What is the principle of operation of the bypass system?

The principle of operation of the Blow-Off system is designed in such a way that the air that turns out to be useless is simply removed from the system, etched into the atmosphere.

However, not all motorists consider this advisable. Automakers share the same opinion. They believe that the resulting excess air can be reused by sending it back to the turbocharger compressor. At the same time, few people take into account that at the moment of each new compression there is an increase in the temperature of both the air supplied to the engine cylinders and the parts of its intake. However, the recirculating system continues to be very popular. It is also called “bypass”, based on the English word bypass, which directly translated into Russian means “bypass”. The operating principle of such a system can be compared to a shock absorber, whose role in this case is to soften the shock along the axis of the turbocharger. The tightness of the system will sooner or later cease to cope with holding an ever-increasing amount of air, which at some point will break out. As a result, a blow to the turbocharger will inevitably occur, which would not happen if a blow-off valve was used. However, the standard equipment of sports cars still uses a bypass system.

The fact is that the air recirculation system eliminates the occurrence of unnecessary noise in the engine compartment, which can cause confusion among inexperienced drivers. For many of them, the origin of the “zilch” remains an unclear and therefore frightening question. By using a bypass air exhaust system, manufacturers can be said to take care of the nervous system of consumers. In addition, such a system is much cheaper to maintain, which is why it is very popular. It is also worth noting that standard bypass systems quite often act as boost limiters, preventing the air counted by the flow meter from being released.

However, some manufacturers have already thought of allowing, if necessary, excess air to be vented forcibly from bypass systems. In particular, on Mitsubishi GTO cars, the bypass valve piston has a special outlet, from where you can bleed off some of the air without even experiencing an extreme need for it. Thus, the bypass system gradually turns into a kind of gentle half-measure.

Bypass valve device

Some experts believe that you should not simply throw excess collected air into the atmosphere. It is acceptable to bleed the collected gas again to the inlet of the turbine supercharger compressor. Such a device is usually called a bypass or recirculating design. Among car enthusiasts involved in auto tuning, there are many adherents of this modernization. However, they ignore the fact that each compression of gas occurs with a parallel increase in the temperature of not only the entire intake unit, but also the air sent through the system. In fact, the built-in bypass loop acts as a shock absorber, helping to soften the impact on the turbocharger axes. Based on this logic, Blow-Off bleed valves relieve the components as much as possible from extreme loads, and the task of recirculation is to mitigate.

What types of bypasses are there?

How to install a Door Closer on a wooden or metal door or gate with your own hands Step-by-step instructions Video

Although the bypass is a fairly simple element, the range of its functions can be significantly expanded through the use of various types of plumbing fittings built into it. The design of the bypass depends on the line in which it is used, the type of residential or industrial buildings with single-pipe heating installed.

Fixed bypass

The simplest bypass design is a bypass unregulated pipe connecting the pipelines between the input and output lines. Such an element is usually installed in apartment buildings, where the absence of a shut-off device prevents accidental blocking or partial blocking of the bypass and, accordingly, disruption of the operation of the entire system and its imbalance.

The unregulated unit is widely used in the common “Leningradka” - a single-pipe line with a large-diameter straight bypass pipe and a chain of heating batteries connected to it in parallel.

Rice. 5 “Leningradka” - a popular piping scheme for a single-pipe structure

Manually controlled bypass

Since part of the coolant passes through the bypass, installed parallel to the connected heat exchange devices, bypassing the heating devices, to increase the supply of coolant to the radiator, its cross-section is made smaller than other pipes, increasing the hydraulic resistance. Typically, the diameter of the bypass in a one-pipe heating system is smaller than the pipes coming from the central riser to the radiator by a quarter of an inch, which in turn have an external size smaller than the riser pipes by the same amount.

It is clear that this system is unregulated and does not allow the system to be used effectively - the radiator with a large number of sections does not always warm up completely due to the coolant escaping through the bypass pipe.

In addition, when installing a heat-conducting line in a private house, it makes no sense to use pipes of different diameters in 1/4-inch increments - obtaining a small cross-section of the bypass jumper relative to the central pipeline by using different sections is a technically difficult task.

