Brick

This is one of the oldest types of chimneys, which is still very popular. They lay a brick chimney made of solid ceramic bricks. The smoke exhaust duct is located in the brickwork.

Brick chimney

The advantages of brick chimneys include:

- resistance to mechanical stress;

- high heat capacity of the structure, allowing the heated chimney to release heat for a long time;

- absolute fire safety, subject to compliance with safety requirements.

Note: The disadvantages of brick chimneys are worthy of detailed coverage. Thanks to this, it will be possible to better appreciate the advantages that other types of chimneys have.

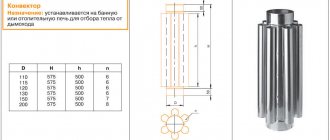

Mounted chimneys

Scheme of a mounted chimney

This type of design is in great demand for home stoves due to its small overall area. They do not occupy huge spaces around furnaces or boilers, but act like extensions of the pipe. To erect them, it is necessary, immediately after the last row of bricks to be overlapped, to lay out a pipe all the way through the roof and ceiling onto the roof.

Disadvantages of brick chimneys

- The rectangular cross-section of the chimney is not a very good solution in terms of draft. In corners, the flow rate of flue gases is lower, which reduces the efficiency of removing combustion products from furnaces.

- Irregularities of the inner surface (protrusions and depressions) reduce the rate of passage of gases. Also, soot and condensation easily settle on such a surface. Combustion products of solid fuels or natural gas contain large amounts of sulfur oxides. An odorant is specially added to the gas, providing that very recognizable pungent odor. A special feature of the odorant is its high sulfur content. Sulfur oxides deposited on the walls of the chimney react with water (condensate), forming sulfurous (weak) and sulfuric (very caustic) acid. These acids cause brick and mortar to break down, reducing the strength of the structure.

- The large mass of a brick chimney forces a separate foundation to be built for it. Moreover, it is advisable to do the foundation for the stove and chimney before the construction of the building begins.

- Complex and labor-intensive installation of brick chimneys, which is incomparable with any other type. The work requires a highly qualified mason and takes several days.

Types of chimneys

Now it’s worth examining the types of chimneys and their features.

Brick

First, it’s worth looking at the advantages of such structures:

- They are resistant to mechanical stress.

- Their heat capacity allows the house to remain warm for a long time.

- If you comply with all fire safety requirements, brick chimneys do not pose a fire risk.

Brick pipes also have their disadvantages:

- Due to its rectangular design, the efficiency of removing combustion products is reduced.

- Gases have a more difficult time passing through a pipe with an uneven surface.

- For a brick pipe you will need a separate foundation.

- Installation is complex and time-consuming.

Ceramic

They are assembled from separate cylinders assembled together. Due to the smooth coating, the surface does not absorb harmful substances. In addition, the advantages include:

- Long service life.

- Possibility of installation both indoors and outdoors.

Disadvantages of ceramic pipe:

- Expensiveness of the product.

- There are several joints per linear meter, which leads to the risk of leakage of harmful substances.

- Installation should only be carried out by specialists.

- The ceramic chimney is installed only in a vertical position.

- Due to its heavy weight, it requires an additional foundation and cannot be installed in every home.

- Requires thermal insulation when placed outdoors.

Welded chimneys

They are usually made from steel pipes and are therefore susceptible to corrosion. The sulfuric acid formed as a result of combustion contributes to the rapid destruction of such a chimney. Another disadvantage is the complexity of installation.

Chimney made of single-wall pipes made of stainless or galvanized steel

It is made in the form of a structure made of metal pipes. Basically, a chimney of this type has many advantages:

- Relatively low price.

- Possibility to position the pipe vertically, horizontally or at an angle.

- Such a pipe does not take up much space.

- If there is appropriate insulation, the chimney can be built-in.

- Light weight structure.

- Due to easy installation, the possibility of self-installation.

The disadvantages include:

- The need for additional insulation for external installation.

- Compared to ceramic pipes, the service life is short.

Sandwich chimney for boiler

Such a chimney looks like a pie made of two pipes, between which there is a layer of insulation.

