01.06.2015

| no comments

Convection ovens are now beginning to enjoy enormous popularity in our country. The Buleryan stove is rightfully considered one of the most popular options for this type of heating device. [contents]

Such devices run on wood fuel. Due to their high efficiency, they are able to warm up the room very quickly. The energy-efficient stove has Canadian roots and is a long-burning device.

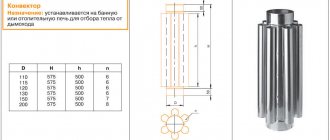

Despite the fact that the Buleryan stove is the same potbelly stove, only modern, its design is strikingly different from its domestic counterpart. A characteristic feature of such a stove is the presence of pipes located below and above the firebox.

In order for the stove to fully cope with heating the house, special attention should be paid to the choice of chimney pipe.

Let's start with the fact that the Buleryan stove is a unique device that plays the role of a heating device and a gas generator. Being an absolutely unique device, it requires the formation of the same chimney.

Installing a chimney structure for this type of device will not cause difficulties even for novice builders.

Popular manufacturers

After you decide what material the chimney is suitable for your Buleryan stove, the next step is to choose a manufacturer. Eight companies are leaders. Let's look at the features of each of them.

- Schiedel . This German company has existed since 1946. Offers only two types of chimneys for Buleryan - steel and ceramic. All models are suitable for apartment buildings, private 1-2-story cottages. Also in the range you can find pipes for connecting to existing brick chimneys. The company provides a thirty-year warranty on its products.

- Bofill . Spanish manufacturer of chimneys, one of the oldest on the market (existing since 1892). It specializes in AISI 304 and 316 stainless steel pipes. The company guarantees thermal and mechanical strength, all products undergo vibration testing and thermal shock testing. The chimneys will remain sealed when the stove heats up to 700 degrees.

- Baltvent . Another company specializing in the manufacture of stove chimneys made of stainless steel (sandwich with insulation). The catalog contains models for multi-apartment high-rise buildings, cottages, and industrial facilities. The production plant is located in Kaliningrad. The steel used by the manufacturer is AISI 316L and AISI 304, which are considered the best in terms of anti-corrosion properties and durability.

- Teplov and Sukhov . The company offers pipes for Buleryans made of a special heat-resistant material - steel with the addition of molybdenum and titanium. This chimney can withstand very high temperatures (up to 1000 degrees) and provides high efficiency. The company's catalog includes systems for residential stoves, as well as systems suitable for industrial buildings.

- Jeremias . German company with the main plant in Bavaria. Additional production facilities are located in the USA, Poland, Russia, Spain. In addition to standard steel structures, it offers customers devices for collective connection - installation of chimneys to which several stoves can be connected at once.

- Vulcan . A Russian company producing double-circuit sandwiches, oval steel systems, simplified single-wall chimneys. Different models of steel are used in production - AISI 321, 316 L, 310. They differ in characteristics and cost, so the client can easily choose an option that is suitable in terms of price-quality ratio.

- Effe2 . An Italian company producing durable ceramic chimneys. A special feature of Effe2 products is their light weight compared to ceramics from other companies. Another feature is complete protection against condensation and, as a result, a long service life. The manufacturer provides a 40-year warranty on its chimneys.

- Tona . The German corporation makes only ceramic chimneys, ideal for Buleryans. It works using a patented technology that makes it possible to obtain a material that is resistant to increased heat and has a low weight. The products are quite expensive, but this is compensated by their long service life. The manufacturer assures that repairs and replacement of chimneys for stoves will not be needed for at least half a century.

Manufacturing options

Today, two options for manufacturing the Buleryan stove are known, based on the materials they are made from: from profile and curved pipes or from a gas cylinder. Each type of system has its own efficiency and varies in implementation complexity:

- From a profile pipe. The Buleryan system made from a profile pipe is a simple design that provides efficient heating of small spaces: a garage, greenhouse, barn or small gym. The stove is easy to manufacture and can be made by any welder from scrap materials.

- From a gas cylinder. Due to the fact that almost every private yard has an old gas cylinder, this type of stove is made quite often. An excellent solution for a country house or garage, and thanks to the shape of the cylinder, it becomes possible to implement interesting design ideas.

