Many owners of private houses or country cottages build a bathhouse on their property, in which both their family members and friends enjoy steaming. There is a lot of debate on the question: is it necessary to do thermal insulation in a bathhouse? The answer to this question is obvious - it is imperative to insulate the bathhouse, regardless of what base the structure is assembled from. And if a wooden structure does not really need insulation, since wood has increased thermal insulation properties, then insulating a bathhouse made of expanded clay concrete blocks from the inside must be done without fail. The fact is that the expanded clay concrete base can freeze in extreme cold, so warming up the room will not only be very difficult, but also very expensive.

How to insulate a bathhouse from expanded clay concrete blocks from the inside and outside

A bathhouse made of expanded clay concrete blocks has now become popular.

It can be used at all times of the year. For this reason, even at the stage of its construction, it is necessary to carefully plan how to insulate a bathhouse made of expanded clay concrete blocks from the inside and outside. The bathhouse is gradually becoming an integral attribute of most country houses. And, most importantly, the bulk of such buildings are used year-round. That is why insulating a bathhouse from the inside is a priority issue that has to be addressed to ensure maximum comfort.

Another important point is the energy efficiency of the building. That is, insulating the walls of the bathhouse from the inside with your own hands will significantly reduce fuel consumption when heating the room. In addition, load-bearing walls and floors with a lower degree of thermal conductivity will retain heat longer.

Thermal insulation from the inside - a guarantee of comfort

Insulation scheme for a log bathhouse

Before insulating a bathhouse from the inside, you need to decide which thermal insulation technologies will be relevant for this case.

The choice of insulation technology is determined by the following criteria:

- construction features;

- climatic features of the region where the facility is operated;

- range of thermal insulation materials available for sale;

- the price of materials in combination with the budget allocated for the implementation of the planned work;

- availability of installation skills;

- availability of the necessary tools.

Let's consider current methods of insulating the most popular stationary baths today.

Last year I decided to build a bathhouse. I’ve wanted it for a long time, especially since the former owners of the dacha plot gave me a ready-made shallow strip foundation (also for a bathhouse), which had to be either used or demolished. The dimensions of the foundation are 4.6 x 4.9 m. Initially, the foundation was planned for a log house, but I would not have been able to handle such a project financially; I would have had to hire builders.

Expanded clay concrete blocks are an ambiguous material, it has disadvantages. The most obvious is increased hygroscopicity. And there is high humidity in the bathhouse. Therefore, expanded clay concrete walls run the risk of constantly becoming saturated with moisture (both drip and steam). This in itself is not scary. But as soon as the frost hits, the moisture inside freezes, and the expanded clay concrete begins to crack and collapse.

Expanded clay concrete is not the most frost-resistant material; it can withstand only 25-50 freeze-thaw cycles. In the conditions of ordinary residential construction, these indicators are not critical. Imagine if you heat up the bathhouse every weekend in winter and then leave it to cool. The frost resistance limit will be exhausted in a year or two!

To prevent this from happening, it is necessary to ensure steam and heat insulation of expanded clay concrete blocks. That is, insulate the wall from the inside using traditional layers of insulation and vapor barrier film. Then the blocks will not get wet and, accordingly, quickly collapse. This is where the pitfalls end.

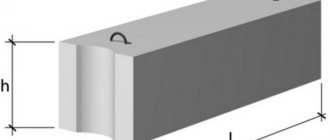

All other characteristics of expanded clay concrete blocks are continuous advantages. This material is especially valued for its increased thermal insulation properties, which are 2-3 times higher than those of brick. And all this against the backdrop of light weight, even blocks 400x300x240 mm (length - width - height) I lifted easily, alone.

And the last thing: expanded clay concrete is a completely environmentally friendly material, there are no “chemicals” in its composition, and when heated, it does not emit anything. So it’s suitable for a bath!

https://www.youtube.com/watch?v=t-Nzx6yvsrg

Let's finish with theory, move on to practice. I will tell you about construction using expanded clay concrete step by step.

- 3 Stage #3 - finishing the steam room and washing room

- 4 Stage #4 - finishing inside the rest room

To prevent the lower crowns of the blocks from getting wet, it is necessary to isolate them from the foundation. To do this, roofing material was laid on the strip foundation - 2 layers.

