Charcoaling process

Not only firewood of various types of wood is used as wood raw material, but also waste from woodworking or furniture production: knots, hemp, sawdust. Peat is used in marshy areas.

During the charring process, wood goes through three stages: pre-drying, thermal decomposition and cooling.

The initial drying and heating of the raw materials in the chamber occurs due to heat supplied from the outside. The heat generation process itself (chemical exothermic reaction) begins when the wood temperature reaches 280°C. Further heat supply is no longer needed.

After burning, the finished coal is cooled to a temperature at which spontaneous combustion of coal is impossible, that is, below 40°C.

During the first day, the mixture of flue gases and charring products still contains a lot of water vapor, which is released during the drying process. Then the mixture becomes drier and can be used as additional fuel in the same stove or, more efficiently, in a nearby one.

Coal burning equipment

To produce charcoal, charcoal kilns of various capacities are used. Such coal is obtained through the process of pyrolysis, that is, the wood is burned without access to oxygen.

Charcoal kilns for the production of charcoal are available as stationary and mobile.

Stationary equipment is used by fairly large manufacturers for the continuous process of pyrolysis of large volumes of wood.

Large stoves are much more productive than mobile ones; they can use several types of fuel, but they are subject to high environmental safety requirements.

Mobile kilns are low-capacity, small in size, and are used either where raw materials are available, such as logging sites, or where the final product is needed, such as construction sites.

In mobile furnaces, the fuel is the same waste wood from which coal is produced.

If the furnace operates on waste, then the benefit is double, and coal is produced without additional fuel costs, and waste is processed, which would still have to be disposed of, costing money and time. This type of charcoal production is the cheapest.

Equipment used

The production of charcoal requires the use of equipment:

- electrical energy generator;

- device for splitting firewood of hydraulic type;

- charcoal kiln;

- chainsaw;

- scales.

The main equipment for the production of charcoal is a charcoal kiln. It is a mechanism in which wood burns to form coals.

The peculiarity of the technology is the need to use a special pyrolysis oven. In the process of pyrolysis, carbon decomposes with a small amount of oxygen. In special charcoal kilns, pyrolysis technology is used, in which the wood burns out, but does not burn completely, turning into coal.

The minimum cost of such stoves is 20-100 thousand rubles. These prices apply to equipment that has already been used. New furnaces with high productivity will cost several times more. Their price reaches 2 million rubles. Modern models are capable of processing wood down to the formation of coal dust, which is in high demand in a number of production areas.

The cost of a standard electricity generator is 20 thousand rubles. The minimum price for a chainsaw and scales starts from 5 thousand rubles. The average cost of all equipment is 150-450 thousand rubles. The final price depends on the quality and performance of the equipment.

Continuous charcoal burning equipment

A separate group consists of charcoal kilns, in which flue gases from burning fuel enter the chamber, pass through the wood, acquire vapors and gases that are products of drying and charring of wood raw materials, and exit outside. In them, the pyrolysis process occurs most evenly, since the wood is in direct contact with the coolant supplied from below. But pyrogases contain high concentrations of chemical compounds that are products of wood decomposition, so additional equipment must be installed for beneficial use or combustion of pyrolysis by-products.

This is how continuously operating vertical retorts work, in the chamber of which wood is dried at the top, pyrolysis takes place in the middle layer, and coal is calcined and cooled at the very bottom.

Charcoal kilns with replaceable containers or retorts also operate continuously. The principle of operation of such installations is that each subsequent batch of raw materials is heated to the required temperature due to the exothermic reaction in the previous one.

In this case, the process of coal formation occurs in each retort independently of the others, and the furnace, into the firebox of which pyrolysis gases are discharged, is located separately from the replaceable chambers.

Retorts and chambers for pyrolysis are made of metal with thermal insulation.

Retort furnaces for charcoal production

The advantage of a business based on the use of very cheap or free raw materials is high profitability and quick return on production.

Nature “produces” wood in sufficient quantities, so a coal production enterprise can operate year-round and at full capacity.

In addition, unlike the wood processing industry, the quality of the raw materials is of little importance, which allows the use of dead wood and trees that are dry and in an upright position.

This article will discuss a detailed plan for organizing a business for processing wood raw materials into high-quality coal for barbecue or for further use for medical purposes.

Our business assessment:

Starting investments – from 300,000 rubles.

Market saturation is average.

The difficulty of starting a business is 5/10.

Charcoal production equipment

If the extraction of raw materials for the production of charcoal will cost the entrepreneur very little, then purchasing high-quality equipment will require spending a lot of money. Even when opening a small business with a productivity of up to 0.5 tons per day, you cannot do without purchasing the following devices and mechanisms:

- Pyrolysis oven.

