Technologies in construction are developing by leaps and bounds. New materials are emerging that make it possible to build faster, without losing quality. And although aerated concrete is not an innovation - it is already three or four decades old - bathhouses have not been built from it before: this material has a fairly high hygroscopicity. But new impregnations have appeared that can significantly reduce the amount of moisture that the material absorbs. But even without impregnation, using modern vapor and waterproofing, you can achieve good results. The average lifespan of a bathhouse made of foam blocks is about 20-30 years. If you're happy with this, start looking for a project.

A gas silicate bathhouse can be built “with one hand”, and the process goes quickly: the blocks are large but light

You just have to remember that aerated concrete is produced using two technologies. In the production of some, hardening occurs in an autoclave - these are gas-concrete and gas silicate. When producing others (foam concrete), a foaming agent is simply added, then the foamed solution is poured into molds and hardens in air.

Autoclaved cellular concrete is considered to be of higher quality. An autoclave is not a cheap piece of equipment, so you can’t make the material using a homemade method. This is reflected in the cost - gas silicate is more expensive than foam concrete - but the geometry of the material and its quality are usually much better. Since it is desirable to make the seams between the blocks as thin as possible, the geometry is very important. Therefore, when purchasing, look for gas silicate blocks with the least deviations. Even if they are more expensive, you will save as a result: the glue costs a lot, if you can make a 1-2 mm seam, its consumption will be small. In addition, with such a seam there will be less heat loss, which means that it will be possible to make a smaller layer of insulation (if they are insulated) and less fuel will be consumed to heat the bath.

It is easy to distinguish gas silicate: due to the fact that lime is the binding element in it, it has a white color. The rest of the porous concrete is gray.

The gas silicate block is easy to distinguish: by color

Gas silicate bath

Experienced craftsmen have a saying that there is no building material from which a steam room cannot be built. The only exception may be frankly toxic building blocks, with a high content of bitumen, phenol and sulfur cements, used for arranging foundations on swampy soils.

Therefore, building a bathhouse from gas silicate with your own hands can be considered quite realistic, especially if the area in which the bathhouse is planned to be built is replete with strong winds. In this case, bathhouse projects made from gas silicate materials turn out to be much more interesting than frames or buildings made from rounded logs.

The gas silicate block is interesting for two reasons:

- You can make it yourself or order it from the manufacturer. At the same time, it is possible to include in the block those characteristics that are most important for building a bathhouse;

- The low price of gas silicate with a fairly high durability of the material. For the money spent on the construction of a timber bathhouse, which will last for a maximum of 10-12 years before repair, you can build a gas silicate box with a service life of 30 years.

Important! Gas silicate is often confused with another cellular material - foam concrete. The technologies for producing blocks are very similar, only the raw materials and conditions for stabilizing the final product differ.

Gas silicate blocks are “printed” from lime and purified quartz sand, in this they are more similar to sand-lime brick. Whereas foam concrete is made from concrete mortar saturated with plasticizers and pore-forming additives.

Is it possible to build a bathhouse from gas silicate blocks?

In order not to resort to listing characteristics and indicators, it can be mentioned that gas silicate blocks of the same density as foam concrete materials have higher strength, retain heat better and do not give secondary shrinkage.

For your information! Aerated concrete material has a very important difference: due to its high porosity, it absorbs water vapor, volatile substances and even gases, like a sponge.

It turns out that building a bathhouse from gas silicate blocks, on the one hand, is very profitable, since with lower costs for walls and compliance with technology, the room turns out to be very warm.

On the other hand, when agreeing to build a bathhouse from gas silicate blocks with your own hands, you need to understand that the high absorption capacity of the walls will haunt the owners of the steam room and bathhouse building for the rest of their lives. If you do not properly insulate the surface, the walls of the bathhouse will absorb odors and water from the atmosphere and soil until they turn into an eternally wet and completely frozen monument.

Bathhouse made of gas silicate blocks: pros and cons

Not everything is as bad with gas silicate as opponents of the new material sometimes try to present the situation. If gas silicate blocks were not suitable for the construction of bathhouse walls, then no one would use foamed silicate material. Despite all the pros and cons, gas silicate baths are actively being built; according to the most conservative estimates, their number is approximately 31% of all new bath buildings.