The Buleryan stove is easy to make with your own hands, no matter what type you decide to make yourself. The choice depends on the capabilities of the master, the availability of material and the skills of the owner

Cost of a complete chimney kit

It will not be possible to name a single price, since the cost of different types of structures will vary greatly. It depends on:

- chimney material,

- modifications,

- length,

- diameter,

- the need for additional accessories (angles, adapters, fasteners),

- presence of decorative elements.

We can only give an average price: a steel pipe will cost 18,000-25,000 rubles, a ceramic pipe will cost 42,000-65,000 rubles. Exact prices are calculated only after drawing up project documentation.

Manufacturing options

Today, two options for manufacturing the Buleryan stove are known, based on the materials they are made from: from profile and curved pipes or from a gas cylinder. Each type of system has its own efficiency and varies in implementation complexity:

- From a profile pipe. The Buleryan system made from a profile pipe is a simple design that provides efficient heating of small spaces: a garage, greenhouse, barn or small gym. The stove is easy to manufacture and can be made by any welder from scrap materials.

- From a gas cylinder. Due to the fact that almost every private yard has an old gas cylinder, this type of stove is made quite often. An excellent solution for a country house or garage, and thanks to the shape of the cylinder, it becomes possible to implement interesting design ideas.

The Buleryan stove is easy to make with your own hands, no matter what type you decide to make yourself. The choice depends on the capabilities of the master, the availability of material and the skills of the owner

How to properly install a chimney system?

Even the most expensive and correct chimney for Buleryan will not cope with the assigned tasks if the rules were violated during installation of the structure. The following lists the main installation features.

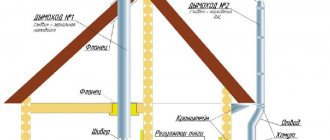

External installation of a chimney

Installation work is carried out according to the following plan:

- A hole is created (in the roof with a vertical outlet or in the wall when the pipe is led out along the facade of the house).

- The chimney elements are assembled and fastened together.

- The distance between the walls of the hole and the chimney device is filled with non-flammable insulation.

- After pulling it out, the structure is attached to the wall or roof with clamps.

- When the chimney system rises above the roof by more than 2 meters, a stretcher is installed to protect from the wind.

If you decide to route the pipe through a window, then cutting out holes is not necessary. This is convenient, but the appearance will not be neat

Options for exhausting the chimney outside

.

In-house chimney installation

When arranging a roof cut, it is important to take into account that the pipe can heat up to 50-60 degrees, and the steam at the exit can have a temperature above 300 degrees. This means that all nearby wall and roof materials must be heat-resistant, and there should be no gas pipes or fuel storage nearby. Between the chimney device and the roofing materials you will have to make a penetration with a fire gap of 25-30 centimeters.

Don't make mistakes, there are consequences

Connecting a chimney for Buleryan

To complete this installation step, you will need an adapter. The role of the adapter is performed by a standard stainless steel pipe. After all installation work, a traction check is required. This is done using open fire. In the oven, open the damper and bring in a lit match or piece of paper. The flame should be drawn steadily into the firebox, the smoke should not go into the room, but should be directed strictly through the chimney.

Adapter for connecting the chimney to Buleryan

Installation option 1

Installation option 2

Technical points

The chimney can be placed inside or outside the building. External installation is used when installing a heating unit in a ready-made house. This technique involves venting the chimney through the wall of the room.

Experts include the following advantages of this technique:

Design and operating features of the unit.

- significant space savings;

- quick and easy installation;

- there is no need to remove this unit through the interfloor ceiling and roof of the building.

The disadvantages include:

- presence of a horizontal section;

- carrying out thermal insulation work;

- unoriginal appearance.

The internal placement of the chimney involves the passage of its vertical sections of stainless pipe inside the building. In this case, the chimney is installed near the internal walls and partitions. It is discharged through the interfloor covering and the roof using special pipes and roof penetrations. To do this, you will need the following tools: hammer, hammer drill, drills, hammer.

Due to the low weight of stainless steel structures, installation work is carried out without installing an additional foundation. The difficulties of such a procedure include ensuring its safe passage through the ceiling, including a safe and sealed chimney exit through the roof.

Experts include the following advantages of this technique:

- presence of good traction;

- providing additional heat from the chimney itself.

The disadvantages of the internal placement of the chimney include:

- carrying out complex installation;

- occupied usable area;

- ensuring the tightness of the chimney passage through the roof;

- provision of additional fire safety measures when the chimney passes through the interfloor ceiling and roof.

