A natural gas convector is ideal for low-heat rooms, or for those where there was no central heating initially, such as garage workshops or basements. This device is an excellent solution for people who are sensitive to cold temperatures; they require an increased temperature regime in a certain room, but they should not overheat rooms powered by a general heating system. When chosen correctly, portable heaters can improve the energy efficiency of the heating system as a whole, allowing you to maintain a sanitary temperature throughout the entire house and heat an additional specific room, such as a children's room.

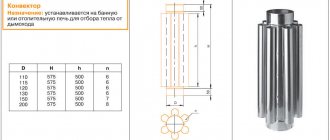

Design and principle of operation of a gas convector

A convector running on main gas is designed for individual heating of isolated objects. Functionally it is similar to an electric heater. The operating principle of such a heater is based on convective heat exchange of air masses, when cold air is heated in the heat exchanger of the convector, the heated layers rise to the top, and cold ones take their place. For these heaters, it is important to place them correctly. It is recommended to install in places with maximum heat loss under the window and as low as possible to the floor.

Gas convector in the living room interior

Gas convector device:

- A housing that performs a protective function. It is made of metal treated with heat-resistant enamel that can withstand the high temperature of gas combustion. Air circulation slots are installed at the bottom and top of the housing.

- An effective heat exchanger for heating air with a developed heating surface made of heat-resistant steel or cast iron, since it has constant contact with open fire.

- A gas burner is a device for burning gas, made of two parts: an igniter with electric ignition and a nozzle.

- A working gas valve-regulator that controls gas flow based on a signal from a protection system or temperature sensor.

- The gas exhaust system ensures the release of flue gases into the environment. It can be of two types with natural and forced draft.

- Thermostat is a device for automatically maintaining a given temperature in the house. It works in tandem with a gas shut-off valve.

- The protection system is a set of sensors for gas pressure and heated air temperature, working with a valve that closes the gas supply in the event of any emergency.

Design and principle of operation of a parapet gas convector

Types of gas convectors

Today on the market you can find various designs of convectors operating on main gas, differing from each other:

- By type of material: steel and cast iron.

- By type of installation: wall, floor, ceiling. The latter are used for heating large industrial and commercial facilities.

- By power: low, medium and high. Such devices operate effectively only in separate rooms. The load is selected from the ratio of 1.0 kW per 10.0 m2. It is easy to calculate that for 80 m2 it is necessary to choose a device with a power of 8 kW.

- By type of combustion chamber: open and closed, which differ in the chimney system. For devices of the first type, exhaust gases are removed through a stationary chimney, arranged according to the stove principle in the space between the walls, which requires additional funds for installation. Models of the second option are easier to install. Exhaust air is removed into the atmosphere through a coaxial pipe.

Advantages and disadvantages

A gas heater is 50% cheaper to operate than a conventional electric convector, which is a strong argument for its use. It can operate during power outages and reach maximum temperature quickly, almost instantly.

Advantages of a gas convector:

- Portability and mobility, they can be placed in any room, you can take them with you when moving, for example, to the country.

- Efficient, more than 90% of the energy contained in the gas is converted into heat.

- Instant heat transfer. The lower limit for heating output for such devices is 25 MJ/h, which is equivalent to 6 kW of electric heating, so one standard gas convector produces the same amount of heat as three 2 kW electric heaters.

- Low specific costs for the production of a unit of thermal energy, 1 Gcal.

- Modern level of security. The protection system turns off the heater based on an oxygen depletion sensor if its level in the room becomes too low, as well as in the event of a flame breakout or the heater overturning.

- Carbon monoxide protection.

- Automatic temperature maintenance using a thermostat.

Disadvantages of a gas heater:

- There is no chimney, in designs with natural circulation, so emissions from the combustion process flow back into the room.

- They should not be installed in bedrooms, bathrooms or other small or poorly ventilated areas.

- Water vapor from the combustion process can condense on walls and ceilings and cause mold to form.

Gas convector Alpine Air NGS-50F

Alpine Air NGS-50F

Photo: https://beru.ru

The unit is similar in characteristics - except that the efficiency is a little lower. But the design is attractive. By purchasing this convector, you will immediately get rid of heating problems and the need to heat the boiler and constantly maintain the desired coolant temperature. Alpine Air NGS-50F does everything for you. Its minimum service life is 50 years, so it will also be enough for your children. Works on both main and reduced gas. An excellent heat exchanger allows you to bring the device to the required power in literally a matter of minutes. The price is rather high, but it is a very modest payment for the almost complete absence of problems with heat supply.