I laid the walls in the floor of the block (the thickness is 300 mm), in a dressing. The masonry was carried out using cement mortar (cement and sand in a ratio of 1:3), water was added in order to obtain a dense but fairly plastic consistency. The layer of mortar that I applied to the blocks being laid was about 2 cm. I built the partitions from the same blocks (although using technology it was possible to use thinner material).

The first row of expanded clay concrete blocks is laid on waterproofing (roofing felt)

To form door and window openings, a run of corners was made along the top. The next crown of expanded clay concrete blocks rested on them.

Purlin from the corners above the doorway

At this stage, all the walls were built up to the ceiling; the bathhouse was divided by partitions into a steam room, a washing room, and a relaxation room.

The laying of expanded clay concrete blocks is made into the floor of the block

Externally, expanded clay concrete blocks need protection from moisture and wind. The traditional protective layer is ordinary cement plaster.

The solution was mixed in a ratio of 1:4 (cement and sand). First, I plastered the bathhouse once and rubbed it with a trowel until smooth. After drying, the next day I applied another coat and wiped it off again. The total layer of plaster was approximately 1.5 cm.

Plastering bath walls with cement mortar

At first I thought that I would putty the outer layer of plaster, then I changed my mind and decided to immediately paint it with facade paint. I picked up an expensive acrylic-based paint in a light beige color. Before painting, I went over the plaster with a primer for exterior use, then applied 2 layers of paint. The gray color of the plaster was completely covered up.

2 layers of facade paint were applied to the plaster

The “pie” of insulation in the steam room and washing room was chosen as follows: basalt wool, Izospan FB vapor barrier, 2 cm ventilation gap, lining.

To begin with, 50x40 mm bars were sewn vertically onto the walls in increments of 50 cm. For fastening to the walls, ordinary dowels were used. Expanded clay blocks, in my opinion, hold firmly any type of fastening. The width of the bars must match the width of the insulation. In my case it is 50 mm.

After fixing all the bars, basalt wool S=50mm was tightly placed in the spaces between them.

Basalt wool is laid between the lathing slats

Izospan FB, a vapor barrier membrane on kraft paper, trimmed with foil, was sewn onto the top of the bars using a stapler. This vapor barrier is not cheap, but it increases the insulating properties of the entire “pie” of the inner lining, thanks to the foil coating. The main thing when installing a vapor barrier is to strive for complete tightness of the layer.

We invite you to familiarize yourself with the Foundation for a bath made of foam blocks

Izospan FB vapor barrier membrane sheets are mounted on sheathing slats

It is advisable to create a ventilation gap between the vapor barrier and the lining. Some bath attendants ignore it, but it’s still better to be safe. A sufficient thickness of the gap is 2 cm. To do this, I placed a counter-lattice made of slats 2 cm thick on top of the vapor barrier (along the existing bars).

Aspen lining is sewn along the slats, painted with a special impregnation for wooden bath surfaces - Supi Saunasuoja (Tikkurila). This acrylate-based impregnation protects wood from fungus, mold and blue stains. After painting, the lining acquires a light matte shine.

Steam room walls lined with aspen clapboard

Inside the rest room, I provided a different cladding option. There are no high temperatures or high humidity here, so the materials for insulating expanded clay concrete blocks may not be as functional as in a steam room or washing room.

The pie here looks like this: expanded polystyrene foam (EPS), bath foil, ventilation gap, lining.

The scheme for covering the rest room looks the same as in the steam room. First, a sheathing of bars is placed on the expanded clay concrete walls, and layers of EPS (5 cm thick) are tightly placed between them.

Insulation of the rest room with PPS slabs

On top of them is a vapor barrier made of aluminum foil with the seams taped. The foil is sewn onto the sheathing and punched with a stapler. A ventilation gap of 2 cm is provided by a counter-lattice - strips nailed to the sheathing posts. The counter-lattice is covered with aspen paneling.

Foil protects the insulation and expanded clay concrete blocks from moisture

Unlike a steam room, the relaxation room has low temperatures, so the structure of the wooden fibers of the lining can be emphasized with varnish. Which is what I did. I used Unica Super yacht varnish from Tikkurila in 2 layers.

The lining in the rest room is varnished

Walls made of expanded clay blocks, ideally, should be warm, protected from steam and moisture. In my bathhouse, the thermal insulation characteristics of the blocks (which are already quite large) are increased due to the insulating layer. The vapor and waterproofing barrier is made using foil insulators. As a result, the bathhouse is heated in a couple of hours, and after the evening procedures it dries completely by the morning.