- Hydraulic cleaver.

- Chainsaws.

Pyrolysis furnaces for the production of charcoal come in two types:

A charcoal kiln for the production of charcoal allows you to establish a non-stop production process.

To install such equipment, you will need to rent or build a room, and raw materials will need to be transported to the processing site by vehicle.

Despite some difficulties in the process of setting up production, this version of charcoal burning equipment is purchased by the majority of entrepreneurs who decide to organize a business in the production of charcoal.

Modern charcoal kiln

Modern installations are retort furnaces for charcoal, in which the coolant is completely separated from the working chamber. Such equipment allows you to largely automate production cycles, which allows you to further reduce costs.

The mobile unit is a car trailer on which the pyrolysis oven is installed.

Such a furnace does not allow for a non-stop coal production process, and the output of finished products per unit of time will be significantly lower than that of stationary installations.

The advantage of a mobile furnace is that production can be moved directly to the logging site.

It is impossible to provide a mini-factory for the production of charcoal with a sufficient amount of raw materials using only the labor of hired workers.

In order to optimize costs as much as possible when preparing logs for heat treatment, you will need to purchase additional equipment.

The use of even one hydraulic splitter will allow you to produce a sufficient number of logs for the operation of a stationary stove in non-stop mode.

Such a device can be controlled by one operator, so it is enough to hire 2 - 3 people for a non-stop charcoal production cycle.

The hydraulic splitter can be powered by a 220 or 380 volt electrical network or driven by an internal combustion engine. Using a hydraulic splitter with a gasoline engine mounted on a chassis, it is possible to provide mobile-type pyrolysis furnaces with a sufficient amount of crushed raw materials.

Chainsaws are necessary for cutting down tree trunks, as well as for cutting them into smaller logs.

As a rule, hydraulic splitters allow you to work with pieces of wood up to 60 cm long, so the use of these devices will also reduce labor costs when preparing wood for chopping.

Making Charcoal: Production Process

The charcoal production technology consists of several stages:

Drying of raw materials

Even if dried trunks are used to prepare charcoal, a residual amount of moisture is still present in such material. Therefore, immediately after grinding, the wood undergoes a drying process.

For effective drying, raw materials are placed in special charcoal barrels, in which moisture is removed using hot smoke.

To reduce costs as much as possible, the drying unit is placed in close proximity to the pyrolysis furnace, from which heat is extracted.

Batch cycle charcoal burning equipment

The simplest design of a charcoal kiln is an ordinary two-hundred-liter metal barrel into which wood is placed and set on fire. Additional heat is not supplied, and vapors are discharged through a special small hole. The production of low-quality coal, with a yield of less than fifteen percent, is dirty, but practically cost-free.

Today there are designs of charcoal kilns in which the walls of the chamber are heated by a coolant, from which the heat is transferred to the firewood in it. These are, as a rule, charcoal burning kilns of a periodic cycle, where the entire process of burning coal occurs at certain intervals: firewood is loaded, re-coalmed, the finished coal is unloaded, firewood is loaded again, and so on.

In mixed-action devices, wood is periodically loaded and finished coal is unloaded, but some part of the wood is always in the process of pyrolysis.

Stoves can also be made of metal or brick.

Three chamber charcoal kiln

The vapor-gas mixture, which is removed from the pyrolysis chamber, condenses as it cools. Pyrolysis liquid (liquid) and non-condensable gases, since they are not yet widely used, are used as additional fuel in the combustion chamber. The removal of by-products for afterburning is provided for by the design of the furnace. The effect of this design is not only in saving fuel, but also in protecting the environment.

Three-chamber charcoal kilns provide a continuous cycle of coal production. In each chamber, one of the stages of the cycle takes place separately, and the initial drying of the raw material occurs due to the heat that is obtained during the combustion of pyrolysis gases. In addition to saving fuel, such stoves have many other advantages. Since the loading of wood and the unloading of finished coal occur at different times, the operating personnel are more evenly loaded. The cost of a three-chamber oven is lower than a single-chamber oven of the same volume, and efficiency and service life are higher due to load distribution.

Such equipment is designed for long-term operation in large industries, and if it is equipped with a gas generator boiler, then sawdust and shavings can be used as fuel.

Types of charcoal kilns

Improvements in the technology for producing charcoal have led to the emergence of special furnaces. They have different capacities and can process industrial quantities of raw materials. There are the following types:

- Stationary. Designed for large volumes of wood, can operate on different types of fuel. Installed by large manufacturers. The disadvantage of this option is the need to comply with environmental safety standards.