Rice. 6 Bypass in the heating system with radiators

Therefore, it is more practical to install a control valve in the bypass adapter in the system - this will allow you to manually change the supply volume by reducing the cross-section of the jumper and accordingly adjust the heating temperature of the heat exchangers. If a “Leningrad” with a horizontally located straight line is installed in individual housing, then the amount of coolant passing through the radiators is adjusted using thermostats or ball valves installed at the inlet and outlet of the radiators.

It should be noted that inserting a ball valve into the bypass line of an apartment building is unacceptable and is a serious violation, leading to imbalance and failure of the entire heating system along a single-pipe vertical riser.

How to install automatic bypass

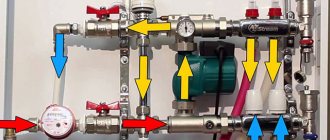

An automatic bypass with a valve is usually installed parallel to the compression electric pump; a check valve is used as a valve that closes the passage channel. The system operates in such a way that when the electric pump is running, the heat carrier passes through the connection branch of the pump, which draws liquid from the main line and the bypass branch into itself.

In this case, a check valve, made in the form of a ball or a shut-off curtain, is sucked in by the flow and blocks the bypass channel. When the electric pump is turned off, its blades stop and partially block the channel, the locking element of the check valve is not retracted by the electric pump and opens the channel under pressure. As a result, the coolant follows a path where the hydraulic resistance is lower, that is, along the bypass pipe.

Rice. 7 Ball bypass valve in a heating system - principle of operation and appearance

A bypass with a valve is installed on two-way tees, two fittings of which are connected in a line, and a circulation electric pump with two shut-off valves and a filter is connected to the third outlet.

There is another type of automatic bypass - injection, in which the assembly with the pump is welded into the curved pipeline of the main line. When the pump is running, the main volume of coolant passes through it, and if the electric pump is turned off, the coolant freely flows into the main line through the bypass channel.

A similar design is found much less frequently in everyday life due to the complexity of installation when using polypropylene or plastic pipes, the need for soldering and welding when using copper or steel pipes.

Operating principle of Blow-Off and bypass systems

Not every motorist is completely satisfied with their vehicle. Some people are not satisfied with its appearance, others are not delighted with its technical characteristics. This forces drivers to look for ways to turn an ordinary car into a real supercar, a dream car.

The desire to achieve perfection forces us to resort to tuning, but without the appropriate knowledge we can only make it worse and not get the expected result. Therefore, in order to avoid “breaking wood”, before implementing ideas in practice, it is necessary to study in detail the theoretical part of the issue.

As an example, we suggest you consider such a device as the Blow-Off valve, the complexity of installation of which and the problems that arise during its use on various cars are constantly discussed.

What is a Blow-Off valve and what is it for?

The purpose of the Blow-Off valve is to squeeze out excess air from the turbocharging system. It would seem that the very principle of the design of racing cars, and even more so race cars, completely contradicts this, but in fact this is not entirely true.

The engine control system reacts to the release of gas at the moment of acceleration by switching to braking mode, completely cutting off the fuel supply to the cylinders. At this moment, a predictable drop in unit speed occurs, while the turbocharger, by inertia, continues to operate as usual.

To get a clearer picture, we should dwell in more detail on its role in the structure of the car.

The purpose of a turbocharger is to supply the engine with an excess amount of compressed air. What does this mean in practice? Since the operation of the device begins immediately after the engine is started, air constantly flows into its cylinders until it is turned off.

Moreover, the complete shutdown of the turbocharger occurs only some time after stopping the engine. This means that the unit is always supplied with more air than it can consume. Compressed air will be prepared even after a sharp closing of the throttle, which occurs when the accelerator pedal is released, although not as effectively as during acceleration.

At this moment, air accumulates in the intake tract, in the area between the throttle valve and the compressor, remaining unclaimed.

For normal operation of a two-liter four-cylinder engine at 5000 rpm, at least 80 liters of air are required, despite the fact that the total volume of the unit, including air ducts, rarely exceeds ten liters. A full revolution of the crankshaft with the same engine operating mode is completed in just 12 milliseconds.

