What materials are used?

Modern devices, which are installed on heating devices instead of a chimney, are made from high-quality materials - high-alloy steel. It must be heat-resistant in order to withstand the effects of high temperatures that are formed from the influence of hot gases from the heating system.

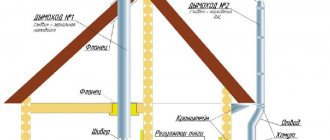

Double wall chimney

The chromium content in such an alloy should reach 13%. Also, the metal for the device must have anti-corrosion properties and be resistant to aggressive acids.

In rare cases, the outer surface of the convector chimney is made of bush hammered stone, jadeite, marble, soapstone. This option is no less advantageous, since natural material promotes uniform distribution of thermal energy and its accumulation inside the housing.

Modern capabilities of convectors

Among the proposed systems there are various models that differ in design features and operational characteristics. They are united only by the source of heat resources, namely the chimney. In order to make a complete choice, you need to familiarize yourself in detail with the qualities of existing models.

Convector devices

The convector is offered in the form of a device that produces heat exchange; it is installed directly above the heating unit or stove. The main role of such a device is to increase the rate of heating of the room. These units are used to supply warm air to added areas.

Such structures have an additional useful characteristic - they block the effects of infrared rays emanating from the chimney.

Convectors are made from special high-alloy steel, which has a sufficient margin of safety and is resistant to high temperatures. This material also exhibits corrosion resistance and does not react to the influence of chemical factors.

Convector models are divided into two main types. The first group is designed to deliver warm air to one room, and the second is designed to heat 2 adjacent rooms. The design of this device is presented in the form of a pipe placed on top of the chimney. A special channel allows you to take in cold air and deliver it in a heated form to a heated room.

Modular designs

Modular models have the most productive effect; they are used in private buildings or baths. The difference between this system is the many components from which the overall model is assembled. This feature opens up wide possibilities for creating a design that adapts to the existing chimney configuration.

The main element in this system is a sandwich pipe, which is mounted using additional shaped fragments. This product is designed in the form of 2 circuits separated by a layer of thermal insulation. The internal component is made of stainless steel - it has heat-resistant characteristics, and the outer layer is made of galvanized steel.

Thermal insulation for sandwich pipes is basalt wool, which can withstand heating up to 1000 degrees.

The service life of the modular system is from 10 to 12 years. If one element fails, it can easily be replaced with a new one. Black enameled chimneys are considered the most practical modular designs. They have a number of tangible advantages:

- special resistance to high temperature conditions;

- immunity to acidic and alkaline environments;

- fire resistance, increasing service life;

- aesthetic indicators of appearance.

The modular design allows you to profitably use even the most inaccessible areas of the chimney pipe, increasing the overall efficiency of the unit.

Horizontal designs

There are 2 ways to install systems - vertically and horizontally. In most cases, the first option is chosen, but the second option allows for heat extraction with the greatest efficiency.

But the systems under consideration have certain disadvantages. To avoid blockages, they should be installed in strict accordance with building regulations. Auxiliary windows are built into such systems for periodic cleaning. Inspection holes should also allow you to monitor the state of channel blockage.

There are also hybrid designs that combine vertical and horizontal systems. This arrangement allows for the most efficient use of the chimney's energy resource, increasing its performance.

Devices for barbecues

These units are suitable for ovens intended for cooking, and there are 2 types due to design features. The first ones are arranged in the form of a rectangular box with an open top. At the bottom of the structure there are special openings for air intake.

The second model is distinguished by control valves that allow you to control the flow of heated gas. The hoods of these systems consist of a dome-shaped hood up to 1.5 m in diameter and a pipe that connects to its upper part. When choosing a model for such a stove, you should take into account its design features.

How it works?

The convector chimney consists of two parts:

- internal casing, which is made of a metal pipe with a wall thickness of 1 mm;

- outer casing made of metal pipe with a wall thickness of 0.5 mm.

This design is installed immediately at the outlet of the heating device. It acts as a starting chimney.

The length of the unit ranges from 50 cm to 1 m. The more massive the installation, the more thermal energy it can transfer to the environment due to the accumulation of a significant volume of hot air and steam. The small design is ideal for a building with low ceilings.

The principle of heating air with a convector

This installation works by circulating hot air streams. It does not allow carbon monoxide to pass through, which is formed during fuel combustion. Cold air enters the inner casing of the convector, where it is heated by the chimney, after which it enters the pipeline, which is located under the ceiling of the room. Hot air comes out through it, which cools over time and again enters the heating system.

Structural features

Such an installation may consist of several pipes, depending on the number of rooms that it will heat. There may be two or four. Metal pipes with a wall thickness of 0.5 mm, which have an internal diameter of 115 mm or 120 mm, are connected to the nozzles. The size of the pipeline depends on the output design parameters.

Steel pipes pass into the adjacent room through a hole in the wall. This unit must be made heat-resistant. It is recommended to insulate the hole using basalt fiber, which will prevent heating of the inner surface of the enclosing structures.

The length of the pipeline depends on the distance between the heating device and the wall. The larger it is, the lower the temperature the outer surface of the installation will have. For installation, use pipes of standard length - 0.5 m. If necessary, you can change the length of one structural element.

Chimney-convector dimensions [ads-mob-1][ads-pc-1]

How to heat an adjacent room: chimney-convector

To do this, weld the required part of the pipe using material of the required thickness and diameter. In rare cases, a corrugated pipe is used as a convector chimney. This is justified in cases where it is not possible to install a straight section.