Advantages of a sandwich chimney:

- When placed outdoors, it does not require additional insulation.

- Due to its lightweight design it is suitable for any type of home.

- No separate foundation required.

- You can install it in literally 1-2 days.

- Can be installed in the wall of the house.

- Possibility of self-assembly if you have the appropriate skills.

There are not many disadvantages of a sandwich chimney:

- High cost compared to other single-wall metal structures.

- The service life is lower compared to a ceramic chimney.

Single-circuit modular steel chimneys

A steel chimney is assembled from several elements. Most of the elements are a section of steel pipe. However, the design also includes more complex elements - tees equipped with glasses to collect condensate.

The material for the chimney elements is acid-resistant, heat-resistant stainless steel (stainless steel) with a wall thickness of 0.6-1 mm. Pipes manufactured taking into account these requirements have a long service life. In practice, different types of stainless steel and even galvanized steel are used. Galvanizing is the worst solution. The protective layer of zinc quickly burns out under the influence of temperature and the unprotected walls of the channel begin to collapse under the influence of water and acids.

Single-circuit steel chimney

Advantages of single-circuit steel chimneys:

- smooth inner surface that prevents the deposition of soot and condensation;

- round cross-section, providing good traction and uniform gas flow rate;

- light weight;

- simplicity and low complexity of installation;

- sufficiently high resistance to corrosion;

- maintainability.

Disadvantages of single-circuit steel chimneys:

- high thermal conductivity leads to rapid cooling of gases and the formation of large amounts of condensate. Pipes require large indentations where the chimney passes through the wooden elements of buildings (ceiling, walls, roofing).

- short service life of the chimney - no more than 15 years.

How to choose a pipe and not make a mistake

The choice of chimney pipe, in addition to the owner’s wishes, is influenced by objective factors. If the heating system is installed during the construction of a house, then the choice of design solution for the chimney is limited only by the equipment requirements. If this is replacing a pipe in a residential building, then a steel chimney is the optimal solution.

We recommend that you read: How to make a cap for a chimney pipe with your own hands?

You cannot skimp on smoke removal. From here:

- Rule one: do not skimp on the choice of materials.

Note! The efficiency and durability of a chimney depends not only on its material, but also on compliance with operating rules. Large and insufficient (when the chimney does not warm up for a long time in cold weather) loads are equally harmful for the chimney.

Overheating of the pipe leads to its cracking. Underheating allows a large amount of condensate and harmful emissions to settle on the walls, which also leads to the destruction of the structure, therefore:

- Rule two: the pipe must match the equipment used.

For example, the heat resistance requirements for steel (thickness, alloy) for a sandwich pipe vary depending on the fuel used. GOST 5632-61 lists the permitted steel grades for heat-resistant use. When buying a sandwich, it is important to pay attention to the grade of steel. When constructing a brick pipe, it is worth using fire-resistant materials.

- Rule three: Purchase the necessary pipe elements according to plan.

For example, when installing a modern sandwich, it is necessary to install a damper (furnace damper), condensate collectors, and revisions for cleaning and removing condensate resins.

- Rule four, although it can be put in first place: it is better to draw up a chimney exhaust project with a specialist, even if you plan to install it yourself.

A professional project will allow you to arrange the chimney in the best way: the pipe will be of the required length, made of suitable materials, and the design of the smoke exhaust device will be correct.

Steel sandwich chimneys

Double-circuit sandwich chimneys are products made from two steel pipes of different diameters inserted into one another. The space between the pipes is filled with non-flammable insulation. Thanks to insulation, sandwich pipes have low thermal conductivity, providing additional benefits:

- slow cooling of flue gases and high speed of their passage through the channel;

- minimal condensation formation;

- possibility of external installation without outlet through the roof;

- simplified requirements for installation inside the building and outlet through the roof.

Sandwich chimneys

There is only one disadvantage of this type of chimney - the price. They are noticeably more expensive than other types of steel chimneys.