At the moment the gas is released, the excess air will definitely find a weak link, which will be dealt a crushing blow. The intercooler wall, the throttle valve itself, the turbocharger axis, and the compressor impeller may get in its way. In general, anything, including air duct pipes and rubber hoses.

The Blow-Off valve is designed to prevent this .

Place the device in the engine compartment. By the way, skeptics believe that the Blow-Off valve contributes to the enrichment of the mixture, interferes with the normal operation of the engine, due to which it constantly stalls, and also contributes to an increase in the flame escaping from the exhaust pipe. However, most often such consequences arise due to improper installation and operation of the device.

It itself bleeds off the very unclaimed air remaining between the throttle valve and the compressor, thereby providing reliable protection for the turbocharger. In other words, having a Blow-Off valve, you can, without thinking, sharply reduce the speed, brake aggressively, and the device will notify you that the action performed is completely safe with a light “zilch”.

What is the principle of operation of the bypass system?

The principle of operation of the Blow-Off system is designed in such a way that the air that turns out to be useless is simply removed from the system, etched into the atmosphere. However, not all motorists consider this advisable. Automakers share the same opinion. They believe that the resulting excess air can be reused by sending it back to the turbocharger compressor. At the same time, few people take into account that at the moment of each new compression there is an increase in the temperature of both the air supplied to the engine cylinders and the parts of its intake.

However, the recirculating system continues to be very popular. It is also called “bypass”, based on the English word bypass, which directly translated into Russian means “bypass”. The operating principle of such a system can be compared to a shock absorber, whose role in this case is to soften the shock along the axis of the turbocharger.

How to choose

Sealant for muffler types, DIY repair instructions

There are several useful recommendations that allow you to correctly and competently decide on the choice of bypass:

- The product must have all the necessary certificates and documents, technical passport.

- A certificate of conformity is required, as well as a hygienic certificate confirmed by a seal.

- Carefully examine the welding areas. They often have pores, which indicates poor build quality. There shouldn't be any time on a good bypass.

- Check threaded connections. They should twist and unscrew freely.

Installation

Do-it-yourself Toyota Corolla repair Verso since 2004

To install a bypass, it is recommended to use the services of specialists. They will not only perform installation, but will also inspect the entire system, determine the presence of defects, defects and possible leaks.

Mount the device in close proximity to the radiator, but as far as possible from the risers. If required, a tap is additionally installed on the bypass, which will allow heating to circulate using the radiator rather than the installed bypass.

Introducing the bypass into the riser will require the use of shut-off valves. Mount the element in a horizontal position, which avoids air accumulation.

Operating rules

There are several recommendations, if followed, you will significantly extend the service life of not only the bypass itself, but also all systems where it is directly involved.

The bypass design must include exclusively ball valves. Their features allow the system to operate in optimal mode and quickly close or open bypass channels when required. Plus, this type of cranes has proven itself to be the best. It is recommended to open and close the system at least twice a year

It doesn't matter whether the system works or not. These are preventative measures that extend service life. Use exclusively high-quality fittings, which will allow you to forget about possible problems and troubles for many years

If you ignore this recommendation, you will need to replace the taps. They cannot be repaired, as they are beyond repair. The replacement procedure will cause many problems and questions if you undertake it yourself. And the services of specialists cost money.

A bypass is needed in itself in the heating system, and these are mandatory measures when installing it. But this element serves as an additional way to save on electricity. Considering the cost of utilities in our time, small expenses on the purchase of a bypass will very quickly pay for themselves by saving the cost of paying for electricity in the house.

For reference, current prices for high-quality bypasses range from 2 to 4 thousand rubles. Not much, but very useful and effective.

We do not recommend installing it yourself if you do not have such experience. When installing the circulation pump, specialists will be able to install your bypass at the same time. This will not be difficult for them, but you will save your own time, effort and nerves, and also guarantee the long-term operation of the entire structure for a long time.