The pipeline that passes cold air is placed at a distance of 200 mm from the floor. There is no need to raise it any higher. Cold air is heavy and sinks lower than hot air. To improve the movement of flows inside the installation, a special fan is installed at the lower outlet of the pipeline in the adjacent room.

All parts of the pipeline are secured using heat-resistant sealant. After the convector chimney, a regular pipe is installed to remove combustion products from the heating system. You can also use a sandwich construction.

Maintenance and cleaning

For the economizer to function fully, it is necessary to regularly carry out preventive inspection and repair of all its parts. As a rule, this task comes down to updating the sealant layer if necessary, as well as cleaning the internal gas outlet pipe.

The pipe should be cleaned simultaneously with the stationary chimney, if necessary, completely or partially dismantling the convector system, using a mechanical (using special brushes) or chemical (using specialized compounds for cleaning stainless steel chimneys) method.

The most popular tube heaters

The most popular models of tube convectors are Termofor units. There are two types of devices available:

- chimney-convector 1, which can heat only one room;

- chimney-convector 2 for heating two adjacent rooms.

Chimney-convector - for adjacent rooms

Termofor consists of several pipes that have standard sizes - 0.65 m or 1 m. The diameter of the internal part is 115 mm, and the outer casing is 220 mm.

Termofor 1 consists of two pipes, which are equipped with decorative overlays. The model for heating several rooms has an angular shape. Transform 2 is equipped with a set of four pipelines and linings.

This installation is similar in principle to a coaxial pipe. To increase the productivity of the unit, an additional air duct is installed on the convector pipes. It improves air circulation inside the unit.

Installation benefits

Termofor is a unique design that has the following advantages:

- can be used both for sauna stoves and other heating devices;

- increasing the productivity of the heating system. If you install this design, the heat from fuel combustion and the energy that is generated by the movement of hot gas and steam in the chimney are used;

- thanks to the presence of special holes in the structure, heating of adjacent rooms occurs quite quickly;

- Thermofor protects the room from intense infrared radiation from the chimney;

- this installation operates productively regardless of the ambient temperature;

- many models have the function of blocking pipeline channels, which allows you to regulate the heating intensity;

- The transformer is quite durable because it is made of high-quality materials;

- This unit is safe. It can be installed even in wooden houses.

Stove in a house with a convector on the chimney

Advantages

The convector chimney has a number of advantages that make it a worthy alternative to conventional cast iron or bimetallic radiators and even an entire water heating system in small country houses, summer kitchens and bathhouses.

- Versatility - coaxial convector chimneys are suitable for a conventional wood stove, and for solid fuel or gas boilers.

- Increasing the productivity of a heating device through the use of secondary thermal energy of heated smoke, gases and water vapor.

- Efficiency - the design can heat three rooms at once: the one in which the boiler is located, as well as one or two adjacent ones.

- Durability - thanks to the use of durable metals and alloys in the manufacture of the casing, the service life of the structure can reach decades.

- Fire safety - the chimney-convector device isolates the heat source, protecting surrounding materials from overheating. Due to this, such chimneys can be installed in wood-burning bathhouses and houses made of timber.

- Protection from infrared radiation - the metal casing acts as a screen that absorbs excess heat.

Note! The main advantage of a chimney-convector is an increase in the efficiency of heating equipment. With its help, you can double the efficiency of a low-/medium-power boiler or furnace while maintaining fuel consumption and without the need for thermal insulation of the room.

Another advantage of the design is increased strength and increased service life of furnace equipment as a whole. Coaxial convector chimneys are made of durable alloy steel. It resists the effects of high temperatures and aggressive acids contained in exhaust smoke.

We recommend that you read: Thermal insulation rules for heating pipes - how to choose material, calculate thickness and install

How to make a heat exchanger for a chimney with your own hands?

Necessary materials

To create your own chimney with an air convection effect that resembles Termofor, you need to use the following materials:

- at least 8 thin pipes with a diameter of 32 mm and a length of 600 mm;

- pipeline 0.6 m long with an internal diameter of 57 mm;

- massive pipe with a diameter of 0.3 m;

- 2 sheets of high-quality metal measuring 350x350 mm;

- piece of plywood 350x350 mm.

To make a kind of heat exchanger, it is best to use food-grade stainless steel. It is capable of operating at high temperatures and is resistant to aggressive substances. A structure made from this material will serve you for decades.

Square and round stainless steel pipes

Galvanized steel is also suitable for the unit. You just have to take into account that it can release toxic substances if it heats up above 200°C. But in most cases, conventional home furnaces emit gases in a smaller temperature range. Therefore, galvanized steel can be safely used.

Step-by-step manufacturing instructions

- Cut two circles with a diameter of 150 mm from metal sheets.

- Make nine holes on the resulting circles. One in the center with a diameter of 57 mm, and the other along the contour of the sheet with a diameter of 32 mm.

- Carry out the same steps with a piece of plywood. It will act as a template.

- Insert pipes into the finished plywood circle. The sheet should be placed in the middle of the pipeline.

- At the ends of the pipes, attach a metal circle that needs to be welded to them.

- Remove the template and weld another metal circle to opposite ends of the pipes.

- Insert the finished structure into a cylinder with a diameter of 0.3 m and weld it. All joints must be treated with fireproof sealant.

- Homemade Termofor must be covered with a layer of stove varnish.

Drawing of a convector for a chimney

Connect this unit using pipes to the stove equipment.

The convector chimney is an original design that allows you to obtain the maximum amount of thermal energy using a small amount of fuel.

[ads-pc-2][ads-mob-2]