Pavel B.

Bathhouse walls made of expanded clay concrete blocks

To insulate a bathhouse made of expanded clay concrete blocks, you will need tools and a set of materials: a construction tape measure, a knife and scissors, a brush and brushes, gloves and goggles, buckets, a spatula, a primer, reinforcing mesh, insulation, adhesive composition, a vapor barrier membrane, a waterproofing film, fasteners.

Preparatory work for insulating a bath consists of cleaning the insulated surfaces from foreign deposits and bumps, oily liquids, dust and dirt. Walls made of expanded clay concrete blocks are plastered to seal all cracks and level the surfaces. On a flat surface, the insulation is fixed more securely, especially since the process is carried out using glue. Before laying thermal insulation, the walls must be dry.

At this stage, the amount of necessary materials is calculated based on the total surface area, and the budget for their purchase.

Thermal insulation materials for expanded clay concrete blocks

This building material has the following advantages:

- environmental friendliness and absolute non-toxicity;

- insignificant moisture absorption, non-susceptibility to the destructive effects of steam and liquid;

- excellent thermal insulation properties that help retain heat in the room;

- relatively light weight expanded clay concrete blocks.

Thermal protection of a bathhouse, due to the specific use of this building, requires the use of various methods of thermal insulation in each section. For this reason, it is necessary to have knowledge and experience on how to insulate a bathhouse made of expanded clay concrete blocks shown in the photo.

To ensure high-quality thermal protection, you need to take into account the structural features of the structure and the influence of the environment on its various elements. Of course, insulating a bathhouse made of expanded clay concrete blocks from the inside differs from external thermal insulation.

This building material is made from several components using vibrocompression technology. The process consists in the fact that baked and foamed clay (expanded clay is made of it), as well as sand and cement, are thoroughly mixed and compacted under high pressure and vibration loads. The resulting expanded clay concrete block is characterized by lightness and at the same time increased strength.

Insulation of a bathhouse made of expanded clay concrete blocks from the outside is carried out using glass wool, mineral wool or polystyrene foam. First, the walls are checked for stability and calculations are made of the designed facade and the load exerted by thermal insulation and finishing materials is calculated.

It is necessary to take into account that:

- The walls must be reinforced with a mesh that provides the entire structure with the required stability.

- When the thickness of bath walls is more than 70 centimeters, there is no need to install powerful thermal protection, since expanded clay concrete blocks are a heat-saving building material.

You can insulate walls from such blocks in one of the following ways:

- Brick lining of the outer part of the bathhouse building, but this option is quite expensive and therefore few people use it.

- By using a thermal insulation material such as thermal fiber, mineral wool or polystyrene foam. All of them have good heat-saving qualities and relatively low cost.

To carry out heat protection measures when building block baths, the following are most often used:

- Thermal fiber. The advantage of glass wool is its environmental friendliness and safety for human health. It is used as thermal protection for both internal and external walls. Before installing the insulation, you need to clean, dry the wall and plaster it. Plaster enhances the thermal insulation properties of enclosing structures.

- Minvatu. Before insulating a bathhouse made of blocks using this material, it is necessary to clean the wall and build a frame in advance. Then only you can install the mineral wool. Its greatest advantage is its environmental friendliness. This material is able to resist the spread of fire and prevent heat loss. When carrying out thermal insulation work, the mineral wool is certainly covered with a layer of vapor barrier.

- Styrofoam. Its main advantage is its affordable price. Among the disadvantages, noteworthy is the flammability of the material and its damage by insects. He also needs protection from rodents. When using polystyrene foam, the thermal insulation layer must be covered with a reinforced mesh.

Insulation of baths made of expanded clay concrete blocks with foam plastic. Expanded clay blocks are an inexpensive and accessible building material. But its thermal insulation qualities are significantly inferior to those of natural wood, so a bathhouse built from expanded clay concrete needs insulation.

Functionally, the bathhouse is intended for healing procedures, therefore all materials used for its construction must be of high quality and environmentally friendly. This also applies to insulation materials, whose action is aimed at maintaining a comfortable temperature in the premises. The negative impact of samples that are not resistant to its changes and emit harmful substances is greatly enhanced by the extreme “climatic” conditions of the bathhouse.