Gas convector Alpine Air NGS-50F 4.9 kW

Advantages:

- high power

- interesting design

- high reliability

- two modes

- natural convection and forced

Flaws:

- not detected

Criterias of choice

The efficient operation of a gas convector will depend on the correct choice, as with electric heaters, gas devices have their own design differences that must be taken into account when choosing.

Functional features of the heater:

- The remote control allows you to set the temperature and fan speed settings, while some models have both wired and wireless versions, which allows you to control the device from a distance.

- Thermostats make it easier to set the operating temperature.

- Programmable timers will help with energy saving. Most can be programmed to turn on/off within 24 hours.

- Child locks are available on some models.

- Electronic ignition of the burner ensures energy savings.

- Filter cleaning warning function.

When choosing the right model, the specific operating conditions of the unit, the purpose of the room, the geometric configuration of the heating object, for example, for a garage, the heated volume and the required indoor air temperature are taken into account.

Heat exchanger material

The operation of the convector is based on the combustion of fuel in the chamber, so the heat exchanger is exposed to strong thermal effects, and if its metal burns out, this will completely deactivate the convector. An equally important condition for the long-term operation of an internal boiler is its corrosion resistance, which resists the aggressive effects of flue gases. Therefore, it is natural that the boiler material should be as durable and corrosion-resistant as possible. The main materials used in convectors for these purposes are steel, aluminum and cast iron.

The best option is a steel heat exchanger, with increased heat resistance, small dimensions and weight, and a relatively low cost.

Aluminum, despite its excellent thermal conductivity, is an expensive metal and does not have heat resistance. Cast iron has increased fragility; under the influence of sudden temperature changes it can crack, and ultimately damage the heater.

Combustion chamber type

For this type of heater, open or closed combustion chambers are installed. The first option has an exhaust hood that takes air from the room and releases exhaust gases through a vertical pipe into the atmosphere. The simplest gas convectors operate with an open gas combustion system, which has obvious disadvantages - air intake for combustion from the room and the need to install a complex, expensive smoke exhaust system passing through the ceiling.

Therefore, heaters with a closed combustion chamber are better and more environmentally friendly. In such a device, movement in the gas-air duct of the convector is ensured by a special blower fan built into the coaxial chimney. Flue gases are removed through the inner pipe, and air masses are introduced into the chamber through the outer ring.

Power and heating area

In order to choose the right thermal power of the heater, you will need to take into account many factors: the climate zone of your residence, the height of the ceiling and the total heated area, whether adjacent rooms have heating, the state of thermal insulation, whether sunlight enters the room, glazing area. It is almost impossible for a person who does not have a special education to perform such a calculation, therefore, to select thermal equipment, they use the average practical ratio of interrelated quantities:

The required kW power depends, first of all, on the area to be heated and the climatic zone of residence. In order to choose the best gas heater for rooms with ceilings no higher than 2.5 m:

- Northern regions - 1000 W for every 8.5 m2 of area.

- Central region - 1000 W for every 10.0 m2.

- Southern regions - 1000 W for every 16.0 m2.

An example of selecting convector power in relation to the heating area for the central part of Russia:

- Low-power unit, area 29 - 42 m2, load 2.9 - 4.2 kW.

- Medium unit, area 50 – 60 m2, load 5 – 6 kW.

- Powerful unit, area 62 – 82 m2, load 6.2 – 8.2 kW.

For heating efficiency, it is recommended to choose convectors with a margin of heating capacity in order to minimize heat loss. Gas consumption will remain virtually unchanged.

type of instalation

In order to make a choice of device according to the type of installation on the wall or on the floor, you need to take into account the actual conditions of the site. The preferred option is wall installation. It does not take up a large volume, being located under the window and creating a thermal curtain between the cold air coming from the window and the internal air in the room. Despite their many advantages, such devices are limited in power to 10 kW, and therefore are not used for large objects. Wall heaters typically last between 8 and 12 years.

To heat large areas, floor-mounted devices are used. They are large in size and weight and last more than 20 years. The final decision on choice is made taking into account the safety of installation and operation of the heater. The biggest threat to your home when using one of these heating appliances is the risk of fire. Convection technology uses intense heat to heat the air, so you need to place these heaters away from flammable materials and household items that can heat up and burn.