Requirements for pipes for installing chimneys

For high-quality operation of the chimney, it is necessary to create good natural draft. Norms and requirements for pipes have been developed and approved by state standards. Compliance with these standards when installing a chimney guarantees the safe operation of your heating equipment.

Requirements for smoke exhaust pipes to ensure stable draft:

- The vertical distance from the furnace firebox to the pipe head should not be less than 5 meters.

- Horizontal sections of the chimney reduce the level of draft. To connect the stove to the chimney, it is allowed to install a meter-long horizontal section (with a rise of 2 cm). In some projects, an increase in the horizontal part to 2 meters is allowed. To ensure good draft from the furnace, a vertical pipe of 1 m is installed, to which a horizontal section is connected.

- Pipe sections with an elevation angle of 45 degrees are allowed.

- The total length of inclined and horizontal pipe sections is no more than 3 m for heating boilers and 2 meters for classic stoves and fireplaces.

- Combining several heating appliances into one chimney network is possible if the appliances are located on the same floor. The cross-sectional area of the combined chimney cannot be less than the sum of the cross-sectional area of all channels.

- The pipe outlet to the roof is located as close as possible to the ridge. The head must rise above the ridge by at least 50 cm if the pipe is no further than 1.5 m.

- There is a dependence of the height of the pipe on its distance from the ridge. Thus, the pipe outlet at a distance of 1.5 to 3 m is allowed flush with the ridge. Further 3 m - the head of the pipe with the level of the ridge should form an acute angle of no more than 10 degrees.

- The chimney must be sealed throughout. The intake of air from outside leads to the formation of reverse draft and the release of toxic combustion products into the house.

In addition to the requirements for the pipe, there are requirements for the oxygen level in the heated room. A stove with a chimney sucks in and absorbs a large volume of oxygen during combustion. It is necessary to ensure a flow of fresh air into the room. For a living space, it is enough to open the window. In industrial furnaces, forced ventilation is installed in the supply.

We recommend that you read: Using metal corrugation for cable wiring

Requirements and standards for smoke exhaust ducts: see.

Ceramic

This type of chimney appeared in Russia quite recently, but quickly became popular, despite the high price. The smooth surface of the ceramic chimney does not require frequent cleaning. Each ceramic chimney element includes:

- chimney made of special fire-resistant ceramics;

- a thermal insulation layer made of non-combustible material, ensuring safe passage through walls and roofs;

- protective cover made of lightweight cellular concrete.

Ceramic chimneys

This type of chimney combines all the advantages:

- smooth inner surface;

- round cross-section and smooth, good traction;

- excellent thermal insulation and sealing;

- heat and fire resistance;

- ease of installation;

- durability.

The only disadvantage of ceramic chimneys is their high cost. They can be used for smoke removal from any stoves, fireplaces, boilers and water heaters.

Which pipe is better to choose for a bath?

You have fulfilled your old dream: you installed a bathhouse next to your house. Everything turned out just great. All the work has already been done. The stove has been built. It would seem that you can just take it and flood it. But there remains a small problem that upsets the whole idyll: it is necessary to install a pipe for the stove.

After installing the sauna stove, the time comes to select the right pipe, which will ensure uninterrupted heating of the room. This design has different qualifications for localization, and also differs depending on the materials used.

Types of chimney pipes by location

Chimney pipes differ in external and internal ones; the bathhouse owner should decide on this issue in advance.

External installations are not adjacent to the fireplace stove; they are mounted outside, along the facade of the room, and ensure fire safety. In this case, you will not have to make holes in the roof and wall, but the heat transfer consumption will be significant.

Internal installations are mounted above the furnace. If the implementation of this type of pipe takes a little longer, this pays off with the advantage of stable heat retention in the room.

Types of chimney pipes depending on material

Every bathhouse owner wants to experience comfort and enjoy health-improving treatments. To do this, you need to choose the right modern materials for the structure, so brickwork will not work. Ceramic pipes show excellent heat transfer results, but their use for a bathhouse is impractical.