To the advantages listed above, you can add several more important advantages:

- The bathhouse box turns out to be light, so the building can be erected on relatively weak soils; all that is needed is proper drainage of surface and “deep” water;

- Gas silicate blocks are easy to process, cut with a regular hacksaw, their low weight simplifies the laying of walls;

- If you use the porosity of gas silicate correctly, you can achieve the formation of a special microclimate in the bathhouse.

We are not talking about a steam room or a waiting room; there is always high humidity, so porosity can only do harm. Another thing is a relaxation room or a glassed-in veranda of a bathhouse. In this case, gas silicate blocks can select and release water vapor, creating a certain microclimate in the bathhouse.

Unfortunately, such miracle projects - saunas from gas silicate blocks are rarely created with your own hands. For cladding the internal walls, a dense gas silicate material with micropores is used, allowing only air and water vapor to pass through, but blocking any other heavy gases and volatile substances. Such material is quite expensive, and in addition, special knowledge and skills are required. This is the main disadvantage of gas silicate blocks; you cannot build a good bathhouse “by eye”.

In addition, gas silicate is afraid of moisture and strong temperature changes, accompanied by the formation of water condensate. When planning the stove and chimneys, one must take into account the fact that the material cannot withstand heating above 400°C.

Preparation of materials and tools

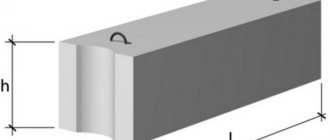

When purchasing gas silicate blocks, you need to take into account the characteristics of the building material:

- According to production technology, deviations from standard dimensions by 1.5 mm in length and height are allowed.

- The average density is 600 D. Compressive strength at this density is up to 3.2 MPa.

- The building material for the construction of walls is made in the shape of a rectangle.

- Standard length is 500–625 mm. Thickness - 200–400 mm. Height - 200–500 mm.

Principles for choosing gas silicate blocks:

- For laying walls, it is better to choose blocks with a density of up to 500 kg/m3.

- The optimal frost resistance indicator is

- Blocks must be inspected for visual defects and deviations from standard dimensions.

- For the construction of partitions, it is better to use blocks 30 cm high and 20 cm wide.

If the bathhouse is two-story, it is recommended to use gas silicate blocks with a density of 600 kg/m3. Frost resistance index - F50.

Tools, consumables for building a bathhouse:

- fittings of different diameters;

- roofing felt, film for vapor and waterproofing, insulation;

- wooden slats, bars, boards, rafters, ceiling beams, logs;

- metal corners;

- shovels;

- grinder with discs;

- drill with different attachments (whisk, wood drills);

- screwdriver with bits;

- roofing material;

- wall chaser, trowel, spatula;

- mallet, hacksaw;

- graters of different grain sizes;

- glue for blocks;

- Decoration Materials;

- building level, tape measure.

Additionally, you will need cement, crushed stone, sand, materials, and individual parts for laying communications.

Screwdriver (Photo: Instagram / tcestom.irk)

Project of a bathhouse made of gas silicate blocks

The construction of a full-size bathhouse from a light and non-rigid material will require special measures, such as reinforcing and strengthening the walls with concrete belts, using a full-fledged slab foundation or installing piles. Therefore, either professional builders or desperate fans undertake to build a full-fledged bathhouse 6x6 m or 6x7 m from gas silicate blocks.

Most lovers of good steam are limited to bathhouses with a maximum wall size of no more than 6 m. There is also a positive side to this; due to the high popularity of 6 by 4 m bathhouse projects made from gas silicate blocks, choosing a suitable option will not be difficult.

Classic steam room made of gas silicate

The construction of a bathhouse measuring 6x4 m will fit perfectly into a home yard. Despite the fact that this is not a tiny annex steam room with a dressing room, which is extremely difficult to use without a shower in the house.

Thanks to the use of gas silicate blocks, a warm and spacious building is obtained, so much so that there is enough space for a full-fledged recreation room and a small terrace covered with a roof slope.

It should be noted that there is a very correct layout of the interroom passages inside the bathhouse. Thanks to the use of a “snake”, that is, a layout when the doors in the passage rooms are located at the maximum distance from each other, the steam room is well protected from drafts. And four window openings provide a qualitatively high level of ventilation in the room.

A simpler version of a home sauna made of gas silicate is shown in the photo below.

In this project, the design of the bathhouse is simplified to the minimum; most of the free space is allocated for a relaxation room and steam room.

This is more of a summer version of a bathhouse for a summer cottage. In this case, most of the time between visits to the steam room is spent under a canopy.

