About the future design

The design of the oven for baking bread consists of the following parts:

- hearth (bottom or floor of the stove);

- vault (dome);

- entrance arch;

- chimney.

The device is installed on a special stand, which in turn rests on a foundation slab. The chimney pipe is located at the front of the structure. This position of the chimney helps to simultaneously heat the bread during baking from all sides.

This is explained by the fact that, under the influence of draft, the flames rise to the dome roof, envelop and heat the entire inner surface of the stove.

Photo of a wood-burning oven for bread

Unlike a Russian stove, this device has a less thick layer of masonry (12 cm), so it heats up faster. Bread can be baked within 45 - 60 minutes after the start of the combustion process.

Features of the bread chamber device

Regardless of what type of bread baking oven it is classified as, it must meet certain requirements. These requirements apply to the external and internal structure of the furnace.

- The dimensions of the chamber must exceed the total volume of the dough being placed, since during the baking process the products increase and this must be taken into account.

- To make high-quality bread, it is not enough just to have baking skills; you need to have the appropriate equipment. If you provide heating from below and from above, you can achieve uniform baking of the buns. However, such an idea can only be realized in electrical and oil-based devices.

If you remember how homemade bread turns out, the first thing that comes to mind is a textured crust. She is sweet for our memories, but is rejected by buyers. The presence of such a crust indicates a lack of moisture. Industrial furnaces are equipped with special devices that dose water in the form of fine dust.

Not every oven is capable of heating to high temperatures, due to its design features, and yet baking bread requires a temperature varying from 300°C to 500°C degrees.

Freshly baked bread from the oven

Materials

To build an oven for baking bread with your own hands with a diameter of up to 110 cm you will need:

- fireclay bricks – 260 – 300 pcs.;

- cinder block measuring 20x20x40 cm for laying a podium under the device;

- fatty clay and sand or ready-made fire-resistant masonry mortar Mortar “SHA-28”;

- reinforcing steel with a diameter of 10-12 mm;

- cement M50;

- basalt mineral wool slabs 5 cm thick;

- expanded clay - it can be replaced with perlite or silicate-calcium slab;

- OSB or moisture-resistant plywood;

- crushed stone and sand;

- pipe with a diameter of 100 - 130 mm made of stainless steel or ceramic;

- boards for formwork;

- waterproofing material - polyethylene or roofing felt.

Types of brick bread ovens

Electrical devices

Bread ovens are conventionally divided into several types depending on the structure and additional characteristics. It is believed that this type of design is the most cost-effective and convenient to use. Using electric ovens at home is convenient, and the cooking process does not take much time; the operating principle is the same as that of a multicooker. You need to select the desired program and pour the ingredients into the bowl, after a certain period of time, pick up the finished product.

Wood burning devices

This type is especially relevant for areas where there are problems with the supply of electricity and all cooking and heating occurs due to structures whose combustion is carried out by supplying firewood. A wood-burning baking oven has the following positive aspects:

- provides a unique taste and aroma of freshly baked sourdough bread;

- the ability to bake buns and bread in large batches;

- other dishes are also prepared in bread ovens;

- The dimensions of a wood-burning structure, as a rule, are not very large, so it can be built in any convenient place.

Brick devices

It is an ideal option for country houses and cottages. Brick ovens allow you to bake various types of bread in just half an hour. After completing the process of cooking bread products in a well-melted structure for another 8 hours, you can prepare many other dishes, such as jams, desserts, etc.

Tools

The set of tools must be prepared in advance and consist of:

- tile cutter;

- Bulgarians;

- containers for preparing mortar and concrete;

- shovels;

- electric drill with a mixer attachment;

- trowel;

- mallet hammer;

- rubber hammer;

- rules;

- clamps;

- saws;

- tape measure, plumb line and building level.

Furnace structure and operating principle

The operating principle of any oven is as follows: heating - loading dishes - baking process and maintaining temperature. Pompeian ovens are convenient for use in bakeries. Thanks to its dome-shaped shape, the heat is evenly distributed throughout the oven, which facilitates quick and even baking of any baked goods. Pompeii ovens consist of: a hearth (working surface), a dome, an arch and a chimney.

There are wood-burning stoves whose arches resemble the shape of a turtle's shell. They are also considered domed, but are intended exclusively for bakeries. Up to several tens of kg of baked goods can be prepared in such ovens at a time.

This stove cannot be confused with any other - it has an elongated mouth up to 1.5 m wide and several dampers. And if you look inside, you will be surprised by the internal scale of this equipment —

a loaf of bread for the whole country will fit here. In Russia, such stoves are not used. They can only be found in family bakeries. Other establishments prefer to use simple domed wood-burning stoves.