Installation steps for a bypass valve (for radiators and with a circulation pump)

Installing a bypass in a heating system equipped with a circulation pump is done as follows:

- excess liquid is drained from the common pipe;

- a section of pipe measuring 40 cm is removed from the coolant;

- holes of the required diameter are cut at the ends of the pipe to connect the bypass;

- a filter is installed on the cut areas;

- then the bypass valve is installed;

- the hydraulic pump crashes.

Important! Installation of incoming water distribution screws is carried out in the direction of the general flow of the pipeline.

For heating batteries, the following installation scheme applies:

- the diameters of the bypass and main pipes are checked;

- the following are mounted at the connecting ends: single-pipe jumpers and an adjustment valve;

- Next, the valve is installed at the closest possible distance from the heating radiator.

Important! Before inserting the bypass, the pipe must be checked for the presence of an air lock.

Necessary tool

You can install the bypass line yourself using installation tools, the list of which consists of the following items:

- tape measures for measuring the length and volume of a pipe;

- level for adjusting heating devices and water supply slope;

- pliers for removing and maintaining individual parts of the heating system;

- adjustable wrenches for joining the structure;

- a set of keys for installation (regular);

- metal cutter;

- screwdrivers: Phillips and flathead;

- pipe cutter (for large diameter pipes);

- welding machine;

- a grinding machine for leveling the corners of pipes and pipes;

- hammer drill;

- gas burner.

What is a bypass for and how does it work?

The single-pipe heating distribution scheme is still in demand in individual construction, but in old multi-storey buildings this solution was often used, so installing a bypass pipe was considered a non-discussable and necessary option.

Special purpose:

- Ensuring uninterrupted operation of individual components of the heating system without turning off the heat. Repair or replacement of mechanisms, equipment and individual elements in the heating system is facilitated by the fact that the inlet and outlet shut-off valves (supply and return) of the coolant are closed, and the working fluid is redirected through a jumper pipe, as a result of which the broken unit can be easily dismantled or repaired. This is why a bypass is needed in a heating system, but this is not the only purpose of the bypass;

- The functioning of a single-pipe heating system can be improved, since it has a significant drawback: the temperature from the heated coolant is unevenly distributed over the radiators due to their sequential connection scheme. Thus, the temperature in the very last radiator will always be the lowest. To obtain the same temperature on all batteries, install a bypass in front of each heating device - radiator, battery or register. Here, the purpose of the bypass is that a certain volume of media is directed bypassing the radiator sections, and gets hot even into the furthest battery. In this case, the diameter of the pipe jumper in a single-pipe heating system must be equal to or less than the diameter of the pipes of the main circuit;

- Maintain the operation of heating systems during an emergency power outage, since the circulation pump does not function, and the presence of a bypass will make the movement of coolant uninterrupted.

Blow off and Bypass - what is it and what is it for in a car

A car is a rather complex mechanism that consists of a huge number of parts. A beginner has to understand the design and structure of a vehicle for a long time. Of course, knowledge accumulates along with experience, and after 10 years you can safely tell what a car is like, what is included in the fuel and brake systems. But some, even experienced motorists with extensive experience, will not be able to name what some parts are needed for.

Probably every driver has heard terms such as “bypass” or “blow-off” at least once. Not everyone knows what these words even mean. Let's take a brief and clear look at what these elements are and why they may be needed in a vehicle.

Today, even the most inexpensive cars have turbocharging - such a system no longer surprises anyone, as it was a decade ago. For those who understand the mechanism, it is no secret that the turbine pumps up pressure at the moment when the engine requires it when operating at high load. But any pressure has a limit value, which is called “wastegate”. But it can limit the pressure limit of the turbine itself during acceleration. But what to do if the driver squeezes the gas, picks up speed, and an obstacle appears on the road? Of course, the first reaction is to press the brake pedal. The speed will begin to drop, but the turbine is an inert unit. Even after braking, the air is pumped for some time. At the same time, it does not enter the engine, since the throttle is closed.

Where does the air go? Just for this case, experts came up with a blow-off with a bypass. Let's briefly look at the operating principle. A blow-off valve is a standard pressure relief valve that is set to operate at a specific pressure. It crashes into the air line from the intercooler to the throttle. When pressure begins to increase in this area, the valve opens and releases excess air to the street. It is at this moment that the characteristic sound that sports cars make on the track is heard.