Features of the operation of chimney pipes

When using a stove, a number of questions may arise related to the operation of the chimney. Below are answers to the most common ones.

How long does a chimney last?

The operating time depends on the material of the chimney and the intensity of use. It also affects how often and with what the owner cleans his Bulleryan.

If you remove soot, remove condensation, and load the system correctly, then steel models will last 5-7 years, multilayer steel pipes - 12-17 years, ceramic chimneys - more than 40 years, brick ones - over half a century. Failure to comply with the rules for using the structure reduces the service life by three times.

Why does wind get into the chimney?

The wind blows into the chimney and interferes with the normal outflow of smoke when the rules for calculating and installing stove parts have been violated:

- The total height of the structure should be three meters.

- The chimney must rise above the roof by at least half a meter.

- All seams must be carefully treated with sealant.

If these rules are not followed, the wind will freely “walk” through the pipe.

Why does condensation appear, how to avoid it?

Water does not accumulate only in ceramic and multi-layer steel chimneys. In other cases, condensation cannot be avoided. It can be reduced by additional thermal insulation, which prevents temperature changes and the formation of “dew”.

If it is not possible to reduce the accumulation of water, then you need to wipe the outlet manually 1-2 times a month. Prolonged accumulation of water is dangerous for the chimney - the liquid mixes with substances from the smoke and corrodes the walls.

Why does soot accumulate, how to clean it?

When burning wood and other solid fuels, soot appears. There is no need to panic - this is a normal process, you just need annual cleaning (1-2 times a year).

Attention: mechanically cleaning the passage is prohibited, as scratches will appear, which will disrupt the operation of the chimney. It is safer to clean walls with chemicals.

It’s bad if soot formation occurs too quickly (when cleaning is required after 2-3 months). The problem may be:

- violation of tightness,

- horizontal pipes are too long (should not exceed 2 meters),

- using low-quality fuel for the stove.

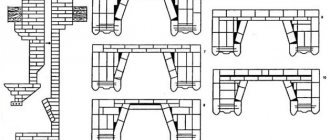

What elements should a chimney consist of?

Required elements:

1. Main pipe. Displayed vertically. Pipes can be single-walled (not insulated) and insulated (sandwich). Go to the chimney pipe section2. Tee. Serves for joining the horizontal and vertical sections of the chimney. The use of elbows (corners) for these purposes is not recommended, because During operation of the stove, condensation forms on the walls of the chimney. If you use an elbow, then all the condensate will drain into the oven. To prevent this from happening, use a tee. In addition, the tee will be useful if you need to clean the chimney. Go to the chimney tees section

3. Watering can Installed as a plug on the underside of the tee (now shown upside down for clarity). You can put a hose on the pipe and drain the condensate, for example, into a bucket or sewer. Go to the chimney watering cans section

4. Fungus Protects against precipitation getting into the pipe. Go to the chimney fungi section

5. Fastening Attaches the chimney to the wall. Because pipes have a maximum length of 1 m, therefore, they need to be fastened at least every meter. Go to the chimney fastening section

Additional items

1. Horizontal pipe Connects the furnace pipe and the tee. It is used if the vertical pipe is located at a distance from the stove itself (for example, if the chimney is routed through an external wall). 2. Kryza Serves as the basis for a sealed passage of the chimney through the roof. Layed in a herringbone pattern - the bottom part is laid on the roof covering; the top one is slipped under the covering. A pipe is inserted inside. The distance between the pipe and the roof is covered with comfrey. Go to the chimney roof section 3. Okapnik Covers the distance between the chimney and the roof. Structurally, it is a clamp with a “skirt”. Go to section 4. Deck Covers the lower part of the tee with a watering can. Can only be used with insulated pipes (the photo shows it “upside down” for clarity). Go to the decks section

Making a chimney with your own hands

Experts do not recommend making pipes for Buleryans yourself unless you have the appropriate knowledge and experience. This process is not easy and responsible. If you still want to try to install a chimney yourself, then we will briefly describe the difficulties that you will encounter in the process.

Materials and tools

It is difficult to assemble and install a chimney yourself. You need to purchase a large set - steel pipes for the Buleryan stove, tees, plugs, clamps, deflectors, floor dividers, outlet bends, brackets, etc. Before purchasing, you must make all calculations of the length and diameter of all parts. The picture below shows an example of what may be needed to install a steel chimney:

Attention: you can only assemble and install steel systems for Bulleryan yourself. Ceramic chimneys are too complex; it is better to entrust work with them to specialists.