We invite you to familiarize yourself with the stove for the bath, cook it yourself

This fibrous insulation is obtained by processing basalt rocks. The natural composition of the insulation guarantees its absolute harmlessness. Sometimes the reputation of basalt wool is spoiled by some manufacturers who add slag impurities to it, trying to reduce the cost of their products.

The insulation does not rot and is not edible by insects and rodents. This guarantees trouble-free service of the material for at least half a century. Regardless of its fibrous structure, the material is quite strong and has a “strength” indicator of 80 kPa.

Basalt wool is a type of non-combustible material. It can easily withstand temperatures up to one thousand degrees Celsius.

This material is used for external and internal insulation of baths, as it is produced in the form of rigid slabs, semi-rigid mats and soft rolls with varying densities of their structure.

Glass wool for bath insulation

The insulation has a fibrous structure, but is inferior to basalt wool in its technical characteristics. The material is made from broken glass with the addition of sand, dolomite, soda, etc.

Having a thermal conductivity coefficient of 0.052 W/K*m, it has good insulating properties, but is completely unsuitable for internal insulation of a steam bath for the only reason: glass wool cannot withstand temperatures above 450 degrees. Therefore, it is not recommended to insulate the area that is located in close proximity to the stove.

Glass wool is used for thermal insulation of the attic and bathhouse roof, reducing the cost of this process by 20-30% compared to the use of basalt insulation.

Expanded clay for insulating floors and ceilings

“Airy” expanded clay granules are obtained by quickly firing low-melting clay. This material is used in the form of backfilling the horizontal elements of the bath structure - the ceiling and floor.

Various calibers of insulation in the form of gravel, crushed stone and sand are used in construction. The insulation effect is obtained from expanded clay when it is poured onto the surface in a layer of over 25 cm.

Foam plastic for thermal insulation of baths

Bathroom insulation with this material is ideal for external wall surfaces. The facades of buildings are covered with polystyrene foam, and then they are plastered or covered with decorative finishes.

It cannot be used inside bathhouses due to the harmful phenol fumes emitted by the foam and its flammability.

External insulation of a bathhouse refers to options for thermal insulation of walls and foundations. Let's consider this issue in more detail.

Thermal insulation diagram of the bathhouse facade

High-quality insulation of a bathhouse made of expanded clay concrete blocks from the outside is carried out by facing masonry with the placement of insulation between the bricks and the main wall. This is an expensive insulation option and, despite its effectiveness, is not used often. The problem is the high price of facing bricks and the complexity of its installation.

The second method involves external cladding of walls made of expanded clay concrete blocks with PVC panels or siding, under which insulation is placed. As an acceptable option, 50 mm thick foam plastic sheets can be attached to the walls as a heat insulator in two rows in a checkerboard pattern with overlapping seams. The panels are fixed on pre-installed vertical guides. Instead of polystyrene foam, you can use basalt insulation, covered with a vapor barrier material to protect against moisture.

Another option for insulating walls from the outside is lining the bathhouse with slab insulating material, for example, polystyrene foam. It is attached to the wall with glue and plastic dowels. A reinforcing mesh is glued onto the foam plastic, which is covered with decorative plaster.

Insulation of the foundation of a bathhouse made of expanded clay concrete

To thermally insulate the foundation of a bathhouse, they use materials that are moisture resistant, inedible for rodents and are not afraid of temperature fluctuations. The ideal and most popular option is polystyrene foam. After the concrete has polymerized, the outer side of the foundation is covered with waterproofing and covered with heat insulation slabs. They are located on the surface of the base in a checkerboard pattern in two layers of 50 mm each. Then the insulation can be covered with “warm” plaster.

The complex of works for insulating a bathhouse made of expanded clay concrete blocks from the inside includes thermal insulation of the floor, walls and ceilings. Each of these structures deserves special attention.

Insulation of a wooden bath floor

The principle of thermal insulation is the same - laying insulation between rigid layers and protecting it with insulating membranes. In a wooden structure, the heat insulator is located between the subfloor and the finished floor, and in a concrete structure, between the base and outer layers of cement mortar.

The wooden floor is insulated in the following sequence:

- On both sides of the lower edge of the beams along their entire length, cranial bars are stuffed, which are necessary for constructing a subfloor.

- Low grade boards, pre-cut to a size slightly smaller than the pitch of the beams, are placed on the cranial beam.

