace is easy to find in the technical data sheet. To compare with the required one, you should pay attention to the rated power at which the stove can operate for a long time without consequences.

Determining the power of self-built stoves is not an easy task, when solving it it is necessary to take into account the influence of many parameters: surface area, firebox volume, type of fuel used and others. The average value can be obtained by multiplying 400 kcal/h by its free surface area.

As for the location, do not forget that fireplace stoves can heat the air in no more than three adjacent rooms. The ideal place to install a fireplace stove in a frame house is the living room, where time is most often spent.

A good solution for placing the stove is in the wall. Thus, adjacent rooms will be heated from it. In the end, the best option is a stove with a heat exchanger or water boiler . In this case, the location no longer matters much.

Material

When building a brick oven in a house, you can be sure that all the individual wishes of its owners will be taken into account. But this will require a certain time investment in finding a good craftsman, and the construction process itself can drag on for a long time. That is why factory-made heating stoves have become most popular.

If you choose between cast iron and steel stoves for a frame house, it is important to know that cast iron has a greater heat capacity than steel. As a result, such furnaces require long-term heating, but are capable of delivering heat for a long time.

To heat the air in the room faster, the best option is a stove-fireplace made of sheet steel. It heats up instantly, but cools down faster than cast iron .

In addition, you should pay attention to the cladding material. When using ceramics or stone, the body takes longer to warm up, but the time for subsequent heat radiation increases significantly.

Useful: ZIPS: sound insulation for frame cladding