Step-by-step assembly instructions

After all the parts have been purchased, you can begin assembling the structure and installing it. There are several options for collecting external and internal chimneys.

To connect parts, welding and pressing of seams are used. For precise convergence, it is necessary to make recesses at the ends of the pipes for nozzles, on which elements of a smaller diameter are “placed”. The two assembly methods are shown in the picture below:

The space between the parts is filled with non-flammable fiber insulation. Tip: to simplify the procedure, it is recommended to purchase a ready-made modular chimney kit. This will eliminate the need to independently select individual pipes and related accessories, and will protect you from errors in calculating the diameter and length of individual elements.

Connection

Setting up a stove assembled and installed by yourself completely coincides with the process of connecting the finished system. As was described earlier in the article, the main requirement at this stage is to check the tightness of the seams (the chimney should not allow smoke to pass through) and the correct draft.

The latter is checked by opening the stove shutter and holding a burning match (smoke should not go into the room, but should be clearly directed upward, the flame should be even, without fluctuations from the wind from the chimney).

The right chimney for Buleryan

Due to some design features, special attention is paid to the corrosion resistance of the material for the manufacture of the chimney pipe.

Most experts agree that the most suitable material for making a chimney structure with your own hands for this type of heating device is acid-resistant stainless steel. A stainless steel chimney will provide the pipe with the necessary degree of reliability and durability.

If you are planning to install a smoke exhaust pipe with your own hands, then pay special attention to the inner surface of the walls of the structure. They must be perfectly even and smooth, which will improve draft and low condensation characteristic of this type of furnace.

Installing a stainless steel pipe will not take much time, but knowing some of the subtleties will greatly simplify this process. All elements of the chimney structure installed outdoors and exposed to low temperatures, if you install the pipe yourself, are subject to high-quality thermal insulation.

As a thermal insulation material, experts recommend using a layer of basalt fiber with a thickness of 30 to 50 mm, which will prevent overcooling of the elements and the formation of condensation in the lumen of the pipes.

No less important conditions are the high resistance of the pipe material to high temperatures, its ability to provide stable smoke removal, fire safety, as well as simple and quick installation.

Conclusion

The chimney is an important attribute of any stove. The quality and safety of the heating system depends on the correct selection and installation. It is important to carefully approach the selection of materials, designs, and manufacturers. To assemble, mount, and connect an economizer, you need to know the rules - if you lack knowledge and experience in installing furnaces, it is better to entrust this task to specialists. They can also be called in the event of a device breakdown or if the structure needs to be cleaned.

( 1 ratings, average: 5.00 out of 5)

Features of furnace installation

Before installing Buleryan, you should make sure that in the room in which it will be installed, it is possible to organize a constant flow of fresh air necessary for its proper combustion. Correct installation of the chimney will ensure uninterrupted operation of the device.

The choice of location for installing the unit also requires special attention. The location for installing the stove must be chosen in such a way that the device can provide the most efficient heating of the room, and there is also free access to its combustion chamber for cleaning from combustion products.

It is very important to prevent fire that the floor under the unit is made of non-combustible materials.

In addition, the stove must be installed on a metal stand with a height of at least 20 cm or on a brick base. If the floor in the room is made of flammable materials, then in order to prevent a fire, the area in front of the firebox must be protected with a steel sheet.

As a result of the fact that the operating time of this furnace is significantly increased, the most stringent requirements are imposed to increase the efficiency during operation of the unit.

And if you decide to install a chimney for Buleryan yourself with your own hands, then you need to pay special attention to the choice of material and the conditions for installing the chimney pipe.

Long-burning heating stoves Breneran (Buleryan)

The manufacturer that produces long-burning stoves, Breneran, has accumulated impressive experience in the production of such equipment. These products have decent demand on the Russian market. The company gives a 2.5 year guarantee for the reliability and safety of its products.

The production company Laotherm has been present on the Russian market since 1993. Previously it produced equipment under the Buleryan brand. Since 2005, the products received a modern brand name - Breneran.

Advantages of heating stoves Buleryan (Breneran)

- High ergonomic qualities.

- Ease of use.

- Safety when using and working with fuel materials.

- Aesthetically attractive appearance.

- An excellent combination of cost and quality and technical characteristics.