- The subfloor is ready. Then it is covered with waterproofing. It is better to choose a membrane with vapor barrier properties. It is spread to cover all the beams and cover the perimeter of the lower parts of the walls with a start of 20 cm. The material is fastened to the structural elements with a stapler, the joints of the sheets are taped.

- Insulation is laid on the vapor barrier layer, which is covered with a layer of waterproofing material. The expensive membrane can be replaced with a layer of roofing felt with carefully taped seams. The free space around the floor drain pipe is filled with foam.

- To complete the insulation process, clean floor boards are laid, excess insulation is cut off, and baseboards are screwed in place.

There should be an air ventilation gap of 3-4 cm under the finished floor to dry the structure.

External insulation

It is important to carefully understand how to insulate a bathhouse from the outside with your own hands in order to avoid possible mistakes. Insulation of a bathhouse made of expanded clay concrete blocks from the outside is carried out using glass wool, mineral wool or polystyrene foam. First, the walls are checked for stability and calculations are made of the designed facade and the load exerted by thermal insulation and finishing materials is calculated.

It is necessary to take into account that:

- The walls must be reinforced with a mesh that provides the entire structure with the required stability.

- When the thickness of bath walls is more than 70 centimeters, there is no need to install powerful thermal protection, since expanded clay concrete blocks are a heat-saving building material.

You can insulate walls from such blocks in one of the following ways:

- Brick lining of the outer part of the bathhouse building, but this option is quite expensive and therefore few people use it.

- By using a thermal insulation material such as thermal fiber, mineral wool or polystyrene foam. All of them have good heat-saving qualities and relatively low cost.

Advantages of using expanded clay concrete blocks

- environmental friendliness;

- high-quality thermal insulation;

- low moisture absorption.

Expanded clay concrete is made from sand, cement and clay, so this building material is environmentally friendly. Low moisture absorption protects the block from the destructive effects of water and steam. Expanded clay concrete blocks are quite light, so insulating the walls of a bathhouse from the inside with this material will not be too expensive. A house made of monolithic expanded clay concrete will also cost less than a brick or gas silicate house.

Preparation for thermal insulation of a bathhouse made of expanded clay concrete blocks

- If the mineral wool does not have a foil layer, then it needs to be added, and foil polyethylene foam, which you see in the photo above, is excellent for this. The thickness of such material varies from 2 to 20 mm, and by covering a layer of mineral wool with this, you significantly increase the effectiveness of thermal insulation.

We suggest you familiarize yourself with How to properly drain water from a bathhouse: where does the water go, drainage, drainage, how to drain into a barrel at the dacha, photos and videos || Where to drain water from a bathhouse in the country

U-shaped belt suspension brackets (pawns)

- For wooden lining, that is, for cladding a steam room, you need a lathing that will be attached to brackets, or it will be thick bars, between which insulation for the bath will be installed. The second option is simpler, but installing timber on a block wall is not so easy, even if it is plastered. The fact is that if the thickness of the sheathing is 100 mm, then anchor bolts will be needed to fasten it, which is not entirely acceptable for a wall made of such material.

Mineral wool is inserted through the consoles

- We continue to consider how to insulate a cinder block bathhouse from the inside and will install the sheathing. Place some kind of waterproofing material on the wall, under the brackets, and then attach the consoles themselves with bod profiles. Mineral wool is threaded directly through the pawns, and then carefully covered with foil polyethylene foam, trying to ensure that no holes remain.

Advice. If you are interested in insulating plastic windows, then I can disappoint you - they are not insulated. Just so that they transmit less heat, you can use two-chamber or three-chamber double-glazed windows, as well as a thick, five-chamber plastic profile.

Insulation of the ceiling in the bathhouse

- Do-it-yourself thermal insulation and waterproofing of the ceiling occurs, in principle, in the same way as insulating the walls of a bathhouse. only the mounting plane changes. Considering that there cannot be foam blocks on the ceiling, but, for example, a wooden floor or a concrete slab, timber can be successfully used as a sheathing.

Advice. To make it easier to install mineral wool on the ceiling so that it does not fall, use nylon thread. From beam to beam, a constriction is made in the form of a mesh, fixing the material.

Bathroom floor insulation

- Almost any materials are suitable for the floor in the bathhouse, for example those that are used to insulate the loggia, that is, extruded polyethylene foam or expanded clay. After all, you will still be pouring a cement screed, so both will do, but expanded clay is much cheaper. The thickness of the thermal insulation layer will depend on the degree of soil freezing and the general temperature in your area.