Bypass is almost the same element, but has some differences. At the same time, excess air does not go outside, but into the intake system, specifically at the turbine inlet. The main difference between one system and the other is that the first actually removes air, and the second is simply a buffer - it distributes air around the second circle. The second type is used on many production cars. Firstly, it does not make extraneous noise. Secondly, the bypass avoids air shortage for the engine.

Bottom line . Bypass and blow-off are words that every motorist has heard. However, not everyone knows what it is and why it is used in cars. These elements allow you to remove excess air in the systems of turbocharged cars.

Bypass types

So, it should immediately be noted that all models of this device, according to their characteristics, can be divided into two large groups. Each of them has its own characteristics, which will significantly affect the principle of operation of radiator batteries or water supply systems.

- The first group includes devices with a check valve. As a rule, such devices are used for circulation pumps. This bypass does not work all the time, but when necessary. The operation occurs as follows: after turning on the pump, the valve automatically opens due to excess pressure, and then begins to flow hot water or other heat carrier. After the pump has finished operating, the bypass also automatically stops working. However, you should be careful: if rust gets in, the device may fail.

- The second type includes devices without a valve. This type will ensure reconstruction or repair without shutting down the entire heating system.

What is the principle of bypass?

Indeed, for a Russian-speaking person this name sounds very unusual. But it is precisely the meaning of this term that clearly speaks of the purpose of the element.

If you try to translate the word “bypass” literally from English, then dictionaries give a lot of different definitions, which, however, come down to one fundamental concept - the nouns “detour”, “detour”, “detour”, verbs “bypass”, “bypass” , “choose a different direction” and the like. This means that it is reasonable to assume that what is meant is some kind of device that allows for alternative rather than direct movement.

This is how it really is. In plumbing systems, a bypass is a section of pipe installed in such a way that a path is opened for liquid (coolant in the case of heating, or water in the case of water pipes) not only through any device, but also bypassing it. This "shorted" flow can become uncontrollable when the bypass is kept constantly open and the fluid flow obeys only the laws of hydraulics. Often, control devices are placed on the bypass - from simple valves to automatic devices that change the cross-section of the passage depending on changes in external conditions.

Perhaps the simplest and most common example of a bypass is a jumper pipe between the connections to the heating radiator

Since we are talking only about heating systems, the bypass can be installed:

- In radiator piping, which is more typical for single-pipe heating systems.

- In the piping of the circulation pump - in autonomous systems.

- In mixing units of water heated floor systems.

- To create a “small circulation circuit” in boiler piping (typical for units operating on solid fuel).

Bypass vs. Blowoff

Of course, it is possible to protect the turbocharger from excess pressure without emitting the excess into the atmosphere. You can leave it within the intake system, directing the bleed air back to the inlet of the turbocharger compressor. Such a system is called recirculating or bypass. Many tuners, for whom “everything is useful in the household,” remain supporters of this system, turning a blind eye to the fact that each compression is accompanied by an increase in the temperature of both the intake parts themselves and the air supplied to the engine. And a closed volume is not capable of containing an ever-increasing amount of air. The bypass system acts as a kind of shock absorber, softening the shock along the axis of the turbocharger. If blowoff is installed in order to relieve the turbocharger from stressful loads, then the bypass can only slightly soften it, but cannot avoid it. Despite this, car manufacturers use a bypass system. Firstly, this is due to the desire to reduce unnecessary, and sometimes incomprehensible, sounds in the engine compartment for many owners. Unfortunately, or fortunately, not every sports car buyer is a sophisticated racer or turbo maniac. Secondly, such a system is cheaper to maintain. Thirdly, it is this system that does not allow the air counted by the flow meter to be vented. Many standard bypass systems also work as a kind of boost limiter. For example, on Mitsubishi GTO cars, a hole is made in the bypass valve piston that bleeds off some of the air, even when this is not necessary. Which, in general, allows us to call such a bypass system a gentle half-measure. One can only sympathize with the owners of turbo cars without standard bypass valves and blowoff valves installed. For them, every release of gas can cause a forced stop. An engine equipped with a turbo needs a bleed valve, like a general in the army. You can argue about the advantages and disadvantages of blowoff and bypass systems for a very long time, sometimes until you become hoarse. Therefore, many manufacturers are trying to satisfy the arguments of both, producing valves capable of operating both as a blowoff and a bypass. One of such companies producing universal valves is GReddy; their type R, type S, even type RS can leak both into the atmosphere and into the bins of air ducts. The benefits of bleed valves are obvious. What makes them so difficult for many tuners to use?! And as always, everything is outrageously simple. A simple lack of knowledge of the functioning of the standard control system can completely ruin any improvement.