Country version of a bathhouse made of blocks

If the size of the garden plot allows, then using a standard design for a sauna building made of gas silicate blocks, you can easily expand the structure and turn it into a place for a summer vacation for the whole family.

In this case, you will need to abandon the terrace in favor of a full-fledged canopy with a brick stove and barbecue, a place for a guest table and a kitchenette in the corner. In this option, the rear partition covering the stove and the canopy space is built from heavier red brick, so the area in front of the entrance to the bathhouse will need to be concreted with a screed.

Requirements for structures

Requirements for the construction and placement of a bathhouse made of different materials are specified in SNiP 30-02-97. The developer must comply with a number of rules:

- The minimum distance from the bathhouse to the neighboring area is 1 meter. If there are residential or outbuildings made of wood on the neighboring property, the distance from the bathhouse to them must be at least 15 meters. The minimum distance to residential buildings is 8 meters. The distance to the well is 15 meters. The distance to bushes is 1 meter, to tall trees is 4 meters.

- The building should not cast a shadow on the neighboring property.

- The bathhouse should be located at the highest point of the site so that its foundation is not flooded by rain and melt water.

- If a wood stove is installed inside, it should not create smoke in residential buildings. Therefore, when choosing a place for a bathhouse, you need to take into account the features of the “Wind Rose” for a given area.

- The bathhouse should be visible from the windows of a residential building.

Sanitary standards for private buildings are specified in SNiP 30-02-97. Fire safety requirements:

- Heating appliances should be installed at a low height from the floor. It is better to place the stove on two rows of fireclay bricks.

- There must be a working fire extinguisher in the dressing room.

- The walls and floor around the stove should be covered with metal reflective screens. It is better to protect the surfaces underneath with a layer of non-combustible material.

- Electrical appliances must be grounded.

- An effective ventilation system must be installed inside the bathhouses. For a steam room or shower room, it is better to make a forced system with fans.

- The chimney in the area where it passes through the ceiling must be closed with a special sleeve or a layer of non-combustible material.

- Wood that will be used to decorate bath rooms must be impregnated with fire-protective agents.

Finishing materials used in the bathhouse for finishing walls, ceilings, and floors should not emit harmful substances during operation.

Impregnation of lining (Photo: Instagram / sosnovuydvor)

Do-it-yourself bathhouse made from gas silicate blocks

The smaller the size of the walls, the easier it is to install a gas silicate box, the smaller and lighter the foundation for the building is required. In some cases, it is possible to make a foundation for a bathhouse from gas silicate blocks, such as Minsk. Due to the high density and closed structure of the bubbles, the material practically does not absorb liquid water, and thanks to the excellent thermal insulation of gas silicate, the bathhouse building is well protected from freezing of the base and partially from soil heaving.

Stages of construction work

The first step when building a bathhouse is to make a full-fledged cushion under the foundation, remove turf and clay to a depth of at least 50 cm, and remove all layers of soil in which moisture can accumulate.

Most bathhouse projects made from gas silicate blocks, photos, require a solid foundation.

It is best if it is a concrete slab laid on a sand and gravel bed and EPS insulation. Walls made of gas silicate, even in a one-story version, require support, so a rigid concrete foundation will be the best solution to the problem.

The second step is to lay out the plinth and waterproofing of the walls. The starting and last rows of aerated concrete blocks are always reinforced with a concrete belt with a reinforcement frame. The roof and floor must be insulated, most often with fill-in insulation.

Immediately after installing all the elements of the roof and roof, you need to complete the external finishing of the walls, before rain and dampness destroy the bathhouse frame.

Important! To avoid the blocks getting wet, the building is covered with a protective film.

As soon as the roof and ceilings of the bathhouse are assembled, you can close the walls; it makes no sense to start finishing earlier, since the walls have not taken their size under the weight of the rafters and beams.

Exterior decoration

The walls of the bath box must be protected and insulated at the same time. It is important that the outer surface of the gas silicate blocks “breathes”, that is, water vapor and air are able to freely penetrate through the thickness and escape into the surrounding space.

Therefore, correct and reliable finishing of the outer surface of the walls of the bathhouse is carried out as follows:

- Initially, timber and roll insulation are sewn onto the walls, usually mineral fiber mats;

- The second step in insulation is to install a vapor barrier membrane;

- The next step is to sew a lining made of PVC, aspen or galvanized steel onto the sheathing.

In this case, the bathhouse turns out to be warm, the walls do not get wet and always remain dry, even if the steam room is heated several times a day.