- Mobile. These are compact devices of small size that are easy to move, install and easy to operate. They are used at logging sites and construction sites. They conveniently use wood waste as the main source of the final product.

Waste recycling brings great benefits, since residues are simultaneously disposed of and coal is mined without fuel costs.

Mobile charcoal kiln

Continuous equipment

A common type of charcoal kiln that provides a cyclical process is called continuous. In them, the gases formed as a result of pyrolysis are again directed into the wood, combined with vapors and gases still released, and exit the furnace. These measures are required for more uniform additional heating. The disadvantage of the method is the high final concentration of chemical compounds. To neutralize them, it is advisable to install additional equipment that will burn them. It should be located separately from the main ovens.

They work according to this scheme:

- vertical retorts. Calcination occurs at the bottom, pyrolysis occurs in the middle, and drying occurs at the top;

- ovens with replaceable containers:

Retorts and chambers for charcoal burning are assembled from metal with mandatory thermal insulation.

Batch cycle units

The simplest option for a charcoal kiln is a regular 200 liter barrel. It ignites the stored raw materials; it does not involve the use of additional heat. Steam and gas are discharged through an opening in the container. The result is a low quality product with a yield of about 15%, contaminated, but practically costless.

Another type of charcoal kiln is one with heating of the walls of the chamber, which transfers heat to the filling. Typically this is a periodic cycle design. The following sequence of actions occurs in it:

- loading wood;

- over-charging;

- unloading;

- repeating the cycle from loading.

In such a device, part of the wood is constantly in the process of pyrolysis.

Portable batch charcoal kiln

Three chamber oven

A 3-chamber charcoal kiln allows you to use fuel economically and does not harm the environment. In it, the gas-vapor mixture is removed from the main chamber, cools and condenses. The resulting liquid and other non-condensable gases are used as an additional source of heat, added to the firebox.

Three-chamber furnaces are continuous - each compartment has its own stage. It is important that in the first chamber drying is achieved due to the heat from the combustion of pyrolysis gas mixtures. In addition to saving fuel, such stoves are useful:

- uniform use of working personnel, since loading and unloading occur at different times;

- duration of use. When installed in large enterprises and retrofitted with a gas generator boiler, the equipment is designed to use sawdust as a fuel source;

- the most affordable price compared to single-chamber options of the same volume, but greater efficiency due to the distribution of the load across different areas.

Factory Mobile Charcoal Kiln for Home Use

Single chamber oven

Single-chamber furnaces allow processing up to 8 tons of raw materials monthly. A full cycle requires 1 to 3 days of work. They are purchased both for individual use and for industrial production for the purpose of processing food industry waste and residues from wood processing plants.

The difference between industrial designs and smaller options for single-chamber furnaces lies only in the volume of processed raw materials and the ease of transporting equipment. In some countries, charcoal stoves are used at home - this coal is then used for cooking over fire.

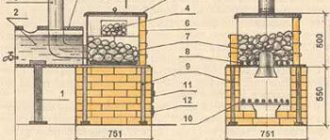

Diagram of a simple portable charcoal kiln

Single chamber charcoal kiln

Charcoal can be produced in small quantities (up to 8 tons per month) in a single-chamber furnace. The full production cycle depends on the model of the device and can take 1-3 days.

Such a stove can be used in private households, in public catering establishments, for the purpose of recycling production waste and substandard products in small woodworking enterprises.

The production principle in them and large-sized industrial furnaces is no different. Single-chamber furnaces are usually smaller in size, they also contain less raw materials, but they also take up less space and are easy to transport if necessary.

The production of charcoal kilns for home use has long existed abroad. Grilled or barbecued dishes are prepared using environmentally friendly charcoal.

Charcoal stove

The charcoal oven is quite complex, and it is very difficult to replicate its design at home. The cylindrical or rectangular body has a combustion chamber, on top of which 2 closed containers filled with raw materials are loaded - retorts. The wood is heated from the outside, through the walls of the retort, and uses the heat generated by the wood during the reaction process. The operation of the furnace in various modes is shown in the diagram:

An industrial furnace for the production of charcoal is designed in such a way that while pyrolysis is taking place in one container, drying is taking place in the second, the pyrolysis gases are burned and pass through a retort with wet raw materials. This sequence is followed further until the final product is obtained. It turns out that the internal volume of each vessel is divided into zones, in each of which a certain process occurs:

After calcination, the containers with coal are unloaded and new ones are placed in the oven. Before packaging and sending to the warehouse, the product undergoes crushing to the required fraction size, and, if necessary, briquetting. The apparatus where all operations are carried out using this technology is a continuous charcoal furnace. However, there is another technology, but it is more complex and expensive, although it provides high performance.