What it is

It is not difficult to understand that even initially insignificant defects in the operation of engineering systems and communications can turn into serious problems. The discomfort and even danger to health caused by heating malfunctions can hardly be overestimated. That’s why attentive, thoughtful homeowners should be busy preventing such problems. The bypass, which is widely used in heating circuits and plumbing systems, plays a significant role in it. Its design is not particularly complicated - it is just a jumper in the form of a pipe, supplemented with control devices.

The bypass valve ensures the passage of liquid (drinking water or coolant in the heating system) away from one or another technical unit. Quite simply, this is a workaround for water in case of unforeseen situations. If everything works normally, the flow moves calmly and measuredly along the jumper. But under certain conditions, the locking element closes and the liquid rushes away from the previous trajectory. This effect is achieved because the diameter of the bypass is invariably smaller than that of the pipe that supplies water to it.

The use of such a device allows:

- make service work on pipelines much easier;

- increase the efficiency of equipment;

- reduce unproductive energy costs;

- radically solve the problem of filling pipes and other water infrastructure with air;

- guarantee relatively stable performance even in unusual situations.

Sometimes you may come across arguments that installing a bypass is unprofitable. In fact, this is not so - when installing such a device, you can significantly save energy. The reduction in water supply to the batteries is up to 35%, and therefore it is possible to reduce thermal energy consumption by approximately 15%. Since many real systems consume a lot of heat, there will be no negative consequences. A more detailed picture can be understood in consultation with specialists.

Types of bypass valves

Gate valves fall into two main categories:

- Bypass that does not include a valve (direct acting). The coolant with this type of valve circulates through the pipes.

- Bypass including a return valve. This type of jumper is used for individual and general pumping stations to supply water to residential premises. Works when turned on (in open mode) and turned off (in closed mode).

Differences and scope of use

Both categories of bypass valves are divided into subtypes:

- Bypass valve in automated operation. Mounted on the piping of gravity and pump heating systems. During normal operation of the electronic supercharger, the automatic bypass is closed, and when stopped, it is open.

Why do you need a bypass in a heating system?

To understand why a bypass is needed and to appreciate the importance of installing this element, you should consider the main types of wiring of household heating systems. When installing household heating systems, a distinction is made between sequential (single-pipe) and parallel (two-pipe, collector) supply of the working fluid to heat exchange units; in the first case, the coolant passes sequentially through all devices, gradually cooling at the end

In a sequential scheme, the coolant is supplied to the heat exchangers from the highest point or from the bottom, while it circulates in a closed ring, returning to the boiler through the return pipes

When installing household heating networks, a distinction is made between sequential (single-pipe) and parallel (two-pipe, collector) supply of the working fluid to heat exchange units; in the first case, the coolant passes sequentially through all devices, gradually cooling at the end. In a sequential scheme, the coolant is supplied to the heat exchangers from the highest point or from the bottom, while it circulates through a closed ring, returning to the boiler through the return pipes.

A single-pipe system requires less materials when placing and is widely used in multi-apartment housing; during installation, the installation of a bypass jumper helps to avoid the main drawback - weak heating of the most remote radiator in the network. The purpose of the bypass is to create an additional path bypassing all radiators, ensuring the supply of coolant of the same temperature to each of them, this contributes to more uniform heating.