Interior decoration of a bathhouse made of gas silicate blocks

It is best to start finishing work indoors with a steam room. First of all, vertical sheathing slats are sewn onto the walls. You can use aspen or pine with a section of 50x50 mm. The material can be fixed to a gas silicate wall using ordinary self-tapping screws. The steam room must be insulated with mineral wool and foamed polyethylene with a foil surface. A vapor barrier like Metaspan must be sewn on top of the mineral insulation.

Horizontal rows of aspen lath are placed on top of the warm cake, on top of which the lining of the steam room is laid.

The washing compartment of the bathhouse is covered with tiles without any options. The gas silicate is first primed with liquid waterproofing, otherwise in winter moisture from the ceiling can flow into the wall and tear off the lining.

The rest room of the bathhouse is most often simply sheathed with clapboard along the laid sheathing strips. If there is no supply and exhaust ventilation in the room, then a vapor barrier film will need to be laid under the tree, and gratings will need to be installed in the ceiling part of the walls.

For summer bath options, the lining can be sewn directly onto the walls from gas silicate blocks.

Registration Features

A classic bathhouse with a shower, steam room, dressing room and corridor is classified as ancillary buildings that do not need to be registered. If the building has two floors, living rooms, communications and a massive base, registration is required. A building permit can only be obtained if all requirements are met. To do this, you need to contact local authorities and prepare several documents:

- Passport or power of attorney from the owner of the plot, which is confirmed by a notary.

- Site plan indicating the location and size of the bathhouse.

- Complete project for future construction.

- A document confirming the right to own the land.

- Application for obtaining permission to carry out construction work.

Local authorities must respond to the request within 10 working days after submitting documents for verification.

Drawing up a site plan (Photo: Instagram / kavaler.land)

Baths made of gas silicate blocks: photo

Buildings made from light foam silicate can be not only warm, but also beautiful.

After laying the exterior finishing, it is almost impossible to guess what exactly the bathhouse is built from.

Washing tiles

There should not be any significant temperature changes in the washing room, so I decided to do without special waterproofing. Just cover the gas silicate with tiles and that’s it.

I bought high-strength ceramic tiles with a thickness of 8 mm. I laid it on frost-resistant, moisture-resistant glue. The glue was spread on the wall in a layer of about 10 mm, and the tile was pressed against it. All rows were controlled horizontally and vertically by the building level.

Laying tiles on gas silicate blocks

Bathhouse made of gas silicate blocks: reviews from owners

Semyon Stepanovich Ivliev, 69 years old, Tver:

We built a gas silicate bathhouse ourselves. A month later, a crack appeared along the blank wall. Experts said the cause was shrinkage of the foundation. It was made just according to the mind, to match the brickwork. It turned out that the box was too light and the soil was heaving. They caught it in time; the neighbors across the street had a wall that was completely bent into a bubble. We had to dismantle part of the masonry and seal it with concrete, in the end we lined the bathhouse box with bricks, as planned, and that was the end of it.

Valery Eduardovich, 60 years old, Moscow:

My son-in-law bought a ready-made sauna project using gas silicate blocks. They built according to the accompanying note to the plan. The walls are made of gas silicate, 50 cm thick, despite the fact that the box itself is only 6x5 m. The foundation is slab, and the roof is made of ready-made sections, covered with corrugated board. It turned out to be a little more expensive, but the sauna box has been in use for three years now, and no problems. But some kind of smell appears in the spring, in the summer, as the sun warms up, everything disappears.

Recommended Posts

Ventilation of the foundation of a bathhouse

Aerated block bathhouse

Bathhouse projects with an attic

Finishing a bathhouse with a block house inside

Japanese bath

Do-it-yourself bath drain

Calculation of dimensions

The size of the bath depends on several criteria:

- Availability of free space on the site.

- A constant number of visitors to the bathhouse.

- Required number of rooms. There should be three main rooms in the bathhouse - a steam room, a shower room, and a dressing room. If necessary, you can add a recreation area, terrace, corridor.

You also need to pay attention to calculating the space inside each room. Standards:

- The dimensions of the steam room are 2x2 meters.

- The minimum width of the locker room is 1 meter. Visitors will not cling their elbows to the walls when changing clothes. Minimum width - 120 cm.

- Shower room - 1.5 m2 per visitor.

When calculating the size of the dressing room, you can use a simple rule - the more free space, the better. The optimal dimensions are 3x3 meters.