Characteristics and design of charcoal kiln

Manufacturers of charcoal kilns, both foreign and domestic, indicate the working volume of one chamber and the total number of chambers in the kiln as the first characteristic. Then the volume of firewood with a given size and humidity that can be loaded into the oven at a time is usually indicated. This indicator is important for compliance with the next parameter - the duration in hours of the main working cycle.

To determine the operating efficiency of a particular model, two parameters are set for wood of the same species - the estimated amount of firewood loaded into the pyrolysis chamber and the yield of coal from it.

The last to be indicated are the overall dimensions of the stove and its weight. If the device is not intended to be transported, this data may not play a special role, but during transportation it may become decisive.

As a rule, a household single-chamber stove is a metal barrel laid with a slight slope or installed on supports with a firebox built into the lower part.

The firebox itself, the stove body, the pipe box and the hatch door are made of steel with a thickness of at least 3 mm, and the outer lining is 1 mm.

The double-sided welds that connect the body shells are reinforced with bandages, which are made from a rectangular pipe, giving the structure rigidity and additional strength if pressure suddenly increases in the container.

To reduce heat loss, thermal insulation material is laid between the chamber body and the outer casing. This measure increases the efficiency of the furnace. The inside walls of the firebox are lined with refractory bricks.

Devices for afterburning charring products can be supplied separately.

Furnaces for the production of charcoal

The technology for making charcoal has been known to mankind for many centuries. Even in ancient times, people noticed that coal is much more efficient than firewood. At first, coals were collected from forest fires, then they began to make charcoal themselves. To do this, they dug a hole in the ground, put logs in it, covered it with earth, and lit a fire on top, which was maintained for a long time. After a few days, coals formed in the pit.

The secret is that when there is a lack of oxygen, the wood does not burn, but turns into coal - the process of pyrolysis. This method has been adopted by modern manufacturers of charcoal kilns. They have improved the process to improve yield and make charcoal safe for the environment and people.

Furnaces for the production of charcoal come in different modifications, small-sized household and large charcoal kilns and complexes consisting of one, two or three chambers.

Find out more about all the configurations and characteristics of charcoal kilns: Charcoal kilns

Charcoal is produced in furnaces under high temperature without oxygen as a result of wood pyrolysis. charcoal is a flammable, solid, porous (up to 80%) black substance with a characteristic bluish sheen. Depending on the density, it is quite fragile and can break and crumble under mechanical stress.

Household charcoal stoves

Small, inexpensive stoves for the production of charcoal can be used in private households, installed in the garden or in the yard of a private house. Small costs for equipment will allow you to obtain high-quality charcoal, which can be used for cooking barbecue and charcoal dishes, and also sold to neighbors. Small batches of coal will allow you to provide yourself with highly efficient fuel. In some households, fireplaces are heated with coal, which is much more profitable than heating with wood.

Charcoal gives a stable heat, does not spark, and provides warmth in the house. In private households, coal can also be used for blacksmithing. If you have a forge and an anvil, then your own coal produced in a charcoal kiln will more than meet the needs of a small workshop. Small-sized coal stoves take up little space; they are equipped with a system for afterburning pyrolysis gases, so they do not emit smoke or harmful impurities into the atmosphere. The operation of the stove is simple and straightforward.

DIY charcoal stove

A barrel on a stand is the simplest design, but for greater efficiency and fire safety, the barrel must be installed on a non-combustible base or buried in a hole.

You can make your own charcoal kilns from brick or metal. The drawing can be found on the Internet, as well as fairly detailed descriptions. True, you need to understand that the quality of a homemade stove and the final product is much lower, and there will not be large volumes of coal.

You can make a coal pit at your summer cottage, or you can build a charcoal kiln out of barrels. To do this, you need to dig a hole of such a diameter that a barrel can fit into it, which also needs to be lined with bricks, cut a hole in the bottom of the barrel with a diameter of approximately 100 mm and place it in the hole with the hole down.

Then you need to line the barrel with bricks, close the cracks at the top with some fireproof material, and insulate the top bottom with mineral wool. That's all, you can get your own coal for the fireplace and barbecue.

The double barrel design is more efficient and reliable. A container, which is half the volume, is placed in a larger one, filled with firewood and tightly closed with a lid, and fine wood waste is poured into the space between the walls and set on fire, then the large barrel is also closed with a lid into which a pipe is inserted. But both of these stoves are only suitable for outdoor use and far enough away from them.