Rice. 3 Metal bypass design and its connection

The second important function of the installed bypass pipe is to ensure uninterrupted delivery of coolant to all radiators in the event of a breakdown or disconnection of one of them in a series circuit. From the diagram in Fig. 1 it is clear that in the absence of a bypass between the pipes, if one of the radiators fails (leakage, blockage), the delivery of coolant to subsequent circuits stops, as a result of which residents are left without heat, and the entire system is in danger of freezing.

The third purpose of the bypass is to maintain constant coolant circulation in the event of a breakdown of the heating system’s compression pump. If a bypass is used, the system works naturally, providing circulation bypassing the pumping branch - this guarantees uninterrupted heating of the premises in the home. It should be noted that to ensure a natural circulation mode when the pump is turned off, an appropriate design is required (large diameter pipes, slopes); if these conditions are not met, the circular movement of the liquid due to thermal expansion should not work.

An important advantage of the bypass is the ability to turn off any radiator for repair, preventative maintenance or replacement. This is achieved by placing two ball valves on the radiator inlet and outlet fittings; after they are locked, the radiator can be easily removed for repair, maintenance, or expansion of additional sections

The bypass performs similar functions when installed in parallel in the circuit of a compression electric pump - with the help of two ball valves, the electric pump is easily disconnected from the heat-conducting network for repair, maintenance, replacement of equipment without draining the water and stopping the heating of the premises.

Fig.4 The principle of operation of the bypass in the heating radiator circuit

Why do you need a bypass?

The bypass valve allows you to relieve strong excess pressure in the intake tract that occurs when the throttle is closed (instantly interrupting the supply of air and fuel to the combustion chamber). The turbocharger is not able to stop quickly when you take your foot off the gas pedal - it continues to pump air. If you do not relieve the pressure, the air will return to the turbine impeller, which threatens its failure over time. This phenomenon is called turbocharger surging, and in simple words they say that the turbine gets hit in the teeth. The effect is accompanied by hissing sounds.

Thus, the bypass is used to solve the problem with the return air pressure, and also allows, due to the air that is sent back to the turbine, to rotate at high speeds, eliminating the effect of “turbo lag” and failures in operation.

Coolant flow control

Adjusting the water flow in the system makes home heating more efficient and less energy-consuming. Excess coolant from the radiator is returned to the pipeline. Water passes through the bypass, bypassing the main pipe.

With such installation and operation, the bypass allows for repair work on radiators at the height of the heating season without disconnecting from the general system.

The device allows you to increase the speed of filling the heating system, as well as draining the coolant.

Operation with a circular pump

Installation in a system with a circulation pump

A heating bypass is indispensable when operating a circular pump. In situations where there is no electricity in the network, the pump cannot operate. A bypass with valves automatically redistributes the coolant flow from the pump to the main pipeline.

In manual mode, without a valve, the taps associated with the flow of water into the system are closed. Thus, the system switches from forced circulation to natural circulation.

Read about the difference between natural and forced circulation.

The bypass must be installed in a horizontal position, since in a vertical position air pockets may form, which negatively affects the operation of the system.

Single pipe system

A bypass for heating radiators allows you to update and improve the operation of single-pipe heating.

This work scheme is almost never used in modern construction in apartment buildings and private homes. In Soviet-era buildings, single-pipe heating is a fairly common occurrence.

The bypass in this case will regulate the flow of coolant, making the indoor climate comfortable.

The device is located close to the radiators, away from the vertical risers. The bypass must be equipped with temperature regulators. Thus, the device allows you to regulate the temperature in the room even with a single-pipe system.

When choosing, the diameter of the bypass pipe should be smaller than that of the main pipeline. This will allow, according to the laws of hydrodynamics, the coolant to bypass the battery through the bypass.

Scope and intended use

During a power outage, the need for a bypass for the circulation pump (its installation) ensures continuity of operation and eliminates emergency mode.

In pipeline structures, the shutter valve is designed for backup drainage of incoming liquid to a separate line (spare). If problems arise with water pressure in the pipes, the bypass valve closes access to the heating radiator, directing water in the opposite direction or to a separate channel.