Dressing room with decoration (Photo: Instagram / apartbani)

Insulation for block walls

A distinctive feature of the bath is the high temperature level during its use. Therefore, for a steam room, the choice of insulation must be limited. We generally recommend not using the following materials to insulate a bathhouse from the inside :

- mineral wool;

- polystyrene foam and polystyrene foam;

- glass wool

When heated, mineral wool They are definitely harmful to the human body. The same situation is with the release of harmful substances from polystyrene foam and expanded polystyrene under the influence of temperature.

We can say an unequivocal “no” to glass wool It is dangerous to use: protection of hands, skin, eyes and respiratory tract is required. It is subject to deformation under the influence of high temperature (which is typical for a bath). Over time, it may begin to emit an unpleasant odor.

Nevertheless, these insulation materials are popular due to their availability and low price.

A good material for insulation can be ecowool : it is environmentally friendly, when applied using the “wet” method, it fills the entire surface, creeping even into small cracks. But this is also its disadvantage: you cannot do without special skills and equipment to apply it.

Peat blocks and foam glass have proven themselves to be modern and high-quality materials . They are not exposed to moisture, are fireproof, but, alas, quite expensive. At the same time, peat blocks are rare - only a few companies produce them in Russia.

Foil roll insulating materials work well (see link above). They need to be overlapped and glued with aluminum tape.

Insulating a bathhouse from the inside is a labor-intensive but necessary process. You will be able to recoup your costs due to the fact that with proper insulation, you will need significantly less firewood (or other type of fuel) than you would spend trying to heat a bathhouse insulated from the outside.

Internal insulation goes well with the upholstery of the bathhouse and finishing materials. You provide: warmth, safety and a beautiful aesthetic appearance.

You may also need the following materials for insulating baths:

Vapor barrier: which is better?

membranes, foil and foil materials, films can be used as a vapor barrier In principle, if there was no need to protect the thermal insulation layer, then the need for vapor barrier would disappear - the matter would be limited to ventilation and that’s all.

The main battles, of course, are over foil. We recommend reading our article, which provides arguments regarding which vapor barrier is best for a steam room in a bathhouse.

In general, the need for foil, as well as the harm from it, cannot be considered unambiguous statements. Because a lot depends on what bath regime a person prefers. And it turns out that what is good for one is detrimental for another.

If we talk exclusively about vapor barrier, without reflecting infrared radiation, then foil is an excellent insulator; it does not allow vapor to pass through completely. True, condensation falls on its surface and rolls down, but that’s why we leave the ventilation gap in order to ventilate the lining and prevent it from rotting from this moisture.

Membranes are different: single- and multi-layer, single- and double-sided, multifunctional... The essence of their action is not to allow steam to pass to the thermal insulator, but to pass in the opposite direction, allowing it to release absorbed water vapor from somewhere else.

Multifunctional membranes also act as both a heat and water insulator, and therefore are expensive. In multi-layered ones, moisture accumulates between the layers and then gradually evaporates.

Films are also different, so it is best to ask sellers what temperature they are designed for. You need ones that can withstand 100 degrees and above.

Installation of a “pie” of insulation from the inside

In addition to the very need to insulate the bathhouse from the inside, it is important to make the right insulation pie.

- lathing on a load-bearing wall;

- insulation;

- vapor protection and waterproofing;

- ventilation gap (can be arranged with a sheathing device, it is required);

- Decoration Materials.

For lathing, you can use wooden blocks or a metal profile. We recommend treating the former with an antiseptic to increase service life, and choosing metal profiles from the galvanized category (not subject to rust).

It is best to use dowels as fasteners: they will make it easier to work with blocks, which have a stronger structure than wood, and will provide a tighter connection. Although, in order to save money, it is permissible to use wood screws.

A ventilation gap is left between the finishing materials and the layer of vapor and water protection so that condensation can flow down without affecting the insulation.

Insulation of walls in a bathhouse made of foam blocks (the diagram is suitable for all block walls of bathhouses)

Thermal protection of floor covering

The insulation of a bathhouse built from expanded clay concrete blocks begins with measures to insulate the floor. A layer of slag (it can be replaced with expanded clay or glass wool) at least 35 centimeters thick is poured directly onto the ground. A reinforced concrete screed is placed on top of it, and ceramic tiles are laid on top.

Only if the insulation of the bathhouse foundation is properly arranged can heat loss during the operation of the building be significantly reduced.