Features of external work

Initially, it is advisable to prepare and plaster the facade in order to achieve acceptable evenness of the walls and fill existing cracks and crevices. Most often, the facade of aerated concrete baths is sheathed with mineral wool or expanded polystyrene. In the first case, the walls are first covered with rolled materials to protect the insulation from moisture.

If polystyrene foam boards are a priority, they can be fixed on external surfaces without worrying about laying guides in advance; This is where special glue or polyurethane foam comes in handy. Next, the panels are additionally fixed with dowels, the joints and seams are filled with foam. A sheathing for installation of siding is stuffed on top: this sheathing will help protect the insulation from mechanical damage and exposure to ultraviolet radiation.

Thermal protection of floor covering

The insulation of a bathhouse built from expanded clay concrete blocks begins with measures to insulate the floor. A layer of slag (it can be replaced with expanded clay or glass wool) at least 35 centimeters thick is poured directly onto the ground. A reinforced concrete screed is placed on top of it, and ceramic tiles are laid on top.

Only if the insulation of the bathhouse foundation is properly arranged can heat loss during the operation of the building be significantly reduced.

Features of internal insulation technology

Expanded clay concrete products have a porous structure, so they retain heat excellently and prevent moisture from accumulating inside the material. Before insulating a bathhouse made of blocks from the inside, it is necessary to lath the internal walls. For this purpose, wooden slats with a thickness of at least 5 centimeters are used.

A layer of mineral wool, basalt insulation, or polystyrene foam is placed on the already prepared sheathing. To ensure waterproofing of the structure, the thermal insulation material is completely covered with aluminum foil (or foil film). In this case, the greatest attention is paid to the tightness of the joints.

In order to better insulate the bath, experts recommend using a vapor barrier using foamed polypropylene, which is coated with aluminum foil. This material can withstand heat up to 150°C. To insulate the seams, use aluminum foil (read: “Which aluminum foil is best for a bathhouse”).

At the end of the work on internal thermal insulation, the installation of finishing material begins. For this purpose, wooden lining or other products are used. Particular attention should be paid to the arrangement of the air gap. To do this, wooden slats are placed on the waterproofing layer, and then finishing material is attached to them.

The technological process of constructing expanded clay concrete steam rooms begins with the installation of beacons at the corners of the site. A rope is pulled between them and they begin laying the blocks, not forgetting to first clear the surface of various debris that can deform the structure being built. The excess solution is removed immediately, since after it hardens it will be more difficult to do. A reinforcing mesh is laid every two rows.

Insulating the bathhouse from the inside is necessary to maintain heat in the steam room.

They begin to install the roof, which can be single-pitch or gable. To build a roof, anchor bolts are fastened to the support beams. The roof is sewn up and roofing materials are laid. For year-round use of the steam room, it is insulated with mineral wool, which has a heat-insulating and water-repellent effect. The insulation of a bathhouse made of expanded clay concrete blocks is carried out from the inside of the room and is intended to retain heat in the steam room.

The outside walls are covered with a layer of waterproofing and protective material from the wind. To decorate the steam room from the inside, tiles or wood are used, and facing material – wood – is also used on the outside. When building a steam room made of expanded clay concrete, you will need the following materials and tools:

- for preparing concrete mortar - cement, crushed stone, sand, water;

- expanded clay blocks, the number of which is determined when calculating consumables;

- thermal insulation material;

- bitumen mastic;

- roofing felt;

- mineral wool;

- wood for cladding inside the steam room;

- reinforcing mesh;

- tiles;

- tile;

- rafters;

- bucket;

- shovel;

- building level;

- pegs;

- roulette;

- Master OK;

- anchor.

Ceiling insulation

First of all, you need to insulate the ceiling in the bathhouse, performing work in the following sequence:

- using a stapler, ordinary roll paper is attached to the ceiling;

- wooden blocks measuring 5x5 cm are stuffed on top of the paper, the width of which should correspond to the width of the selected roll insulation;

- basalt construction wool is laid in a tight fit between the wood beams;

- if non-foil insulation is used, foil should be placed on top of the cotton wool;

- each joint is connected with aluminum construction tape;

- strips are placed on top of the foil, onto which the lining or other finishing material of the ceiling will later be fixed.