Stainless steel sandwich pipes are double-circuit modules made of stainless steel types, which are supplemented with special materials for thermal insulation. They show high performance and do not accumulate condensation. Installation work does not involve large costs due to the lightness of the design. Another advantage of steel pipes is their ability to be painted in any color, with a steel thickness of 1 mm considered optimal.

Types of smoke exhaust structures

The chimney for a steam room can be external or internal. In our country, you can often find internal options. Among their advantages is the absence of violation of the architectural style, as well as saving heat in the room. Which chimney is better for a bath? All the heat remains inside the steam room. Internal systems are good because they have better traction. They are also easier to care for. The internal structure also does not require insulation.

External chimneys are not entirely traditional for use in our country; they have an original appearance, and there is no need to make a hole in the ceiling. Internal chimneys do not interfere with design elements and retain heat with high efficiency. They have better traction and are easy to maintain.

Popular schemes for installing sauna chimneys

The main task of the chimney is to ensure heat retention and quickly remove combustion products. The ideal placement is if the structure is close to the wall; alternatively, a stronger wall is used. If you plan to use several stoves, it is recommended to install a separate chimney for each, so as not to lose draft power.

Installation of chimneys for a bathhouse for a metal stove

The installation of a chimney begins with connecting a stainless pipe to the stove pipe. In this case, it is important to take into account the diameter of the pipe and the height of the entire chimney. If you place a mono pipe, heat exchanger or samovar-type tank on the stove as the first part, then you must take into account that single-wall parts must be located at least 30 cm from the ceiling. Don’t forget about the passage elements in the ceiling and roof.

If the oven is brick

Many bathhouse owners build such structures themselves. When laying bricks, 2 channels are formed, which are subsequently connected. It is advisable to lay out an additional row above the core of the fireplace stove so that the structure does not crack in the near future. It is important to observe the standard pipe cross-section so that the gases do not have time to cool before the required time.

Asbestos-cement

Asbestos-cement pipes are used in the construction of chimneys for heating devices, the flue gases of which have a temperature of no more than 300 degrees. They are not suitable for conventional ovens. These limitations are caused by the unsatisfactory heat resistance of chrysotile cement.

Asbestos-cement chimney pipes

Advantages of asbestos cement chimneys:

- light weight (if we compare brick chimneys);

- round section;

- simple quick installation;

- very low price.

Price is the deciding factor here. This is the material that can be taken, as they say, “by the bottle.”

Disadvantages of asbestos cement chimneys:

- low strength;

- poor heat resistance;

- lack of thermal insulation;

- complexity of bending;

- unreliable connection with rubber couplings;

- porous wall structure;

- Frequent cleaning of chimneys.

The last point deserves special attention - the ignition of soot in asbestos-cement chimneys is a serious problem. For safety reasons, regular cleaning of such chimneys is necessary. Therefore, the use of this type of chimney has significant limitations.

Types of chimney systems based on gas movement

Forced draft chimney systems are not typical for private households. We will choose from chimneys that operate on the natural ability of heated gases to rise upward.

Note! The trajectory of gas movement directly affects the draft force, the efficiency of the stove and the degree of contamination of the chimney.

The following types of chimney systems are distinguished according to the trajectory of gas movement:

- Multi-turn. These are smoke exhaust channels that have a snake trajectory. The hot gases do not immediately go to the exit, but change their direction up and down several times. The snake can be oriented vertically or horizontally. Typically, this is 3 turns in the chimney of a traditional brick oven. The multi-turn chimney system requires regular cleaning. The slightest mistake in the design leads to a critical decrease in natural draft, as well as contamination of the channels with soot. The brick chimney is gradually losing ground to more modern pipes made of metal and ceramics.

- Single-turn chimney systems have a gas exit trajectory with one rise and fall. Here the gases do not have time to cool down much, so the draft remains good. The furnace does not become so dirty, and due to the absence of a significant temperature difference, the destruction of the masonry is not as intense as with a multi-turn system.

- Ductless chimneys - smoke from the firebox rises into a large chamber-hood and is then discharged outside. There can be several output channels at the same time. The peculiarity of a ductless chimney is that the stove heats up more intensely in the upper part and the heat is localized under the ceiling.