Gas convector KARMA BETA 5

Fuel consumption

Once the power has been determined, you can begin to calculate the fuel. According to current standards, gas is calculated for each object separately, at T outside air in the area where the object is located. This data can be obtained from SNIP for heating.

To calculate gas fuel use the formula:

G = N / (QH x 0.95) , where:

- G – estimated gas flow, m3/hour;

- N – thermal power of the convector, 100 m2 – 10.0 kW;

- QН – lower calorific value of gas – 10.175 kW/m3;

- 0.95 – convector efficiency, %.

Hourly gas calculation:

10 / (10.175 x 0.95) = 1.034 m3/h

Daily indicator:

1.034 x 24 = 24.8 m3/day

Seasonal consumption, with a heating period of -185 days:

24.8 x 185= 4593 m3/season

It should be clarified that this calculation is approximate; the actual consumption will depend on the parameters mentioned above.

Additional functionality

There are several such functions that consumers additionally choose:

- Timer for setting the operating period;

- fan to improve convection;

- control valve to control combustion mode;

- thermostat to support the operating mode and working in tandem with a gas valve;

- an automation and safety system monitors the stable operation of the heater and turns it off in the event of an emergency due to gas pressure, lack of air, or gas contamination in the room.

Nuances of calculations

Knowing the monthly gas consumption, you can determine the annual need for gas fuel. These calculations are valid for main gas and will differ slightly for liquefied gas. The heating season depends on the geographical location of the installation. It is determined in a tabular manner according to SNIP 01/23/99 “Construction climatology and geophysics”. For example, for the city of Moscow – 214 days.

Calculation of gas for heating: 36.96 X214 = 7909 m3, although in fact this is the maximum possible consumption, since the minimum outdoor temperature in winter will only be a few days, and the average temperature will be much higher. And it is she who will determine the actual fuel consumption. But to select equipment, the maximum calculation is taken to ensure reliable operation of the heater at the lowest temperatures.

Convector using bottled gas

This gas convector has its own characteristics that must be taken into account when choosing a model. The most optimal version of the device with a cast iron heat exchanger and control unit.

Similar to natural gas, power is also taken into account here, but you need to understand that these units are space efficient, so a separate one is installed for each. For apartments, devices with a closed chamber with a coaxial chimney are recommended, but even then it is not allowed to be installed in a multi-storey building due to the high explosion hazard of cylinder installations.

Convector using bottled gas

Many home owners equip such heating along with the installation of gas tanks that are filled with gas for the entire heating season.

Calculations for determining the volume of required gas are similar to those above, except that the lowest specific heat of combustion of liquefied gas is assumed to be 12.8 kW/kg, and the efficiency is 0.92. For the above example, heating a house with an area of 150 m2, calculation of the need for liquefied gas:

15 / 12.8 x 0.92 = 1.27 m3 / h of liquefied gas.

Daily consumption is 1.27 x 24 = 30.57 m3, and

Monthly consumption – 30.57 x 30 = 917 m3 As is obvious, in the case of using liquefied gas it will be required less per month by almost 170 m3. However, this does not mean that in general such heating will be cheaper, since its cost is much higher than main gas. In addition, liquefied gas is inferior to natural gas in many other respects, so liquefied gas convectors are installed only in areas where there is no central gas supply.

Gas convector on natural gas

This model is preferable for autonomous heating, but in order for it to work effectively you need to know the differences and advantages of the modifications that are sold through the retail chain

After determining the required power of the unit, the next thing you need to pay attention to is the installation method, which can be wall-mounted or floor-mounted. The first ones are small in size and weight, while being quite efficient, but limited by a productivity of 10 kW

For heating large industrial premises, such as garages or repair shops, it is recommended to choose floor-mounted options. These models have a large weight and size due to the developed heating surface of the heat exchanger.

Modern gas convectors are equipped with closed combustion chambers. They are mounted together with a coaxial chimney. Due to the fact that air is taken from the street, they do not burn oxygen during the heating process, which creates positive sanitary and hygienic conditions in the room and is a huge plus, despite the increased cost of installation, up to 30% compared to open ones combustion devices.