The R-sauna company offers to buy a Buleryan stove at economical prices. The variety of assortments in different price categories is an excellent opportunity for the consumer to choose the optimal furnace equipment. There are also models equipped with a hob. Such devices are used not only for space heating, but also for cooking - this is an excellent solution for country houses and premises without centralized utilities.

Our catalog contains gas generator and bath models, equipment with a hob, heating equipment for water heating, fireplaces, barbecues, barbecue stoves, as well as spare parts, accessories and add-ons for stove equipment.

For what reason is it worth buying a Breneran stove, preferring it over analogues from competing manufacturers?

Buleryan long-burning stoves have enough advantages. Brand devices are in demand due to:

- Enviable quality and reliability in operation - which allows the manufacturer to provide a warranty of up to two and a half years.

- Technological and production control over product compliance with declared standards and characteristics.

- Efficiency of operation in extreme conditions, which has been tested by time, specialists and consumers.

- Positive feedback from well-known customers, many awards at competitions, exhibitions, and fairs.

Device

Construction of the Breneran furnace.

(Click to enlarge) These types of fireplace stoves consist of a massive outer casing, the thickness of which is 3 mm, as well as a heat-resistant firebox made of 5 mm steel. In addition, the package includes an additional water tank made of stainless steel.

The operation of such a device follows the same principle as that of a gas generator. After solid fuel burns, the resulting gases enter special ejectors for more complete combustion.

It is due to this that it is possible to achieve such high efficiency indicators, about 80%. In addition, such furnaces can operate in several modes. The first is fast heating, and the second is gasification. Accordingly, each of them performs its function, one allows you to quickly increase the temperature, and the second maintains it at the desired level.

It all happens as follows: special air ducts are put on pipes with a large diameter, which supply heated air to the required rooms. In addition, even cheap aluminum options that can withstand average temperatures can be used as these pipes. Due to this, even the smallest oven allows about 5 cubic meters of air to pass through it.

You may be interested in an article about pyrolysis stoves for home heating.

Read the article about the features of the furnace by Professor Butakov-Engineer here.

What is a drip irrigation system?

In a drip system, water flows to the plant through special pipes connected to the main source of water supply on the site. These pipes are laid between crops. They have built-in drippers, through which water flows directly to the root of each individual plant.

Drip irrigation system diagram

The drip irrigation system is not very complicated; some people even assemble and install it themselves. It consists of 7 main parts.

- Drip tapes are pipelines, which are, in fact, the basis of the entire structure.

- The controller is a mechanism that controls the time, quantity and volume of watering.

- Filters are necessary to purify water, but sometimes they are not installed.

- Valves for regulating water supply.

- Droppers.

- Fertilizer application unit – simplifies the application of fertilizers.

- Water meter (to control consumption).

There are a lot of different diameters of pipes, taps, types of drippers, etc. Depending on all these details, you can adjust the rate of watering for individual crops - somewhere the water will flow in a larger volume, and somewhere in a smaller volume. True, the more perfect the system, the more expensive it will cost, but those who have tried drip irrigation speak mostly positively about it - the cost fully pays for itself.

Advantages

The classic version of the Breneran stove is an all-metal structure that includes a large number of pipes that create forced convection.

Therefore, the heated air quickly heats up and spreads throughout the room.

And due to its clever design, the stove manages to take air from under the floor, warm it up in a matter of seconds, and then direct it upward, creating circulation. On average, the outlet temperature is up to 150 ˚С

It is worth noting that the burning time of one bookmark in such a stove will depend on many factors. So, it could be:

- firewood quality;

- total height of the chimney;

- in what mode the stove is operated;

- various nuances of the Breneran installation.

So, for example, some bathhouse attendants manage to provide heating for up to 12 hours in a row in one load. Although at the same time, it will not be possible to provide high-quality heating. It is most correct that with one load the furnace operation lasts an average of 7 hours. This will allow you to achieve maximum effect.

The main advantages of such furnaces are:

- high productivity (about 80%);

- greater efficiency;

- possibility of heating in a short period of time;

- versatility, allowing use both in the house and in the bathhouse;

- independence from stationary fuel sources (gas, electricity).

Considering the simplicity of the entire design of such a stove, in most cases it surpasses its main competitors in the form of gas boilers for private homes in many respects.

The most important thing is that it does not release any harmful substances into the air. In addition, an important point is that the design of such furnaces has been tested by time.