Note! A common disadvantage of traditional chimney systems is uneven heating of the stove. The heat is localized in the upper part and does little to warm the living area of the room.

Modern wood stoves, coal and gas boilers make it possible to control the combustion process. Here, the configuration of the chimney does not play a decisive role in the level of heat transfer. The chimney system faces the challenge of effectively removing combustion products without the need for complex maintenance.

We recommend that you read: Why do you need a ventilation fungus and how to install it?

Choosing the right one

Any owner knows that building a house begins with a heating stove. When choosing pipes for a chimney, you must first consider what fuel will be used.

Usually it comes in the form:

- gas;

- liquid fuel;

- solid fuel;

- bulk fuel.

It must be taken into account that each type of fuel has its own characteristics, certain features, that is, it is different:

- combustion temperature;

- temperature of exhaust gases;

- chemical composition of smoke.

When choosing pipes, you need to pay attention to the following:

- If the chimney pipe is intended for wood-burning home and sauna stoves, solid fuel boilers, fireplaces, then they must be able to withstand high temperatures of up to and more than 700 degrees Celsius, but should not exceed more than 1000 degrees.

- For gas flues, the operating temperature should be about 200 degrees Celsius and no more than 400 degrees.

- If chimneys are chosen for sawdust, pellet, liquid fuel boilers, then their operating temperature ranges from 250 to 400 degrees Celsius.

An important indicator is the thickness of the inner wall of the product:

- for diesel, gas, pellet boilers up to 0.5 mm;

- for stoves, sauna stoves, fireplaces from 0.7 to 1.0 mm;

- for coal stoves – 1.0 mm.

You need to know how to wrap a chimney pipe. Usually this is basalt thermal insulation. It is also always of different thicknesses for different systems.

- If the boilers are gas, liquid fuel, pellet or sawdust, then the thickness of the thermal insulation should be from 28 to 50 mm. It is necessary to take into account the materials used in the building structures of the house;

- If fireplaces, stoves, solid fuel boilers, then the insulation thickness is up to 100 mm, the type of material of the building structures is also taken into account.

We must remember! Ceramic chimneys are considered the most unpretentious; they are ideal for all appliances and no matter what material the houses are built from.

Differences in chimneys depending on location in space

The types of chimneys for stoves can differ not only in the configuration and type of material used. If we take the differences depending on placement as a basis, then there will be only two subtypes - horizontal and vertical. Horizontal is created specifically in cases where you need to create an additional heat source. However, we must not forget about the disadvantages of this kind of systems, because due to their “lying down” position, the channel is often clogged, soot and soot build-ups are formed, which are extremely labor-intensive to remove. Therefore, special “hatches” are provided for preventive cleaning.

The vertical outlet is classic; not even a single horizontal channel can do without it. However, such systems have one drawback, namely, uneven heating of the channel throughout. In addition, there are cases when, due to high gas resistance, partial smoke occurs in the room. Therefore, the peculiarity of its operation is that when kindling it is necessary to always open the damper, and then, when the fire has flared up, close it, allowing natural draft to cope with the task.

Exploitation

If the choice is made, then it remains to be taken into account that the service life of the chimney will depend on proper operation. Therefore, when using, you must consider and follow the following rules:

- all constituent elements must be connected hermetically;

- It is imperative to regulate the temperature and draft during use;

- you need to take a serious approach to arranging a ventilation channel;

- all heads must be protected from atmospheric influences;

- do not forget about condensate, it must be drained correctly;

- use a casing on the chimney pipe;

- the entire system must be cleared of soot in a timely manner;

- fuel must be selected without foreign inclusions;

- burn fuel in accordance with established norms and rules;

- excessively intense combustion should be avoided;

- correctly calculate the distance from the chimney to the gas pipe;

- avoid hypothermia;

- The system must be inspected periodically.

By following simple rules you can extend the service life of any type of chimney.

Before installing a fireplace or stove, you always need to first think through the chimney system and choose the right pipes. Then the heating device will last a long time and will delight household members not only with its appearance, but also with its performance.