Nuances of installation and operation

Open type portable gas heaters are not recommended for use in bedrooms, bathrooms or hallways. Some models specify the minimum room size and mandatory ventilation requirements for heating appliances. The installation of gas equipment must comply with the state standard regarding the safety of gas installations.

Basic requirements for safe installation of a gas convector:

- It is prohibited to place devices in fire hazardous areas. The heater is placed under the window.

- The chimney pipe must be mounted externally and equipped with an outlet.

- Installation, dismantling, adjustment and commissioning of gas equipment is carried out only by certified Gorgaz specialists.

- After installation work is completed, commissioning work is carried out.

- Before the first start-up, open the gas inlet valve and check all joints on the gas line with a brush and soap solution.

- A piezo igniter is started to ignite the gas. It is possible that during the first hours of operation of the installation there will be a smell of burning oil due to the burning of the walls of the combustion chamber; in the future, the operation of the convector should be odorless.

Gas convector Hosseven HDU-5 DK

Manufacturers and popular models

Gas convectors are popular devices especially in areas where there is no central heating and there is a main gas pipeline. In addition, many buyers use this type of heating as a peak heating system when the main heating is not enough in severe winter conditions.

Popular models according to the 2021 rating are:

- KARMA BETA 5. Heater for small individual houses with an area of up to 60 m2. The device is quite efficient with an overall efficiency of up to 89%, providing a thermal power of 4.7 kW with a relatively low gas consumption. Thermal range: from +13C to +38C. Good system for protecting and regulating the heating process. The disadvantages include the high price - 19,672 rubles.

- Alpine Air NGS-50F is a Turkish convector with a power of 4.9 kW for a heated area of 50 m2. The model of this Alpine series has an efficiency of about 87%. The device is equipped with an Italian Polidoro burner and Sit shut-off and control devices, which guarantee 50 years of trouble-free operation. The price of the set is 20,560 rubles.

- Hosseven HDU-5 DK is another heater from the best Turkish brand with a power of 4.5 kW and an estimated heating area of 50 m2. The manufacturer guarantees reliable operation for up to 50 years, since the device is equipped with a cast iron heat exchanger and an Italian burner. The unit has a high efficiency for this class of equipment - 90%. The price of the model is 21,400 rubles.

A gas convector running on natural gas is the most energy-efficient equipment among heating equipment of a similar type. Modern advances in materials science and information technology have raised their efficiency to a new level, and therefore they have become more often used in autonomous heating schemes, having a long service life of several decades.

Gas heating convectors: advantages and disadvantages

There are many advantages, and they all come from the most important advantage - the efficiency of the convector operation. This is affected not by its design features, but by the energy capacity of natural gas - if we compare this resource with the same electricity, then with their relatively equal cost (1 kW of electricity is slightly cheaper than 1 m³ of gas), there is a tenfold difference in the ability to release thermal energy. Let's just say that the heat that is generated by 1 kW of electricity is achieved by using 0.1 cubic meter of gas. There is one “but” here – we are talking about each individual convector. If there are ten of them, then there can be no talk of any economical operation - in such situations, liquid heating systems will be much more efficient.

As for the other advantages of gas convectors running on natural gas, they include the following points.

- Versatility. With equal success, gas convectors can operate both on main fuel and on bottled fuel. They are easily rebuilt, which allows you to use liquefied gas for heating the house. And this is neither more nor less, but the ability to use a gas convector on liquefied gas far from the benefits of civilization - for example, with its help you can heat a house in the village.

- Such heating devices do not require coolant. Or rather, it is needed, and ordinary air acts as a coolant, which makes this type of equipment independent of the presence of water in the house.

- Environmental friendliness and safety. We have already said above that gas convectors do not burn oxygen indoors - they take it from the street. They also send all the exhaust gases there, so that a person inside rooms heated in this way can breathe, as they say, deeply.

- Possibility of automation. When installing additional equipment, it is quite easy to switch the convector into autonomous operation mode - it is able to maintain the set temperature indoors, regardless of the weather conditions outside.

Gas heating convectors photo

There are not so many disadvantages of a gas convector - one might even say that there are practically none. These include only their dimensions and lack of mobility - after installation they are almost impossible to move to another place. Also, as a disadvantage, we can note the higher cost compared to their electric counterparts - in principle, even with a twofold superiority in price, gas equipment of this type pays for itself quite quickly and today is the best solution for small houses and other buildings.