If the bakery’s workload is high, then two or more ovens are installed. (The amount of equipment depends not only on the workload, but also on how wide the range of dishes is on the menu).

One simple rule should be remembered: it is not recommended to cook meat dishes and bread at the same time in ovens —

The aroma from one product can be absorbed into another.

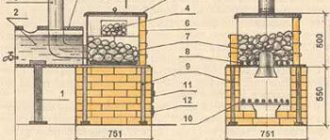

Scheme and dimensions

Its cost directly depends on the size of the device. The smaller its dimensions, the less construction materials and money are spent. However, there are certain sizing standards that, if changed, may reduce the efficiency of the furnace.

The most optimal size is considered to be a furnace with an internal diameter from 80 mm to 110 cm. The width of the arch at the entrance should correspond in size to the height of the dome, and its height should be equal to 0.6 radius.

Diagram of a wood-burning oven for baking bread

Schematic view of the stove

Classification

Baking requires a special type of oven with a bread chamber. Despite the same principle of making bread, ovens differ significantly from each other in a number of ways.

- Based on the heating method, furnace surfaces are divided into two types. Direct heat transfer is characterized by the fact that the surface is heated by the action of a flame. This type includes a wood- or gas-fired baking oven. Indirect exhaust furnaces use a specific medium as a coolant. Examples include electric, convection, and oil bakery ovens.

- Classification by type of heat channel implies the existence of furnaces made of materials with high heat capacity and low heat capacity. The first type includes brick structures, and the second type includes mechanical ones.

- In the distribution by type of fuel used, 4 groups are formed. Electric ovens are designed as compact devices in which you can bake 1-2 loaves of bread. Typically, such an oven is small in size and located in the kitchen of a house or apartment. Liquid fuel ovens operate on a more global scale, are massive and allow bread to be baked in large batches. This is a great option for small businesses. Wood-burning or gas structures can act as an extension to a stove or fireplace, or as a separate unit.

Industrial bread production

- Based on the method of placing products in the chamber, each model can also be classified into one of the groups. The storey placement method is represented by several shelves located in the chamber at a certain height. In order for the bread to be baked throughout its entire volume without the formation of burnt areas, it is necessary to swap trays located on different floors. Tunnel models do not make it possible to move bread to zones with different temperatures, but they allow you to bake products in huge batches. Such specimens can be found at factories that supply the needs of an entire city district. The rotary type of ovens rotates the trays around a vertical axis. In the horizontal plane in the chamber, the heating temperature is slightly different, so this rotation ensures uniform baking. The cradle oven is represented by pallets that can be moved vertically. Unique cradles allow you to place baked goods in a zone with a higher or lower temperature, at the discretion of the technologist.

Good to know: Stove-fireplace with oven, original design for home and garden

Features of operation

Before baking bread, the oven is heated for 2.5-3 hours, and then the ash residues and ashes are swept out of it. Another thirty minutes should be spent on uniform distribution of heat throughout the dome. You can then check the temperature using a bimetallic thermometer and begin cooking the product.

The lining layer of fireclay bricks with a porous structure is able to quickly absorb moisture and release it evenly during cooking, so baked goods from such an oven have a unique aroma.

Advantages of wood-burning baking ovens

- Firstly, dishes cooked in such an oven (including baked goods) are imbued with a pleasant woody aroma, which has the most favorable effect on their taste.

- It is for this reason that bread baked in a wood-fired bread machine will cost more.

- In addition, this stove is considered environmentally friendly, as it is made from natural materials. For example, Pompeian stoves are made of fireclay clay, due to which they hold the temperature longer and emit soft heat, unlike metal ones.

- The operation of this equipment does not depend on the availability of electricity. It is capable of baking bread even in field conditions.

- Economical fuel. Thanks to the use of wood material, the operation of this equipment will cost you much less than electric furnaces.

- Wood stoves are easy to install and assemble.

- Durable.

Often, the disadvantages of such equipment include its large dimensions, but this most often applies to Russian ovens and specialized ovens for bakeries. Dimensions of Pompeii dome ovens —

especially popular in Italy and enjoying no less success in Russia, much more modestly. For example, an oven with a load of up to 19 kg of bread at a time will fit in the kitchen of a bakery of any size, and a household oven for baking up to 6 kg can be installed even in a kitchen in a Khrushchev-era building.

Operating principle and device

Any oven for baking bread is first heated, and then the bread preparations are loaded into it. Modern ovens have a design similar to “antique” ovens; they produce the same aromatic and tasty bread as in brick hearth ovens. And all thanks to the system that is implemented in modern designs:

Operating principle of an industrial stove

The operating principle of a wood-burning bakery is based on a unique valve system, which allows you to maintain a high temperature for baking, even after the fire has finished. Many modern designs are equipped with control panels, which allows you to control the entire bread production process.